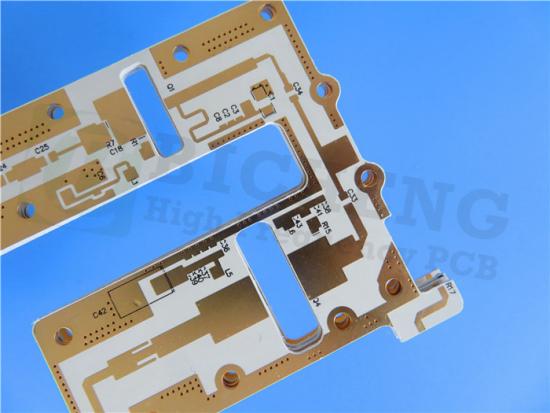

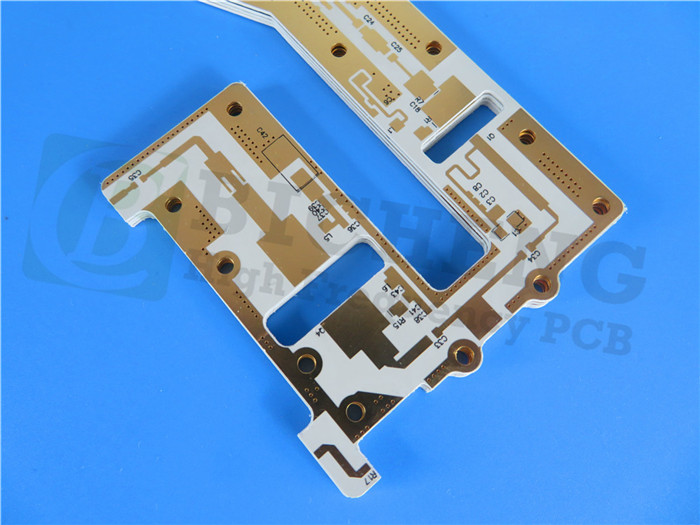

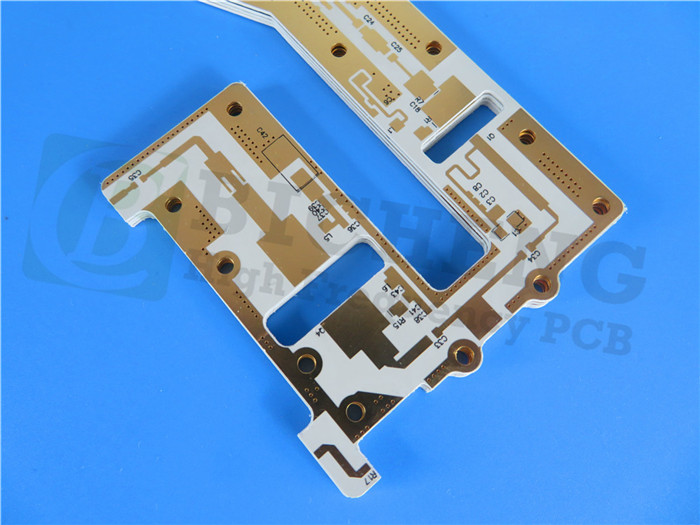

DiClad 527 High Frequency PCB

(Printed Circuit Boards are custom-made products, the picture and parameters shown are just for reference)

Substrate Introduction

Rogers DiClad 527 laminates are composite materials reinforced with woven fiberglass for use as substrates in printed circuit boards. These Diclad 527 PCB laminates offer a higher proportion of fiberglass reinforcement compared to PTFE content. This carefully balanced ratio results in a wider range of dielectric constant (Dk) and improved dimensional stability and registration.

Standard Panel Sizes for DiClad 527:

18" x 12" (457 x 305mm)

18" x 24" (457 x 610mm)

Standard Thicknesses for DiClad 527:

0.020" (0.508mm) with a tolerance of +/- 0.0020"

0.030" (0.762mm) with a tolerance of +/- 0.0020"

0.060" (1.524mm) with a tolerance of +/- 0.0020"

Standard Claddings for DiClad 527:

Electrodeposited Copper Foil

1/2 oz. (18µm)

1 oz. (35µm)

For information on other available PCB configurations, such as additional thicknesses, panel sizes, and claddings, please contact our Customer Service or Sales Engineering teams.

