High

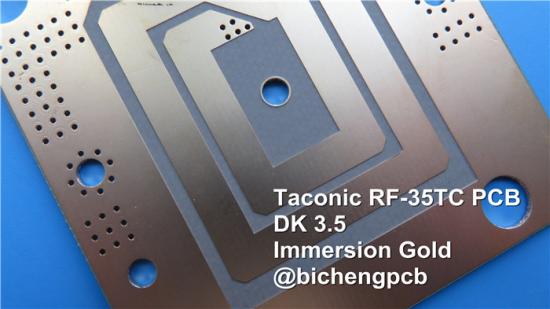

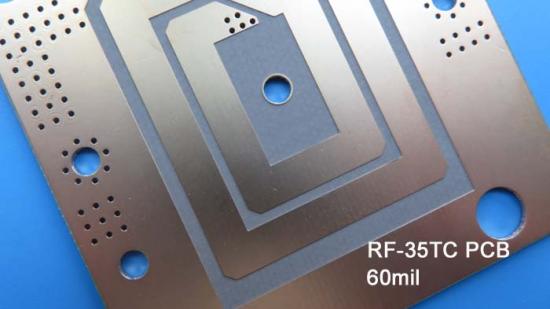

Frequency PCB Built on Taconic RF-35TC DK3.5 With 60mil Thick and Immersion

Gold for Power Amplifier

(PCB's are custom-made products, the picture

and parameters shown are just for reference)

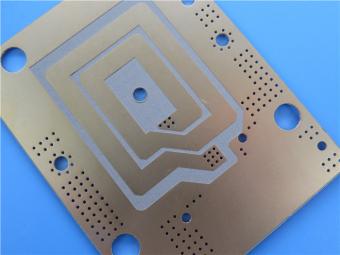

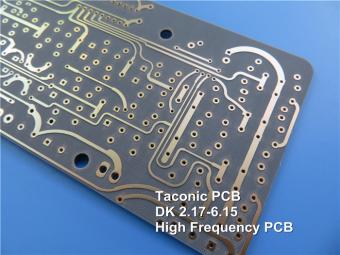

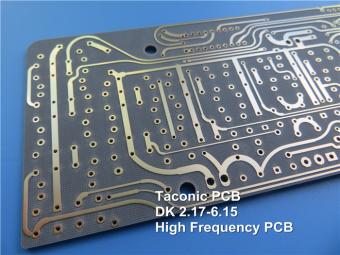

RF-35TC is a PTFE based, ceramic filled

fiberglass high frequency material from Taconic company.

Taconic RF-35TC PCB is made of high-quality

materials and can withstand a wide range of temperatures. It is suitable for

both outdoor and indoor use, and its design is tough. It is thus an ideal

component of your projects. Its main material is epoxy glass, which has a high

thermal shock resistance and flexibility. As a result, the Taconic RF-35TC PCB

can withstand both extreme heat and cold. It will continue to perform admirably

over time.

PCB Specifications

|

Layer count:

|

Double sided

|

|

Base material:

|

RF-35TC DK 3.5

|

|

Dimension:

|

105 x 87mm

|

|

Finished thickness

|

1.6mm ±10%

|

|

Finished Copper

weight:

|

2 oz

|

|

SMOBC:

|

No

|

|

Surface finish:

