How Can TMM6 High Frequency PCBs Enhance Performance and Reliability in Your Microwave Designs?

In the rapidly advancing world of electronics, the demand for high-frequency printed circuit boards (PCBs) that deliver unwavering performance and reliability is greater than ever. For engineers and designers working on the cutting edge of wireless communication, aerospace, and defense technologies, the selection of the appropriate microwave laminate is a critical decision that directly impacts the success of the entire project. Among the premium materials available, Rogers TMM 6 stands out as a remarkably versatile and high-performance thermoset microwave composite. This article delves into the unique properties, significant benefits, and extensive manufacturing capabilities of TMM6 High Frequency PCBs, illustrating why they are an exceptional solution for a broad spectrum of demanding applications.

An Introduction to Rogers TMM6 Thermoset Microwave Material

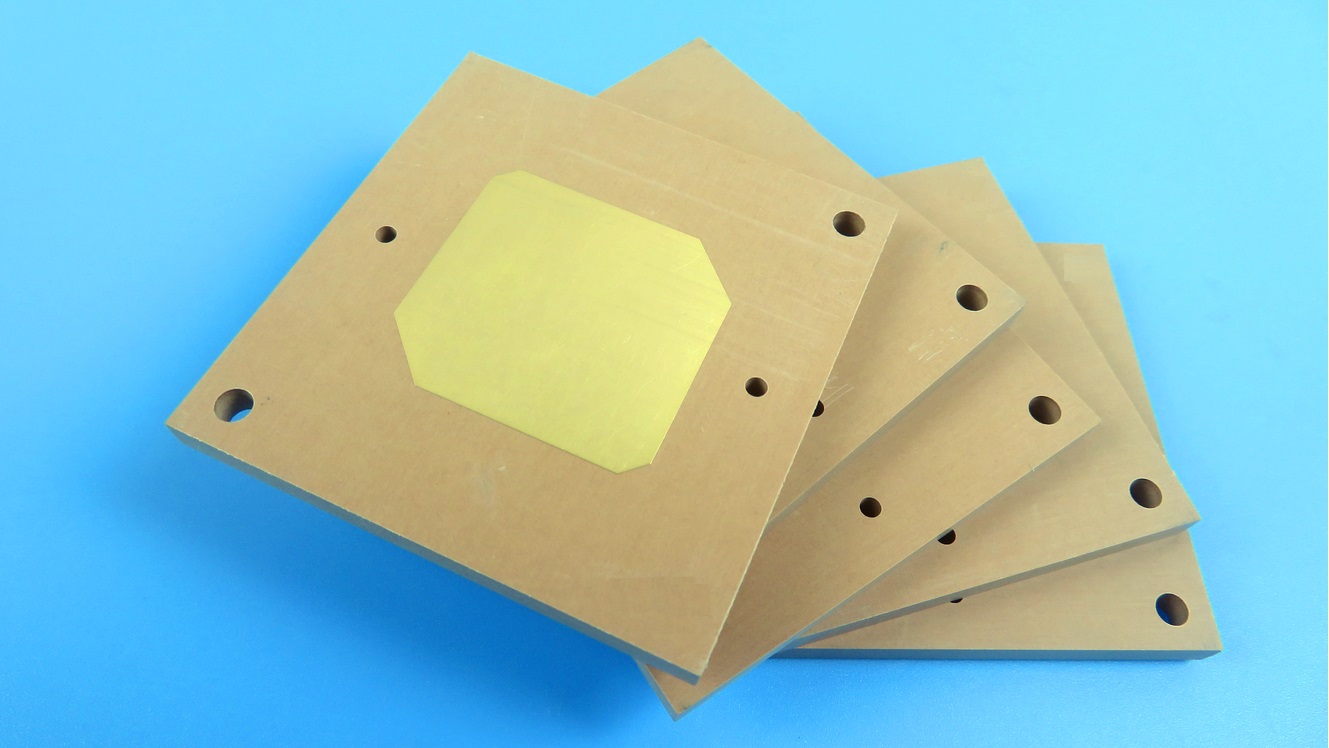

Rogers Corporation TMM 6 is an ingeniously formulated ceramic thermoset polymer composite, specifically engineered to provide exceptional plated through-hole reliability in sophisticated strip-line and micro-strip circuit designs. This material achieves a remarkable synthesis, merging the most desirable characteristics of traditional ceramic-filled PTFE laminates with those of robust thermoset systems. A key differentiator for TMM6 is its unique and stable dielectric constant (Dk) of 6.0, a value that distinguishes it within its product family. Perhaps most advantageously, it delivers this high-performance combination without necessitating the specialized, often challenging, and costly fabrication processes typically associated with handling pure PTFE-based materials, thereby streamlining production and reducing manufacturing complexities.

