Why Choose Rogers RO3003G2 PCB for Next-Generation Automotive Radar Applications?

In the rapidly advancing field of automotive electronics, particularly with the proliferation of Advanced Driver-Assistance Systems (ADAS), the demand for printed circuit boards (PCBs) capable of reliably handling high-frequency signals, especially in the millimeter-wave spectrum, has never been greater. Addressing this critical need, Rogers Corporation has introduced the RO3003G2 high frequency laminate, a significant evolution within its esteemed RO3003 PCB series. This ceramic-filled Polytetrafluoroethylene (PTFE) composite material is engineered specifically to meet the stringent performance requirements of next-generation automotive radar sensors and other sophisticated communication systems. By incorporating direct feedback from the industry, Rogers has optimized the RO3003G2 to deliver exceptional electrical characteristics, establishing it as a premier choice for engineers designing safety-critical automotive applications.

Enhanced Material Properties for Superior Performance

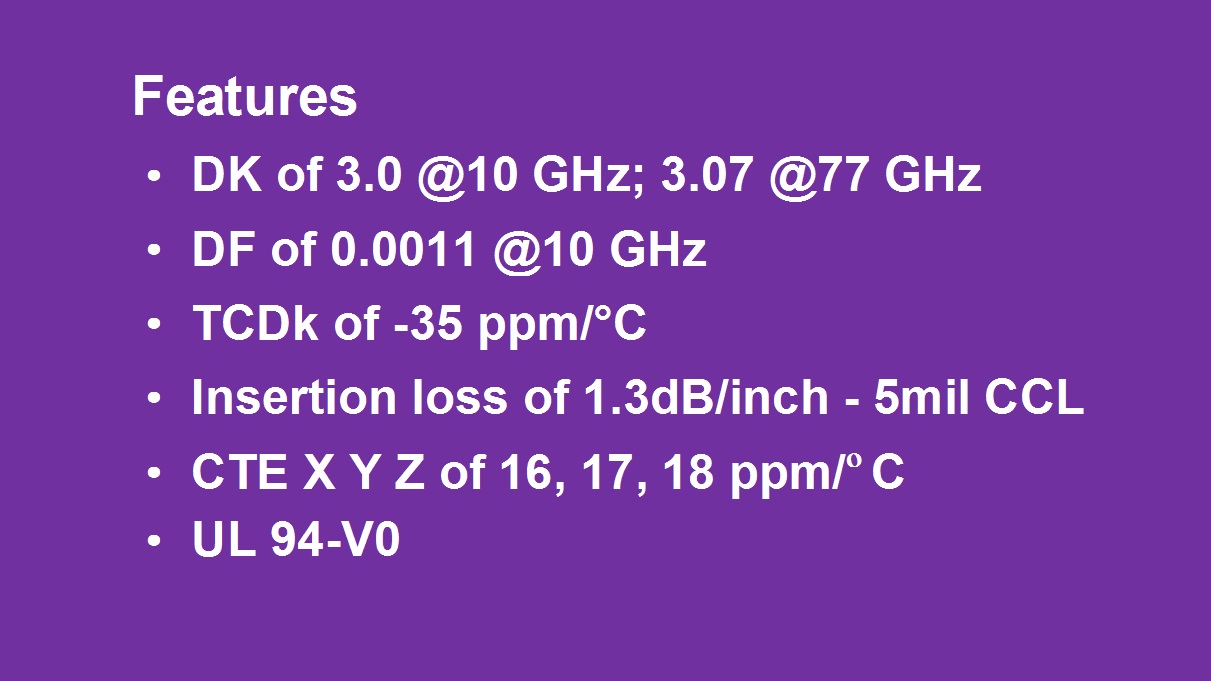

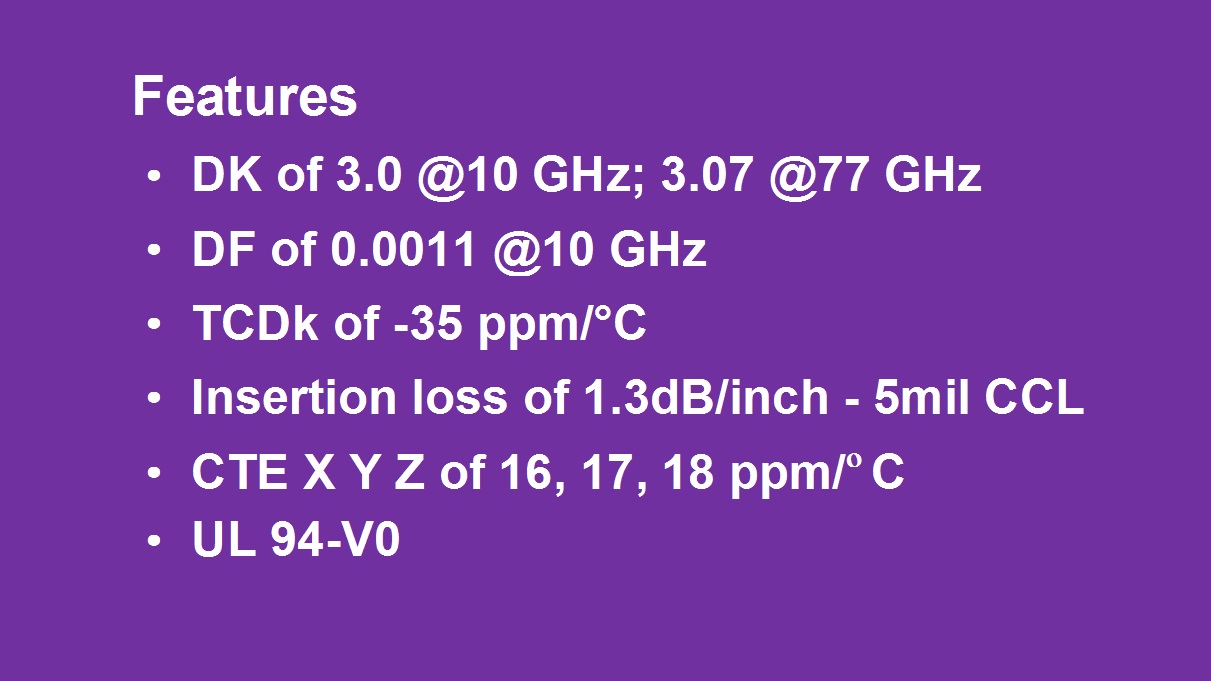

The RO3003G2 laminate stands out due to its meticulously calibrated formulation. The strategic optimization of the resin system and filler content, combined with the use of Very Low Profile Electrodeposited (ED) copper foil, results in a suite of outstanding electrical properties. A key parameter, the dielectric constant (Dk), exhibits remarkable consistency, measuring 3.00 at 10 GHz (using the clamped stripline method) and 3.07 at the automotive radar frequency of 77 GHz (as per the microstrip differential phase length method). This stable Dk across a broad frequency range is crucial for maintaining signal integrity.

