Introduction

Today, we will explore the exciting breakthrough in antenna design with the RO4725JXR antenna grade PCB.

In the realm of antenna design, selecting the right material is a challenging task. Fortunately, the RO4725JXR antenna grade laminates offer a reliable and efficient alternative to traditional PTFE-based laminates that have long been used in antenna design.

With exceptional mechanical and electrical properties, these laminates enable antenna designers to achieve significant gain values while minimizing signal loss. They are compatible with standard epoxy and high-temperature lead-free solder processes, eliminating the need for special treatment in plated through hole preparation. Lamination can be achieved using the RO4400 bondply series at 175°C.

Now let's delve into the details provided in the data sheet.

RO4725JXR Typical Properties

TheRogersRO4725JXRPCBexhibits a process dielectric constant of 2.55 ± 0.05 in the Z direction at 10 GHz and 23°C, as determined by the IPC-TM-650, 2.5.5.5 test method. Its design dielectric constant is 2.64 in the Z direction between 1.7 GHz to 5 GHz, measured using the differential phase length method.

In the Z direction at 10 GHz and 23°C, the laminate demonstrates a dissipation factor of 0.0026 (IPC-TM-650, 2.5.5.5 test method). At 2.5 GHz, the dissipation factor is 0.0022.

The thermal coefficient of the dielectric constant is +34 ppm/°C in the Z direction across a temperature range of -50°C to 150°C (IPC-TM-650, 2.5.5.5 test method).

RO4725JXR high frequency PCB boasts a volume resistivity of 2.16 x 10^8 MΩ•cm and a surface resistivity of 4.8 x 10^7 MΩ at 0.030", measured under COND A using the IPC-TM-650, 2.5.17.1 test method.

With a low PIM value of -166 dBc at 50 ohms on 0.060" thick material and a power level of 43 dBm at 1900MHz, the laminate ensures minimal passive intermodulation.

The electrical strength of RO4725JXR is 630 V/mil at 0.030", according to the IPC-TM-650, 2.5.6.2 test method.

In terms of mechanical properties, the laminate exhibits a flexural strength of 121 MPa in the MD direction and 92 MPa in the CMD direction, as measured by the ASTM D790 test method at room temperature.

Rogers RO4725JXR PCB demonstrates excellent dimensional stability, with less than 0.4 mm/m in the X and Y directions after etching under E2/150°C conditions (IPC-TM-650, 2.4.39A test method).

The coefficient of thermal expansion is 13.9 ppm/°C in the X direction, 19.0 ppm/°C in the Y direction, and 25.6 ppm/°C in the Z direction across a temperature range of -55°C to 288°C (IPC-TM-650, 2.1.24 test method).

In terms of thermal conductivity, RO4725JXR exhibits a value of 0.38 W/mK° at 50°C (ASTM D5470 test method).

Its moisture absorption rate is 0.24% after 48 hours at 50ºC (IPC-TM-650 2.6.2.1 and ASTM D570 test methods).

The RO4725JXR material has a Tg value greater than 280°C (IPC-TM-650 2.4.24 test method) and a Td value of 439°C (ASTM D3850 test method).

RO4725JXR has a density of 1.27 g/cm3 (ASTM D792 test method).

The copper peel strength is 8.5 pli for 1 oz LoPro ED copper (IPC-TM-650 2.4.8 test method).

It is also compatible with lead-free processes.

|

Property

|

Typical Value

|

Direction

|

Units

|

Condition

|

Test Method

|

|

Dielectric Constant, εr Process

|

2.55 ± 0.05

|

Z

|

|

10 GHz/23°C

|

IPC-TM-650, 2.5.5.5

|

|

Dielectric Constant, εr Design

|

2.64

|

Z

|

|

1.7 GHz - 5

GHz

|

Differential Phase Length Method

|

|

Dissipation Factor

|

0.0026

|

Z

|

|

10 GHz/23°C

|

IPC-TM-650, 2.5.5.5

|

|

0.0022

|

|

2.5GHz

|

|

Thermal Coefficient of εr

|

+34

|

Z

|

ppm/°C

|

-50°C to 150°C

|

IPC-TM-650, 2.5.5.5

|

|

Volume Resistivity (0.030")

|

2.16 X 10^8

|

|

MΩ•cm

|

COND A

|

IPC-TM-650, 2.5.17.1

|

|

Surface Resistivity (0.030")

|

4.8 X 10^7

|

|

MΩ

|

COND A

|

IPC-TM-650, 2.5.17.1

|

|

PIM

|

-166

|

|

dBc

|

50 ohm

0.060”

