The world of circuit boards is constantly evolving, with new technologies and materials pushing the boundaries of what is possible. In this era of high-frequency performance and low-cost fabrication, we proudly present the30milKappa 438 PCB. Designed with precision and innovation, this cutting-edge PCB offers superior performance, ease of manufacturing, and a wide range of applications. In this comprehensive product description, we will delve deep into the features, benefits, construction details, statistics, and typical applications of the

Kappa 438 PCB, providing you with the knowledge to make an informed decision.

What material is Kappa 438 made of?

The Rogers Kappa 438 PCB is built on the foundation of Rogers' glass reinforced hydrocarbon ceramic system, a breakthrough technology that combines high-frequency performance with affordability. This unique system allows for low-loss material fabrication using standard epoxy/glass (FR-4) processes, offering a cost-effective solution for circuit board manufacturing. Moreover, the Kappa 438 laminates possess the prestigious UL 94 V-0 flame retardant rating and are compatible with lead-free solder processes, ensuring safety and environmental compliance.

Features: Unrivaled Performance and Reliability

The Kappa 438 High Frequency PCB boasts an array of features that set it apart from conventional circuit boards. Firstly, it utilizes a glass reinforced hydrocarbon thermoset platform, which enhances its strength and durability. This platform is complemented by a dielectric constant (Dk) of 4.38, tailored to meet FR-4 industry standard norms. The Kappa 438 also exhibits tighter Dk and thickness tolerances compared to FR-4, ensuring consistent circuit performance and improved design flexibility.

Another standout feature of the Kappa 438 30mil substrate PCB is its impressive low Z Axis coefficient of thermal expansion (CTE) of 42 ppm/°C. This characteristic enables the board to withstand extreme temperature variations without compromising its structural integrity. Furthermore, the Kappa 438 boasts a high glass transition temperature (Tg) of over 280°C TMA, ensuring reliable operation even under harsh conditions.

In addition, the Kappa 438 PCB offers a thermal coefficient of Dk of -21 ppm/°C during temperatures ranging from -50°C to 150°C. This exceptional thermal stability ensures that the board maintains its electrical performance across a wide temperature range.

Benefits: Unleashing Design Potential

By choosing the Kappa 438 PCB, you unlock a multitude of benefits that drive innovation and enhance your design capabilities. One of the key advantages is its compatibility with FR-4 manufacturing processes. This compatibility allows for seamless integration into existing FR-4 designs, enabling a smooth transition to better electrical performance without costly redesigns.

Consistency is crucial in circuit board performance, and the Kappa 438 delivers just that. With its superior material properties and tight tolerances, this PCB ensures consistent circuit performance, eliminating variations and optimizing your designs.

The Kappa 438 PCB also offers improved design flexibility and plated through-hole reliability. Its advanced construction allows for intricate designs and complex circuitry, empowering engineers to push the boundaries of what is achievable. Additionally, the board's compatibility with automated assembly processes streamlines production, reducing costs and increasing efficiency.

