How Does TRF-45 PCB Material Ensure Reliability in Demanding High-Frequency Designs?

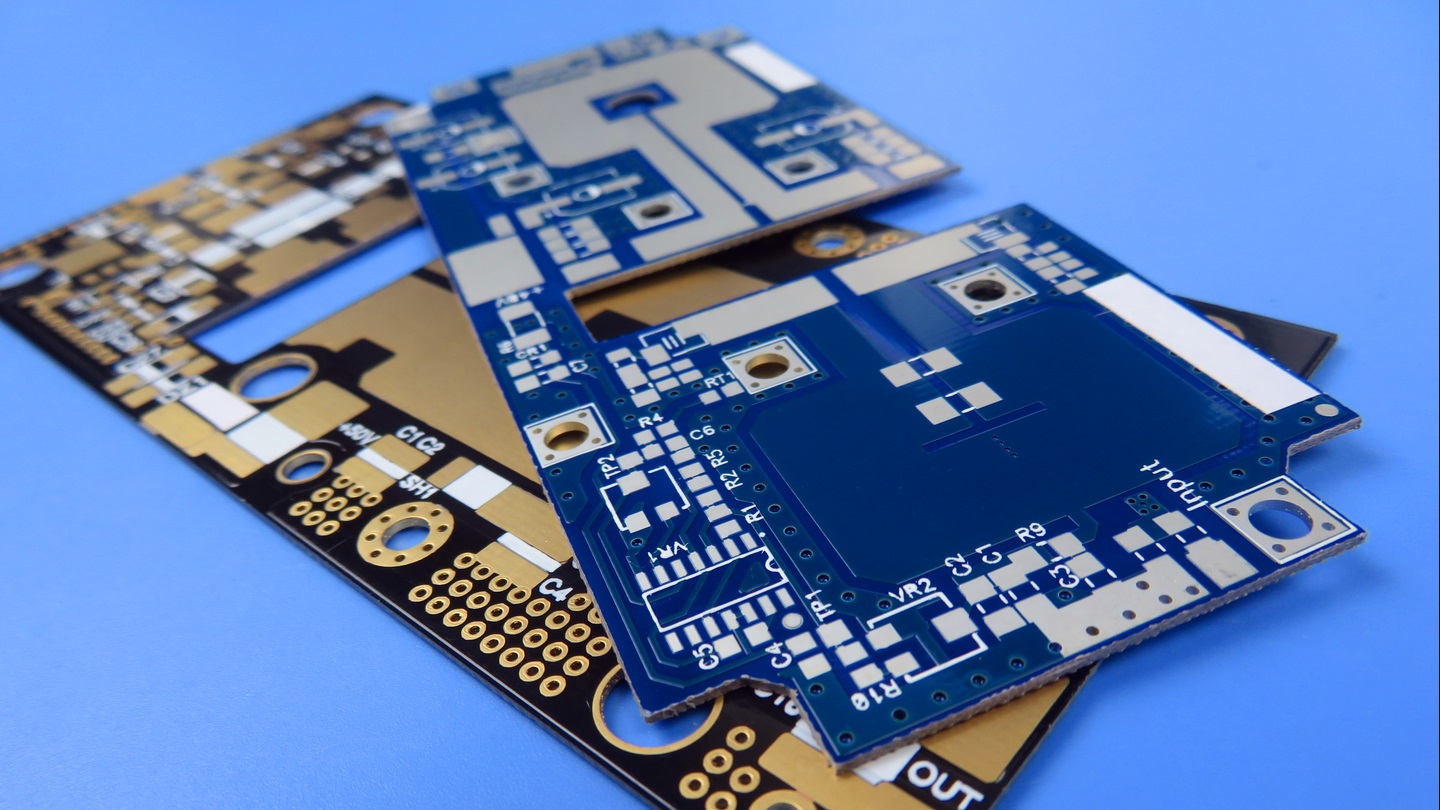

In the demanding world of high-frequency electronics, the choice of printed circuit board (PCB) substrate is a critical determinant of performance, reliability, and ultimate product success. Engineers and designers continually seek materials that offer minimal signal loss, exceptional thermal stability, and straightforward manufacturability. Meeting these rigorous demands,TRF-45 high-frequency materials emerge as a premier solution, representing a significant breakthrough in low-loss, thermally stable PCB substrates. This advanced material leverages Taconic's profound expertise in ceramic technology to deliver unparalleled performance across a wide spectrum of applications.