|

43dBm

1900MHz

|

|

Electrical Strength (0.030”)

|

630

|

Z

|

V/mil

|

|

IPC-TM-650, 2.5.6.2

|

|

Flexural Strength MD

|

121 (17.5)

|

|

MPa

(kpsi)

|

RT

|

ASTM D790

|

|

CMD

|

92 (13.3)

|

|

|

Dimensional Stability

|

<0.4

|

X,Y

|

mm/m

|

after etch

+E2/150°C

|

IPC-TM-650, 2.4.39A

|

|

Coefficient of Thermal

Expansion

|

13.9

|

X

|

ppm/°C

|

-55 TO 288°C

|

IPC-TM-650, 2.1.24

|

|

19.0

|

Y

|

|

25.6

|

Z

|

|

Thermal Conductivity

|

0.38

|

Z

|

W/mK°

|

50°C

|

ASTM D5470

|

|

Moisture Absorption

|

0.24%

|

|

%

|

48/50

|

IPC-TM-650 2.6.2.1 ASTM D570

|

|

Tg

|

>280

|

|

°C

|

|

IPC-TM-650 2.4.24

|

|

Td

|

439

|

|

°C

|

|

ASTM D3850

|

|

Density

|

1.27

|

|

gm/cm3

|

|

ASTM D792

|

|

Copper Peel Strength

|

8.5

|

|

pli

|

1 oz LoPro EDC

|

IPC-TM-650 2.4.8

|

|

Lead-Free Process Compatible

|

YES

|

|

|

|

|

RO4725JXR PCB Capability

To cater to our customers' diverse needs, our PCB capability offers a wide range of options, including single-sided, double-sided, multi-layer, and hybrid PCBs combining different technologies.

Various dielectric thicknesses are available, such as 30.7mil (0.780mm) and 60.7mil (1.542mm), to accommodate different requirements.

We can customize the copper weight to meet specific needs, with options for 1oz (35µm) and 2oz (70µm) copper weights.

Our PCBs come in sizesup to 400mm X 500mm, making them suitable for a wide range of applications.

We provide a selection of solder mask colors, including green, black, blue, red, yellow, and white, among others.

Moreover, our PCBs can be finished with various surface finishes, such as immersion gold, HASL, immersion silver, immersion tin, bare copper, OSP, ENEPIG, pure gold, and more.

|

PCB Material:

|

Hydrocarbon / Ceramic / Woven Glass

|

|

Designation:

|

RO4725JXR

|

|

Dielectric constant:

|

2.55 (10 GHz)

|

|

Dissipation factor

|

0.0026 (10 GHz)

|

|

Layer count:

|

Single Sided, Double Sided, Multi-layer PCB, Hybrid PCB

|

|

Copper weight:

|

1oz (35µm), 2oz (70µm)

|

|

Dielectric thickness

|

30.7mil (0.780mm), 60.7mil (1.542mm)

|

|

PCB size:

|

≤400mm X 500mm

|

|

Solder mask:

|

Green, Black, Blue, Yellow, Red etc.

|

|

Surface finish:

|

Immersion gold, HASL, Immersion silver, Immersion tin, ENEPIG, OSP, Bare copper, Pure gold plated etc..