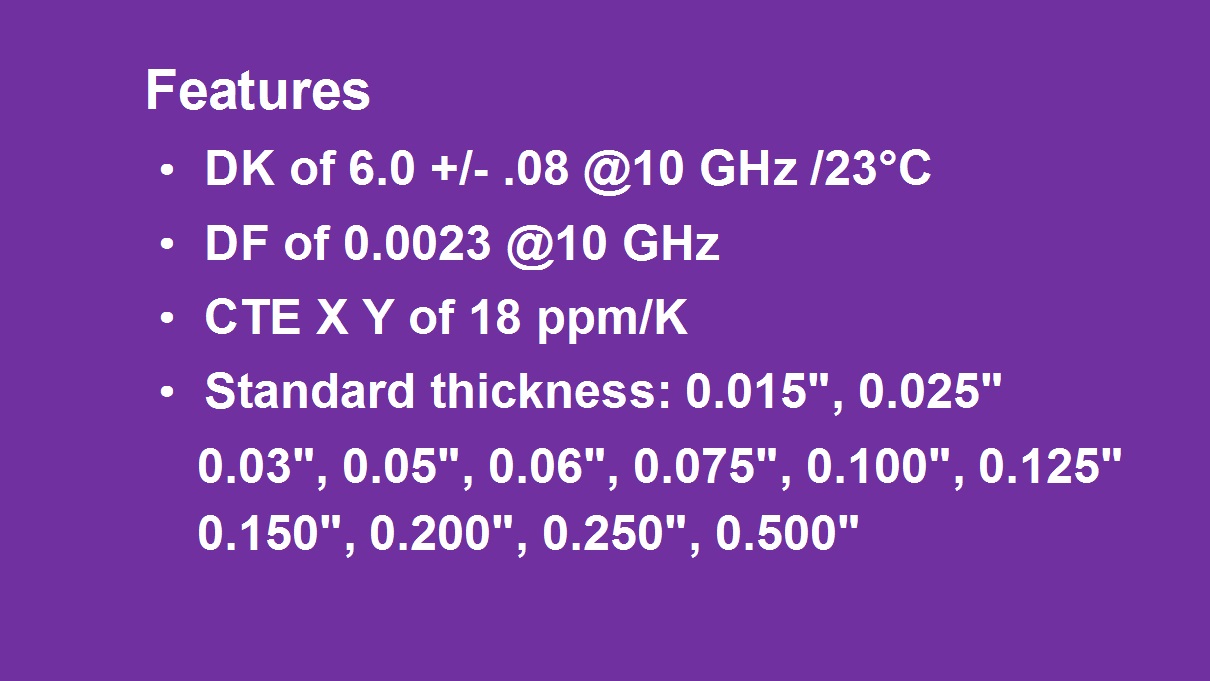

Outstanding Features and Tangible Benefits of TMM6

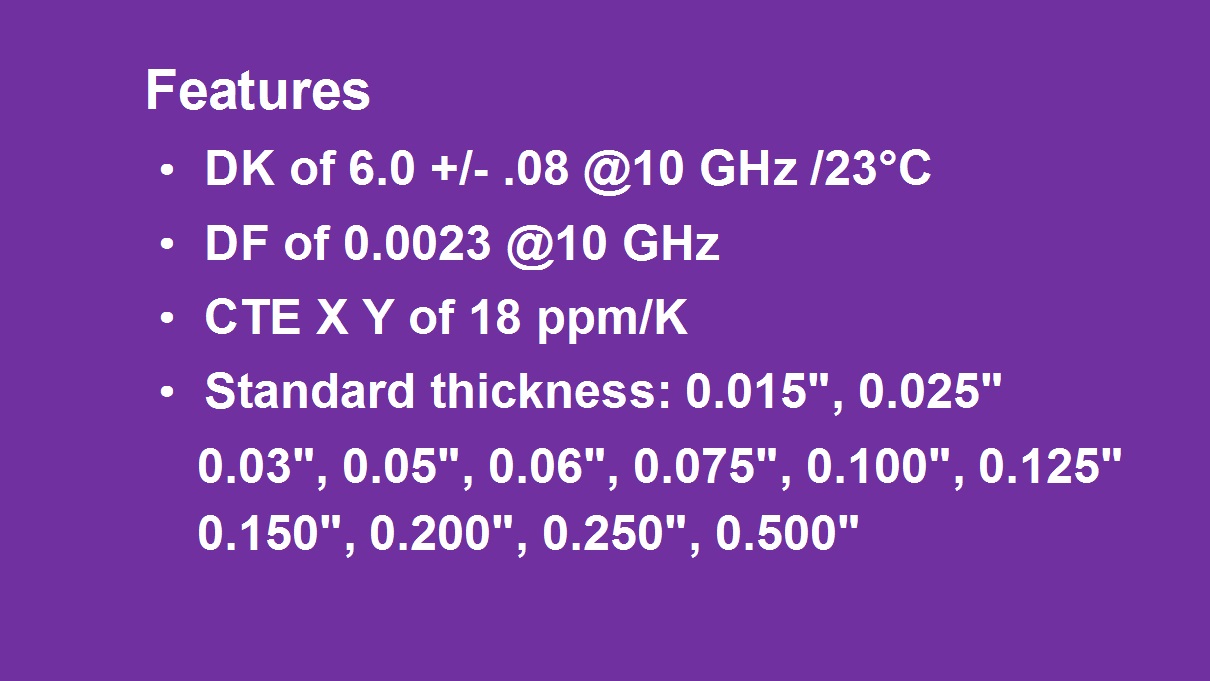

The superior performance of TMM6 DK6.0 PCB is rooted in its meticulously controlled electrical and mechanical properties, which are tailored for stability and precision in high-frequency environments.

1) Electrical Stability: TMM6 exhibits a tightly controlled Dielectric Constant (Dk) of 6.0 with a minimal tolerance of±0.080. This consistency is crucial for impedance matching and predictable circuit behavior. Coupled with an exceptionally low Dissipation Factor (Df) of 0.0023 at 10 GHz, the material ensures minimal signal loss, which is paramount for maintaining signal integrity in high-speed data links. Furthermore, its Thermal Coefficient of Dk is an impressively low -11 ppm/°K, guaranteeing that electrical performance remains stable even under fluctuating thermal conditions.

