Is Your Design Pushing the Limits? Exploring the Advanced Capabilities of TSM-DS3.

In the rapidly advancing world of electronics, where signal speeds escalate and power densities increase, the choice of printed circuit board (PCB) substrate becomes a critical determinant of performance and reliability. For engineers and designers working on the cutting edge, standard FR-4 materials often fall short, leading to signal degradation and thermal management challenges. Enter the TSM-DS3 PCB, a superior laminate solution engineered to excel where conventional materials fail. This advanced substrate is specifically designed to meet the rigorous demands of high-frequency, high-power applications, offering an unmatched combination of electrical, thermal, and mechanical properties.

Unveiling the TSM-DS3 Laminate: A Benchmark in Material Science

At its core, the TSM-DS3 PCB laminate represents a significant leap in material technology. It is a dimensionally stable, ceramic-filled composite that sets a new industry standard for low-loss performance. Its exceptional thermal stability ensures consistent operation even under fluctuating temperature conditions, a common challenge in high-power designs. The most telling metric of its electrical superiority is its exceptionally low dissipation factor (Df) of just 0.0011 at 10 GHz. This minimal signal loss is paramount for preserving signal integrity in high-frequency circuits, ensuring that data transmission remains clean and accurate. While it delivers the robust reliability associated with high-quality fiberglass-reinforced epoxies,Taconic TSM-DS3 far surpasses them in high-speed scenarios.

Key Features that Define Superior Performance

The outstanding performance of TSM-DS3 stems from its innovative composition and engineered characteristics:

1) Optimized Material Composition: TSM-DS3 is formulated as a reinforced material with a minimal fiberglass content of approximately 5%, heavily loaded with ceramic. This unique composition provides the structural integrity needed for fabricating complex, large-format multilayer boards, a domain typically dominated by epoxies, but with far superior high-frequency characteristics.

2) Superior Thermal Management: Developed with high-power applications in mind,TSM-DS3 features a thermal conductivity of 0.65 W/mK. This property allows the laminate to act as a heat conduit, efficiently drawing thermal energy away from sensitive components like power amplifiers and processors, thereby enhancing the overall reliability and lifespan of the assembly.

3) Exceptional Dimensional Stability: The material exhibits very low coefficients of thermal expansion (CTE) in both the X and Y axes. This stability is crucial for surviving demanding thermal cycling requirements, preventing issues like plated through-hole cracking and ensuring long-term structural integrity of the PCB, especially in environments with extreme temperature variations.

