Why is RF-35TC the Ideal High Frequency PCB Material for Demanding RF and Antenna Applications?

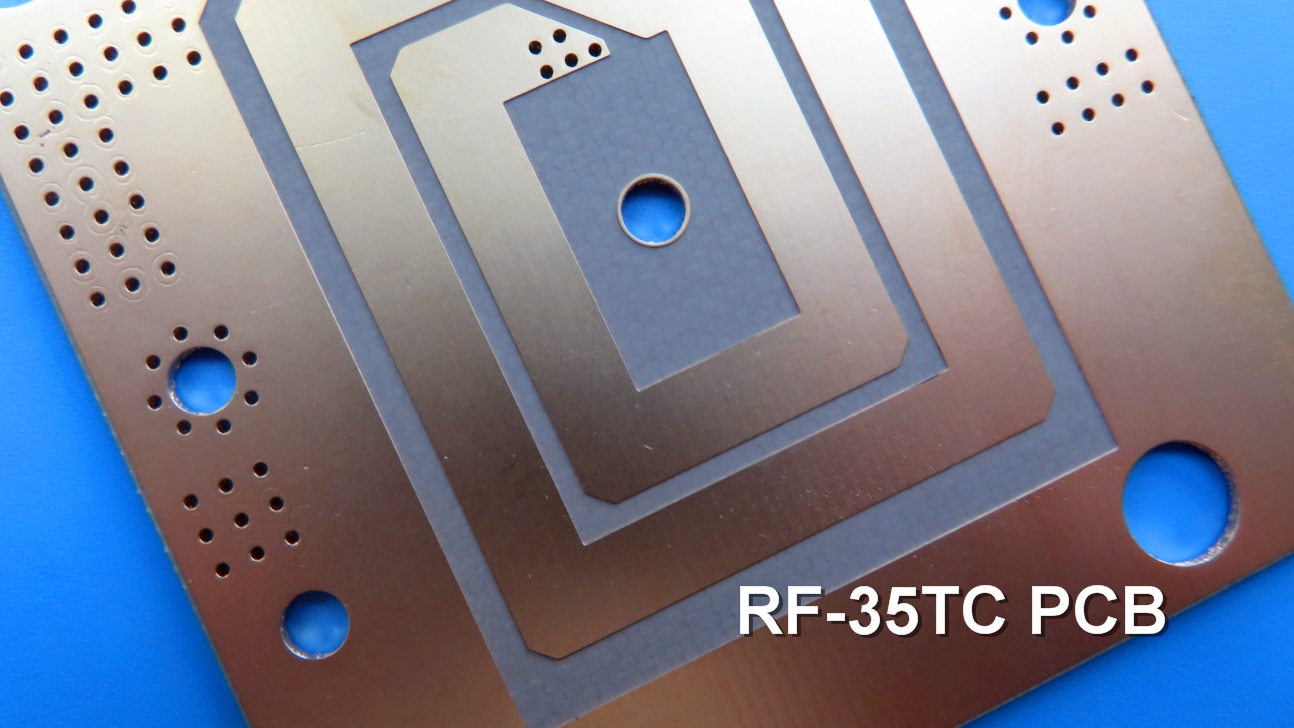

In the rapidly advancing field of high-frequency electronics, the choice of printed circuit board (PCB) material is critical to the performance, reliability, and efficiency of the final product. For engineers and designers working on cutting-edge RF applications,Taconic RF-35TC high-frequency PCB materialstands out as an exceptional solution. This blog explores the unique properties, advantages, and capabilities ofRF-35TC PCBs, illustrating why they are an optimal choice for high-power and thermally demanding applications.

