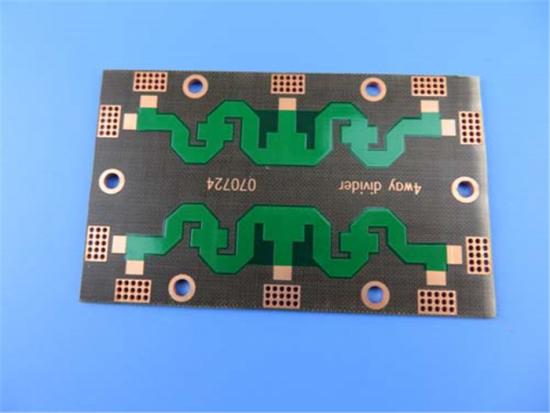

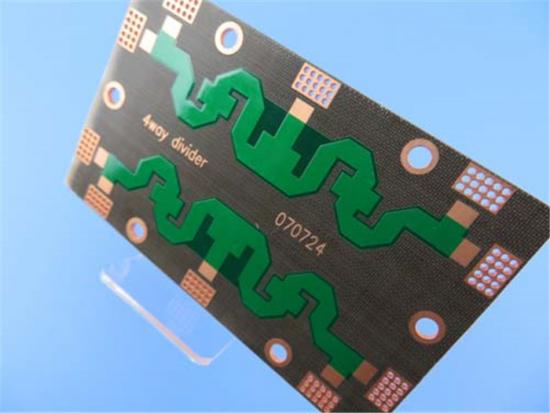

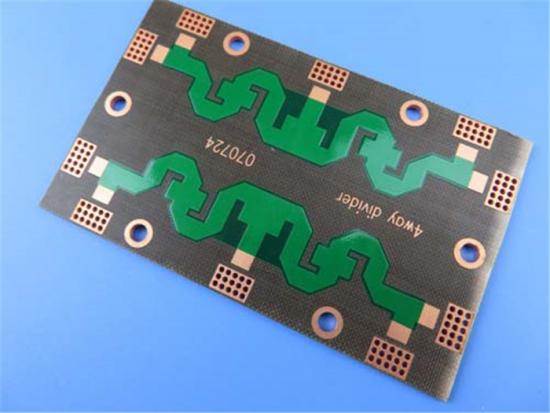

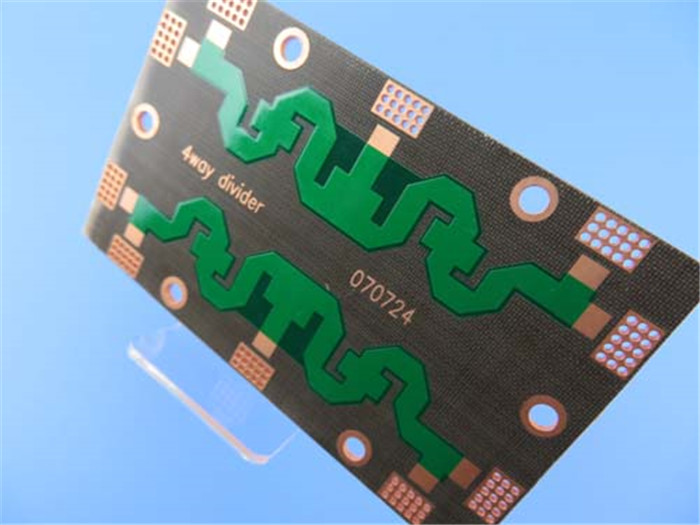

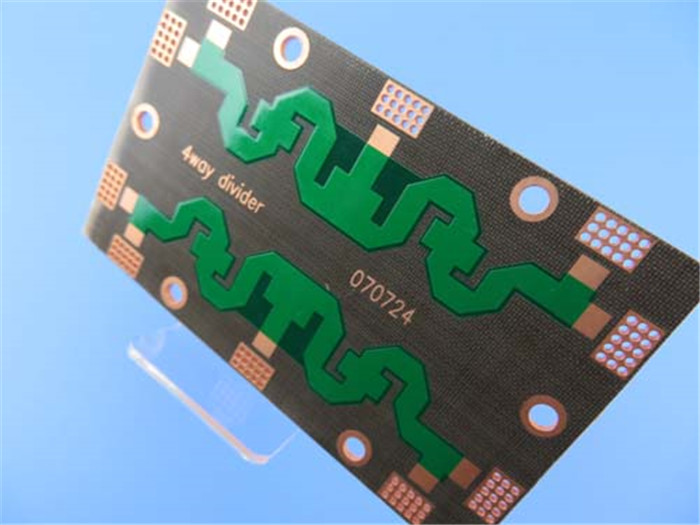

F4BME265 High Frequency PCB DK2.65 PTFE Double Sided With OSP and Green Mask

(Printed Circuit Boards are custom-made products, the picture and parameters shown are just for reference)

