In the realm of advanced circuit materials, Rogers Corporation introduces the groundbreaking

RO3006 laminates, meticulously engineered ceramic-filled PTFE composites that redefine the standards of electrical and mechanical stability. Designed to cater to the demands of high-frequency applications,

RO3006 PCBs offer a host of innovative features and benefits that set them apart as a preferred choice for cutting-edge electronic designs.

Introduction to RO3006 PCBs:

RO3006 laminates are a testament to Rogers' commitment to excellence in circuit material innovation. These ceramic-filled PTFE composites are engineered to provide unparalleled electrical and mechanical stability, ensuring consistent performance across a wide range of temperatures. Unlike traditional PTFE glass materials, Rogers 3006 10mil laminates offer a stable dielectric constant (Dk) that remains unaffected by temperature fluctuations, eliminating the risk of abrupt changes near room temperature.

Features of RO3006 PCBs:

2.1Dielectric Constant:

With a Dk of 6.15 +/- 0.15 at 10 GHz/23°C, Rogers RO3006 PCBs ensure reliable signal transmission and consistent performance.

2.2Dissipation Factor:

Featuring a low dissipation factor of 0.002 at 10 GHz/23°C, RO3006 minimizes signal loss and ensures optimal efficiency.

2.3High Thermal Stability:

With a Td greater than 500°C, RO3006 high frequency laminates offer exceptional thermal resistance, making them suitable for high-temperature applications.

2.4Thermal Conductivity:

Boasting a thermal conductivity of 0.79 W/mK, RO3006 PCBs facilitate efficient heat dissipation, enhancing overall reliability.

2.5Moisture Absorption:

With a minimal moisture absorption rate of 0.02%, RO300610milRogers materials maintain their mechanical properties even in humid conditions.

2.6Coefficient of Thermal Expansion:

The low in-plane expansion coefficient of RO3006 PCBs (X axis 17 ppm/°C, Y axis 17 ppm/°C, Z axis 24 ppm/°C) ensures dimensional stability and reliability.

Benefits of RO3006 PCBs:

3.1Uniform Mechanical Properties:

Ideal for multi-layer board designs with varying dielectric constants, RO3006 PCBs offer uniform mechanical properties across different layers.

3.2Low In-Plane Expansion Coefficient:

By matching the expansion coefficient of copper, RO3006 laminates support reliable surface-mounted assemblies and ensure excellent dimensional stability.

3.3Volume Manufacturing Process:

The economical pricing of RO3006 10mil Rogers substrates makes them a cost-effective choice for high-volume production.

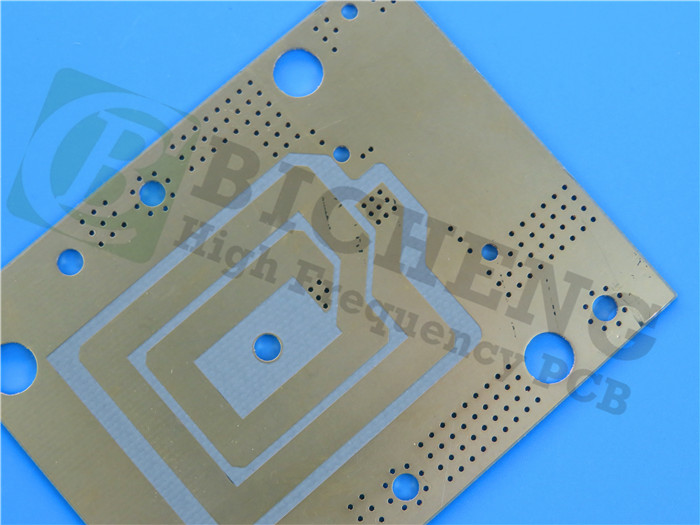

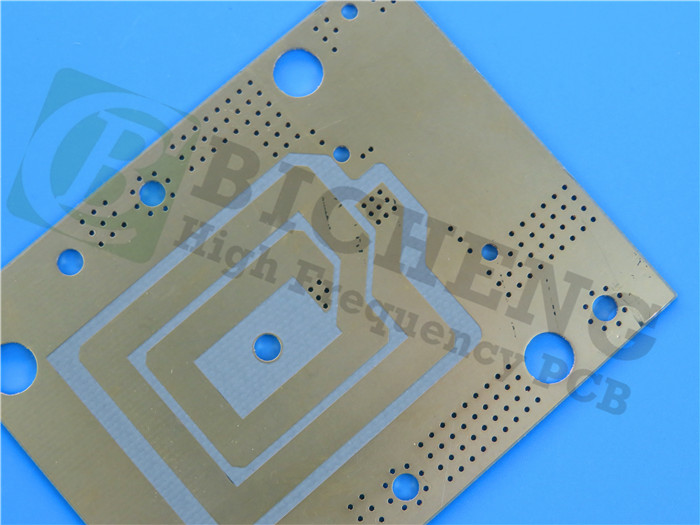

PCB Stackup and Construction Details:

Stackup: 2-layerwholesale rigid PCB

Copper Thickness: 35 μm (each layer)

RO3006 Substrate Thickness: 10mil (0.254mm)

Board Dimensions: 63.44mm x 48.5mm

Minimum Trace/Space: 4/4 mils

Minimum Hole Size: 0.3mm

Finished Board Thickness: 0.3mm

Finished Copper Weight: 1 oz (1.4 mils) outer layers

Via Plating Thickness: 20 μm

Surface Finish: Immersion Gold

Electrical Testing: 100% tested prior to shipment

PCB Statistics

Components: 9

Total Pads: 24

Thru Hole Pads: 18

Top SMT Pads: 6

Bottom SMT Pads: 0

Vias: 19

Nets: 1

Artwork and Standards

Type of Artwork Supplied: Gerber RS-274-X

Accepted Standard: IPC-Class-2

Availability: Worldwide

Typical Applications of RO3006 PCBs

RO3006 high frequency PCBs find extensive use in a variety of high-frequency applications, including:

Automotive radar systems

Global positioning satellite antennas

Cellular telecommunications systems (power amplifiers and antennas)

Wireless communications (patch antennas)

Direct broadcast satellites

Cable systems for datalink

Remote meter readers

Power backplanes

In conclusion, RO3006 Rogers PCB Board represent a pinnacle of innovation in high-frequency circuit materials, combining exceptional electrical properties, mechanical stability, and cost-effectiveness. With their superior performance metrics and versatile applications, RO3006 substrate PCB are poised to revolutionize the landscape of advanced electronic designs across various industries.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com