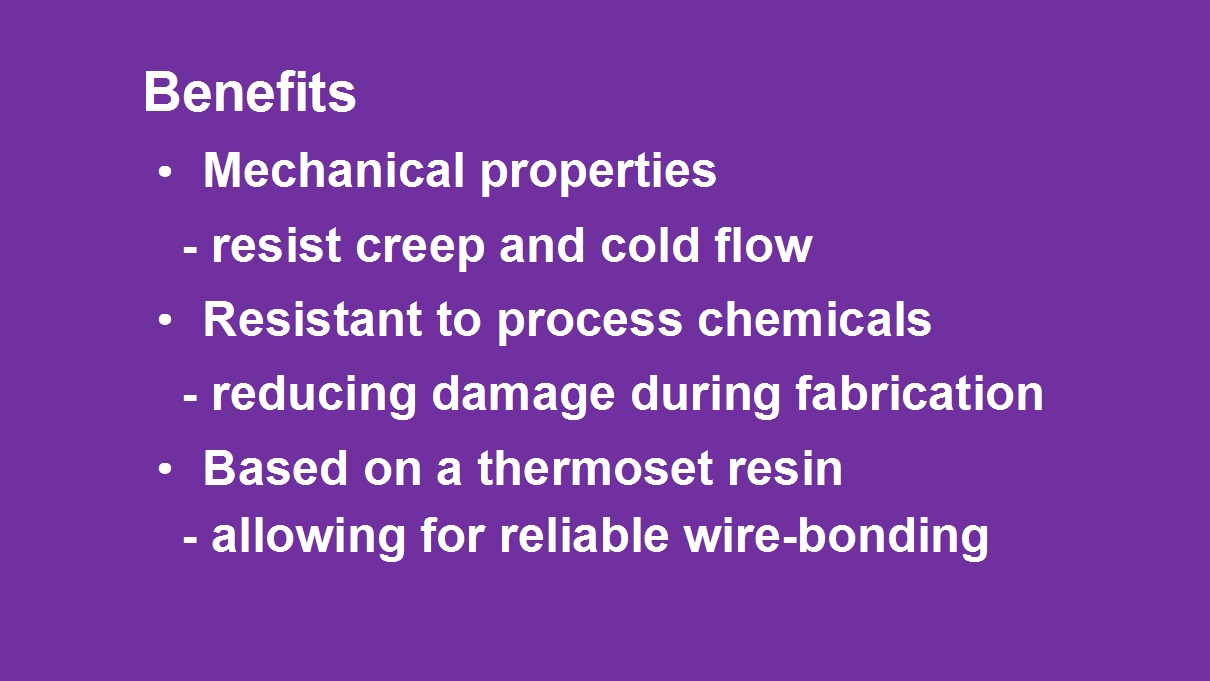

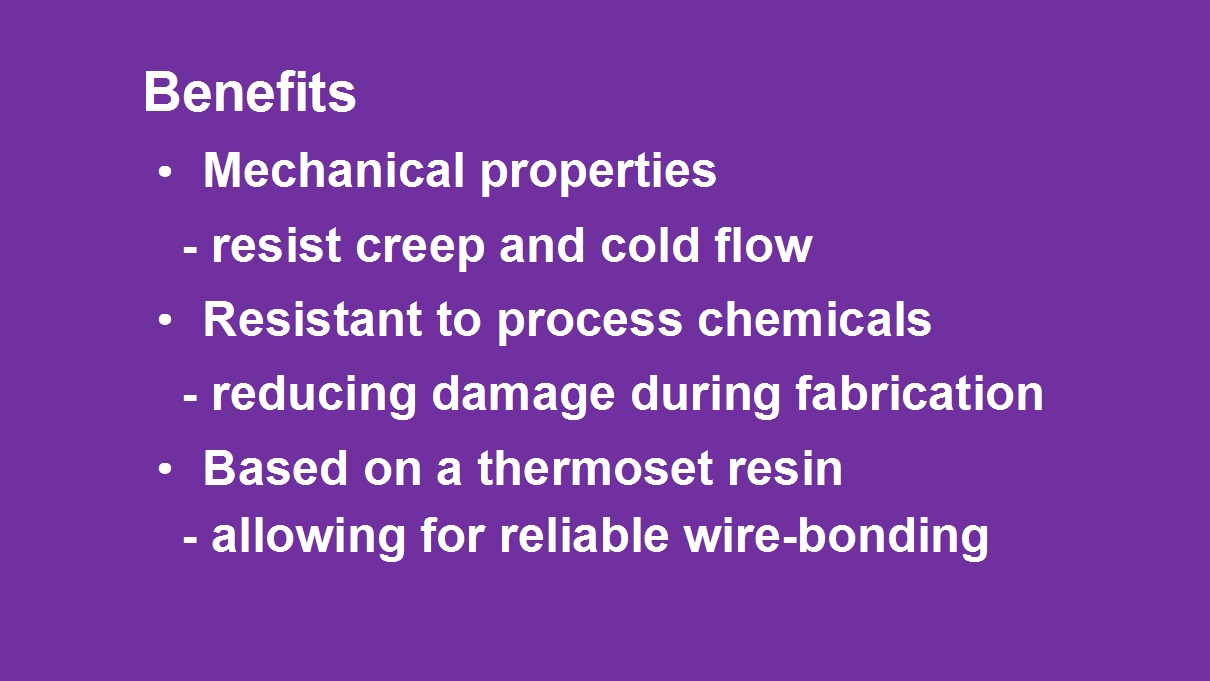

2) Mechanical Robustness: The material’s Coefficient of Thermal Expansion (CTE) is carefully engineered at 18 ppm/°K on both the X and Y axes, closely matching that of copper. This congruence prevents the delamination and reliability issues that can arise from mechanical stress during thermal cycling. Available in a wide thickness range from 0.0015 inches to 0.500 inches, TMM6 offers designers significant flexibility to meet specific mechanical and electrical requirements.