Perhaps even more critical for high-frequency performance is the material's exceptionally low dissipation factor (Df), which is rated at an impressive 0.0011 at 10 GHz. This minimal signal loss directly translates to higher efficiency and greater range for radar systems. Furthermore, the Thermal Coefficient of Dielectric Constant (TCDk) is exceptionally stable, rated at -35 ppm/°C at 10 GHz across a wide operational temperature range from -50°C to 150°C. This thermal stability ensures consistent electrical performance under the harsh and variable conditions experienced in automotive environments, preventing signal drift due to temperature fluctuations.

When these properties are combined, they contribute to very low insertion loss. For instance, a standard 5-mil laminate demonstrates an insertion loss of just 1.3dB/inch when measured by the microstrip differential phase length method. This low loss is paramount for preserving the strength and quality of delicate millimeter-wave signals. Beyond electrical performance, the RO3003G2 laminate features a copper-matched Coefficient of Thermal Expansion (CTE) of 16, 17, and 18 ppm/°C in the X, Y, and Z axes, respectively. This balanced CTE minimizes the risk of plated through-hole failure and other thermal stress-induced damage in complex multi-layer PCB constructions, enhancing long-term reliability. The material also holds the UL 94 V-0 flammability rating and is fully compatible with lead-free assembly processes, meeting essential safety and environmental standards.

