RF-35TCPCB 30mil Taconic SubstrateHigh FrequencyBoard

Introduction

RF-35TC is a fiberglass laminate filled with ceramic and based on PTFE. It possesses the remarkable ability to resist oxidation, yellowing, and upward drift in dielectric constant and dissipation factor.

RF-35TC High frequency PCB exhibits a low dissipation factor while also providing high thermal conductivity. This allows for effective heat diffusion from transmission lines and surface mount components like capacitors.

RF-35TC Typical Properties

To begin, let's delve into the dielectric properties of RF-35TC. At 10 GHz, it has a dielectric constant (DK) of 3.5, which is lower compared to most high frequency PCBs. Additionally, its temperature coefficient of dielectric constant (TCDk) remains consistent at 24 ppm within the temperature range of -30 to 120℃, thus guaranteeing stability.

Moving on to the electrical properties of RF-35TC PCB, it has a low dissipation factor (Df) of 0.0011 at 10 GHz. This indicates minimal signal loss and high signal integrity, unlike RT/duroid 6035HTC with a Df of 0.0013, TC600 with a Df of 0.0017, and TC350 with a Df of 0.002. The RF-35TC material also boasts impressive dielectric breakdown and dielectric strength values of 56.7 kV and 570 V/mil (22,441 V/mm) respectively.

More typical propertiesRF-35TCas follows:

|

RF-35TC TYPICAL VALUES

|

|

Property

|

Test Method

|

Unit

|

Value

|

Unit

|

Value

|

|

DK @10 GHz

|

IPC-650 2.5.5.5.1(modified)

|

|

3.5

|

|

3.5

|

|

Tck(-30 to 120℃)

|

IPC-650 2.5.5.5.1(modified)

|

ppm

|

24

|

ppm

|

24

|

|

Df @10 GHz

|

IPC-650 2.5.5.5.1(modified)

|

|

0.0011

|

|

0.0011

|

|

Dielectric Breakdown

|

IPC-650 2.5.6(in-Plane,Two Pins in Oil)

|

kV

|

56.7

|

kV

|

56.7

|

|

Dielectric Strength

|

ASTM D 149(Through Plane)

|

V/mil

|

570

|

V/mm

|

22,441

|

|

Arc Resistance

|

IPC-650 2.5.1

|

Seconds

|

304

|

Seconds

|

304

|

|

Moisture Absorption

|

IPC-650 2.6.2.1

|

%

|

0.05

|

%

|

0.05

|

|

Flexural Strength(MD)

|

ASTM D 790/IPC-650 2.4.4

|

psi

|

12,900

|

N/mm2

|

88.94

|

|

Flexural Strength(CD)

|

ASTM D 790/IPC-650 2.4.4

|

psi

|

11,700

|

N/mm2

|

80.67

|

|

Tensile Strength(MD)

|

ASTM D 3039/IPC-TM-650 2.4.19

|

psi

|

9,020

|

N/mm2

|

62.19

|

|

Tensile Strength(CD)

|

ASTM D 3039/IPC-TM-650 2.4.19

|

psi

|

7,740

|

N/mm2

|

53.37

|

|

Elongation at Break(MD)

|

ASTM D 3039/IPC-TM-650 2.4.19

|

%

|

1.89

|

N/mm

|

1.89

|

|

Elongation at Break(CD)

|

ASTM D 3039/IPC-TM-650 2.4.19

|

%

|

1.7

|

%

|

1.7

|

|

Young's Modulus(MD)

|

ASTM D 3039/IPC-TM-650 2.4.19

|

psi

|

667,000

|

N/mm2

|

4,599

|

|

Young's Modulus(CD)

|

ASTM D 3039/IPC-TM-650 2.4.19

|

psi

|

637,000

|

N/mm2

|

4,392

|

|

Poisson's Ratio(MD)

|

ASTM D 3039/IPC-TM-650 2.4.19

|

|

0.18

|

|

0.18

|

|

Poisson's Ratio(CD)

|

ASTM D 3039/IPC-TM-650 2.4.19

|

|

0.23

|

|

0.18

|

|

Compressive Modulus

|

ASTM D 695(23℃)

|

psi

|

560,000

|

N/mm2

|

3,861

|

|

Flexural Strength(MD)

|

ASTM D 790/IPC-650 2.4.4

|

psi

|

1.46 x 106

|

N/mm2

|

10,309

|

|

Flexural Strength(CD)

|

ASTM D 790/IPC-650 2.4.4

|

psi

|

1.50 x 106

|

N/mm2

|

10,076

|

|

Peel Stength(½ oz.CVH)

|

IPC-650 2.4.8(Thermal Stress.)

