Rogers AD250C - A New Microwave PCB Material

Check out the Rogers AD250C if you're seeking for a new microwave PCB material. This dielectric-layered, ceramic hydrocarbon-based microwave high-frequency PCB material is reasonably priced. Let's examine this content in more detail. Why is it so successful? Let's proceed with it now.

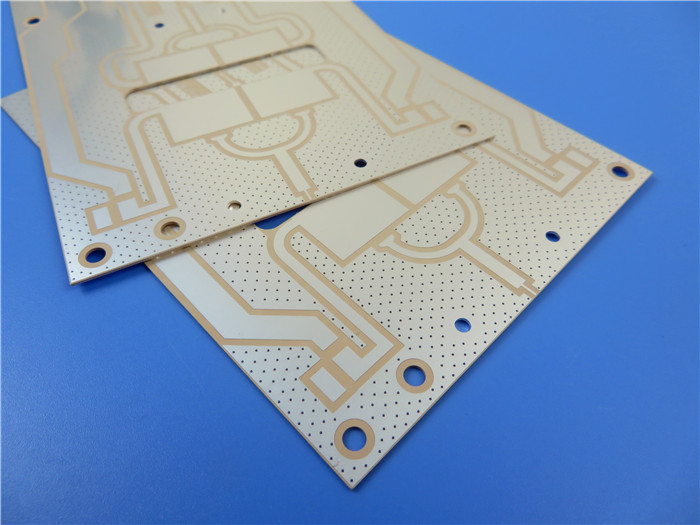

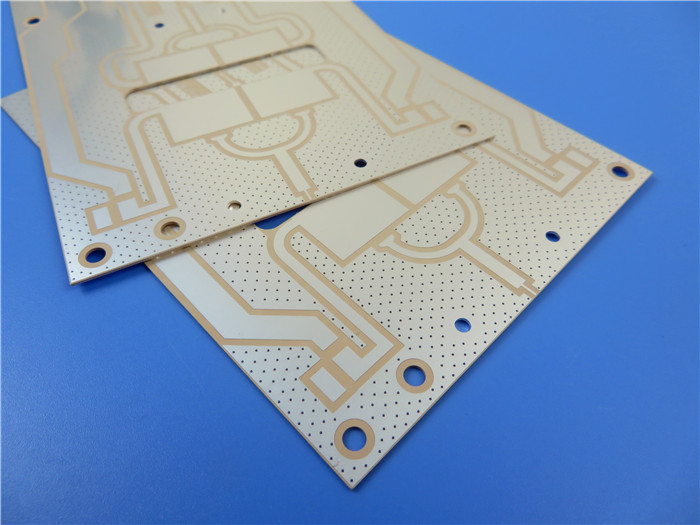

Insulating layer made by Rogers AD250C

You can combine FR-4 and a robust, economical composite to create the high-performance insulating Rogers AD250C layer. The insulating layer has low thermal expansion coefficients and less dielectric loss, making it a great option for

multilayer circuit boards. A high dielectric constant range and a lamination of ceramic hydrocarbons are included in addition to its superior heat management.

