The realm of millimeter wave automotive radar applications is rapidly advancing, calling for cutting-edge solutions that can keep pace with the demands of next-generation technologies. In response to this industry need, Rogers introduces the RO3003G2 high-frequency, ceramic-filled PTFE laminates, a significant evolution of the renowned

RO3003 series.

The Innovation Behind RO3003G2

RO3003G2 laminates have been meticulously crafted based on invaluable industry feedback, designed to cater specifically to the evolving requirements of millimeter wave automotive radar applications. This next-gen laminate offers a host of features and benefits that position it as a frontrunner in the field.

Features that Set RO3003G2 Apart

1)Dielectric Constant:

With a DK of 3.0 +/- 0.04 at 10GHz and 3.07 at 77 GHz,RO3003G2 ensures consistent and reliable performance across varying frequencies.

2)Low Dissipation Factor:

At 10GHz, RO3003G2 boasts a minimal dissipation factor of 0.0011, optimizing signal integrity and transmission efficiency.

3)Thermal Stability:

Exhibiting a thermal coefficient of dielectric constant of -35 ppm/°C, this laminate offers exceptional stability across temperature variations.

4)Copper Compatibility:

The use of Very Low Profile (VLP) ED copper ensures superior copper matching with a CTE of 16ppm/°C (X axis), 17ppm/°C (Y axis), and 18ppm/°C (Z axis).

5)Homogeneous Construction:

Rogers RO3003G2 integrates VLP ED copper and reduced dielectric porosity, ensuring a uniform and reliable construction.

6)Enhanced Filler System:

The laminate features an advanced filler system that contributes to its outstanding performance metrics.

What are the benefits of using RO3003G2 PCB in high-frequency applications?

1)Optimized Performance:

RO3003G2 high frequency PCB excels in minimizing insertion loss, setting a new standard for performance in high-frequency applications.

2)Stable Dielectric Constant:

By reducing variations in dielectric constant throughout the finished PCB, RO3003G2 ensures consistent and predictable signal behavior.

3)Facilitating Miniaturization:

Enabling the trend toward smaller diameter vias, RO3003G2 supports the drive for more compact and efficient electronic designs.

