AI Servers, Robotics, and Cutting-Edge HDI Technology Drive Demand

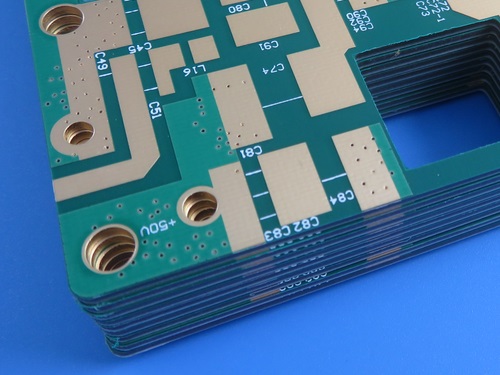

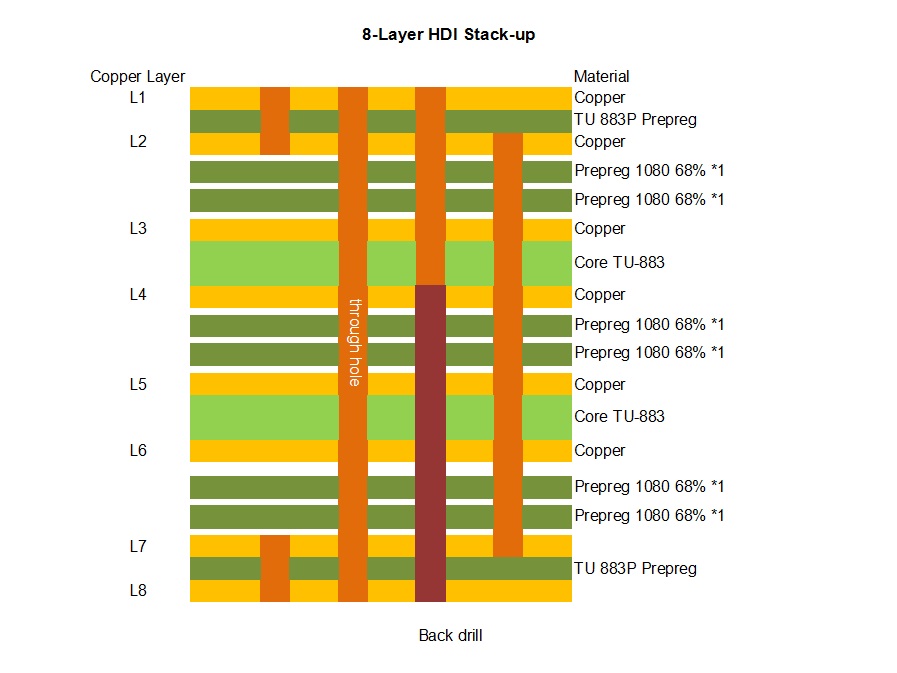

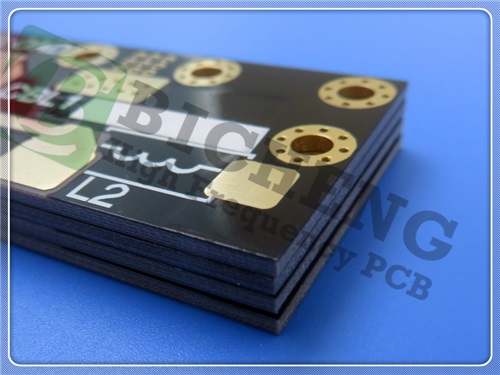

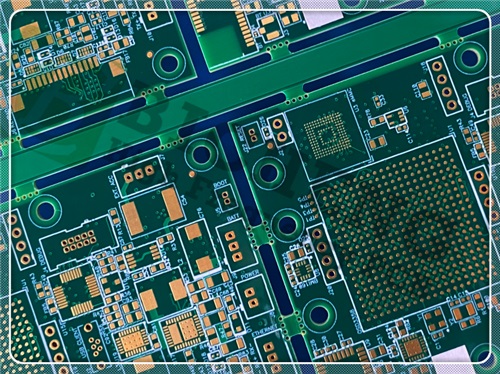

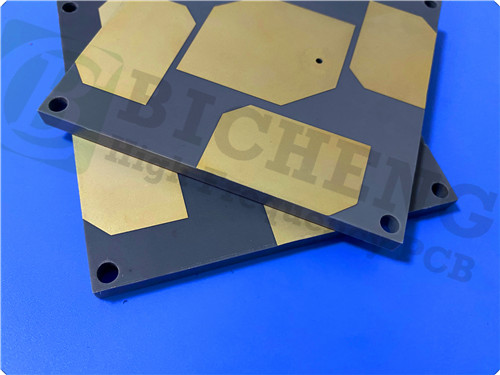

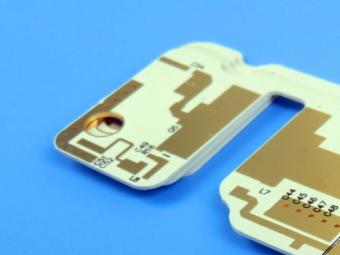

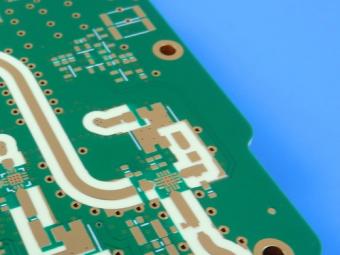

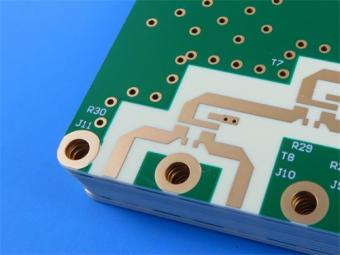

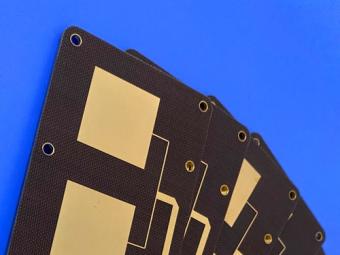

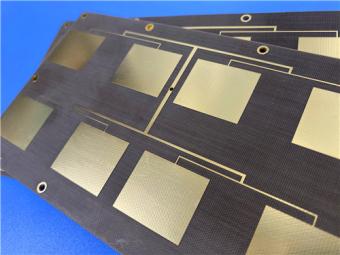

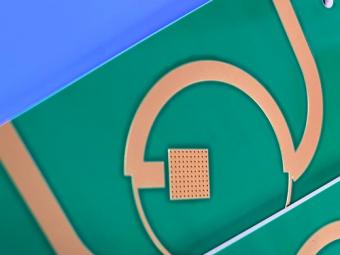

AI Servers, Robotics, and Cutting-Edge HDI Technology Drive Demand The printed circuit board (PCB) industry is undergoing a transformative phase, driven by the rapid advancements in artificial intelligence (AI), robotics, and high-performance computing. As global demand for advanced PCBs surges, companies are racing to innovate and deliver solutions that meet the stringent requirements of next-generation technologies. Among these, HDI (High-Density Interconnect) PCBs have emerged as a critical enabler, particularly in AI servers, robotics, and telecommunications. Our company is proud to announce the successful shipment of our latest 8-layer HDI PCB, manufactured using TU-883 material, a high-performance laminate designed for high-speed, low-loss applications. This product exemplifies our commitment to pushing the boundaries of PCB technology, catering to the ever-evolving needs of the electronics industry. AI Servers and High-Performance Computing: A Catalyst for PCB Growth The AI revolution is reshaping the PCB landscape, with AI servers demanding PCBs that offer unparalleled performance, reliability, and density. According to recent industry reports, the global AI server PCB market is projected to grow