Is DiClad 527 the Right High-Frequency PCB Material for Your Demanding Radar or Aerospace Project?

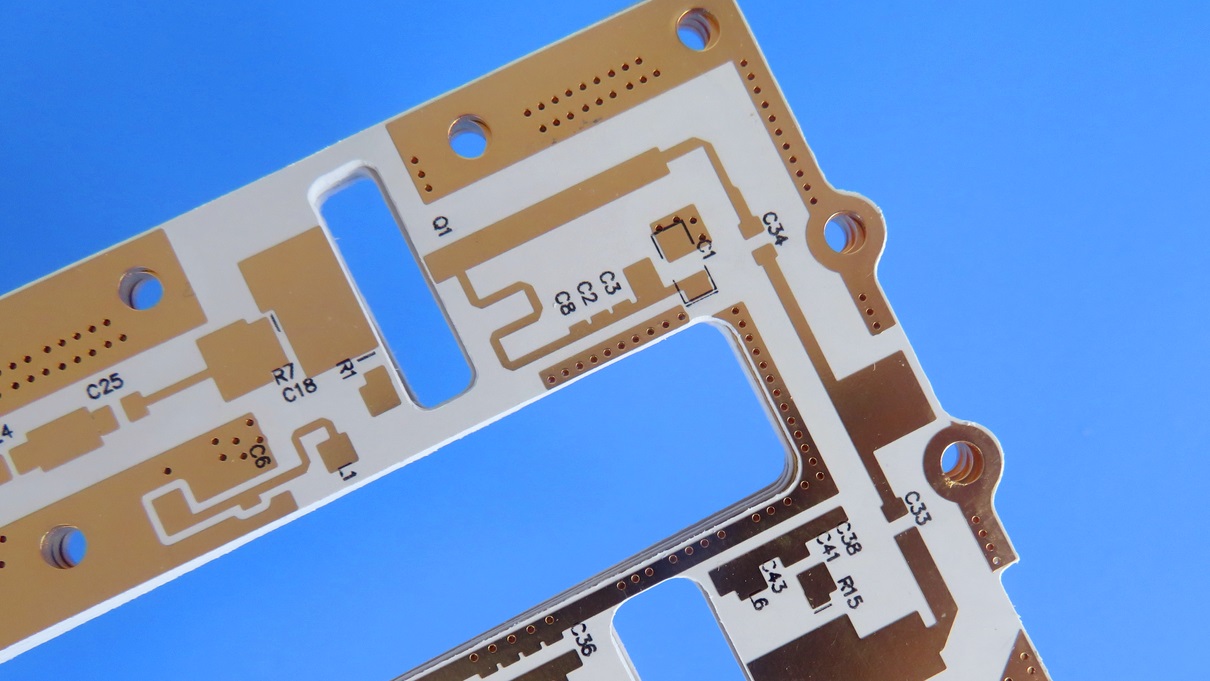

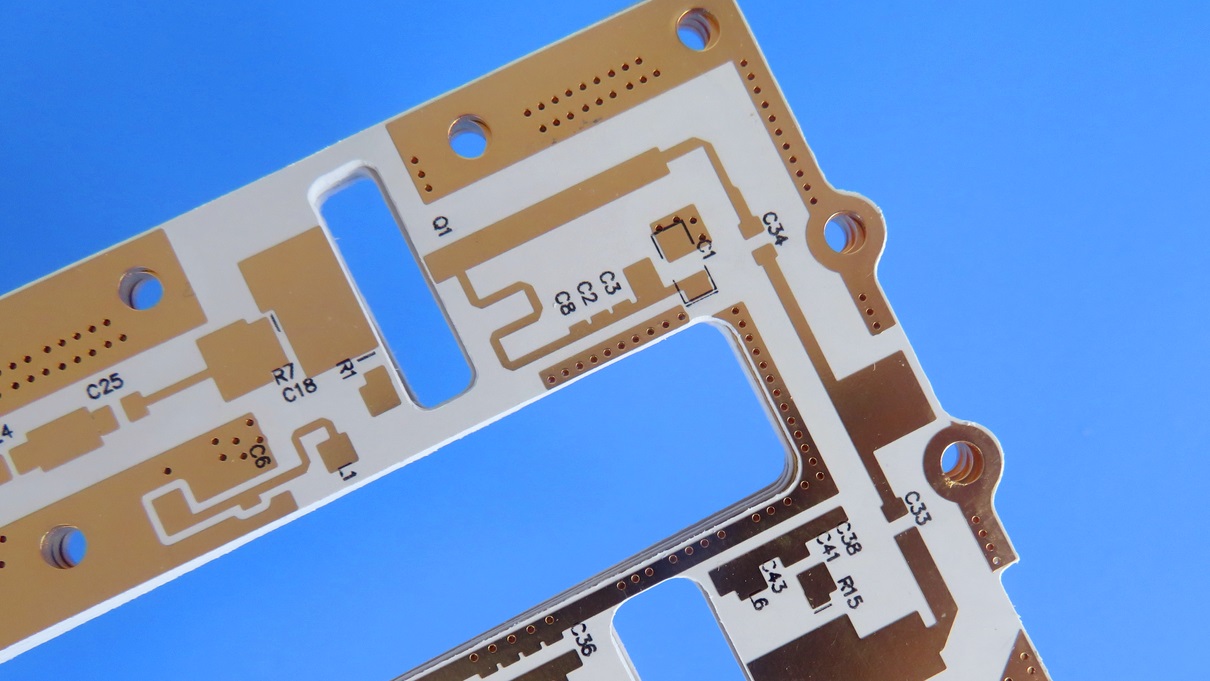

In the demanding world of high-frequency electronics, the choice of printed circuit board (PCB) substrate is paramount to the overall performance, reliability, and success of an end product. Among the elite materials available to design engineers, Rogers DiClad 527 high-frequency laminate stands out as a premier solution. This advanced composite material is engineered to meet the rigorous requirements of applications where signal integrity, thermal management, and operational stability are non-negotiable. This article provides a comprehensive exploration of the DiClad 527 laminate, detailing its unique composition, exceptional material properties, extensive fabrication capabilities, and its ideal application sectors.

An In-Depth Look at the DiClad 527 Laminate Composition

At its core, Rogers DiClad 527 is a sophisticated composite material constructed on a polytetrafluoroethylene (PTFE) base, reinforced with a carefully woven fiberglass cloth. The distinguishing factor that elevates DiClad 527 above many comparable products is its meticulously calibrated ratio of fiberglass reinforcement to PTFE resin. Rogers has intentionally engineered this ratio to be significantly higher, resulting in a laminate that exhibits remarkably enhanced dimensional stability and improved registration accuracy. This robust foundational structure is critical for maintaining precise circuit alignment during the thermal cycling inherent to both the manufacturing process and the operational life of the PCB, ensuring long-term reliability.

Outstanding Material Properties and Performance Characteristics

DiClad 527 is defined by a suite of advanced electrical, thermal, and safety properties that make it an exceptional choice for high-performance applications.