Introduction to RF-35TC High Frequency Material

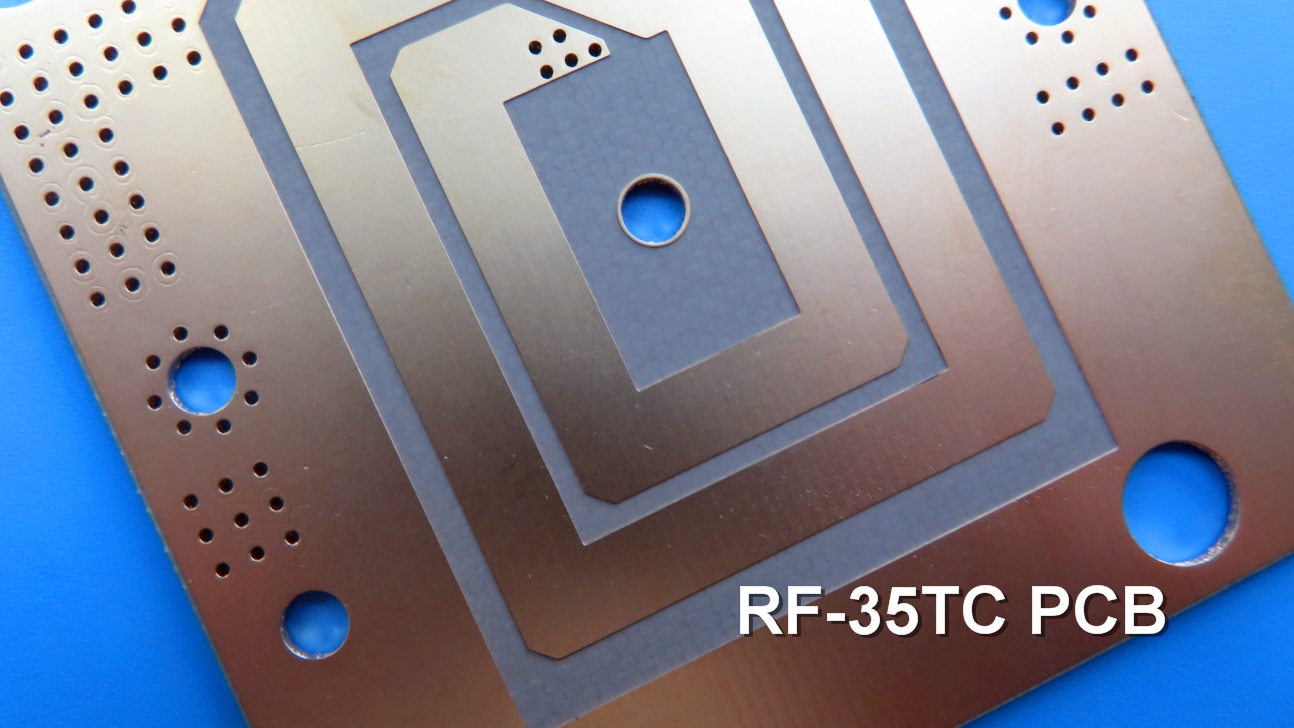

Taconic RF-35TC is a high-performance laminate engineered for superior radio frequency applications. It is constructed on a PTFE (polytetrafluoroethylene) base, reinforced with ceramic-filled fiberglass, which together deliver an outstanding combination of a low dissipation factor and high thermal conductivity. This innovative composition allows efficient heat dissipation away from both transmission lines and surface-mounted components, such as capacitors and ICs, significantly reducing the risk of thermal-related failures.

Unlike competing materials based on synthetic rubber or hydrocarbon resins, RF-35TC is highly resistant to oxidation and yellowing over time. Moreover, it maintains stable electrical characteristics without exhibiting upward drift in dielectric constant (Dk) and dissipation factor (Df), ensuring long-term operational consistency and reliability.

Key Benefits of RF-35TC PCBs

RF-35TC Taconic RF PCB Circuit Board offers a host of significant benefits that make it a preferred material for high-frequency designs:

1.Exceptional Signal Integrity:

With a "Best in Class" loss tangent of just 0.002 at 10 GHz, RF-35TC ensures minimal signal attenuation, making it ideal for high-speed and high-frequency circuits where signal integrity is paramount.

2.Superior Thermal Management:

The material boasts a true thermal conductivity of 0.6W/m/K (unclad), enabling effective heat diffusion from active components. This capability is crucial for maintaining performance and extending the lifespan of high-power RF systems.

3.Stable Dielectric Constant:

RF-35TC demonstrates remarkable stability in dielectric constant across a broad temperature range. This consistency guarantees reliable electrical performance under varying environmental conditions, reducing design uncertainties.

4.Enhanced Antenna Performance:

By integrating RF-35TC into antenna designs, engineers can achieve higher gains and improved radiation efficiency. This leads to better signal propagation and reception, which is essential for communication systems, satellite links, and radar applications.