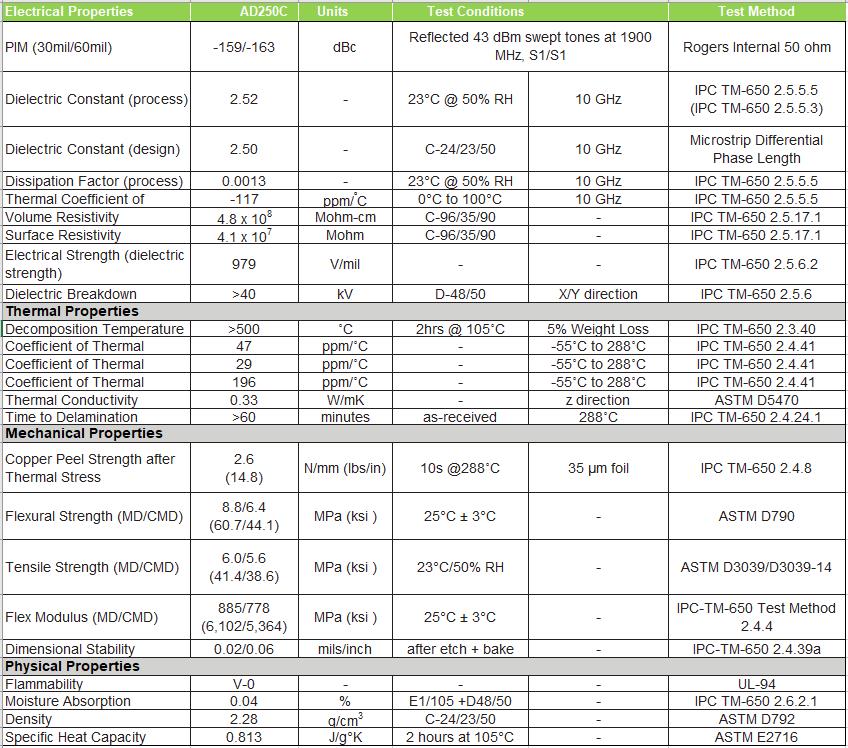

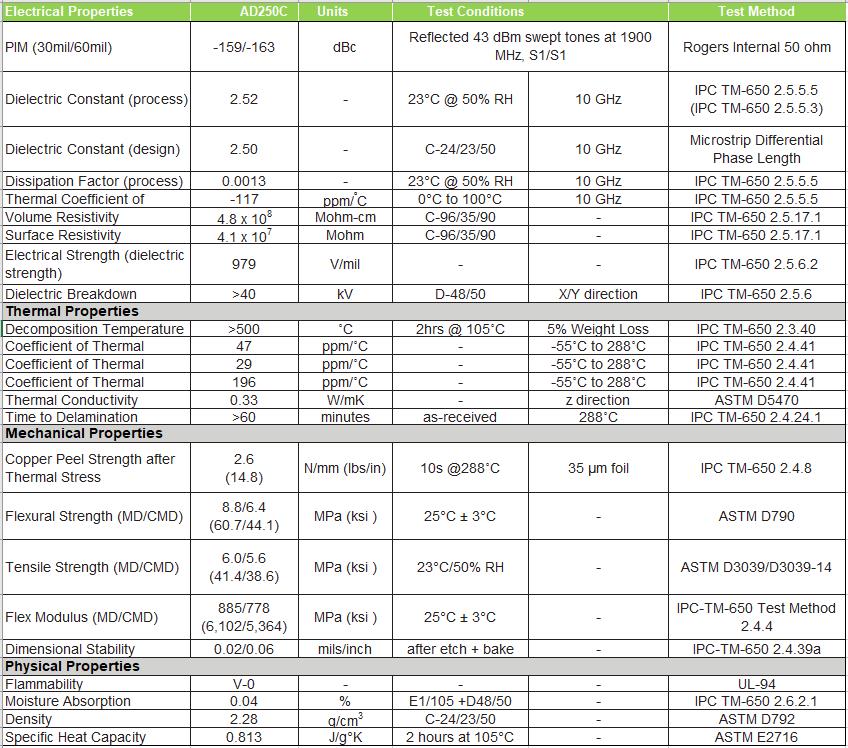

When comparing FR-4 and Rogers materials, you'll see that the former has a higher range of dielectric constants, which leads to reduced signal loss and a higher dissipation factor. It is better for many applications since Rogers material is also more stable at high temperatures. If you require your radio's highest level of sensitivity, Rogers is a better option for high-frequency devices.

This dielectric material is a great option for circuit boards because it has outstanding heat conductivity as well. It is a poor conductor of electricity, nevertheless, due to its dielectric nature. High dielectric constant materials make good insulating layers. Higher dielectric loss materials, however, are inappropriate for conducting large currents. Dielectric breakdown is a process that can occur, and Rogers AD250C is less likely to exhibit this effect than comparable materials.

Rogers AD250C insulating layer is a potential source for another kind of PCB. Although it has a fluoroplastic foundation, this insulating material works better in RF and microwave applications. The Rogers laminates are more expensive than FR4 materials, but they offer superior high frequency characteristics. In addition, when compared to fiber glass, they are less lossy and provide greater electrical performance.