from 5.8 billion in 2024 to 14.5 billion by 2028, driven by the exponential growth in AI workloads and data center expansions. One of the key drivers of this growth is the increasing adoption of NVIDIA’s GB200 NVL72 architecture, which requires PCBs with advanced capabilities, including high-layer counts (24-40 layers) and sophisticated HDI technology. Our company has been at the forefront of this trend, achieving a significant milestone by becoming one of the first manufacturers globally to mass-produce 28-layer accelerator card PCBs using 5th and 6th-order HDI technology. In the latest quarter, our AI server PCB shipments, including products designed for NVIDIA’s GB200, exceeded $2 billion, with high-layer count andHDI boards accounting for 75% of the total revenue. Looking ahead, NVIDIA’s GB200 is expected to ship over 1 million units by 2025, representing nearly 40-50% of its high-end GPU shipments. This surge in demand underscores the critical role of advanced PCBs in enabling the next wave of AI innovation. Next-Generation Materials: PTFE and TU-883 Leading the Way As AI and high-performance computing push the limits of PCB technology, material innovation is becoming increasingly important. NVIDIA’s upcoming GB300 architecture is expected to adopt PTFE (Polytetrafluoroethylene) hybrid PCB, which offer superior dielectric properties, including a dielectric constant of 2.1 and a dissipation factor of <5×10⁻⁴. These characteristics make PTFE an ideal choice for high-frequency and high-speed applications. In parallel, our newly shipped 8-layer HDI PCB leverages TU-883 material, a high-performance laminate renowned for its low dielectric constant (3.39 @ 10GHz...

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com