3) Manufacturing and Operational Advantages: The thermoset nature of TMM6 grants it excellent resistance to creep and cold flow, preserving the physical integrity of the circuit under mechanical pressure and over time. Its high resistance to a wide array of process chemicals mitigates the risk of damage during PCB fabrication, leading to higher yields. The rigid substrate also facilitates reliable wire-bonding, a critical process in many advanced packaging applications. Finally, its compatibility with all standard PCB manufacturing processes, such as drilling, plating, and etching, makes it a user-friendly material that integrates seamlessly into existing production lines, enhancing application versatility.

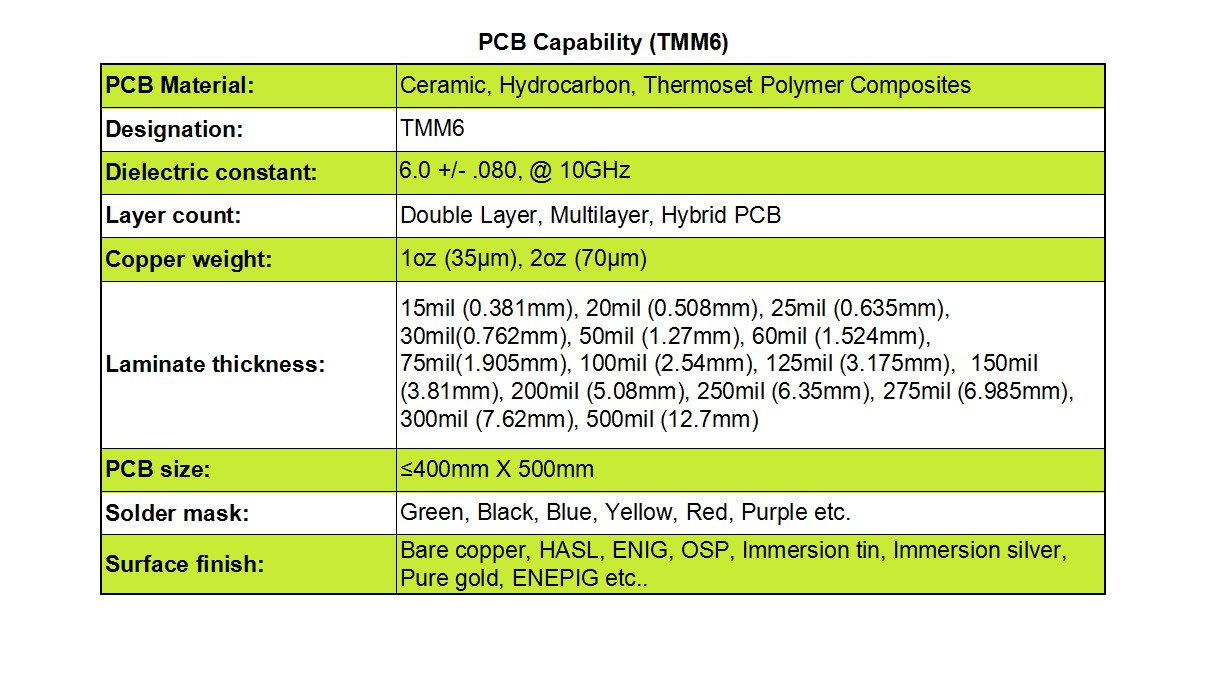

Our Comprehensive TMM6 PCB Manufacturing Capabilities

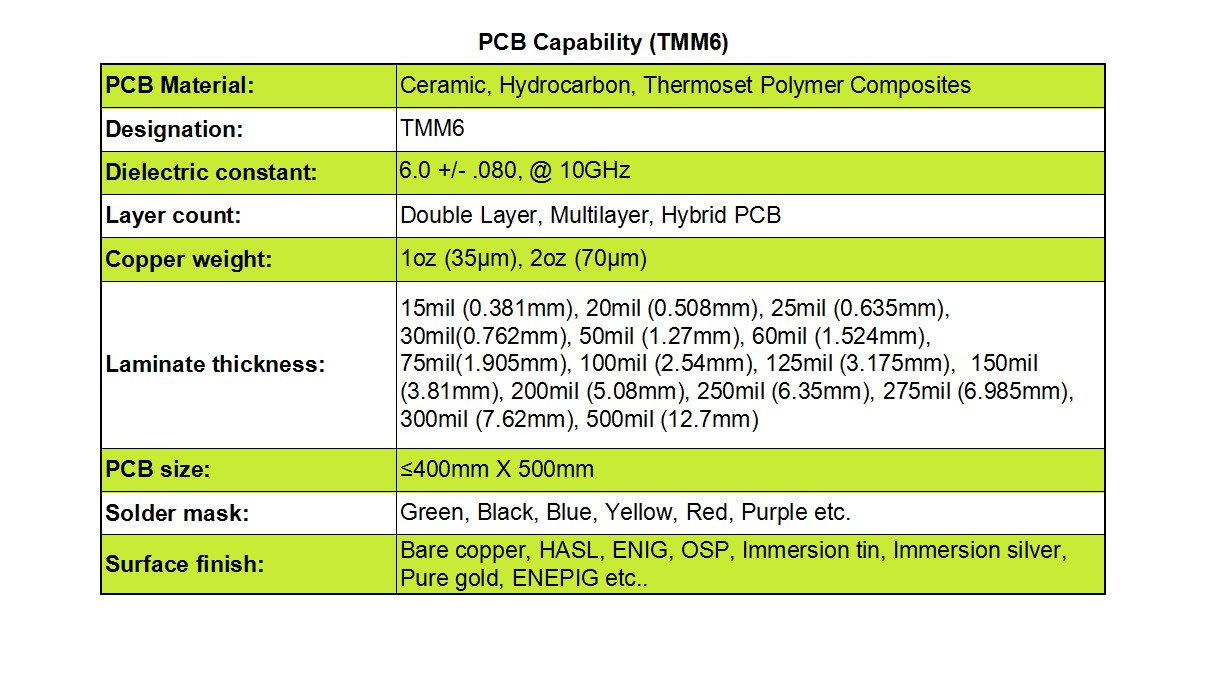

To fully leverage the advantages of this advanced material, partnering with a manufacturer possessing the right expertise and capabilities is essential. Our specialized fabrication services for TMM6 PCBs are designed to meet the most stringent requirements.

We possess extensive experience in producing a variety of board structures, including precision double-layer, complex multilayer, andhybrid PCBs that combine TMM6 with other materials to optimize cost and performance.

We offer a selection of copper weights, typically from the standard 1oz (35 µm) up to 2oz (70µm), to handle different current-carrying needs.