Superior Material Properties for Demanding Environments

At the core of the TRF-45 substrate 's success is its unique composition, which incorporates a woven-glass reinforcement. This structure grants the substrate superior dimensional stability, a vital characteristic for maintaining circuit integrity under thermal stress. A key differentiator forTaconic TRF-45 is its reliably low Z-axis coefficient of thermal expansion (CTE), which it maintains consistently across a broad temperature range, including during the high-heat soldering process. This property is crucial for preventing plated through-hole failure in multilayer boards, ensuring long-term reliability.

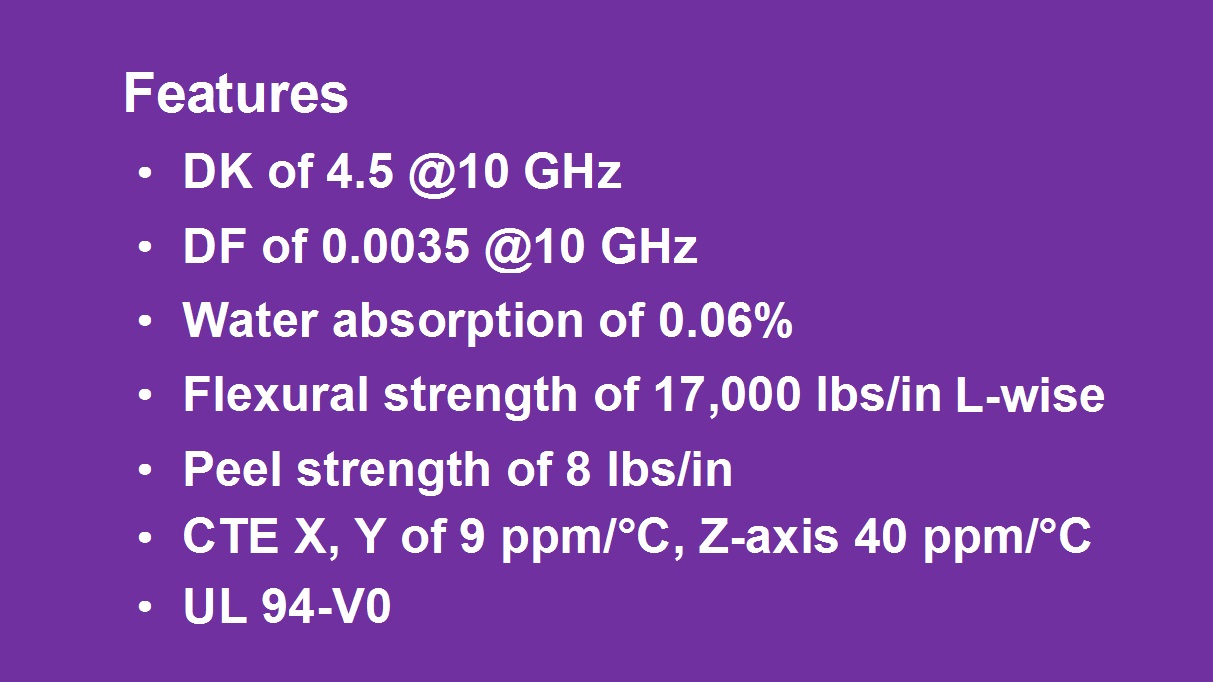

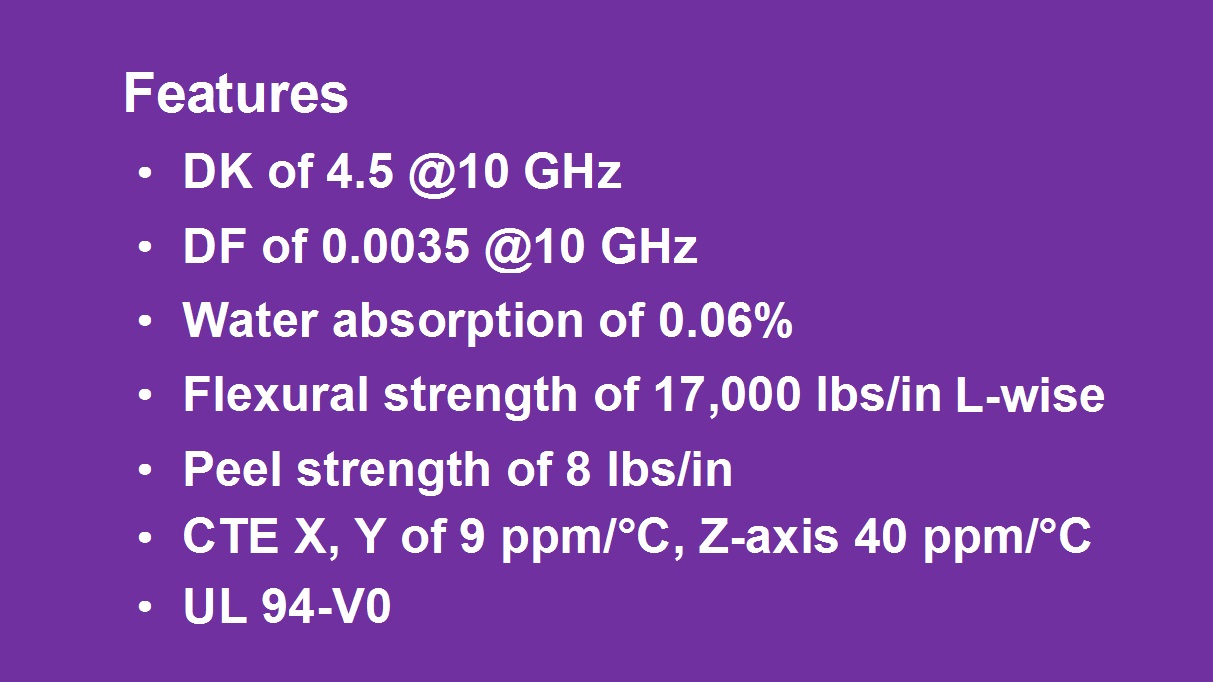

The electrical properties of TRF-45 are equally impressive, making it an ideal candidate for high-speed digital and RF/microwave applications. It boasts a stable dielectric constant (Dk) of 4.5 at 10 GHz, providing predictable electrical behavior for precise impedance control. Coupled with an exceptionally low dissipation factor (Df) of 0.0035 at the same frequency, TRF-45 ensures minimal signal attenuation, preserving signal integrity even at high frequencies.

Further enhancing its robustness, TRF-45 exhibits an extremely low moisture absorption rate of≤0.06%, demonstrating exceptional resistance to humid environments. This, combined with a high flexural strength of 17,000 lbs/in (lengthwise) and 15,000 lbs/in (transverse), ensures mechanical durability. The material delivers outstanding peel strength, exceeding 8 lbs/in, which guarantees strong adhesion between the copper and substrate. Its CTE values—9 ppm/°C on the X and Y axes and 40 ppm/°C on the Z-axis—contribute to excellent thermal dimensional stability. Finally, its UL-94 V0 certification confirms its flame-retardant properties, meeting critical safety standards.

Seamless Integration into Standard PCB Fabrication

A significant advantage of TRF-45 PCB is its compatibility with standard PCB fabrication processes. Unlike some high-performance materials that require specialized equipment or techniques, TRF-45 can be processed using the same conventional methods applied to PTFE woven fiber-glass materials. This includes standard shearing, drilling, milling, and plating operations, which helps streamline production, reduce lead times, and control costs without compromising on the superior performance characteristics of the final product.