|

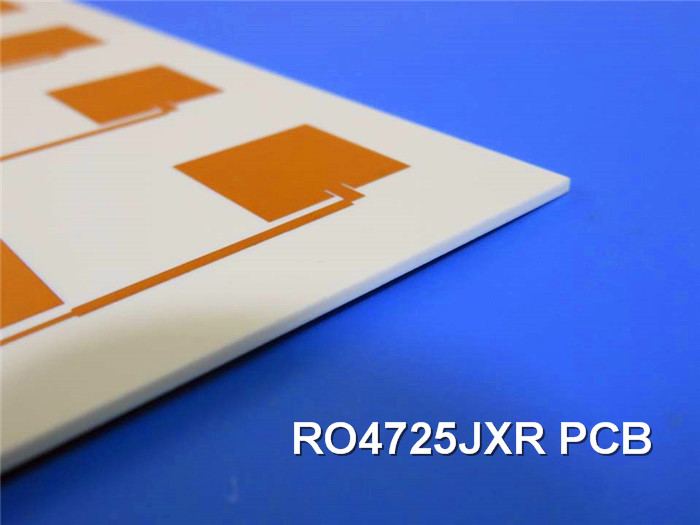

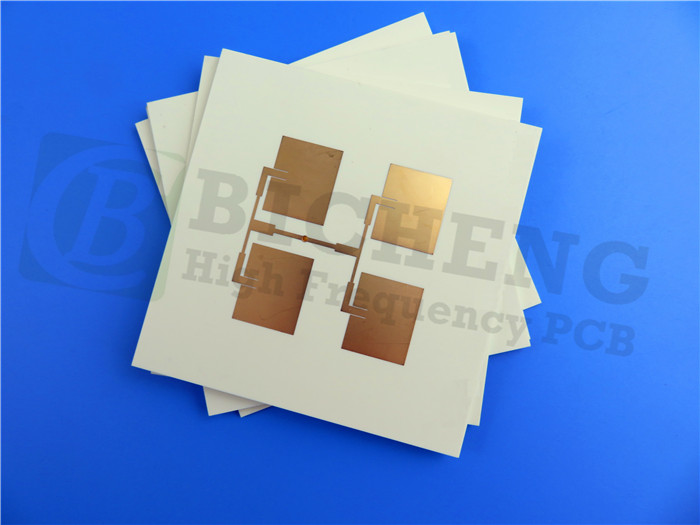

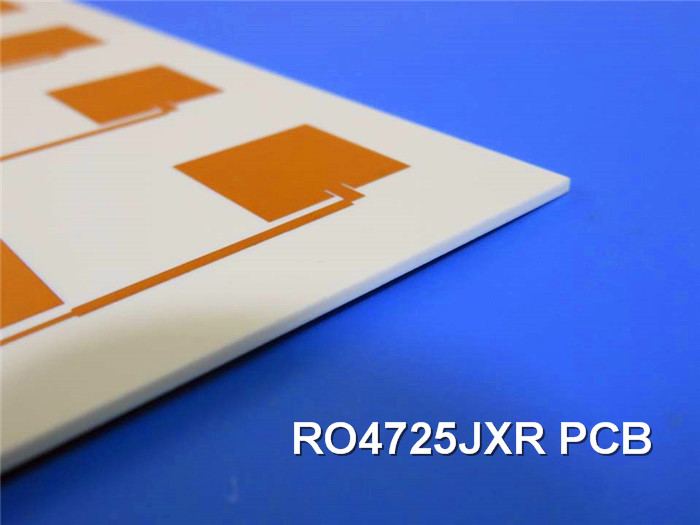

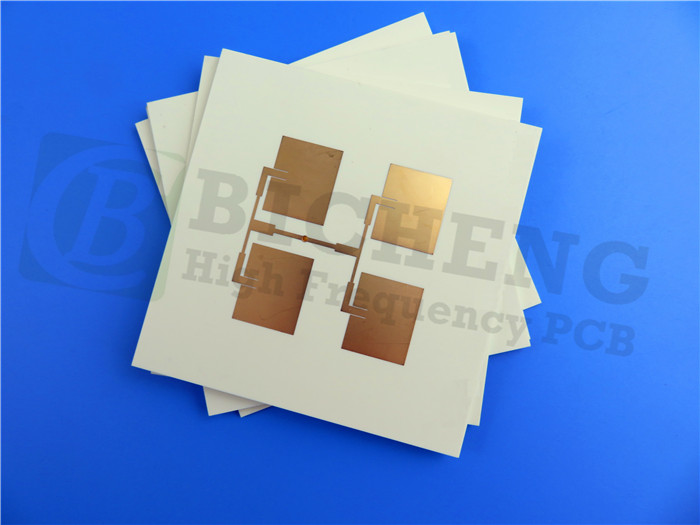

A Piece of RO4725JXR PCB

Displayed on thefollowing is a PCB designed using Rogers RO4725JXR material. This lead-free PCB can operate in temperatures ranging from -40℃ to +85℃. It features a double-sided structure with a 60.7mil dielectric layer and immersion gold (ENIG) on the pads. There is no top or bottom silkscreen or solder mask.

The typical application for this PCB is cellular base station antennas.

Conclusion

When it comes to PCB antennas, utilizing non-PTFE materials like RO4725JXR consistently delivers PIM performance exceeding -164dBc. The unique combination of a specialized thermosetting resin and filler material enables low PIM levels without compromising electrical and mechanical performance.

Whether it's a base station antenna or other passive components like couplers and filters, maintaining the lowest possible PIM level is crucial for ensuring high-quality voice, data, and video communications in the system. Therefore, the choice of RO4725JXR 60.7mil PCB material plays a significant role in determining the achievable PIM level, regardless of the circuit's meticulous design.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com