Our thickness capabilities are extensive, ranging from a slender 15mil (0.381mm) to a substantial 500mil (12.7mm). We can accommodate large-format designs with a maximum PCB size of 400mm x 500mm.

For customization, we provide a full spectrum of solder mask colors (green, black, blue, yellow, red, purple) and a complete suite of surface finishes, including Bare Copper, HASL, ENIG, OSP, Immersion Tin, Immersion Silver, Pure Gold, and ENEPIG, to ensure optimal solderability and environmental protection.

Diverse Applications for TMM6 PCBs

The unique property set of TMM6 makes it the material of choice for a wide range of high-performance applications where electrical stability and mechanical reliability are non-negotiable. Common uses include:

1) Chip Testers and RF Circuitry: Requiring precise impedance control and low signal loss for accurate component testing and high-frequency signal processing.

2) Filters, Couplers, and Power Amplifiers: Where stable dielectric constant and low loss are critical for signal integrity and power efficiency.

3) GPS and Patch Antennas: Benefiting from the material's thermal stability to maintain consistent signal quality and performance across operating temperatures.

In conclusion,Rogers TMM6 High Frequency PCBs represent a pinnacle of material science, offering an ideal balance of electrical performance, mechanical durability, and manufacturing practicality. For projects demanding a stable Dk of 6.0 and exceptional reliability, TMM6 provides a proven and effective solution.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com