|

Immersion Gold

|

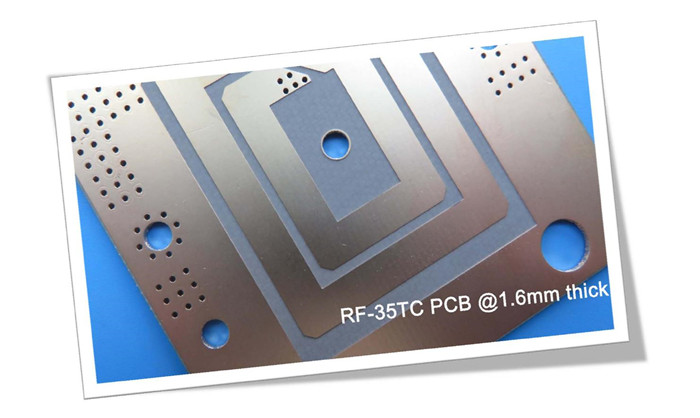

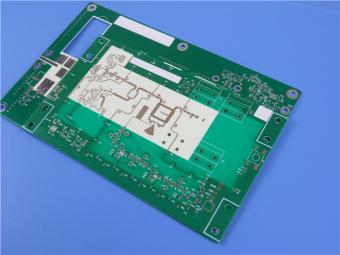

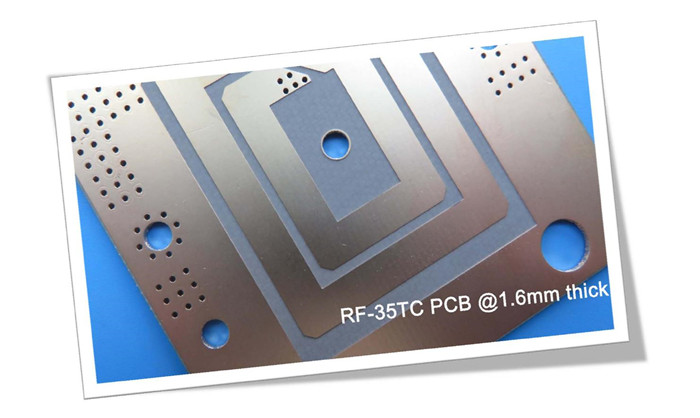

Double sided, RF-35TC substrate, DK at 3.5;

105mm long by 87mm wide; finished PCB thickness at 1.6mm, finished copper

weight at 2oz; No solder mask and silkscreen; surface finish is Immersion gold.

Depending on how you intend to use the Taconic

RF-35TC material, it has a variety of specifications. Its high-quality brass

connection blocks allow it to be used in a variety of applications. At the same

time, its copper ground plane can help improve your installation's overall

performance.

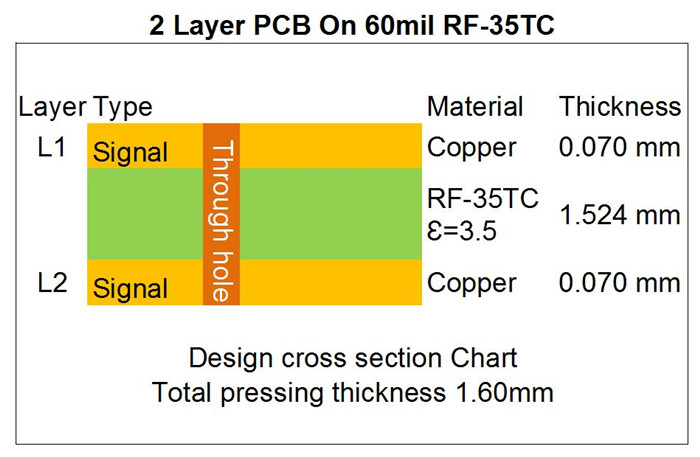

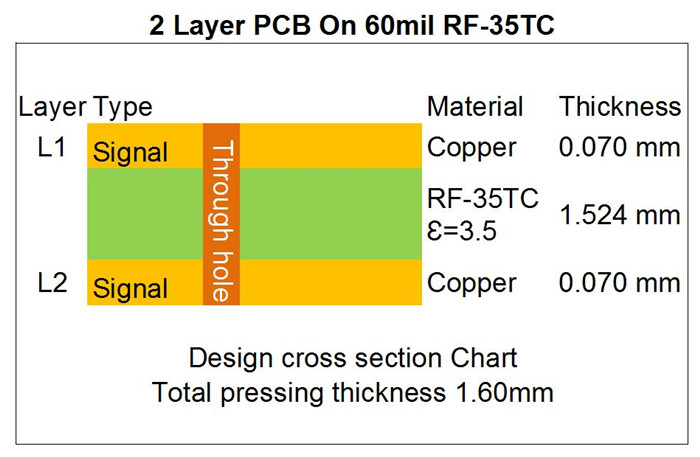

This is the stack up drawing.

Top layer and bottom layer are 2oz finished

copper, dielectric material RF-35TC is in the middle at 1.524mm thick, DK at

3.5

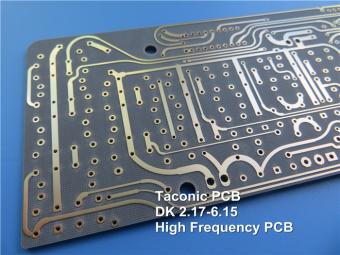

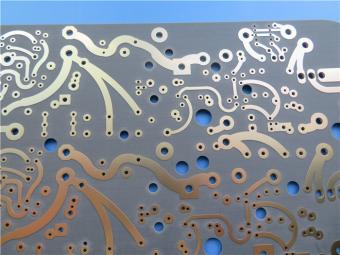

The basic colour of RF-35TC PCB is brown and

grey. Its main applications are power amplifiers, couplers and filters. In

addition, It’s also widely used in antennas, satellite equipment and so on.

