Rogers' RO4730G3 high frequency PCB materials are reliable antenna-grade laminates, fully compatible with conventional FR-4 and high temperature lead-free solder processing. They are an affordable low-cost alternative material to conventional PTFE-based antenna substrates, allowing for designers to optimize cost and performance.

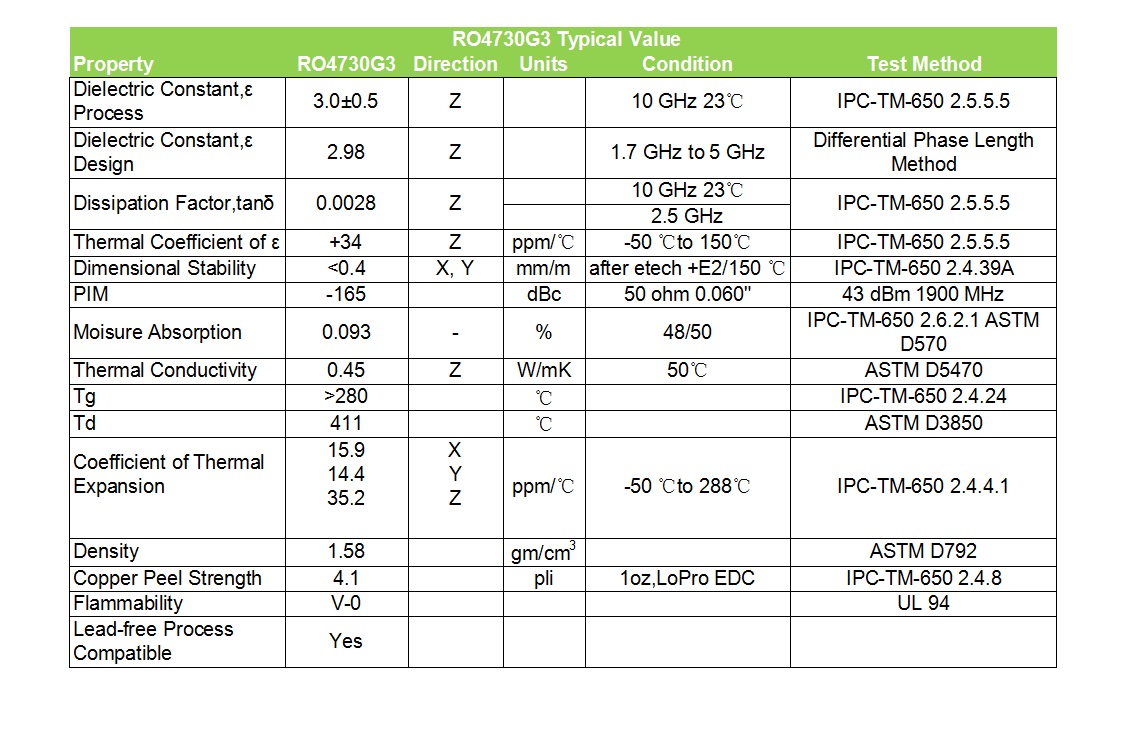

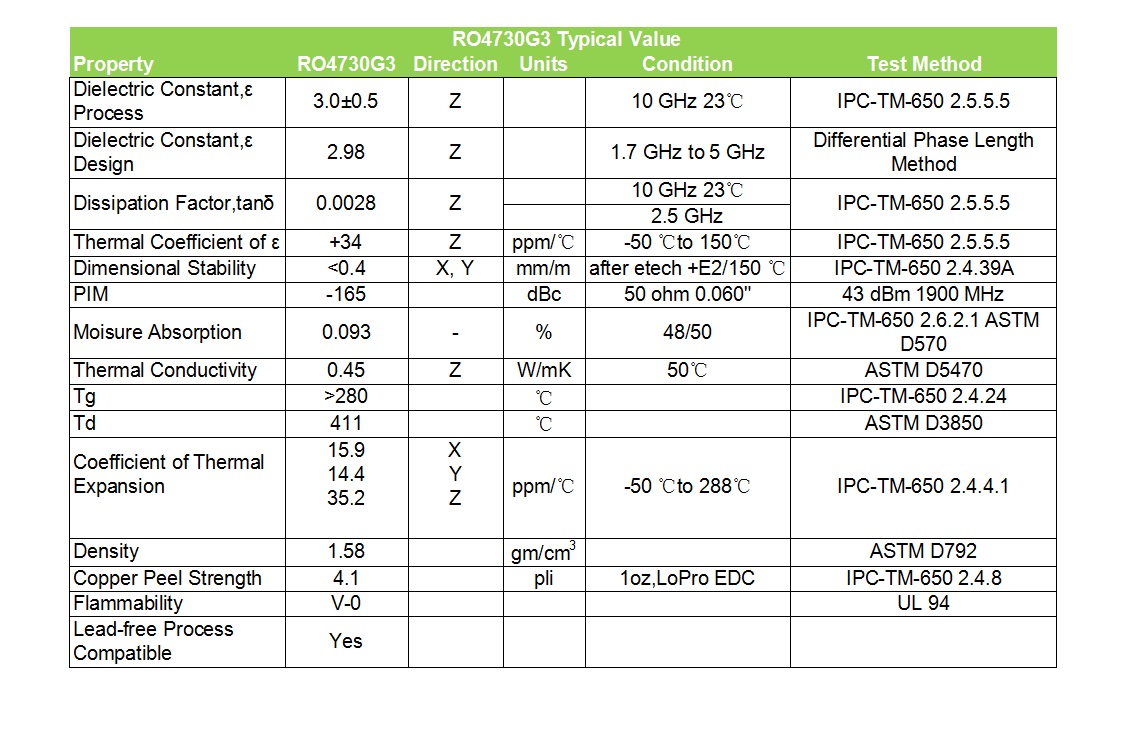

Now let's look at the data sheet to get more detailed properties of RO4730G3.

At first, the laminates have a dielectric constant (Dk) of 3.0 and a loss tangent (Df) of 0.0028 measured at 10 GHz in accordance with IPC-TM-650

The next one is low thermal coefficient of dielectric constant (TCDk). It is as low as 34 ppm/°C from -50°C to 150°C. Ideally, TCDk should be 0 ppm / ℃. In other words, Dk does not change with temperature. So, as a digital reference, a TCDk less than | 50 | ppm / ℃ or lower can be considered better.

Then next one is PIM, passive intermodulation, with value -165 dBc. Rogers company has made a general classification of the intermodulation: when the intermodulation value reaches -143dBc, it is the better intermodulation. It is very good when the intermodulation value reaches -153dBc and excellent intermodulation when the value reaches -163dBc. We can see that RO4730G3 materials exhibit excellent PIM performance.

Water absorption performs 0.093% and thermal conductivity exhibits 0.45 W/m/K. RO4730G3 is high Tg material which is greater than 280℃ and Td value exceeds 411℃.

Well, next is coefficient of thermal expansion (CTE).

The CTE in both the X and Y directions(15.9 and 14.4 ppm/°C) are similar to that of copper. The good CTE match reduces stresses in the PCB antennas.

The typical high glass transition temperature leads to a low Z-axis CTE,which also results in excellent plated through hole reliability.

Rogers RO4730G3 PCB Materials performs 1.58 gm/cm3 density and 4.1 pli copper peel strength. It is UL94-V0 grade flame resistant and environmentally friendly with lead-free process compatibility.