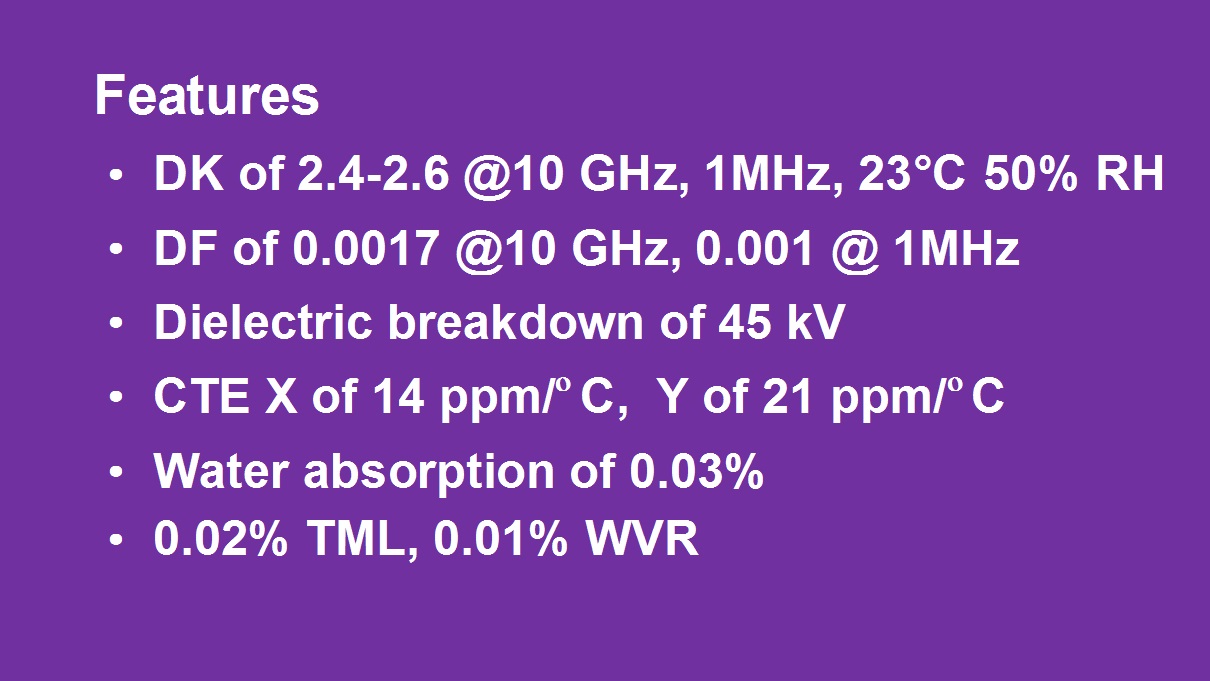

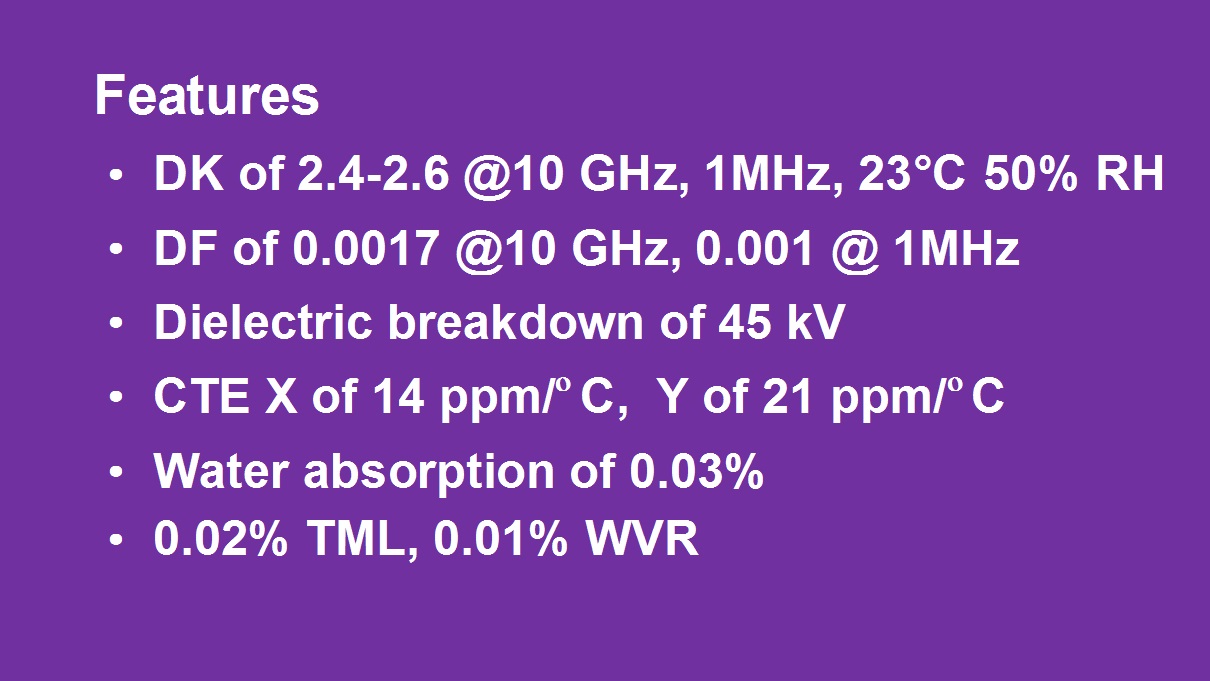

1) Consistent Electrical Parameters: The laminate boasts a stable and predictable dielectric constant (Dk) ranging from 2.40 to 2.60, as verified through testing at both 10 GHz and 1 MHz. This consistency is vital for impedance control in high-speed designs. Furthermore, its ultra-low dissipation factor (loss tangent) is measured at a mere 0.0017 at 10 GHz, which plays a crucial role in minimizing dielectric energy loss and preserving signal strength during transmission.

