What Makes Kappa 438 High Frequency PCB a Superior Alternative to Standard FR-4 Materials?

In today’s rapidly evolving wireless landscape, the surge in data consumption and the rollout of next-generation networks demand circuit materials that deliver enhanced RF performance, reliability, and signal integrity. Traditional FR-4 substrates, while cost-effective, often fall short in meeting these stringent requirements. This is where Rogers Corporation’s Kappa 438 high-frequency PCB material stands out—a purpose-engineered laminate designed to bridge the gap between standard epoxy-glass materials and high-performance RF substrates.

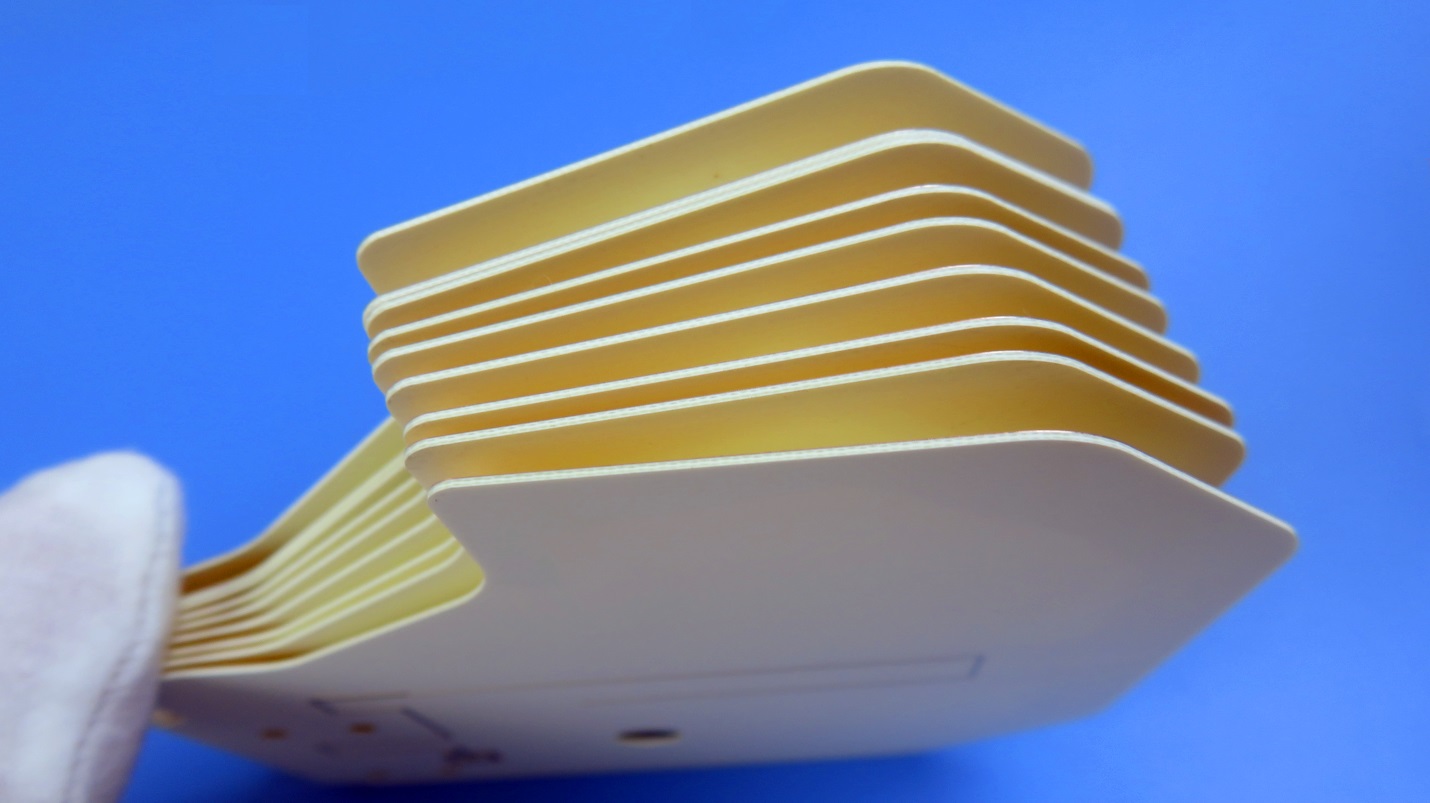

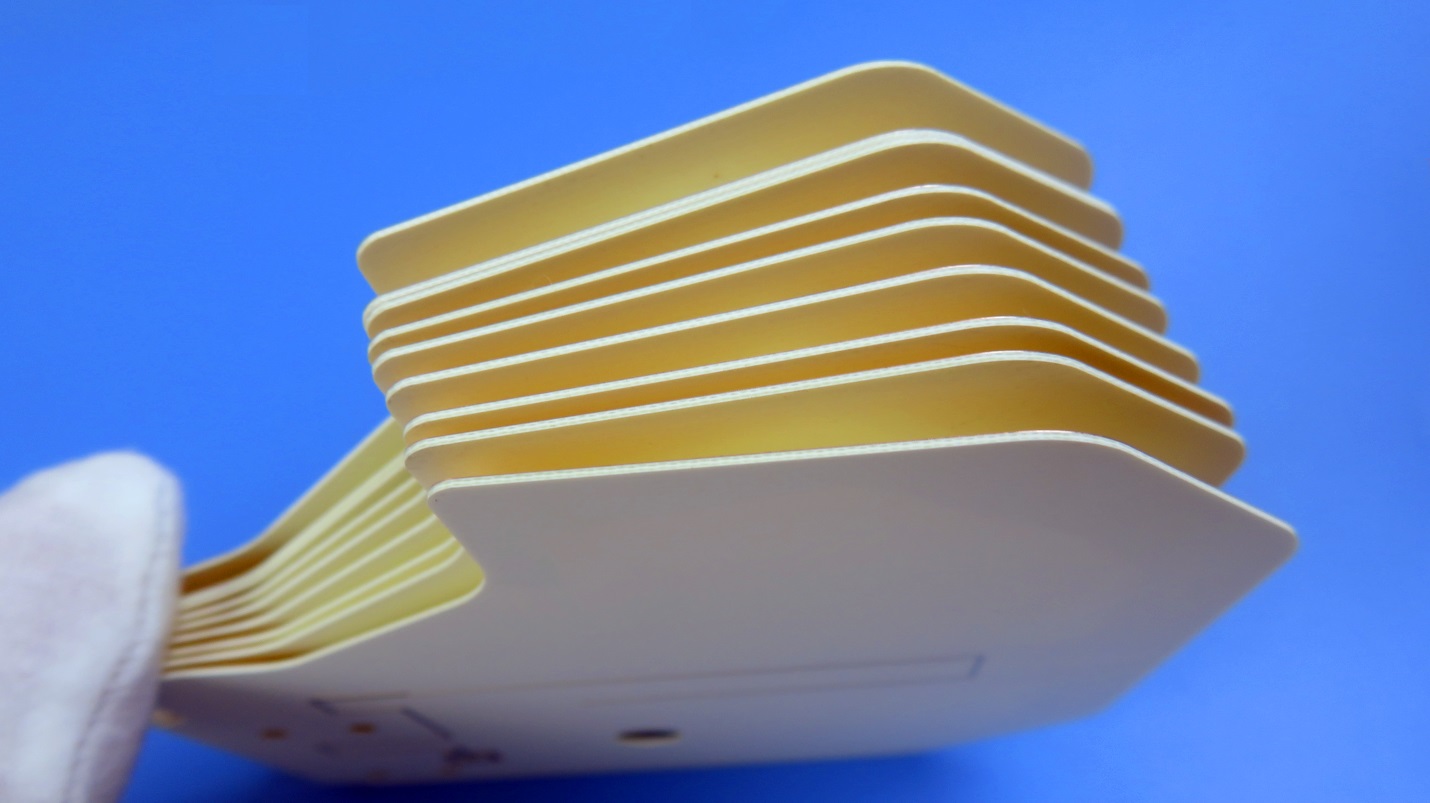

Originally developed to address the escalating needs of the wireless industry, Rogers Kappa 438 offers a unique combination of superior dielectric properties, reduced signal loss, and exceptional thermal stability. Its innovative formulation uses a glass-reinforced hydrocarbon ceramic system that not only enhances high-frequency performance but also allows for cost-efficient fabrication using standard FR-4 manufacturing processes. This means designers can achieve elevated electrical performance without completely overhauling their existing production setups.