Comprehensive PCB Fabrication Capabilities forTSM-DS3

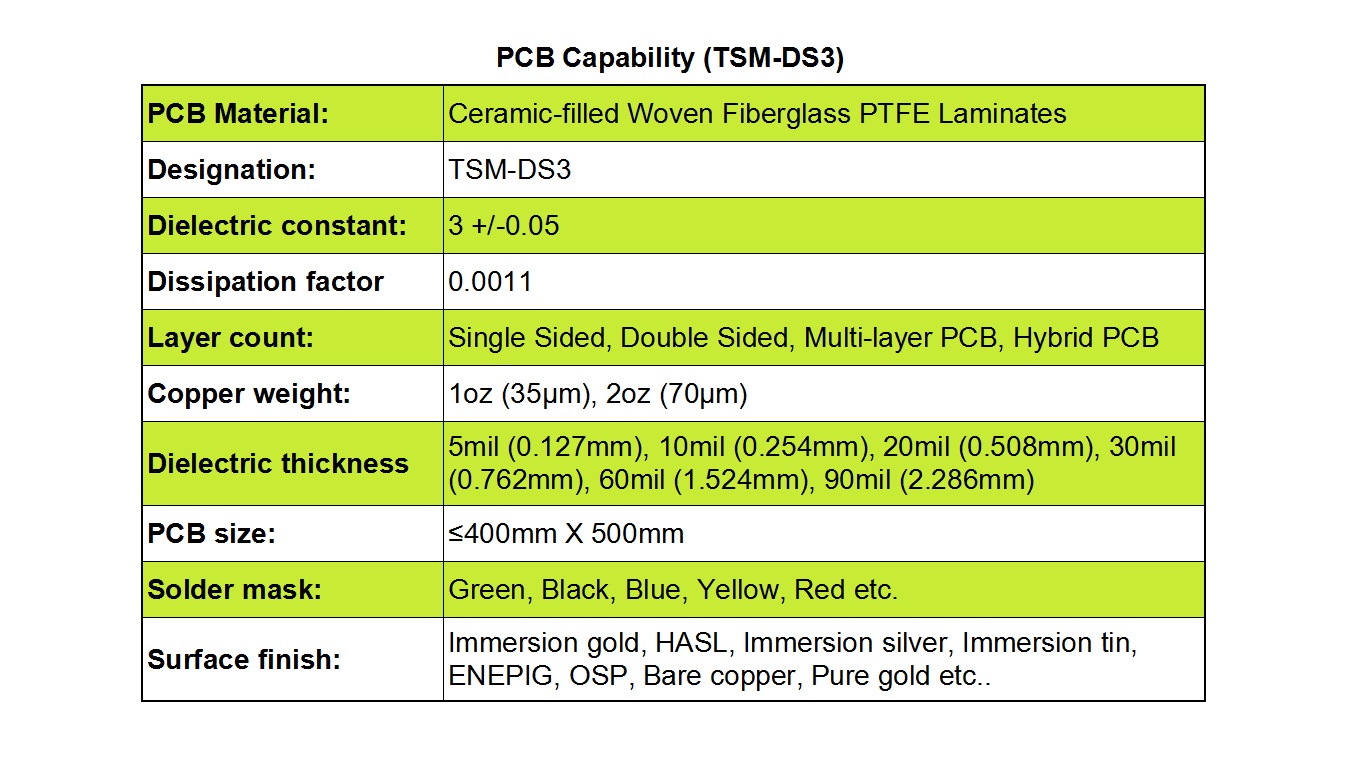

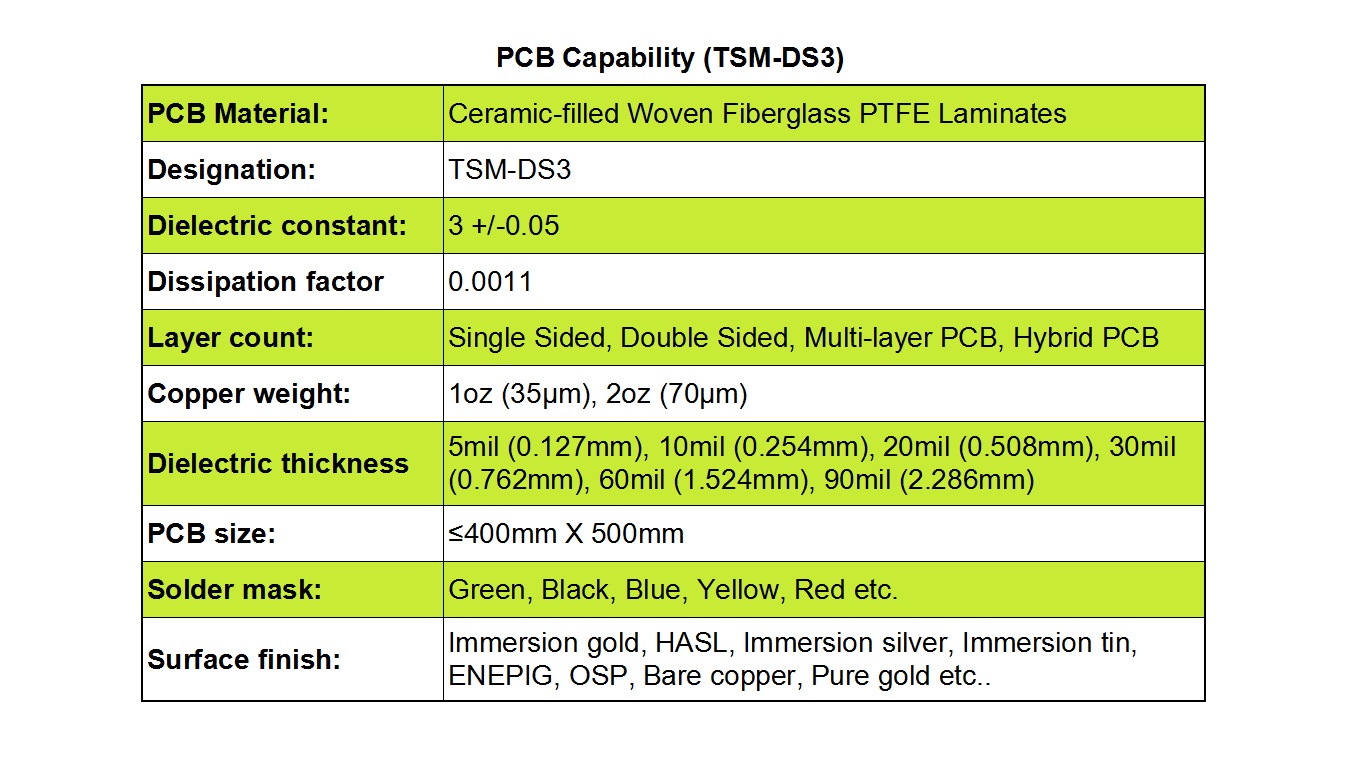

To fully leverage the advantages of this advanced material, our manufacturing facilities are equipped to produce a wide array of PCB configurations. We provide complete flexibility to tailor the board precisely to your design specifications:

1) Board Configurations: We manufacture single-sided, double-sided, and complex multi-layer PCBs. We also specialize in hybrid constructions, allowing for the integration ofTSM-DS3 with other materials within a single board to optimize cost and performance.

2) Material Customization: Designers can select the appropriate copper weight for their current-carrying needs, with standard options including 1oz (35µm) and 2oz (70µm). Furthermore, we offer a broad spectrum of dielectric thicknesses, from a thin 5mil up to a substantial 90mil, with common options like 10mil, 20mil, 30mil, and 60mil readily available.

3) Scale and Finishing: We can accommodate large panel sizes up to 400mm x 500mm, suitable for both prototyping and high-volume production runs. To meet aesthetic and functional requirements, we provide a diverse palette of solder mask colors (green, black, blue, yellow, red, etc.) and a complete range of surface finishes, including Immersion Gold (ENIG), HASL, Immersion Silver, Immersion Tin, ENEPIG, OSP, and bare copper.

Diverse Application Spectrum

The unique property set of TSM-DS3 Taconic RF PCB makes them indispensable across a multitude of high-performance industries. Key applications include:

1) Telecommunications & Radar: Couplers, phased array antennas, radar manifolds, and mmWave antennas for 5G and defense systems, where signal purity and thermal robustness are non-negotiable.

2) Industrial & Test Equipment: Automated Test Equipment (ATE) and semiconductor manufacturing tools that require stable, low-loss substrates for accurate measurements.

3) Extreme Environment Applications: Equipment for oil drilling and other harsh environments that demand unwavering reliability under intense thermal and mechanical stress.

In conclusion, the TSM-DS3 High Frequency PCB is not merely a component but a foundational element for next-generation electronic systems. By offering exceptional signal integrity, superior thermal management, and robust mechanical stability, it empowers engineers to push the boundaries of what's possible in high-frequency and high-power design.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com