|

Ibs./inch

|

7

|

g/cm3

|

1.25

|

|

Thermal Conductivity(Unclad,125℃)

|

ASTM F433(Guarded Heat Flow)

|

W/(mK)

|

0.6

|

W/(mK)

|

0.6

|

|

Thermal Conductivity(C1/C1,125℃)

|

ASTM F433(Guarded Heat Flow)

|

W/(mK)

|

0.92

|

W/(mK)

|

0.92

|

|

Thermal Conductivity(CH/CH,125℃)

|

ASTM F433(Guarded Heat Flow)

|

W/(mK)

|

0.87

|

W/(mK)

|

0.87

|

|

Dimensional Stability(MD)

|

IPC-650-2.4.39 Sec.5.4(After Etch)

|

mils/in.

|

0.23

|

mm/M

|

0.23

|

|

Dimensional Stability(CD)

|

IPC-650-2.4.39 Sec.5.4(After Etch)

|

mils/in.

|

0.64

|

mm/M

|

0.64

|

|

Dimensional Stability(MD)

|

IPC-650-2.4.39 Sec.5.5(Thermal Stress.)

|

mils/in.

|

-0.04

|

mm/M

|

-0.04

|

|

Dimensional Stability(CD)

|

IPC-650-2.4.39 Sec.5.5(Thermal Stress.)

|

mils/in.

|

0.46

|

mm/M

|

0.46

|

|

Surface Resistivity

|

IPC-650 2.5.17.1(after elevated temp.)

|

Mohms

|

8.33 x 107

|

Mohms

|

8.33 x 107

|

|

Surface Resistivity

|

IPC-650 2.5.17.1(after humidity)

|

Mohms

|

6.42 x 107

|

Mohms

|

6.42 x 107

|

|

Volume Resistivity

|

IPC-650 2.5.17.1(after elevated temp.)

|

Mohms/cm

|

5.19 x 108

|

Mohms/cm

|

5.19 x 108

|

|

Volume Resistivity

|

IPC-650 2.5.17.1(after humidity)

|

Mohms/cm

|

2.91 x 108

|

Mohms/cm

|

2.91 x 108

|

|

CTE(X axis)(25-260℃)

|

IPC-650 2.4.41/ASTM D 3386

|

ppm/℃

|

11

|

ppm/℃

|

11

|

|

CTE(Y axis)(25-260℃)

|

IPC-650 2.4.41/ASTM D 3386

|

ppm/℃

|

13

|

ppm/℃

|

13

|

|

CTE(Z axis)(25-260℃)

|

IPC-650 2.4.41/ASTM D 3386

|

ppm/℃

|

34

|

ppm/℃

|

34

|

|

Density

|

ASTM D 792

|

g/cm3

|

2.35

|

g/cm3

|

2.35

|

|

Hardness

|

ASTM D 2240(Shore D)

|

|

79.1

|

|

79.1

|

|

Strain at Break(MD)

|

ASTM D 790/IPC-650 2.4.4

|

%

|

0.014

|

%

|

0.014

|

|

Strain at Break(CD)

|

ASTM D 790/IPC-650 2.4.4

|

%

|

0.013

|

%

|

0.013

|

|

Specific Heat

|

ASTM E 1269-05,E 967-08,E968-02

|

j/(g℃)

|

0.94

|

j/(g℃)

|

0.94

|

|

Td(2% Weight Loss)

|

IPC-650 2.4.24.6/TGA

|

oF

|

788

|

℃

|

420

|

|

Td(5% Weight Loss)

|

IPC-650 2.4.24.6/TGA

|

oF

|

817

|

℃

|

436

|

RF-35TC PCB Capability

Now, let's take a look at our PCB capabilities using RF-35TC material.

|

PCB material:

|

PTFE based Ceramic filled Fiberglass

|

|

Designation:

|

RF-35TC

|

|

Dielectric constant:

|

3.50 @ 10GHz

|

|

|

|

|

Layer count:

|

1-layer, 2-layer, Multi-layer, Hybrid type

|

|

Dielectric thickness:

|

5mil (0.127mm), 10mil (0.254mm), 20mil (0.508mm), 30mil (0.762mm), 60mil (1.524mm)

|

|

Copper weight:

|

1oz, 2oz

|

|

Solder mask:

|

Green, Black, Blue, Yellow, White etc.

|

|

PCB size:

|

≤400mm X 500mm

|

|

Surface finish:

|

Immersion gold, HASL, Immersion silver, Immersion tin, Bare copper, OSP, Pure gold, ENEPIG etc.