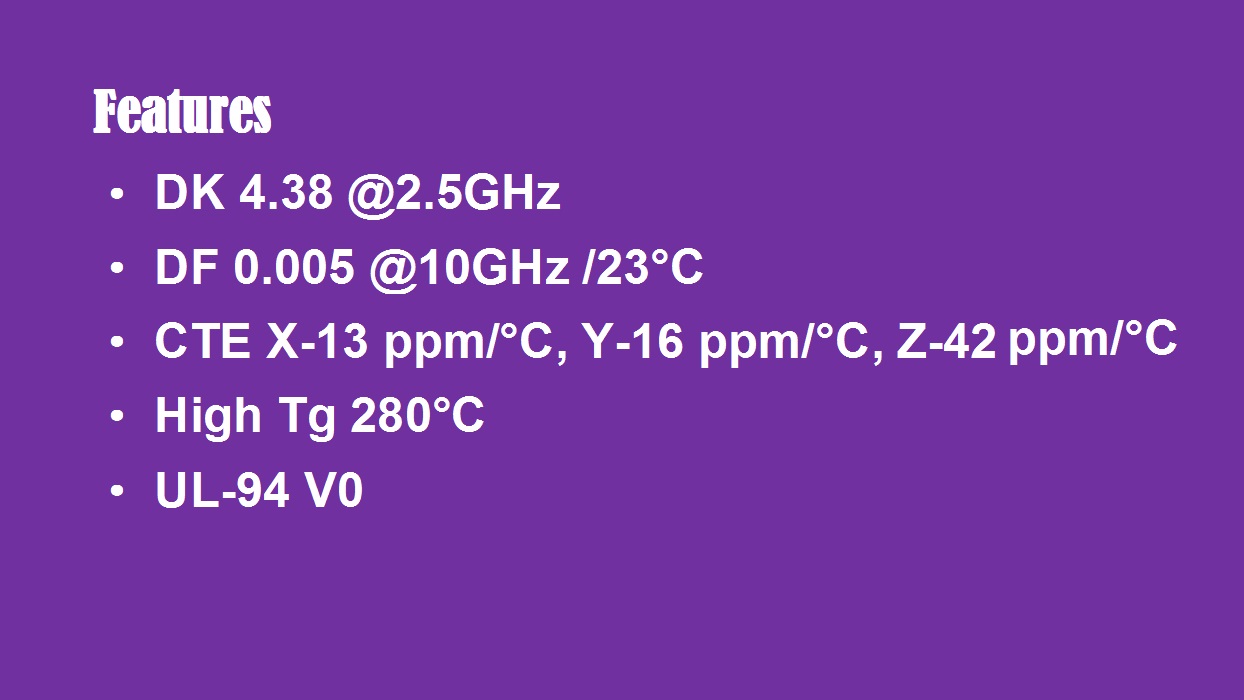

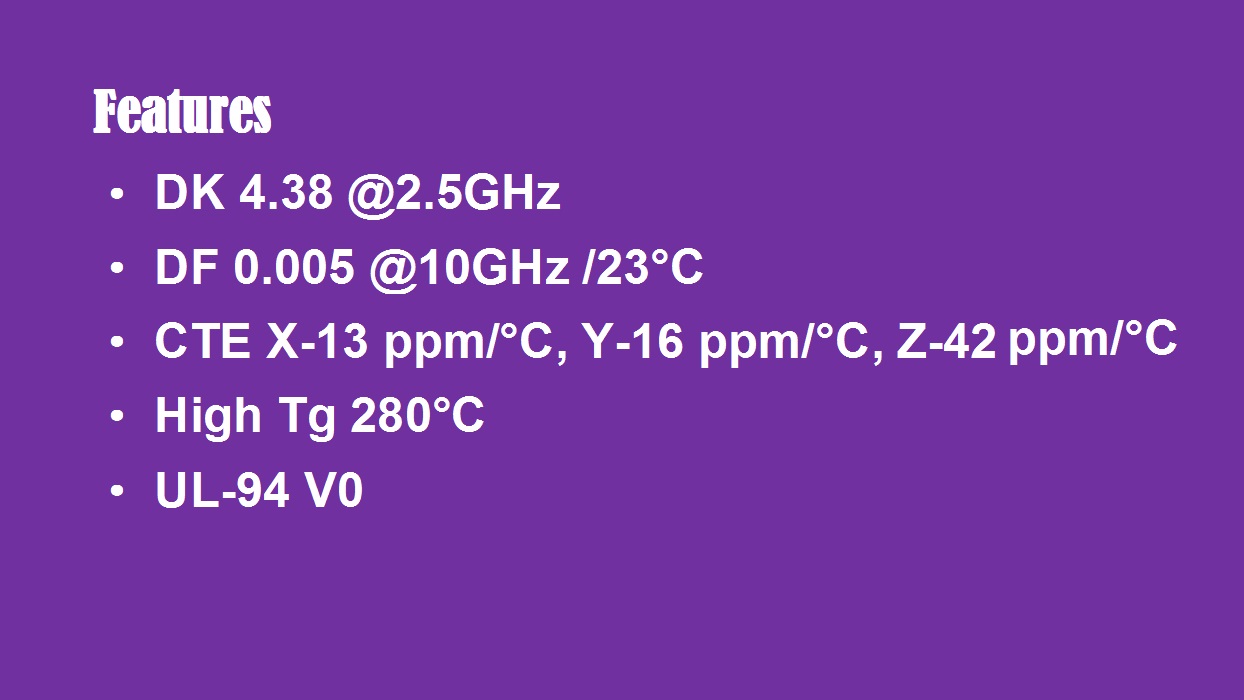

Key Features of Kappa 438 Laminates

One of the most critical attributes of Kappa 438 is its consistent dielectric constant (Dk) of 4.38 at 2.5 GHz. This value aligns closely with common FR-4 standards, enabling seamless integration into designs that require better RF characteristics without drastic impedance mismatches or redesign efforts.

Moreover, Kappa 438 PCB provides tighter tolerances on both Dk and thickness compared to conventional FR-4. This allows for more accurate impedance control, minimizes signal distortion, and improves overall signal integrity—a crucial advantage in high-speed digital and RF circuits.

The material also exhibits a low coefficient of thermal expansion (CTE) across all axes: 13 ppm/°C in the X direction, 16 ppm/°C in Y, and 42 ppm/°C in Z. This dimensional stability under temperature fluctuations ensures greater reliability of plated through-holes and reduces the risk of failure in thermal cycling scenarios.

With a high glass transition temperature (Tg) exceeding 280°C (as measured by TMA), Kappa 438 performs reliably in high-temperature environments, making it suitable for lead-free soldering processes and applications exposed to thermal stress. Furthermore, it complies with UL 94-V0 flammability standards, adding an extra layer of safety for use in critical electronic systems.