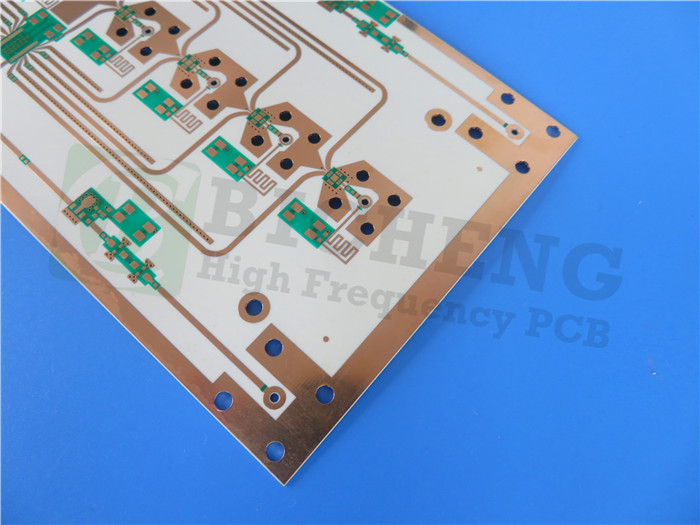

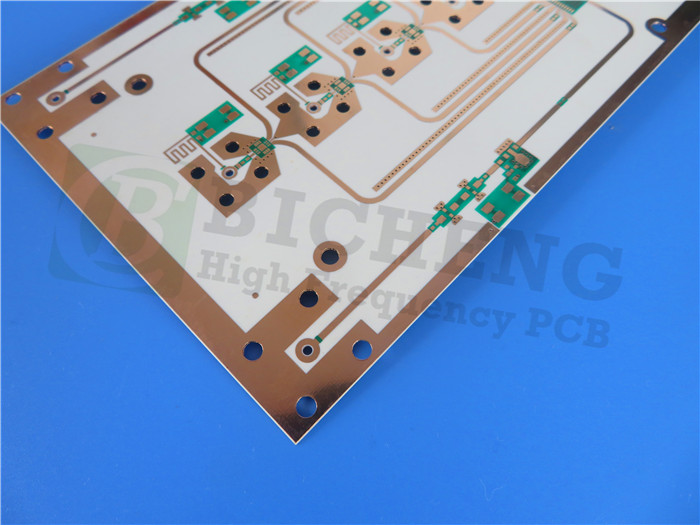

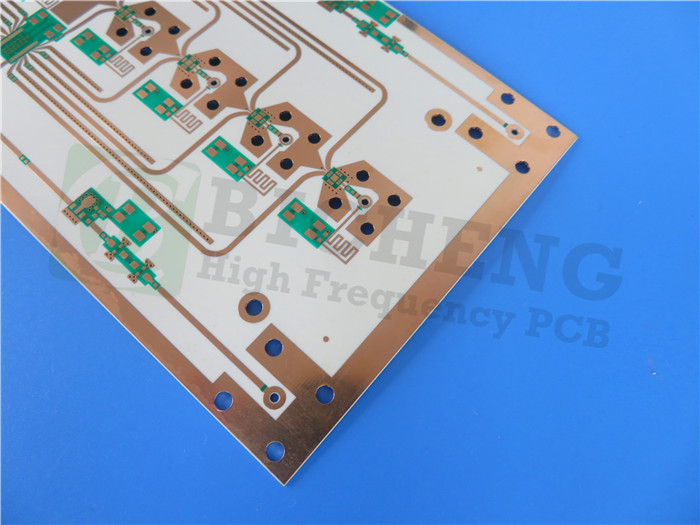

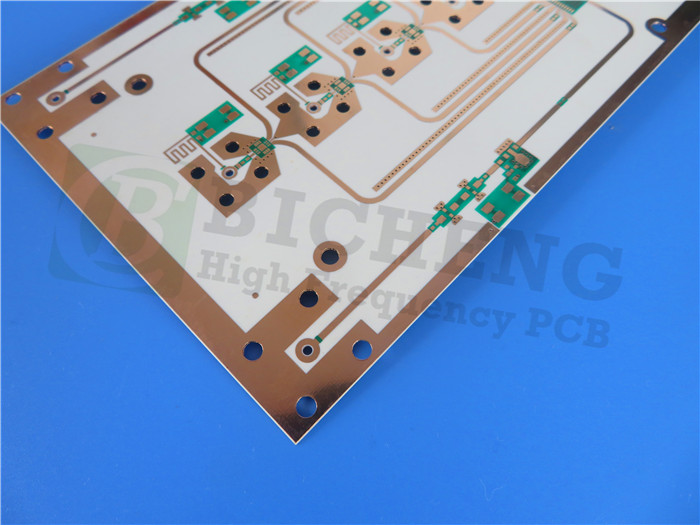

PCB Specifications

Stackup: 2-layer rigid PCB

Copper Thickness: 35 μm (each layer)

Core Thickness: 0.127 mm (5mil)

Board Dimensions: 41.71mm x 64mm

Trace/Space: 4/5 mils

Hole Size: 0.3mm

Finished Board Thickness: 0.2mm

Surface Finish: Immersion Gold

Electrical Testing: 100% tested prior to shipment

Quality Standard: IPC-Class-2

Availability: Worldwide

The Power of Precision

With a meticulous construction comprising 9 components, 27 pads, 21 vias, and 2 nets, RO3003G2 Rogers PCBs exemplify precision engineering at its finest. Each board undergoes rigorous testing and adheres to IPC-Class-2 quality standards, ensuring reliability and performance consistency.

Applications Beyond Boundaries

The versatility of RO3003G2 5mil Rogers substrate PCB extends to a myriad of applications, including adaptive cruise control, forward collision warning, active brake assist, lane change assist, traffic jam pilot, parking pilot, and blind spot detection. Its adaptability and performance make it a preferred choice for cutting-edge automotive radar systems.

Embracing Global Standards

RO3003G2 high frequency circuit board are supplied with Gerber RS-274-X artwork and are available globally, meeting the stringent quality requirements of IPC-Class-2 standards.

In conclusion, the RO3003G2 5mil PCB with its advanced features, superior performance, and global availability stands as a beacon of innovation in the realm of high-frequency applications, particularly in the dynamic landscape of millimeter wave automotive radar technology.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com