Introduction

Today, we will discuss TLY-5Z printed circuit boards (PCBs), which are a type of high frequency PCBs manufactured using lightweight materials.

TLY-5Z 60mil laminates are advanced composites made of glass-filled PTFE, reinforced with woven fiberglass. The glass-filled composition was specifically developed for applications with low weight requirements, such as aerospace.

This results in a composite material that remains dimensionally stable, which would not be achievable with non-reinforced PTFEs. The low-density approach also creates a composite with minimal expansion along the Z-axis, something that cannot be achieved with composites rich in PTFE.

Now, let's examine the data sheet to gain more insight into the typical properties of TLY-5Z laminates.

TLY-5Z Typical Properties

TLY-5Zmaterials demonstrate a low dielectric constant and a low dissipation factor of 2.2 and 0.0015 respectively at 10 GHz.

They also possess excellent volume resistivity and surface resistivity, with values of 10^9 Mohms/cm and 10^8 Mohms respectively.

Furthermore, TLY-5Z high frequency PCB exhibits a high dielectric breakdown voltage of 45 kV and a dielectric strength of 770 V/mil.

In comparison to conventional materials with a dielectric constant of 2.2, TLY-5Z showcases a lower temperature coefficient of dielectric constant (TCDk) of -72 ppm/°C. This range extends from -55 to 150°C. However, its thermal conductivity is relatively modest at 0.2 W/m/K.

On the other hand, the coefficient of thermal expansion is quite favorable. TLY-5ZPCBpossesses half the thermal expansion of substrates rich in PTFE, enabling improved drilling and thermal cycling. The expansion rates are 30 and 40 ppm/ºC in the X and Y directions, and 130 ppm/ºC in the Z-axis.

TLY-5Z laminates PCB boast impressive mechanical properties as well. They exhibit a peel strength of 7 lbs./inch for 1 oz copper and a tensile strength exceeding 9000 psi in both the MD and CD directions. The tensile modulus surpasses 16000 psi in both directions, with an elongation capacity of 6% and 6.9%.

Regarding flexural strength,TLY-5Z Taconic RF PCB performs admirably, with values of 10300 psi and 11600 psi in the MD and CD directions respectively. Additionally, the flexural modulus is remarkably high, exceeding 300 thousand and 400 thousand in the MD and CD directions respectively.

TLY-5Z demonstrates a nominal negative dimensional stability of approximately -0.05% on thicknesses of 10 mils and 30 mils after bake in the MD direction. After undergoing thermal stress testing, it tends to exhibit slightly more negative expansion, with a value of -0.07% on both thicknesses.

As a low-density laminate, TLY-5Z has a density of 1.92 g/cm³. It possesses a specific heat value of 0.95 J/g/℃ and a low moisture absorption rate of 0.03%.

Lastly, TLY-5Z has a Durometer hardness of 68 and is compatible with UL 94V-0 standards.

|

Property

|

Conditions

|

Value

|

Unit

|

Test Method

|

|

Electrical properties

|

|

Dielectric Constant

|

@ 10 GHz

|

2.20+/- 0.04

|

|

IPC-650 2.5.5.5.1 Mod.

|

|

Dissipation Factor

|

@ 10 GHz

|

0.0015

|

|

IPC-650 2.5.5.5.1 Mod.

|

|

Volume Resistivity

|

|

10^9

|

Mohms/cm

|

IPC-650 2.5.17.1

|

|

Surface Resistivity

|

|

10^8

|

Mohms

|

IPC-650 2.5.17.1

|

|

Dielectric Breakdown Voltage

|

|

45

|

kV

|

IPC-650 2.5.6

|

|

Dielectric Strength

|

|

770

|

V/mil

|

IPC-650 2.5.6.2

|

|

Thermal properties

|

|

Tc(D)K

|

(-55 ~150°C)

|

-72

|

ppm/°C

|

IPC-650 2.5.5.6 Mod.