PCB Construction Details: Precision and Durability

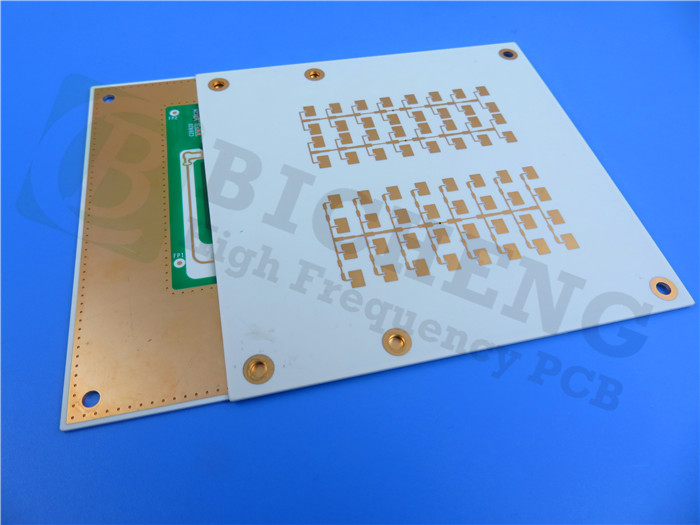

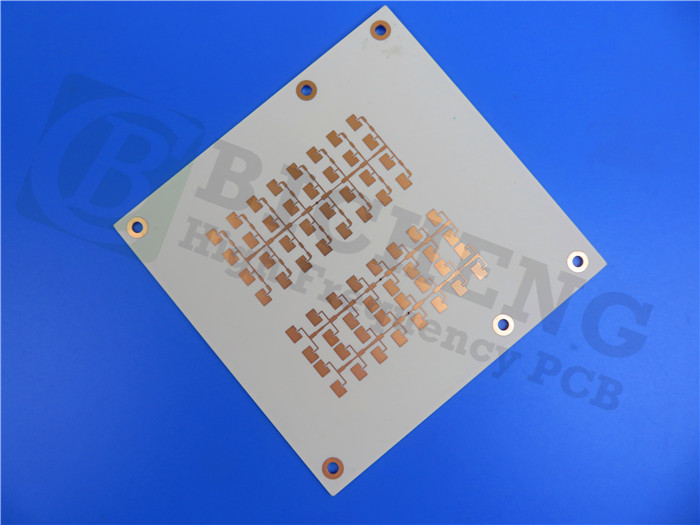

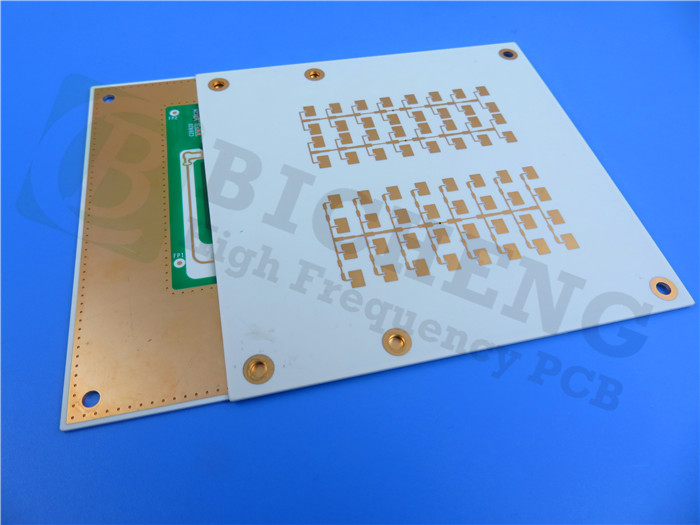

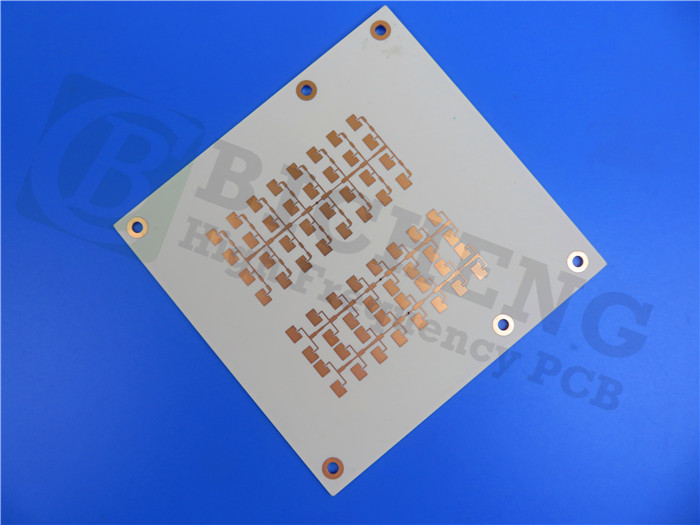

The Kappa 438 PCB features a 2-layer rigid construction, designed to meet the demands of modern electronic systems. The board stackup includes a 35 μm copper layer on both the top and bottom sides, ensuring efficient signal transmission and robust connectivity. The core of the PCB consists of the Rogers Kappa 438 laminate, which is 0.762 mm (30 mil) thick, offering optimal performance and durability.