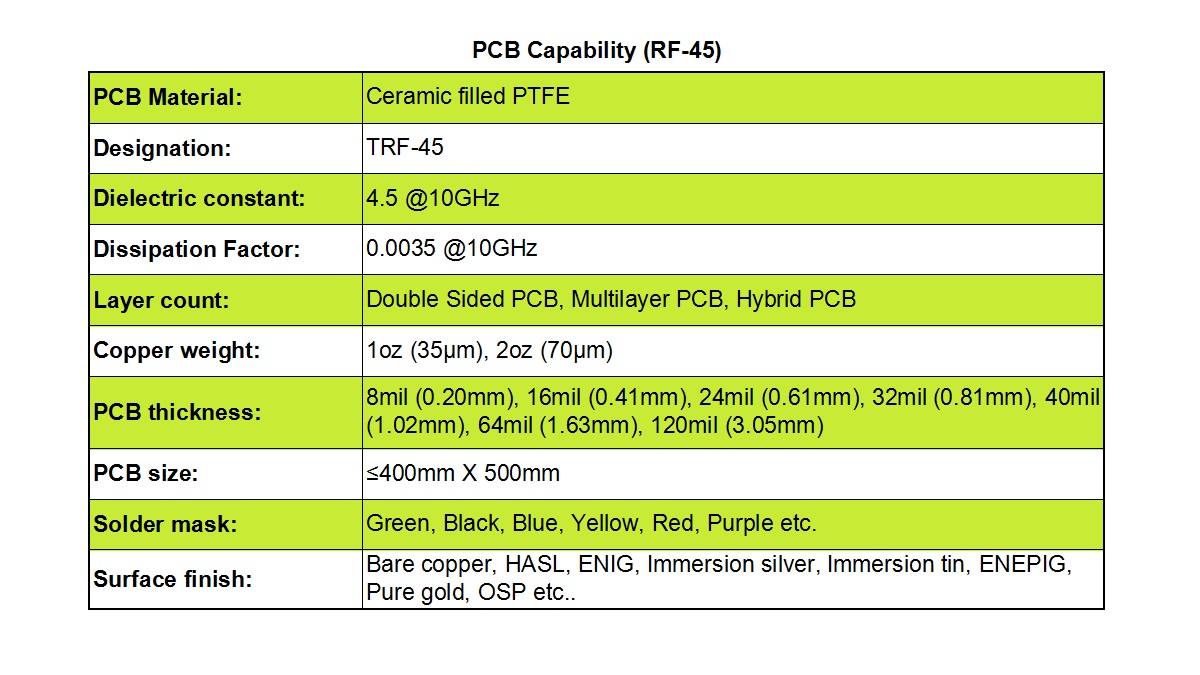

Our Comprehensive PCB Manufacturing Capabilities with TRF-45

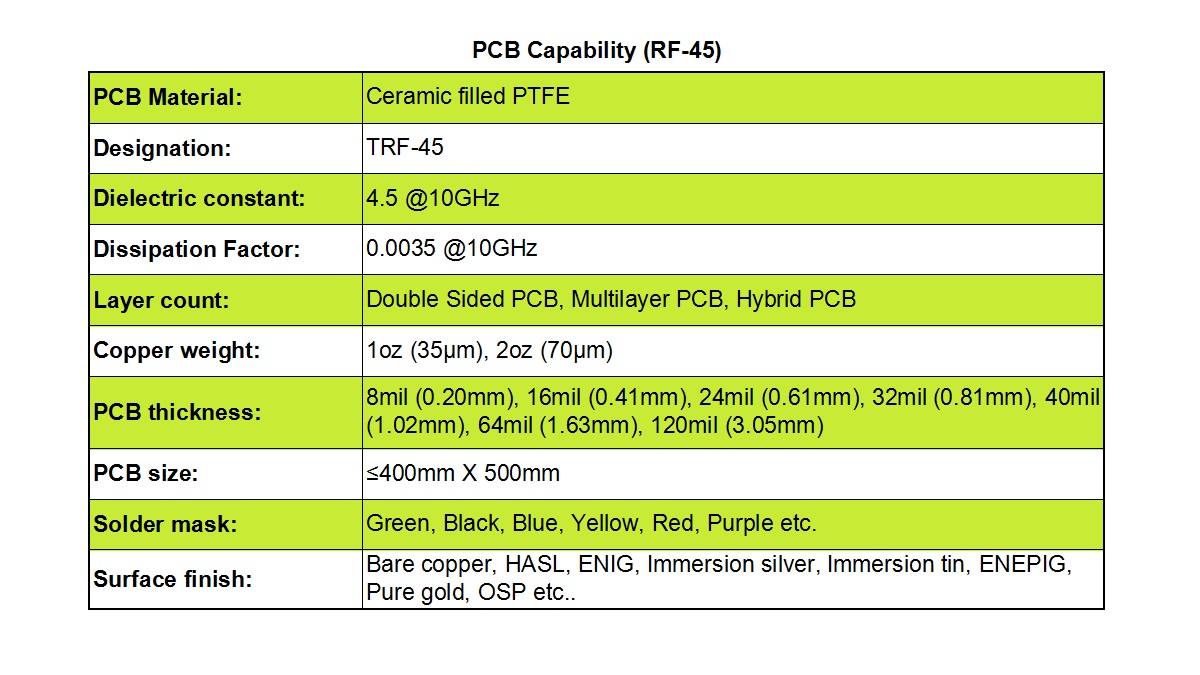

As your dedicated PCB supplier, we empower your designs with extensive manufacturing flexibility usingTRF-45 laminates. We understand that each project has unique requirements, and our capabilities are designed to meet a wide array of design specifications.

1) PCB Types: We offer a full suite of options, including Double-Sided PCBs, complex Multilayer PCBs, and Hybrid constructions that integrate different materials for optimized performance and cost-efficiency.

2) Copper Weight: To fine-tune the electrical and thermal performance of your board, you can select from standard copper weights of 1oz (35 µm) or 2oz (70µm).

3) Layer Thickness: We provide a diverse range of dielectric thicknesses, such as 8mil, 16mil, 24mil, 32mil, 40mil, 64mil, and 120mil, ensuring compatibility with virtually any impedance control or structural requirement.

4) Panel Size: Our manufacturing process can accommodate panels up to 400mm x 500mm, suitable for both compact designs and larger-format boards.

5) Solder Mask: For both aesthetic customization and functional needs, we support a wide selection of solder mask colors, including green, black, blue, yellow, red, and purple.