|

|

Thermal Conductivity

|

|

0.2

|

W/M*K

|

IPC-650 2.4.50

|

|

CTE (25 - 260°C)

|

X

|

30

|

ppm/ºC

|

IPC-650 2.4.41

|

|

Y

|

40

|

ppm/ºC

|

IPC-650 2.4.41

|

|

Z

|

130

|

ppm/ºC

|

IPC-650 2.4.41

|

|

Mechanical Properties

|

|

Peel Strength

|

1 oz. copper

|

7

|

lbs./inch

|

IPC-650 2.4.8

|

|

Tensile Strength

|

MD

|

9137

|

psi

|

IPC-650 2.4.18.3

|

|

CD

|

9572

|

psi

|

IPC-650 2.4.18.3

|

|

Tensile Modulus

|

MD

|

182,748

|

psi

|

IPC-650 2.4.18.3

|

|

CD

|

165,344

|

psi

|

IPC-650 2.4.18.3

|

|

Mechanical Properties

|

|

Elongation

|

MD

|

6

|

%

|

IPC-650 2.4.18.3

|

|

CD

|

6.9

|

%

|

IPC-650 2.4.18.3

|

|

Flex Strength

|

MD

|

10,300

|

psi

|

ASTM D790

|

|

CD

|

11,600

|

psi

|

ASTM D790

|

|

Flex Modulus

|

MD

|

377,100

|

psi

|

ASTM D790

|

|

CD

|

432,213

|

psi

|

ASTM D790

|

|

Dimensional Stability

|

MD

|

-0.05, -0.05

|

% (10mil, 30mil)

|

IPC-650 2.4.39 (Bake)

|

|

CD

|

-0.17,-0.11

|

% (10mil, 30mil)

|

IPC-650 2.4.39 (Bake)

|

|

Dimensional Stability

|

MD

|

-0.07, -0.07

|

% (10mil, 30mil)

|

IPC-650 2.4.39 (Stress)

|

|

CD

|

-0.22, -0.14

|

% (10mil, 30mil)

|

IPC-650 2.4.39 (Stress)

|

|

Density

|

Specific Gravity

|

1.92

|

g/cm3

|

IPC-650 2.3.5

|

|

Chemical / Physical Properties

|

|

Specific Heat

|

|

0.95

|

J/g°C

|

IPC-650 2.4.50

|

|

Moisture Absorption

|

|

0.03

|

%

|

IPC-650 2.6.2.1

|

|

Hardness

|

Durometer

|

68

|

-

|

ASTM D2240

|

|

UL-94 Flammability Rating

|

|

V-0

|

|

UL-94

|

TLY-5Z PCB Capability

For TLY-5Z Taconic RF PCB, we offer double layer boards, multi-layer boards, and hybrid designs.

We have in-house availability of standard thicknesses such as 10 mils, 20 mils, 30 mils, and 60 mils. TLY-5Z can be custom-manufactured in 10 mil increments (0.250mm).

Finished copper on track lines can be achieved with 1oz and 2oz options.

On high-frequency materials, our maximum PCB size is 400mm by 500mm, which can accommodate a single board or multiple designs on a panel.

We provide solder mask options in green, black, blue, yellow, and red.

Surface pad plating includes immersion gold, HASL, immersion silver, immersion tin, OSP, pure gold, ENEPIG, and bare copper, among others.

|

PCB Material:

|

Glass-filled PTFE composites with Woven Fiberglass Reinforcement.

|

|

Designation:

|

TLY-5Z

|

|

Dielectric Constant:

|

2.20 +/- 0.04 (10 GHz)

|

|

Dissipation Factor

|

0.0015 (10 GHz)

|

|

Layer Count:

|

Double Sided PCB, Multilayer PCB, Hybrid PCB

|

|

Laminate Thickness:

|

10mil (0.254mm), 20mil (0.508mm), 30mil (0.762mm), 60mil (1.524mm )

|

|

Copper Weight:

|

1oz (35 µm), 2oz (70µm)

|

|

PCB Size:

|

≤400mm X 500mm

|

|

Solder Mask:

|

Green, Black, Blue, Yellow, Red etc.

|

|

Surface Finish:

|

Immersion gold, Hot air soldering level (HASL), Immersion silver, Immersion tin, OSP, Pure gold plated, ENEPIG, Bare copper, etc..