Our PCB Capability (RF-35TC)

|

PCB Material:

|

PTFE based

ceramic filled fiberglass substrate

|

|

|

Designator:

|

RF-35TC

|

|

|

Dielectric

constant @ 10GHz:

|

3.50

|

|

|

|

|

Layer count:

|

2 Layer,

Multilayer, Hybrid type

|

|

|

Copper weight:

|

0.5oz, 1oz, 2oz

|

|

|

PCB thickness:

|

0.3mm, 0.6mm,

0.8mm, 1.6mm

|

|

|

(10mil, 20mil,

30mil, 60mil substrate)

|

|

|

Solder mask:

|

Green, Red, Black,

White, Blue etc.

|

|

|

PCB size:

|

≤400mm X 500mm

|

|

|

Surface finish:

|

Bare copper,

HASL, ENIG, Immersion tin etc.

|

|

|

|

|

|

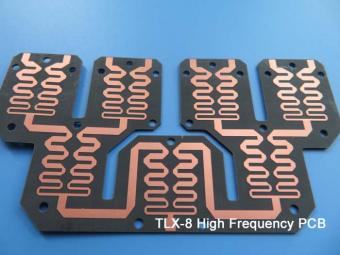

We can provide you with double sided board,

multilayer board and hybrid board. Thickness ranges from 0.3mm to 1.6mm,

maximum size at 400 mm by 500mm; there’re surface finishes of bare copper, hot

air level, immersion gold etc.

RF-35TC offers superior heat dissipation

performance, so it's a type of thermally conductive low loss laminate. It's

best suited for high power applications. Heat dissipates away from both

transmission line on PCB and surface mount components such as capacitor etc.

Appendix: Data sheet RF-35TC

|

RT/duroid

6035HTC Typical Value

|

|

Property

|

RT/duorid 6035HTC

|

Direction

|

Units

|

Condition

|

Test Method

|

|

Dielectric Constant,εProcess

|

3.50±0.05

|

Z

|

|

10 GHz/23℃

|

IPC-TM-650

2.5.5.5 Clamped Stripline

|

|

Dielectric Constant,εDesign

|

3.6

|

Z

|

|

8 GHz - 40

GHz

|

Differential Phase Length Method

|

|

Dissipation

Factor

|

0.0013

|

Z

|

|

10 GHz/23℃

|

IPC-TM-650 2.5.5.5

|

|

Thermal Coefficient of ε

|

-66

|

Z

|

ppm/℃

|

-50℃to 150℃

|

mod IPC-TM-650, 2.5.5.5

|

|

Volume Resistivity

|

108

|

|

MΩ.cm

|

A

|

IPC-TM-650, 2.5.17.1

|

|

Surface Resistivity

|

108

|

|

MΩ

|

A

|

IPC-TM-650, 2.5.17.1

|

|

Dimensional Stability

|

-0.11 -0.08

|

CMD MD

|

mm/m

(mils/inch)

|

0.030"

1oz EDC foil Thickness after etch '+E4/105

|

IPC-TM-650 2.4.39A

|

|

Tensile Modulus

|

329 244

|

MD CMD

|

kpsi

|

40 hrs @23℃/50RH

|

ASTM D638

|

|

Moisure Absorption

|

0.06

|

|

%

|

D24/23

|

IPC-TM-650 2.6.2.1 ASTM D570

|

Coefficient of Thermal Expansion (-50℃to 288℃)

|

19 19 39

|

X Y Z

|

ppm/℃

|

23℃/ 50% RH

|

IPC-TM-650 2.4.41

|

|

Thermal Conductivity

|

1.44

|

|

W/m/k

|

80℃

|

ASTM C518

|

|

Density

|

2.2

|

|

gm/cm3

|

23℃

|

ASTM D792

|

|

Copper Peel Stength

|

7.9

|

|

pli

|

20 sec. @288℃

|

IPC-TM-650 2.4.8

|

|

Flammability

|

V-0

|

|

|

|

UL 94

|

|

Lead-Free Process Compatible

|

Yes

|

|

|

|

|

BICHENG PCB WORKSHOP:

BICHENG PCB EQUIPMENT:

BICHENG PCB CERTIFICATE:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com