Introduction:

In the world of printed circuit boards (PCBs), choosing the right material is crucial for achieving optimal performance. One material that stands out from the rest is the RO3006 PCB 25mil. Manufactured by Rogers Corporation, this PCB is specifically designed to offer exceptional electrical and mechanical stability, making it the ideal choice for high-frequency applications. In this blog, we will delve deep into the features, benefits, and applications of this remarkable PCB.

Features:

The Rogers RO3006 PCB is made from ceramic-filled PTFE composites, which contribute to its outstanding performance. One of its key features is its dielectric constant (Dk) of 6.15 +/- 0.15 at 10 GHz/23°C. This stable Dk ensures consistent electrical properties over a wide range of temperatures, eliminating the step change in Dk that occurs in PTFE glass materials near room temperature. Additionally, the PCB has a low dissipation factor of 0.002 at 10 GHz/23°C, making it highly efficient in transmitting signals.

Another notable feature of the Rogers3006 PCB is its high thermal conductivity of 0.79 W/mK. This property allows for effective heat dissipation, making it suitable for applications that require thermal management. Moreover, the PCB has a high thermal decomposition temperature (Td) of over 500°C, ensuring its reliability under extreme temperature conditions. Additionally, with a moisture absorption rate of only 0.02%, the PCB remains stable and reliable even in humid environments.

Benefits:

The RO3006 high frequency PCB offers several benefits that set it apart from other PCB materials. Firstly, its uniform mechanical properties make it perfect for multi-layer board designs with a range of dielectric constants. This allows for greater flexibility in circuit design while maintaining consistent performance. Additionally, the PCB is suitable for use with epoxy glass multi-layer board hybrid designs, further expanding its applications.

The low in-plane expansion coefficient of the RO3006 25mil laminate PCB is another significant benefit. It matches closely with that of copper, enabling reliable surface mounted assemblies. This property is crucial for applications that are sensitive to temperature changes. Moreover, the PCB exhibits excellent dimensional stability, ensuring the integrity of the circuit over time.

Furthermore, the RO3006 printed circuit board is manufactured using a volume manufacturing process, resulting in economical laminate pricing. This makes it a cost-effective choice for large-scale production.

PCB Stackup and Construction Details:

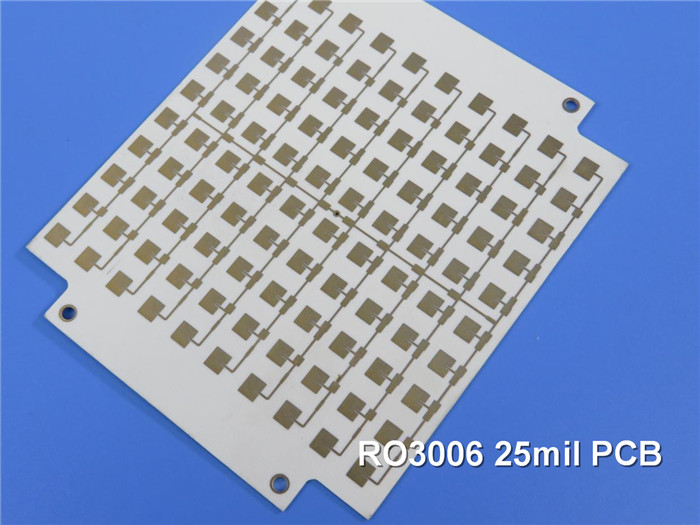

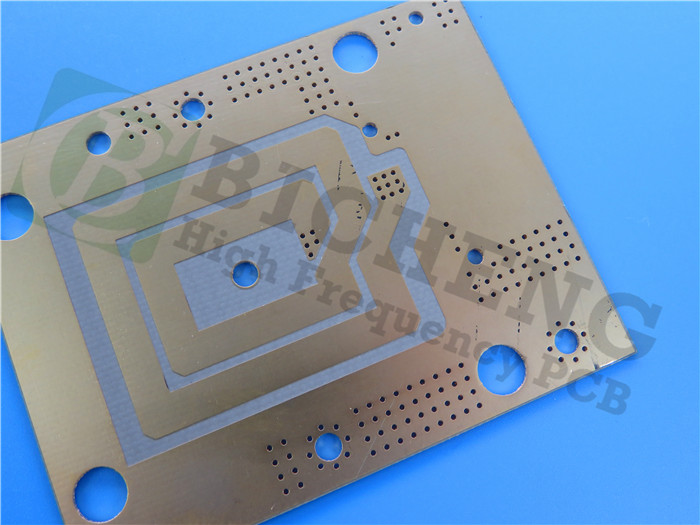

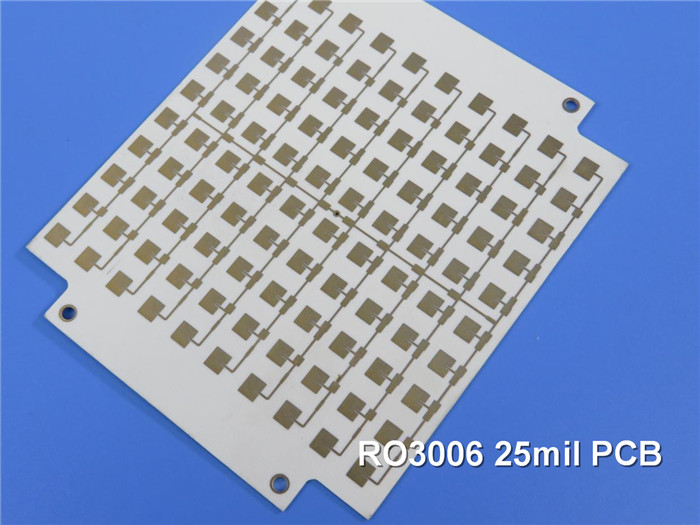

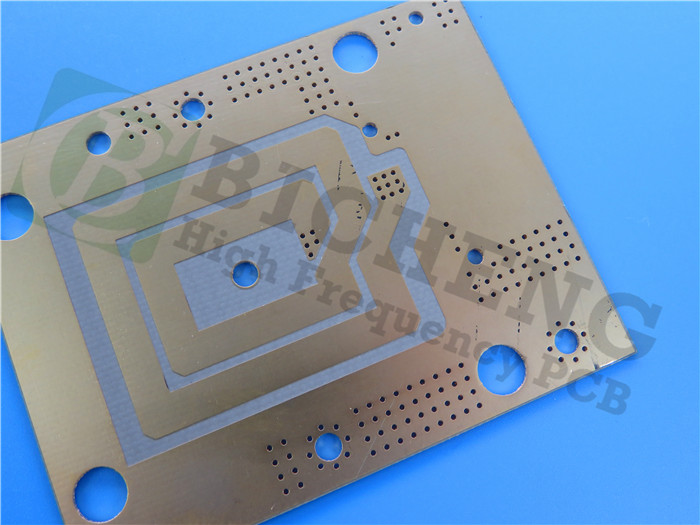

The RO3006 PCB is a 2-layer rigid PCB with a copper layer thickness of 35 μm on each side. The substrate thickness is 25mil (0.635mm), providing a sturdy base for the circuit. The board dimensions are 30mm x 37mm, making it compact and suitable for various applications. The minimum trace/space requirement is 5/5 mils, allowing for precise routing of signals. The minimum hole size is 0.25mm, accommodating various component packages.

The finished board thickness is 0.8mm, striking a balance between durability and space constraints. The outer layers have a copper weight of 1 oz (1.4 mils), ensuring adequate conductivity. The via plating thickness is 20 μm, providing a reliable interconnection between the layers. The surface finish is immersion gold, which offers excellent solderability and corrosion resistance.

It is worth mentioning that the RO3006 PCB undergoes a 100% electrical test prior to shipment, ensuring its quality and reliability.

PCB Statistics and Standards:

The RO3006 PCB boasts impressive statistics. It consists of 15 components and has a total of 50 pads. Out of these, 31 are thru-hole pads, while 19 are top SMT pads. The PCB contains no bottom SMT pads. Additionally, it has 38 vias and 2 nets, allowing for efficient signal routing.

The supplied artwork for the PCB is in Gerber RS-274-X format, which is widely accepted in the industry. Moreover, the PCB meets the IPC-Class-2 standard, ensuring its compliance with industry quality standards.

Availability and Typical Applications:

The RO3006 PCB is available worldwide, making it easily accessible for manufacturers and designers across the globe. Its versatility and exceptional performance make it suitable for various applications. Some typical examples include:

Automotive radar applications

-

Global positioning satellite antennas

-

Cellular telecommunications systems (power amplifiers and antennas)

-

Patch antennas for wireless communications, direct broadcast satellites

-

Datalink on cable systems, remote meter readers, and power backplanes.

Conclusion:

The RO3006 PCB 25mil substrate is a top-of-the-line circuit material that offers exceptional electrical and mechanical stability. With its stable dielectric constant, low dissipation factor, and impressive thermal conductivity, it is the perfect choice for high-frequency applications. Its uniform mechanical properties, low in-plane expansion coefficient, and volume manufacturing process further enhance its appeal. With worldwide availability and a wide range of applications, the Rogers RO3006 PCB is undoubtedly a reliable and efficient choice for any PCB design project.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com