The ceramic hydrocarbons on Rogers AD250C PCB

For controlled or coordinated impedance transmission lines and RF microwave circuits, the low-cost, market-leading RO4000 family of ceramic hydrocarbon laminates is a great option. These substances provide a range of dielectric constants, little thermal conductivity, and great electrical signal integrity. As a result, this laminate is appropriate for many different applications, such as power amplifiers for cellular base stations, automobile sensors, microwave point-to-point communications, RFID tags, etc.

The high-frequency applications benefit from the use of this dielectric PCB material. The PCB can perform better in the electronics industry thanks to the high dielectric constant of the Rogers material while yet having affordable production costs. The Rogers PCB material thus has a wide range of dielectric constants (DK) from 2.50 +/-.04 and is compatible with FR-4.

This material is perfect for multi-layer designs because its CTE is lower than copper's. As a result, when the CTEs of several layers are misaligned, the Rogers PCB experiences less thermal strain. Its dimensional stability is also comparable to that of copper, although it is lead-free. Additionally, Rogers AD250C laminates come in both standard and custom laminate options.

The Rogers material's high dielectric constant makes it perfect for

high-frequency PCBs. This material offers efficient thermal control and less signal loss. For temperature-sensitive tasks, its high-temperature stability is also advantageous. The Rogers PCB is suited for usage in a variety of situations, including high-temperature locations, because to its wide range of dielectric constants.

It has a dielectric layer

The Rogers AD250C's dielectric layer controls a wide range of dielectric constant values and minimizes signal losses. The material is a good insulator and offers great thermal management despite having low conductivity. Additionally, the Rogers material has effective impedance management and reduces signal outgassing. Rogers PCBs have a greater dielectric constant than FR-4 material, in contrast.

The dipole moment of a typical Rogers AD250C is 0.010 m. This dipole moment is equivalent to a very low temperature of roughly 1000 kV. A Rogers AD250C board can often be created using FR4, an epoxy composite made of glass fiber and copper foil lamination. FR-4 laminates with high frequency features are available. While they cost more compared to fiber glass, they become less lossy when exposed at high frequencies.

Another typical material for PCBs is FR-4. It is perfect for a variety of applications and is utilized for single-sided, double-sided, and multilayer boards. In addition to having good mechanical strength, FR-4 can be made to use no lead. Rogers PCBs use a thin FR-4 film for its dielectric layer because it has good thermal conductivity and little dielectric loss.

Rogers AD250C is another kind of PCB material that is compatible with PTFE. It combines the mechanical and thermal characteristics of a fluoropolymer resin with reinforcement from glass fiber. These materials come together to provide an RF laminate material that has less loss, less thermal expansion, and less passive intermodulation. Both base plates made of PTFE and those reinforced with glass fiber can be used with a Rogers AD255C.

Rogers AD250C PCB is cost-effective

The Rogers AD250C's affordable price is only one of its numerous advantages. A cutting bed that securely retains the material, an automatic level sensor, and a routing tool are further characteristics of this type.

Rogers PCBs are often made of FR4 or regular FR4 materials. These boards have a Tg range of between 100 and 288 degrees Celsius. Tg ratings are greater on the Rogers 4003C PCB and Rogers 4350B PCB. These PCBs are typical for high-frequency uses, such as RF PCBs at frequencies of 6 GHz and above. Electrical noise is reduced by the use of FR4.

A great option for microwave high-frequency applications is the Rogers AD250C. It is a cost-effective option due to its chemistry and structure. Additionally, a variety of applications benefit from its excellent performance. The AP-Series and DuPont AP-series products offer exceptional mechanical and thermal qualities, while the AD250C is appropriate for high-frequency and high-gain applications.

You need a good material with good RF capabilities for a high-frequency PCB. A reasonable option for high-frequency PCBs is the AD250C. High-frequency performance is provided while dielectric loss is kept to a minimum. Additionally, it works with printed circuit boards made of PTFE. Additionally, it possesses a low thermal expansion along the z-axis and great mechanical durability. Thermal resistance and high-frequency dielectric are further properties of this PCB material.

The AD250C has reduced dielectric loss in addition to an affordable price. The manufacturer asserts that the RO4830 high-frequency laminate is competitively performing while remaining cost-effective. It is handled via common epoxy/glass (FR-4) circuit construction methods. Additionally, mica is a component of Rogers' RO4830 high-frequency laminates, which offers a wider frequency range at a lower price. In comparison to other laminates, the laminate has a wider range of dielectric constants.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com