Brief Introduction

The PCB we discussed today has a size of 89mm x 61mm, with just 1 piece in a panel.It's a double sided PCB, meaning it has two conductive layers for circuitry. There are no surface mount components on this F4BME265 PCB. Instead, it has through hole components. The layer stackup consists of copper layers with afinishedthickness of 35um (equivalent to1oz). In between, there is F4BME265 material with a thickness of 1.5mm, and then another copper layer of the same35um (1oz) thickness on the other sideafter its plating.

Here’s more details in the table.

PCBSpecifications

|

PCB SIZE

|

89 x 61mm=1PCS

|

|

BOARD TYPE

|

Microwave PCB

|

|

Number of Layers

|

Double sided PCB

|

|

Surface Mount Components

|

NO

|

|

Through Hole Components

|

YES

|

|

LAYER STACKUP

|

copper ------- 18um(0.5oz)+PLATE

|

|

F4BME265 1.524mm

|

|

copper ------- 18um(0.5oz)+PLATE

|

|

TECHNOLOGY

|

|

|

Minimum Trace and Space:

|

6mil/9mil

|

|

Minimum / Maximum Holes:

|

0.9/2.3mm

|

|

Number of Different Holes:

|

3

|

|

Number of Drill Holes:

|

156

|

|

Number of Milled Slots:

|

0

|

|

Number of Internal Cutouts:

|

1

|

|

Impedance Control

|

no

|

|

BOARD MATERIAL

|

|

|

Glass Epoxy:

|

F4BME265 dk2.65

|

|

Final foil external:

|

1oz

|

|

Final foil internal:

|

1oz

|

|

Final height of PCB:

|

1.6 mm ±0.16

|

|

PLATING AND COATING

|

|

|

Surface Finish

|

OSP, Thickness >0.2µm

|

|

Solder Mask Apply To:

|

TOP, 12micron Minimum

|

|

Solder Mask Color:

|

Gloss Green, Taiyo PSR-2000GT600D

|

|

Solder Mask Type:

|

LPSM

|

|

CONTOUR/CUTTING

|

Routing

|

|

MARKING

|

|

|

Side of Component Legend

|

No silkscreen required.

|

|

Colour of Component Legend

|

No silkscreen required.

|

|

Manufacturer Name or Logo:

|

No silkscreen required.

|

|

VIA

|

Plated through hole(PTH), via open.

|

|

FLAMIBILITY RATING

|

UL 94-V0 Approval MIN.

|

|

DIMENSION TOLERANCE

|

|

|

Outline dimension:

|

0.0059"

|

|

Board plating:

|

0.0029"

|

|

Drill tolerance:

|

0.002"

|

|

TEST

|

100% Electrical Test prior shipment

|

|

TYPE OF ARTWORK TO BE SUPPLIED

|

email file, Gerber RS-274-X, PCBDOC etc

|

|

SERVICE AREA

|

Worldwide, Globally.

|

F4BME High Frequency Laminates

F4BME series substrates are made by scientifically formulating and strictly pressing a combination of fiberglass cloth, polytetrafluoroethylene resin, and polytetrafluoroethylene film. Its electrical performance is improved compared to F4B, mainly due to a wider range of dielectric constants, lower dielectric loss, increased insulation resistance, and improved stability. It can replace similar foreign products.

Product Features

◆ DK2.17~3.0 is optional, and DK can be customized

◆ Low loss

◆ F4BME with RTF copper foil has excellent PIM index

◆ Diversified size and cost saving

◆ Irradiation resistance and low exhaust

◆ Commercialization, mass production and high cost performance

Typical Applications

◆ Microwave, RF, radar

◆ Phase shifter, passive components

◆ Power divider, coupler and combiner

◆ Feed network, phased array antenna

◆ Satellite communication, base station antenna

Data Sheet (F4BME)

|

Product Technical Parameters

|

Product Model & Data Sheet

|

|

Product Features

|

Test Conditions

|

Unit

|

F4BME217

|

F4BME220

|

F4BME233

|

F4BME245

|

F4BME255

|

F4BME265

|

F4BME275

|

F4BME294

|

F4BME300

|

|

Dielectric Constant (Typical)