With a finished board thickness of 0.8mm and a 1 oz (1.4 mils) outer layer copper weight, the Kappa 438 strikes the perfect balance between compactness and functionality. The via plating thickness of 20 μm ensures reliable connections between layers, facilitating efficient signal transfer.

To enhance the longevity of the Kappa 438 0.762mm material PCB, it is finished with the Electroless Nickel Electroless Palladium Immersion Gold (ENEPIG) surface finish. This coating provides excellent corrosion resistance and ensures reliable solderability, even after multiple reflow cycles.

To comply with industry standards, the Kappa 438 PCB undergoes rigorous testing. Prior to shipment, each board undergoes a 100% electrical test, guaranteeing flawless functionality and performance.

PCB Statistics: Precision Engineering in Action

The Kappa 438 PCB is more than just a collection of materials—it is a masterpiece of precision engineering. With 27 components and a total of 66 pads, this PCB offers ample space for your electronic designs. It features 45 through-hole pads and 21 top surface mount technology (SMT) pads, providing versatility for component placement. The absence of bottom SMT pads allows for greater flexibility and ease of assembly.

With 40 viasand 3 nets, the Kappa 438 PCB ensures efficient signal routing and connectivity. The board's artwork is supplied in the Gerber RS-274-X format, meeting industry-standard IPC-Class-2 requirements. These specifications ensure compatibility and ease of integration into your manufacturing processes.

Availability: Worldwide Access to Cutting-Edge Technology

We understand the importance of accessibility, and that's why the Kappa 438 PCB is available worldwide. Whether you're in Asia, Europe, North America, or any other region, you can benefit from the superior performance and reliability of this advanced circuit board. Our extensive distribution network ensures that the Kappa 438 is within your reach, no matter where you are.

Typical Applications: Unleashing Innovation Across Industries

The Kappa 438 PCB opens up a world of possibilities in various industries, enabling innovation and technological advancements. Here are a few applications where the Kappa 438 excels:

a. Carrier Grade WiFi/Licensed Assisted Access (LAA):

The Kappa 438 PCB is ideal for high-performance wireless communication systems, ensuring reliable connectivity and efficient data transfer in carrier-grade WiFi and LAA applications.

b. Small Cell and Distributed Antenna Systems (DAS):

In the era of 5G and beyond, small cell and DAS technologies are crucial for expanding network coverage. The Kappa 438 PCB provides the necessary performance and reliability for these demanding applications.

c. Vehicle to Vehicle/Vehicle to Infrastructure Communications (V2X):

The automotive industry is rapidly evolving, with vehicles becoming increasingly connected. The Kappa 438 PCB enables seamless communication between vehicles and infrastructure, supporting the development of autonomous driving and intelligent transportation systems.

d. Internet of Things (IoT) Segments:

The Kappa 438 PCB plays a vital role in the IoT ecosystem, powering smart home devices and wireless meters. Its high-frequency performance and reliability make it an excellent choice for IoT applications where connectivity and data transfer are critical.

Conclusion: Embrace the Future with the Kappa 438 PCB

In conclusion, the Rogers Kappa 438 PCB Material PCB represents a leap forward in circuit board technology. With its superior performance, ease of manufacturing, and compatibility with existing designs, it empowers engineers and designers to push the boundaries of innovation. From high-frequency applications to IoT segments, the Kappa 438 PCB delivers the reliability, performance, and flexibility required for the modern electronic landscape.

Embrace the future of circuit board technology and unlock the potential of your designs with the Kappa 438 PCB. Experience the power of innovation and reliability in one compact package. Contact us today to discover how the Kappa 438 Printed Circuit Board can transform your electronic systems and elevate your projects to new heights.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com