2) Robust Electrical and Thermal Protection: DiClad 527 provides superior electrical insulation, demonstrated by a high dielectric breakdown voltage exceeding 45 kV and an impressive arc resistance rating of over 180 seconds. Thermally, the material is engineered with copper-matched coefficients of thermal expansion (CTE) in the X and Y axes. This unique characteristic ensures that the laminate and the copper foil expand and contract at similar rates under thermal stress, thereby preventing delamination and preserving the integrity of plated through-holes.

3) Enhanced Safety and Suitability for Harsh Environments: From a safety perspective, DiClad 527 complies with the stringent UL 94 V-0 flammability standard, signifying its high resistance to ignition. Its exceptionally low moisture absorption rate of 0.03% guarantees performance stability even in humid operating conditions. Notably, the material also satisfies NASA's outgassing criteria for space-flight hardware, with a very low Total Mass Loss (TML) of 0.02% and a Collected Volatile Condensable Material (CVCM, indicated here by Water Vapor Recovered of 0.01%) value, making it an ideal candidate for aerospace and satellite applications.

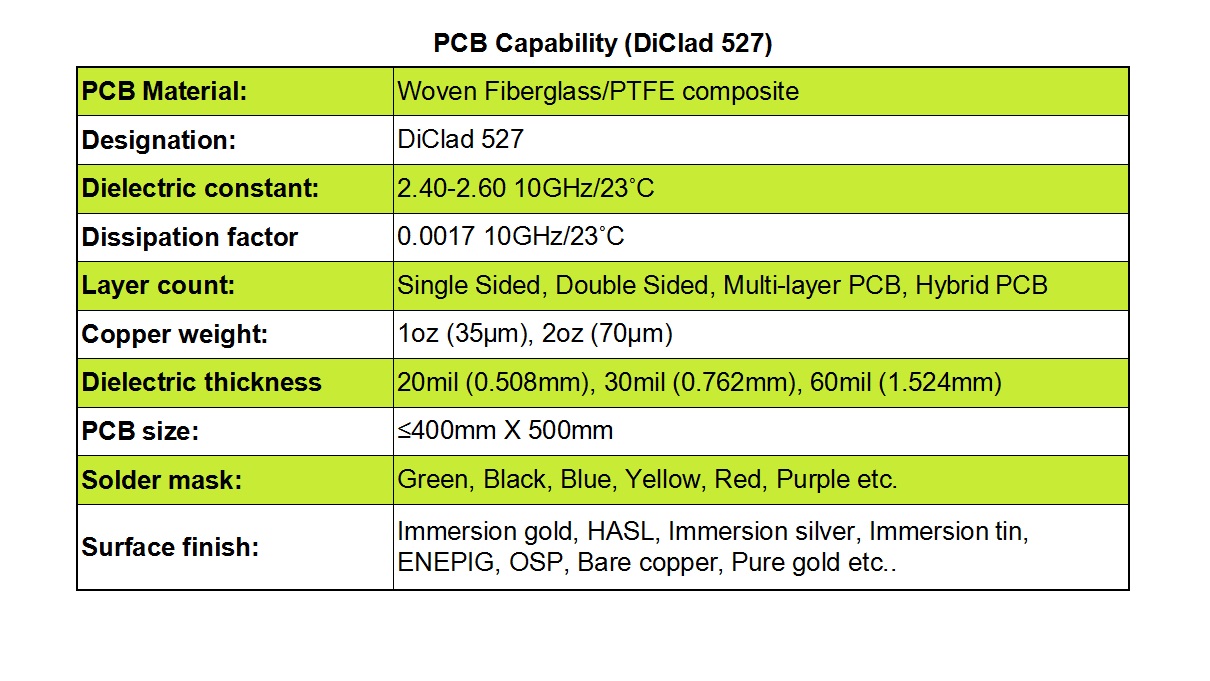

Versatile PCB Fabrication Capabilities with DiClad 527

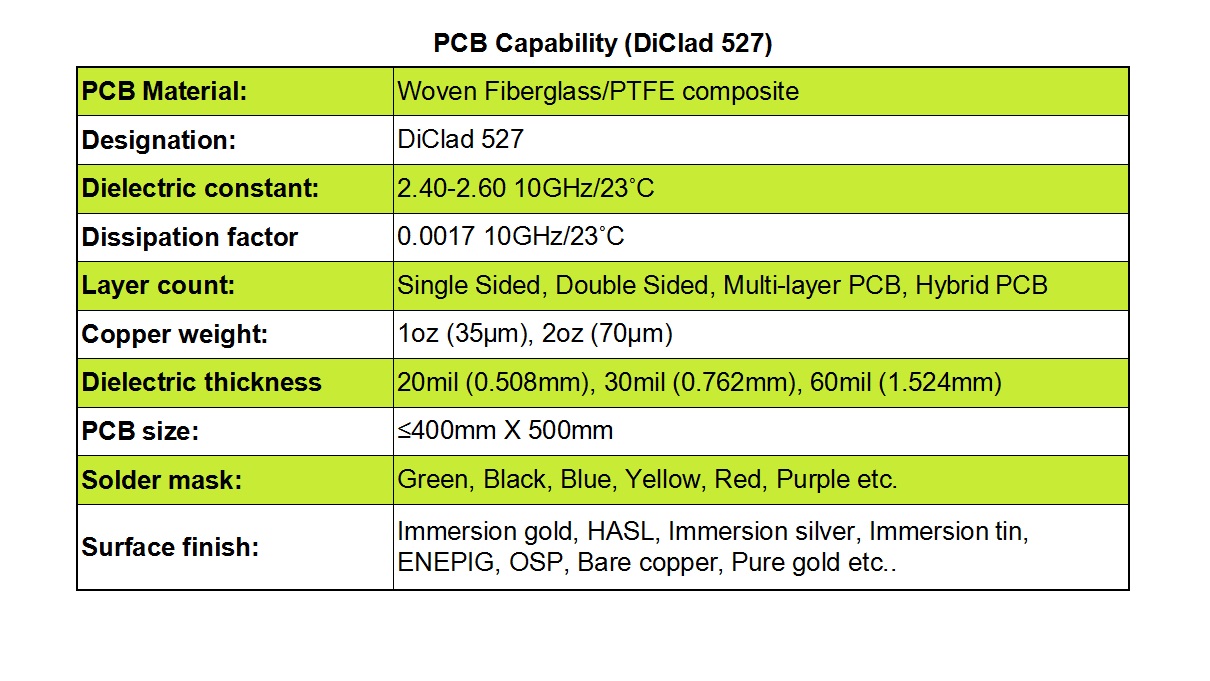

The versatility of DiClad 527 substrate extends to its broad range of PCB fabrication options, allowing designers tremendous flexibility.

Board Configurations: It can be reliably fabricated into single-sided, double-sided, and complex multi-layer board structures. Additionally, it is well-suited for hybrid constructions, where it can be combined with other laminate materials to optimize cost and performance in different sections of a circuit.