5.Robust Mechanical Reliability:

The laminate offers excellent adhesion to Very Low Profile (VLP) copper foil, promoting strong bonding between the substrate and copper layers. This enhances the durability and mechanical robustness of the PCB, even in demanding operating conditions.

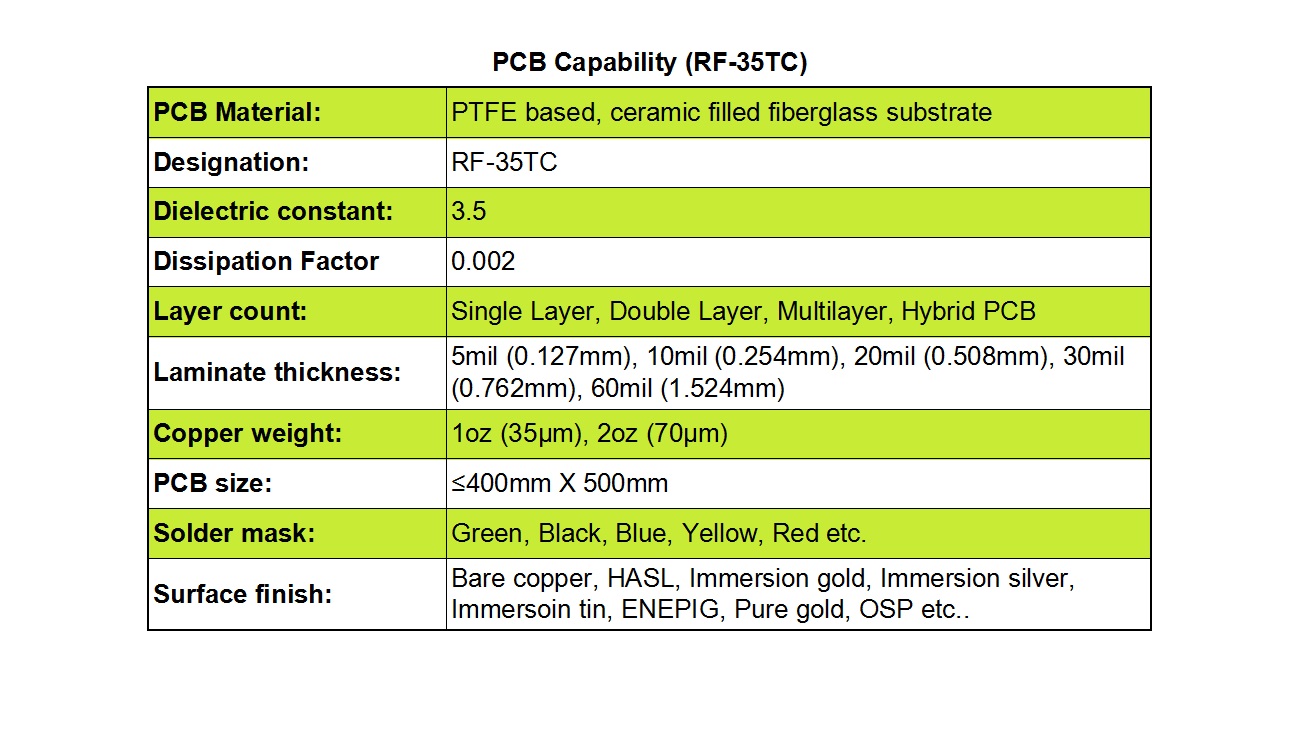

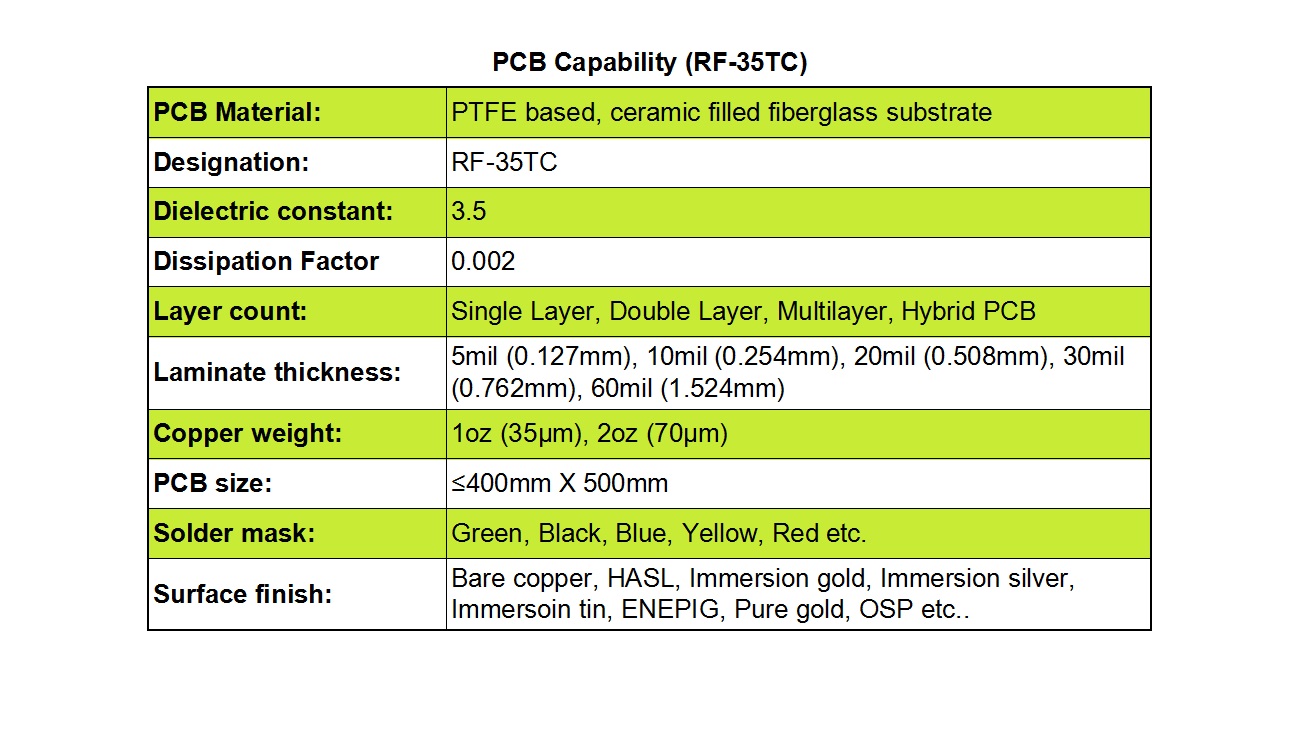

PCB Capabilities with RF-35TC

We provide extensive manufacturing capabilities to accommodate diverse design requirements using RF-35TC high-frequency materials:

1.Layer Configurations:

Our services include single-layer, double-layer, multi-layer, and hybrid board constructions, supporting both simple and complex RF circuit architectures.

2.Thickness Variety:

We offer a wide selection of substrate thicknesses, including standard options such as 5 mil, 10 mil, 20 mil, 30 mil, and 60 mil, to meet specific impedance and mechanical needs.

3.Copper Weight:

Finished copper weights are available in 1 oz or 2 oz, providing flexibility in current carrying capacity and thermal performance.

4.Board Dimensions:

Our manufacturing process supports PCBs up to 400mm x 500mm, facilitating both large single-board layouts and multi-circuit panel designs.

5.Solder Mask Options:

A variety of solder mask colors are available in-house, including green, black, blue, yellow, and more, allowing for customization and branding.

6.Surface Finishes:

We offer a comprehensive range of pad plating and surface finish options, such as bare copper, HASL, immersion gold (ENIG), immersion silver, immersion tin, ENEPIG, pure gold, and OSP (Organic Solderability Preservative), to suit different assembly and environmental requirements.

Typical Applications

RF-35TC Taconic High Frequency PCB are ideally suited for a variety of high-frequency applications where thermal management and signal integrity are critical. Common uses include:

-

RF filters and couplers

-

High-power amplifiers

-

Antenna systems

-

Satellite communication equipment

-

Aerospace and defense electronics

-

Automotive radar and sensors

Whether you are developing next-generation communication infrastructure, aerospace technology, or advanced automotive systems, RF-35TC provides the electrical and thermal characteristics necessary for superior performance and reliability.

Conclusion

Taconic RF-35TC high-frequency PCBs represent a top-tier solution for designers seeking a balance of low loss, exceptional thermal management, and stable electrical properties. With extensive manufacturing capabilities and a proven track record in demanding applications, RF-35TC is an enabling technology for innovative RF and microwave products.

For more information on how our RF-35TC Taconic RF PCB solutions can support your projects, contact our technical team today.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com