|

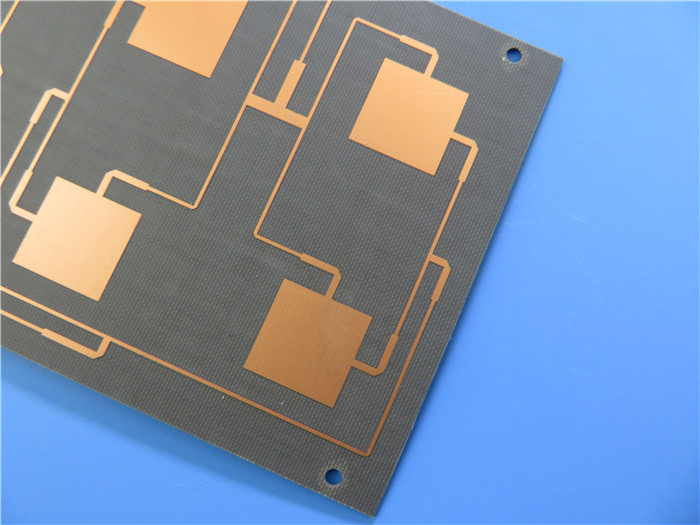

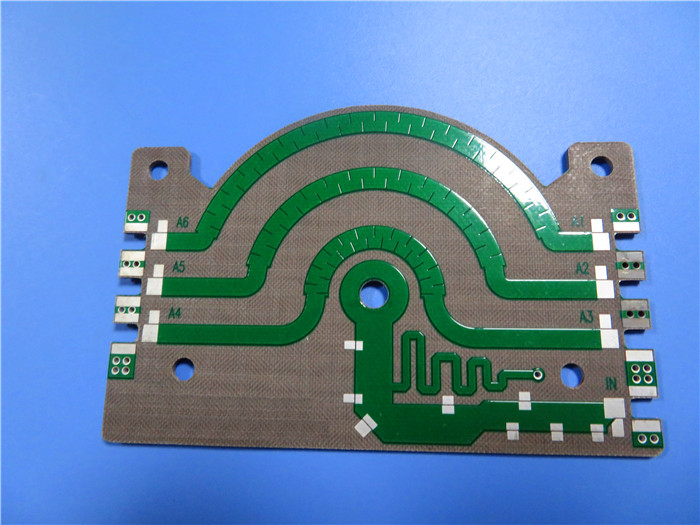

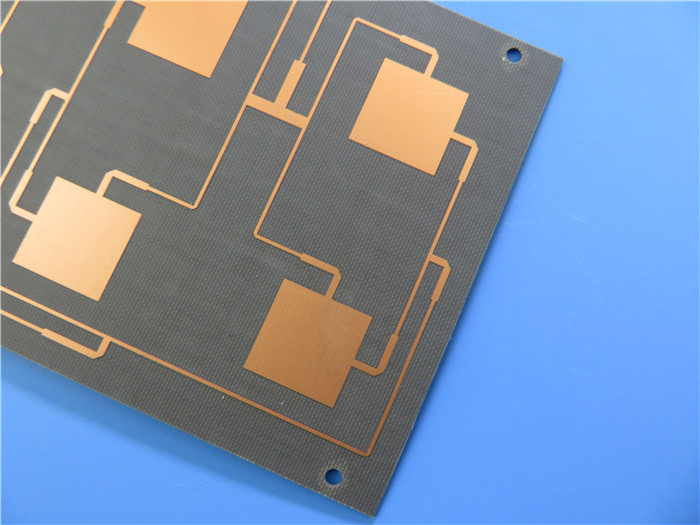

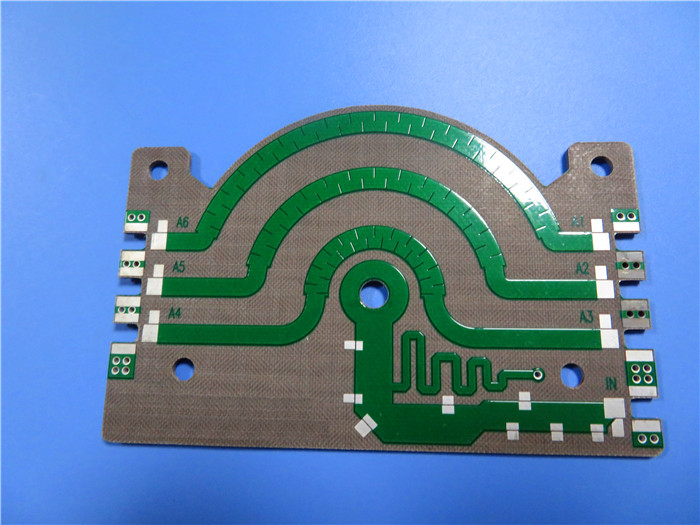

A Sample of TLY-5Z PCB

We are now showcasing a 60mil TLY-5Z printed circuit board with immersion silver, specifically designed for combiners.

These boards are also utilized in aerospace component applications, lightweight antennas for aircraft, and RF passive components, among other uses.

Conclusion

Taconic TLY-5Z PCB is an appealing choice from a cost perspective as well. When compared to traditional copper clad laminates rich in PTFE, the glass-filled structure offers a more cost-effective alternative. TLY-5Z 60mil substrate can be employed in high-volume commercial microwave applications where PTFE-rich substrates prove to be too expensive.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com