6) Surface Finish: To meet specific performance, solderability, and reliability needs, we offer a comprehensive range of surface finishes: Bare Copper, HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), Immersion Silver, Immersion Tin, ENEPIG (Electroless Nickel Electroless Palladium Immersion Gold), Pure Gold, and OSP (Organic Solderability Preservative).

Key Applications TRF-45 PCBs

The versatile property set of TRF-45 Taconic RF PCB makes them exceptionally well-suited for advanced applications where signal integrity and reliability are non-negotiable. These applications include, but are not limited to:

-

Satellite Communication Systems: Including antennas for satellite radio.

-

RFID Systems: For robust and efficient RFID antenna performance.

-

Global Positioning Systems: Ensuring precision in GPS antennas.

-

Aerospace and Defense Electronics: Where performance under extreme conditions is critical.

-

Automotive Radar and Sensors: For advanced driver-assistance systems (ADAS).

-

High-Speed Data Communication Equipment: Including 5G infrastructure and network hardware.

Partner with Us for Your Next High-Frequency Project

TRF-45 High Frequency PCBs provide an optimal balance of electrical performance, thermal management, and manufacturing practicality. By choosing us as your PCB supplier, you gain a partner with the technical expertise and manufacturing capability to transform your high-frequency designs into reliable, high-performing products. Contact us today to discuss how we can support your specific project requirements with TRF-45 technology.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com