|

10GHz

|

/

|

2.17

|

2.2

|

2.33

|

2.45

|

2.55

|

2.65

|

2.75

|

2.94

|

3.0

|

|

Dielectric Constant Tolerance

|

/

|

/

|

±0.04

|

±0.04

|

±0.04

|

±0.05

|

±0.05

|

±0.05

|

±0.05

|

±0.06

|

±0.06

|

|

Loss Tangent (Typical)

|

10GHz

|

/

|

0.001

|

0.001

|

0.0011

|

0.0012

|

0.0013

|

0.0013

|

0.0015

|

0.0016

|

0.0017

|

|

20GHz

|

/

|

0.0014

|

0.0014

|

0.0015

|

0.0017

|

0.0018

|

0.0019

|

0.0021

|

0.0023

|

0.0025

|

|

Dielectric Constant Temperature Coefficient

|

-55ºC~150ºC

|

PPM/℃

|

-150

|

-142

|

-130

|

-120

|

-110

|

-100

|

-92

|

-85

|

-80

|

|

Peel Strength

|

1 OZ F4BM

|

N/mm

|

>1.8

|

>1.8

|

>1.8

|

>1.8

|

>1.8

|

>1.8

|

>1.8

|

>1.8

|

>1.8

|

|

1 OZ F4BME

|

N/mm

|

>1.6

|

>1.6

|

>1.6

|

>1.6

|

>1.6

|

>1.6

|

>1.6

|

>1.6

|

>1.6

|

|

Volume Resistivity

|

Standard Condition

|

MΩ.cm

|

≥6×10^6

|

≥6×10^6

|

≥6×10^6

|

≥6×10^6

|

≥6×10^6

|

≥6×10^6

|

≥6×10^6

|

≥6×10^6

|

≥6×10^6

|

|

Surface Resistivity

|

Standard Condition

|

MΩ

|

≥1×10^6

|

≥1×10^6

|

≥1×10^6

|

≥1×10^6

|

≥1×10^6

|

≥1×10^6

|

≥1×10^6

|

≥1×10^6

|

≥1×10^6

|

|

Electrical Strength (Z direction)

|

5KW,500V/s

|

KV/mm

|

>23

|

>23

|

>23

|

>25

|

>25

|

>25

|

>28

|

>30

|

>30

|

|

Breakdown Voltage (XY direction)

|

5KW,500V/s

|

KV

|

>30

|

>30

|

>32

|

>32

|

>34

|

>34

|

>35

|

>36

|

>36

|

|

Coefficientof Thermal Expansion

|

XY direction

|

-55 º~288ºC

|

ppm/ºC

|

25, 34

|

25, 34

|

22, 30

|

20, 25

|

16, 21

|

14, 17

|

14, 16

|

12, 15

|

12, 15

|

|

Z direction

|

-55 º~288ºC

|

ppm/ºC

|

240

|

240

|

205

|

187

|

173

|

142

|

112

|

98

|

95

|

|

Thermal Stress

|

260℃, 10s,3 times

|

No delamination

|

No delamination

|

No delamination

|

No delamination

|

No delamination

|

No delamination

|

No delamination

|

No delamination

|

No delamination

|

|

Water Absorption

|

20±2℃, 24 hours

|

%

|

≤0.08

|

≤0.08

|

≤0.08

|

≤0.08

|

≤0.08

|

≤0.08

|

≤0.08

|

≤0.08

|

≤0.08

|

|

Density

|

Room Temperature

|

g/cm3

|

2.17

|

2.18

|

2.20

|

2.22

|

2.25

|

2.25

|

2.28

|

2.29

|

2.29

|

|

Long-Term Operating Temperature

|

High-Low Temperature Chamber

|

℃

|

-55~+260

|

-55~+260

|

-55~+260

|

-55~+260

|

-55~+260

|

-55~+260

|

-55~+260

|

-55~+260

|

-55~+260

|

|

Thermal Conductivity

|

Z direction

|

W/(M.K)

|

0.24

|

0.24

|

0.28

|

0.30

|

0.33

|

0.36

|

0.38

|

0.41

|

0.42

|

|

PIM

|

Only applicable to F4BME

|

dBc

|

≤-159

|

≤-159

|

≤-159

|

≤-159

|

≤-159

|

≤-159

|

≤-159

|

≤-159

|

≤-159

|

|

Flammability

|

/

|

UL-94

|

V-0

|

V-0

|

V-0

|

V-0

|

V-0

|

V-0

|

V-0

|

V-0

|

V-0

|

|

Material Composition

|

/

|

/

|

PTFE, Fiberglass Cloth

F4BM paired with ED copper foil, F4BME paired with reverse-treated (RTF) copper foil.

|

BICHENG PCB CERTIFICATE:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com