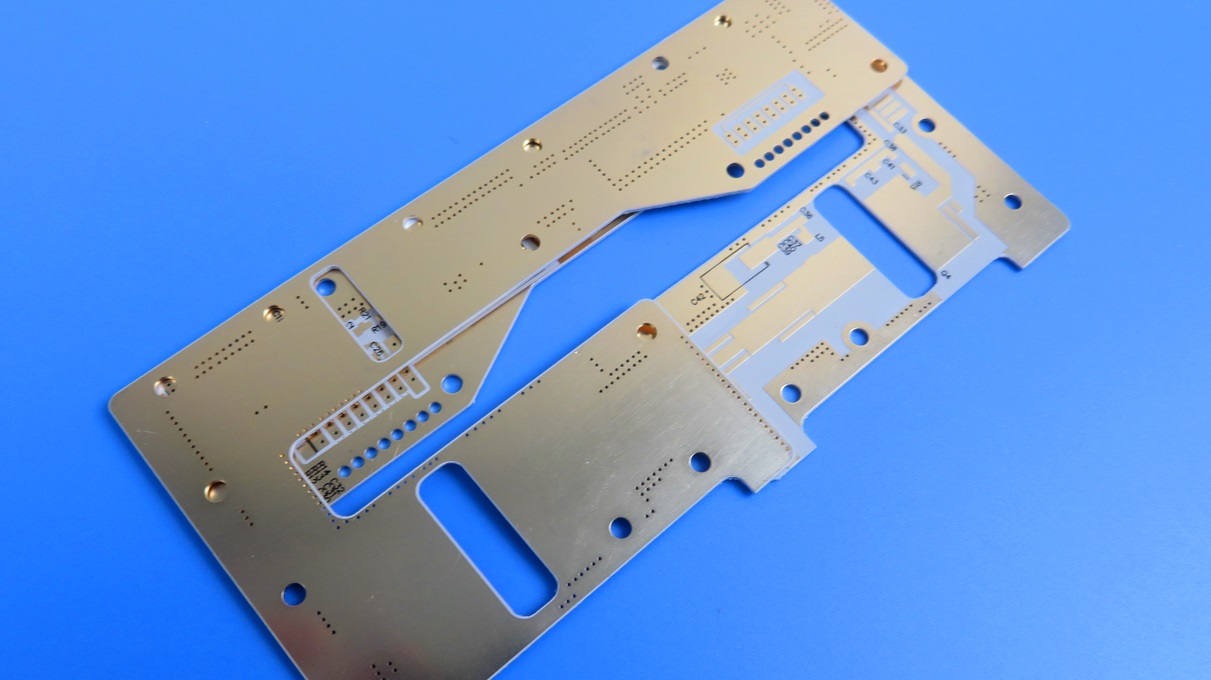

Advanced PCB Fabrication Capabilities with RO3003G2

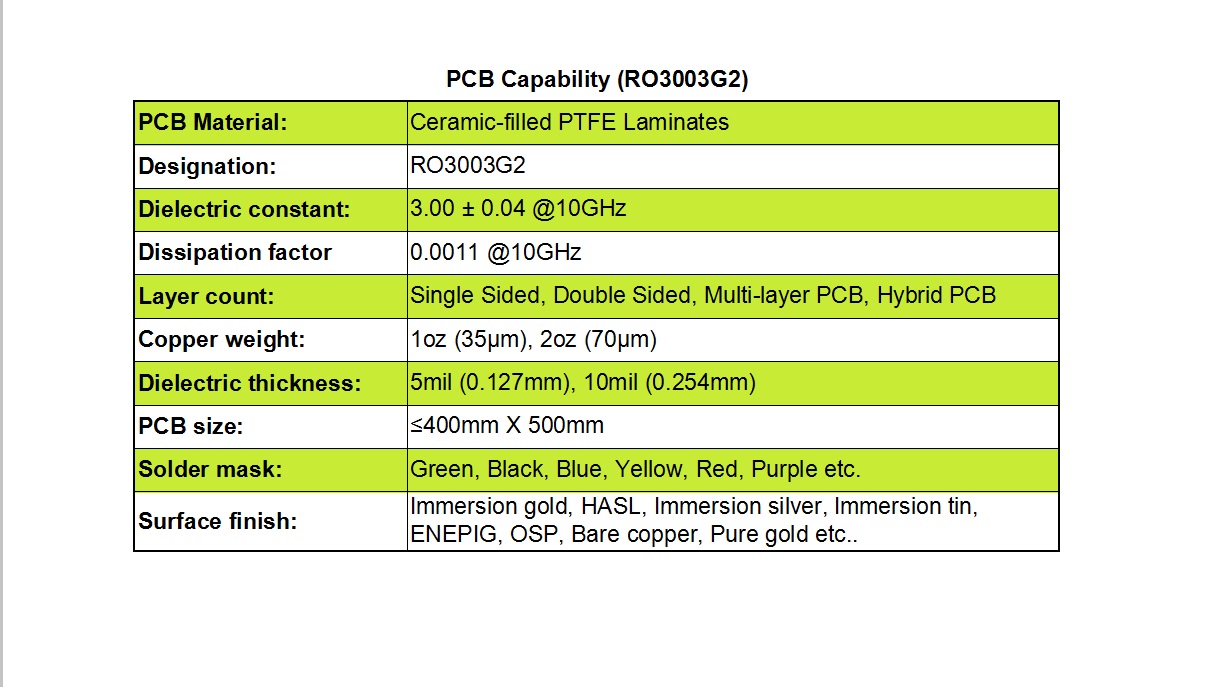

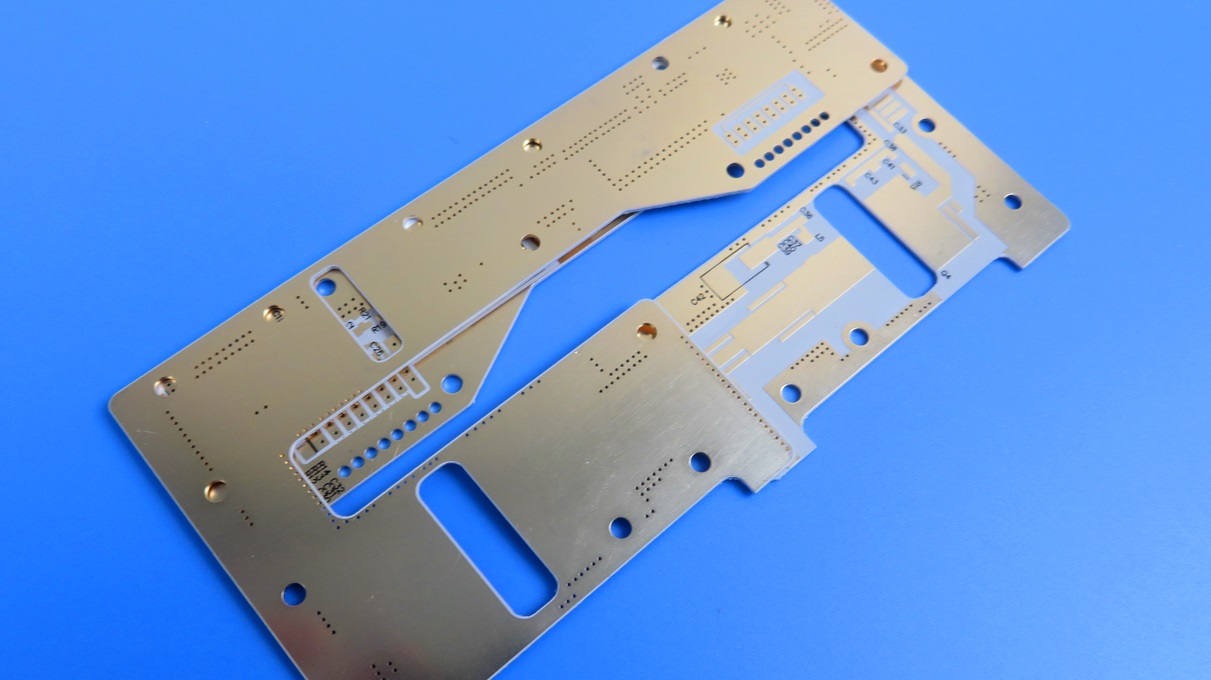

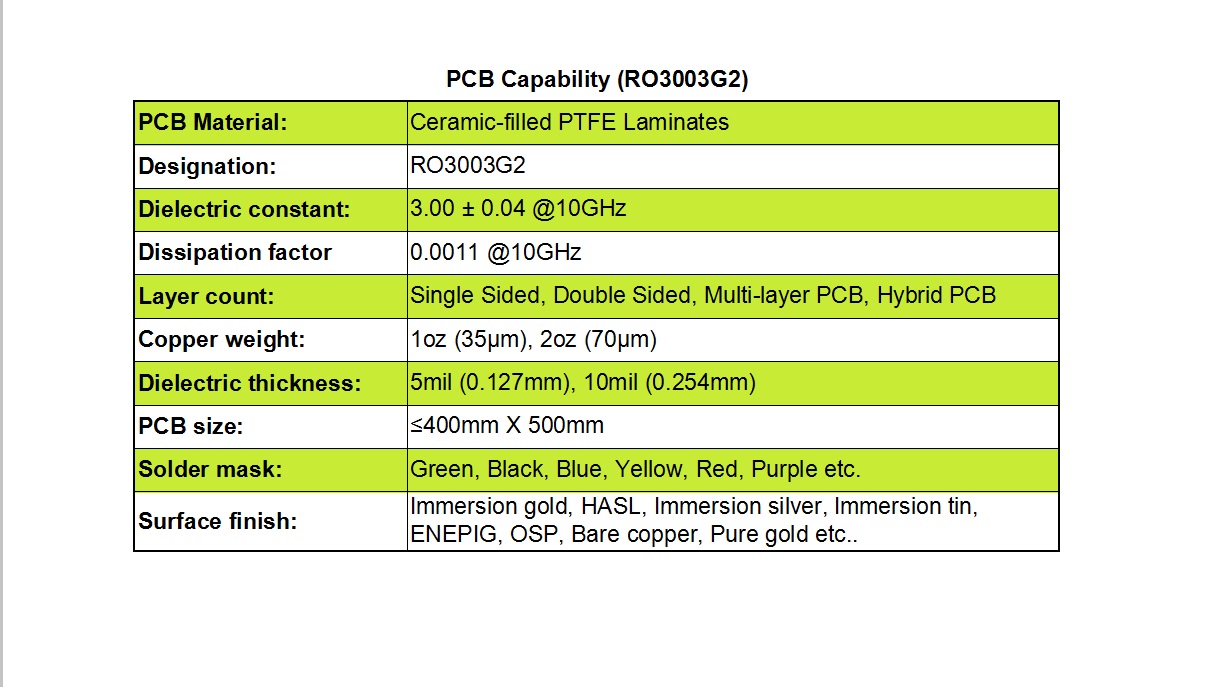

Our manufacturing expertise ensures that the superior properties of the RO3003G2 substrate are fully realized in the final PCB product. We offer versatile fabrication services accommodating a wide spectrum of design complexities, ranging from simple single-sided and double-sided boards to intricate multi-layer and hybrid PCB structures that combine RO3003G2 with other materials. To suit diverse electrical and thermal needs, we process standard dielectric thicknesses of 5mil (0.127mm) and 10mil (0.254mm), and can work with copper weights of both 1oz (35µm) and 2oz (70µm).