Customization Options: To cater to diverse power handling needs, it is available with standard copper weights of 1 oz (35µm) and 2 oz (70µm). The maximum available panel size for fabrication is 400mm x 500mm, accommodating designs for both compact and larger equipment. Aesthetic and functional preferences are met with a wide selection of solder mask colors, including green, black, blue, yellow, red, and purple.

Finally, a comprehensive suite of surface finishes is available, such as Immersion Gold (ENIG), Hot Air Solder Leveling (HASL), Immersion Silver, Immersion Tin, ENEPIG, OSP, and bare copper.

Typical High-Frequency Applications

Given its superior electrical properties, DiClad 527 PCB sare the substrate of choice for a wide array of critical high-frequency applications. These include, but are not limited to:

-

Radar feed networks and commercial phased-array antennas.

-

Low-loss base station antennas for telecommunications infrastructure.

-

Guidance systems and digital radio antennas in aerospace and defense.

-

Other sensitive equipment where minimal signal loss and maximum reliability are essential.

Conclusion

DiClad 527 high-frequency PCB represents a top-tier material solution engineered for success in the most challenging electronic environments. Its optimal balance of mechanical stability, exceptional electrical properties, and proven reliability makes it an indispensable resource for engineers designing next-generation radar, wireless communication, aerospace, and defense systems. When your project demands a substrate that delivers uncompromising performance, Custom DiClad 527 PCB is a proven and reliable choice.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com