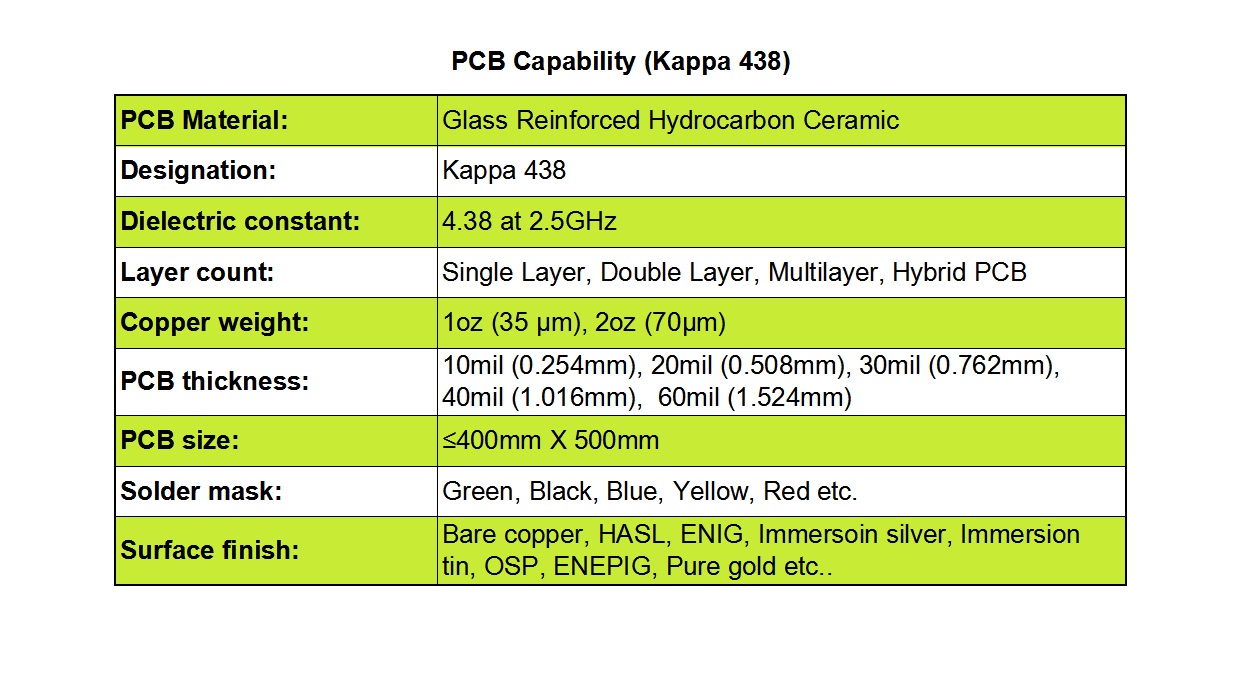

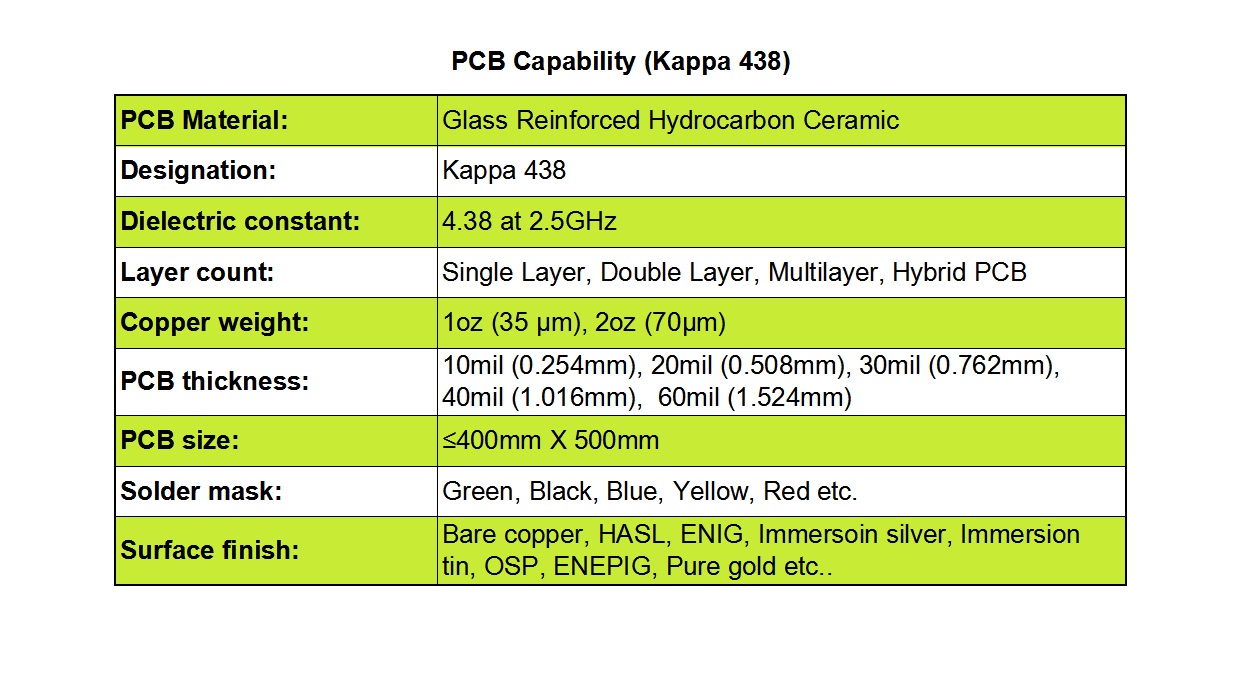

PCB Manufacturing Capabilities with Kappa 438

As an experienced PCB supplier, we provide end-to-end manufacturing solutions forKappa 438-based boards. Our capabilities include:

-

Various layer configurations: single-sided, double-sided, multilayer, and hybrid constructions

-

Copper weights options: 1 oz (35 µm) and 2 oz (70 µm)

-

Thickness range: from 10 mil (0.254 mm) to 60 mil (1.524 mm)

-

Maximum board dimensions: up to 400 mm x 500 mm

-

Solder mask colors: green, black, blue, yellow, and red

-

Surface finishes: bare copper, HASL, ENIG, immersion silver, immersion tin, OSP, ENEPIG, and pure gold

These flexible options allow us to support both prototyping and high-volume production runs for a wide spectrum of design requirements.

Typical Applications

Kappa 438 high frequency PCBs are ideally suited for high-frequency and RF applications where performance and reliability cannot be compromised. Common use cases include:

-

Carrier-Grade Wi-Fi Access Points

-

Licensed Assisted Access (LAA) Systems

-

Small Cell Networks and Distributed Antenna Systems (DAS)

-

Vehicle-to-Vehicle and Vehicle-to-Infrastructure Communication (V2X)

-

Internet of Things (IoT) Devices and Infrastructure

Whether you are designing for telecommunications, automotive safety, or smart infrastructure, Kappa 438 Rogers PCB provides a robust foundation that combines electrical excellence with manufacturing practicality.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com