We support large-format designs with a maximum panel size of 400mm x 500mm, catering to both compact and expansive board layouts. Aesthetic and functional customization is available through a variety of solder mask colors, including green, black, blue, yellow, red, and purple. Designers have a comprehensive selection of surface finishes to choose from, such as Immersion Gold (ENIG), Hot Air Solder Leveling (HASL), Immersion Silver, Immersion Tin, Electroless Nickel Electroless Palladium Immersion Gold (ENEPIG), Organic Solderability Preservative (OSP), bare copper, and pure gold, ensuring optimal solderability and shelf life for your application.

Targeted Applications in Modern Automotive Systems

The RO3003G2 PCB is ideally suited for a host of sophisticated applications where high-frequency performance and reliability are non-negotiable. Its primary application lies in the core components of modern ADAS, including:

-

Adaptive Cruise Control (ACC)

-

Forward Collision Warning (FCW) Systems

-

Active Brake Assist

-

Lane Change Assist (LCA) Systems

-

Traffic Jam Assist / Pilot Systems

These systems rely on accurate and consistent radar data to function correctly, and the RO3003G2 high frequency PCB provides the stable, low-loss signal transmission foundation necessary for their operation. By selectingRogersRO3003G2 PCBs, engineers can design more robust, efficient, and high-performing electronic systems that push the boundaries of automotive safety and autonomy.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com