|

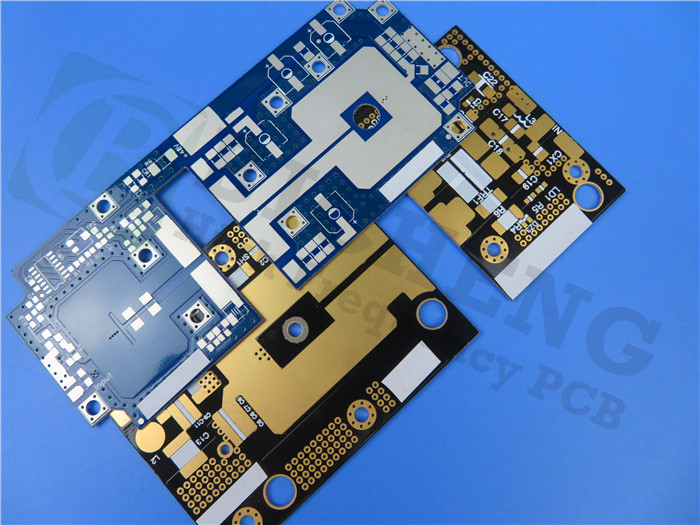

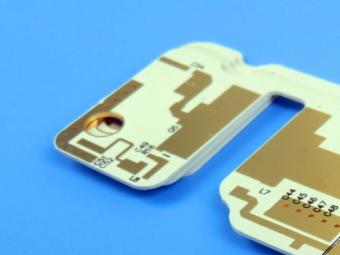

A Piece of RF-35TC PCB

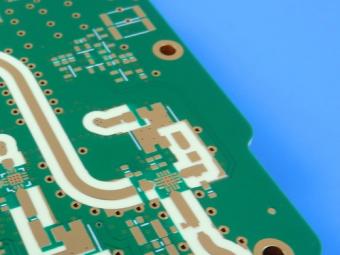

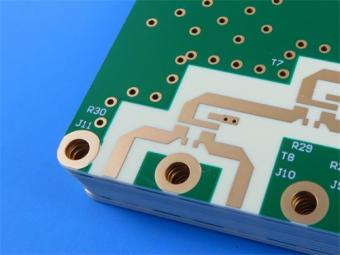

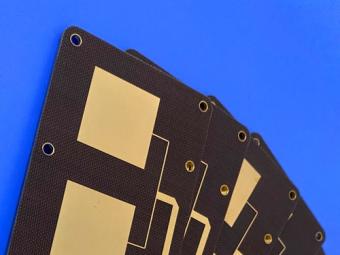

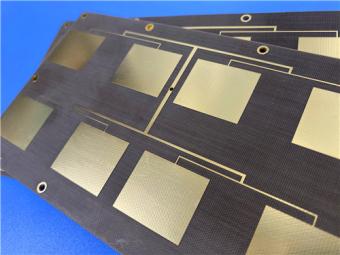

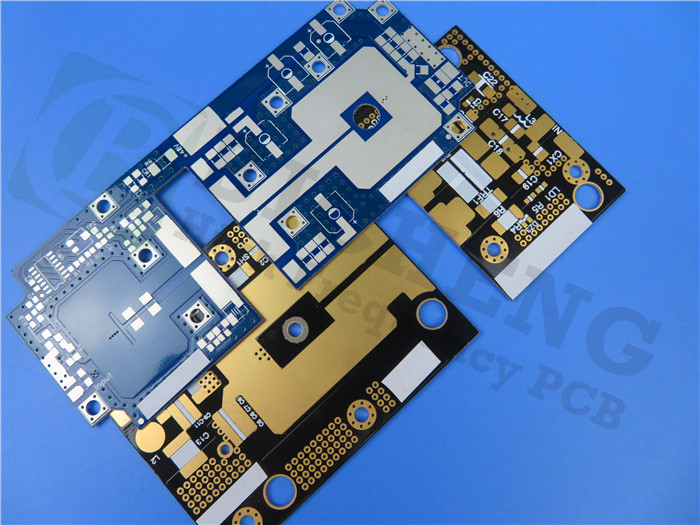

RF-35TC PCBs have a basic color of brown and gray.There is a 30mil RF-35TC PCB with immersion gold and black solder mask, which is commonly used for filters.

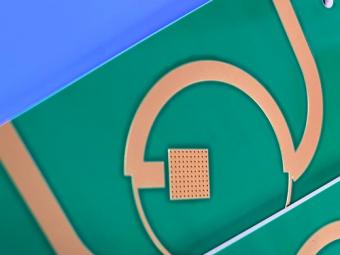

The applications of Taconic RF-35TC PCBs in couplers, antennas, power amplifiers, and satellite equipment among others.

Conclusion

When measuring thermal conductivity, it is important to consider various techniques. Thermal conductivity measured on an unclad laminate provides the true value of the material's thermal conductivity. Measurements on a copper clad laminate (CCL) typically yield higher values due to the reduced thermal resistance at the interface between the laminate and measuring equipment. RF-35TC 30mil material PCB offers superior heat dissipation performance, whether measured with or without copper cladding.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com