Key Features:

1. Dk range: 2.40 to 2.60

2. Low dissipation factor: .0018 at 10GHz

3. Low moisture absorption

Key Benefits:

1. Stable Dk across a wide frequency range

2. Low circuit losses at high frequencies

3. Minimal performance variation in high humidity environments

4. Excellent dimensional stability

5. Consistent product performance

6. Uniform electrical properties across frequencies

7. Reliable mechanical performance

8. Excellent chemical resistance

Our PCB Capability (DiClad 527)

|

PCB Capability (DiClad 527)

|

|

PCB Material:

|

Woven Fiberglass/PTFE composite

|

|

Designation:

|

DiClad 527

|

|

Dielectric constant:

|

2.40-2.60 10GHz/23˚C

|

|

Dissipation factor

|

0.0017 10GHz/23˚C

|

|

Layer count:

|

Single Sided, Double Sided, Multi-layer PCB, Hybrid PCB

|

|

Copper weight:

|

1oz (35µm), 2oz (70µm)

|

|

Dielectric thickness

|

20mil (0.508mm), 30mil (0.762mm), 60mil (1.524mm)

|

|

PCB size:

|

≤400mm X 500mm

|

|

Solder mask:

|

Green, Black, Blue, Yellow, Red etc.

|

|

Surface finish:

|

Immersion gold, HASL, Immersion silver, Immersion tin, ENEPIG, OSP, Bare copper, Pure gold etc..

|

Typical Applications:

1. Radar feed networks

2. Commercial phased array networks

3. Low-loss base station antennas

4. Guidance systems

5. Digital radio antennas

6. Filters, couplers, and LNAs

DiClad 527 Data Sheet

|

Typical Value

|

|

Properties

|

DiClad 527

|

Units

|

Test Conditions

|

Test Method

|

|

Electrical Properties

|

|

|

|

|

|

|

Dielectric Constant

|

2.40-2.60

|

-

|

23˚C @ 50% RH

|

10 GHz

|

IPC TM-650 2.5.5.5

|

|

Dielectric Constant

|

2.40-2.60

|

-

|

23˚C @ 50% RH

|

1 MHz

|

IPC TM-650 2.5.5.3

|

|

Dissapation Factor

|

0.0017

|

|

23˚C @ 50% RH

|

10 GHz

|

IPC TM-650 2.5.5.5

|

|

Dissapation Factor

|

0.0010

|

|

23˚C @ 50% RH

|

1 MHz

|

IPC TM-650 2.5.5.3

|

Thermal Coefficient of Dielectric

Constant

|

-153

|

ppm/˚C

|

-10 to 140˚C

|

10 GHz

|

IPC TM-650 2.5.5.5

|

|

Volume Resistivity

|

1.2 x 109

|

MΩ-cm

|

C96/35/90

|

-

|

IPC TM-650 2.5.17.1

|

|

Surface Resistivity

|

4.5 x 107

|

MΩ

|

C96/35/90

|

-

|

IPC TM-650 2.5.17.1

|

|

Dielectric Breakdown

|

>45

|

kV

|

D48/50

|

-

|

ASTM D-149

|

Arc Resistance

|

>180

|

|

-

|

-

|

ASTM D-495

|

|

Thermal Properties

|

|

|

|

|

|

|

Coefficient of Thermal Expansion - x

|

14

|

ppm/˚C

|

-

|

50˚C to 150˚C

|

IPC TM-650 2.4.41

|

|

Coefficient of Thermal Expansion - y

|

21

|

ppm/˚C

|

-

|

50˚C to 150˚C

|

IPC TM-650 2.4.41

|

|

Coefficient of Thermal Expansion - z

|

173

|

ppm/˚C

|

-

|

50˚C to 150˚C

|

IPC TM-650 2.4.24

|

Thermal Conductivity

|

0.26

|

W/(m.K)

|

|

|

ASTM E1461

|

|

Mechanical Properties

|

|

|

|

|

|

|

Copper Peel Strength

|

14

|

Lbs/in

|

10s @288˚C

|

35 μm foil

|

IPC TM-650 2.4.8

|

|

Young’s Modulus

|

517, 706

|

kpsi

|

23˚C @ 50% RH

|

-

|

ASTM D-638

|

|

Tensile Strength (MD, CMD)

|

19.0, 15.0

|

kpsi

|

23˚C @ 50% RH

|

-

|

ASTM D-882

|

|

Compressive Modulus

|

359

|

kpsi

|

23˚C @ 50% RH

|

-

|

ASTM D-695

|

Flex Modulus

|

537

|

kpsi

|

23˚C @ 50% RH

|

|

ASTM D-3039

|

|

Physical Properties

|

|

|

|

|

|

|

Flammability

|

V-0

|

|

|

C48/23/50 &

C168/70

|

UL 94

|

|

Moisture Absorption

|

0.03

|

%

|

E1/105+D24/23

|

|

IPC TM-650 2.6.2.2

|

|

Density

|

231

|

g/cm³

|

C24/23/50

|

Method A

|

ASTM D792

|

NASA

Outgassing

|

Total Mass Lost

|

0.02

|

%

|

125°C, ≤ 10-6 torr

|

NASA SP-R-0022A

|

|

Collected Volatiles

|

0.00

|

%

|

|

Water Vapor Recovered

|

0.01

|

%

|

BICHENG PCB CERTIFICATE:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com