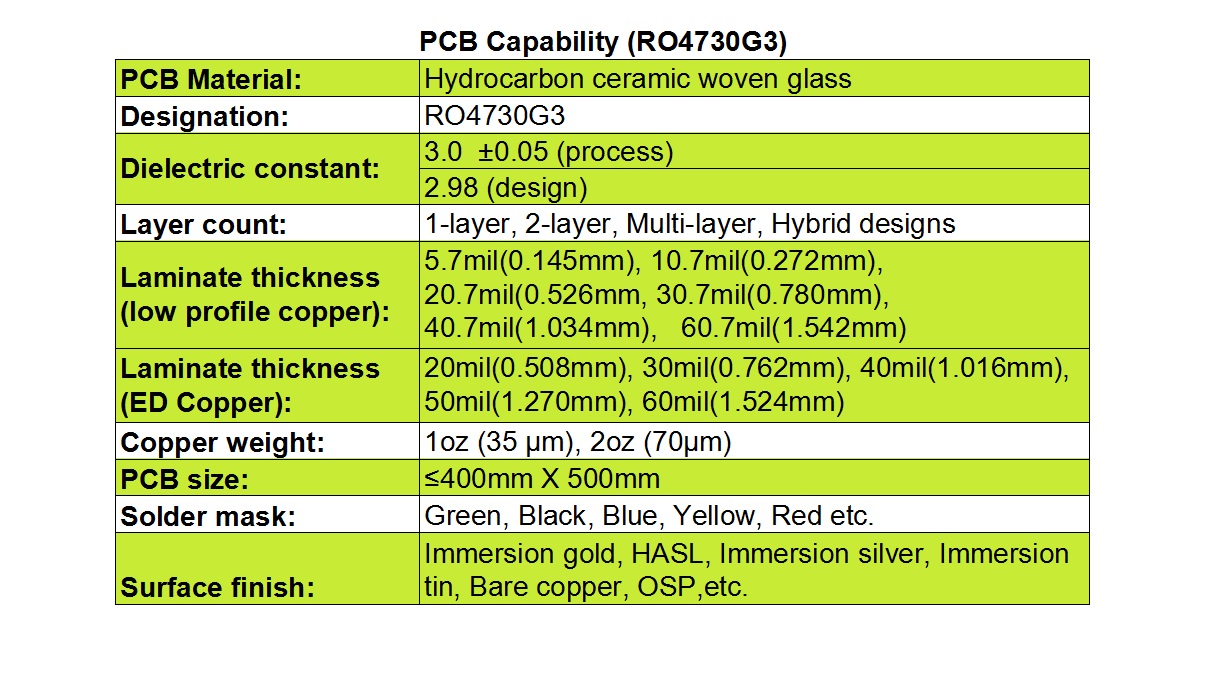

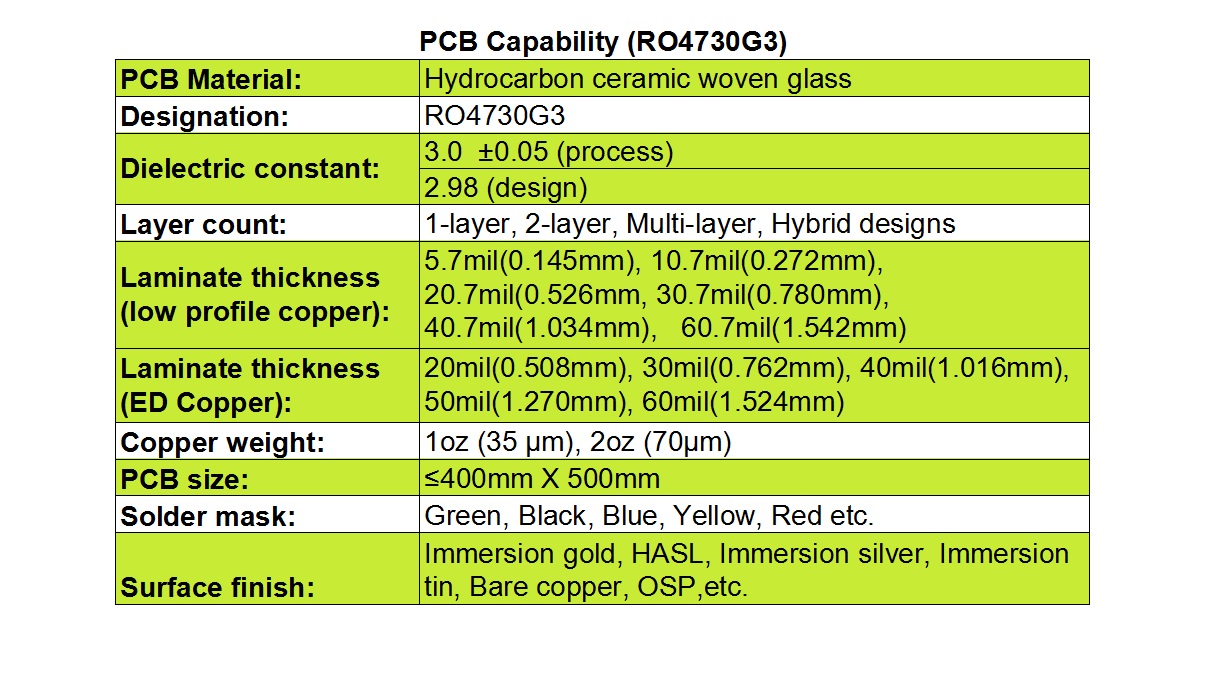

PCB capability

For RO4730G3 PCBs, we can provide you with single layer board, double layer board, multi-layer board and hybrid types.

RO4730G3 PCB circuit board have low profile copper and ED copper with different thickness. LoPro copper has the thickness of 5.7mil, 10.7mil, 20.7mil, 30.7mil and 60.7mil etc. ED copper has the thickness of 20mil, 30mil, 50mil and 60mil etc. Finished copper on PCB, no matter LoPro or ED copper, can be 1oz and 2oz.

The maximum PCB size on RO4730G3 substrates is 400mm by 500mm; it can be a single board in the sheet and also can be different designs in this panel.

Solder mask of green, black, blue and yellow etc is available in house. There’s immersion gold, HASL, immersion silver, immersion tin, bare copper etc applied to the pads surface finish.

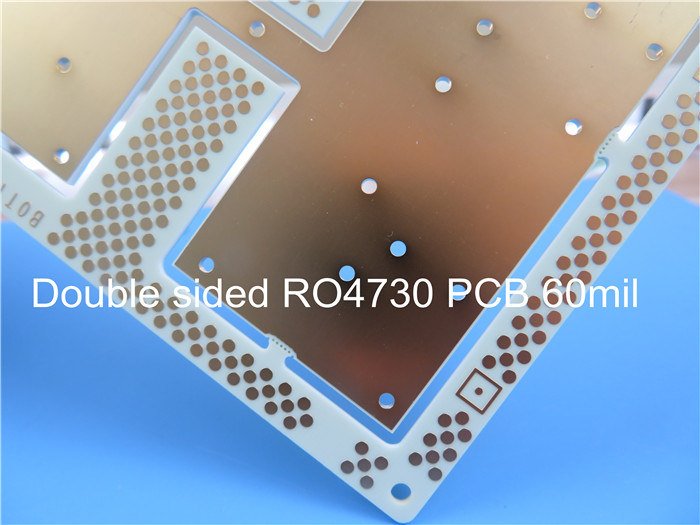

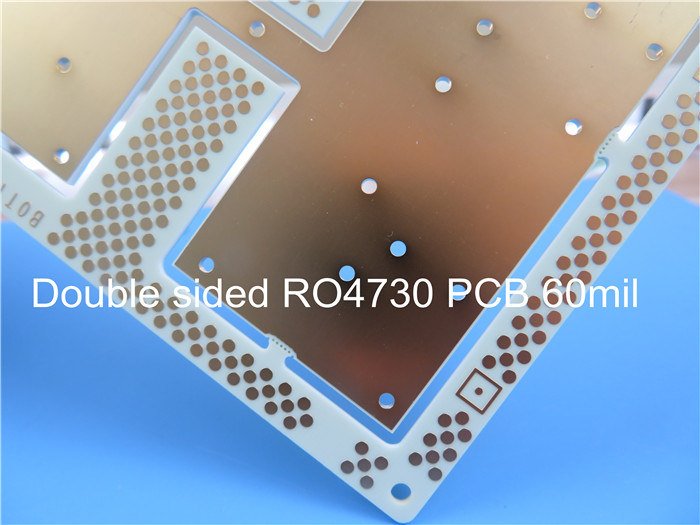

The following is a type of

60mil RO4730G3 PCB, double-sided with immersion gold for base station antennas.

Besides, RO4730G3 PCB has the features of low insertion loss, light-weight 30% lighter than PTFE or fiber glass material.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com