High Demand for HDI: Printed Circuit Board Industry Seizes New Opportunities

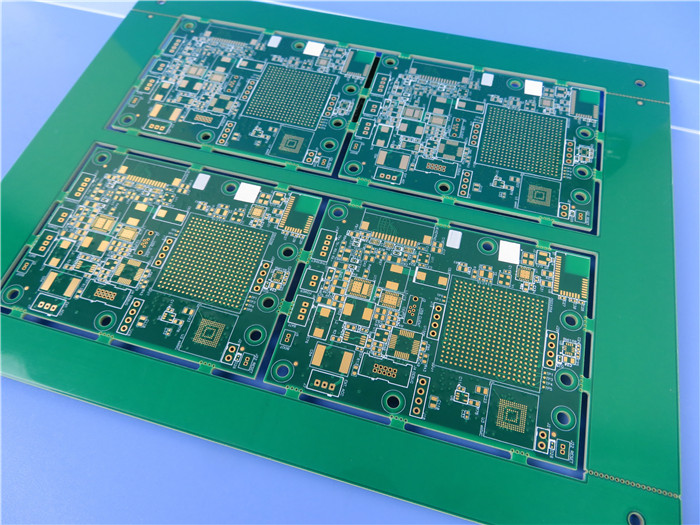

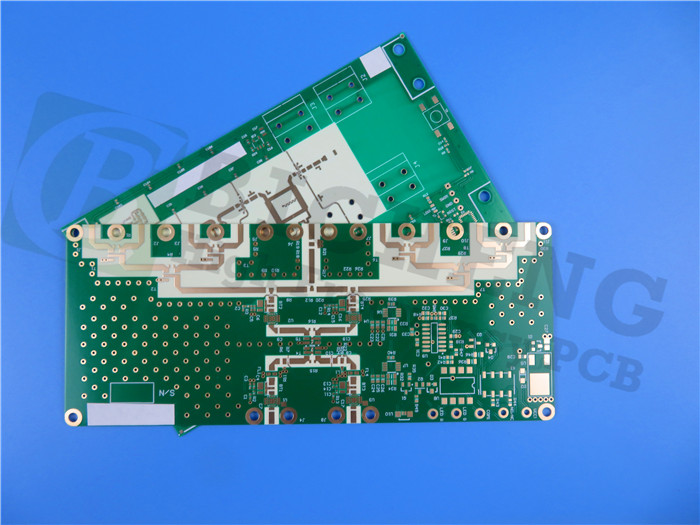

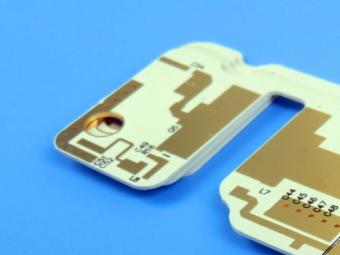

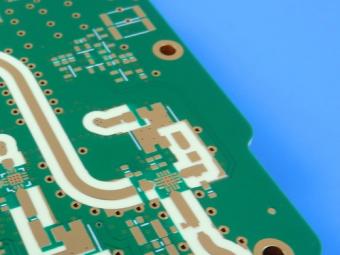

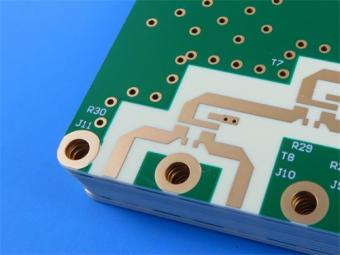

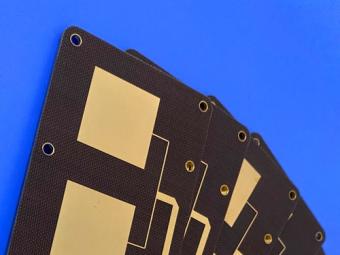

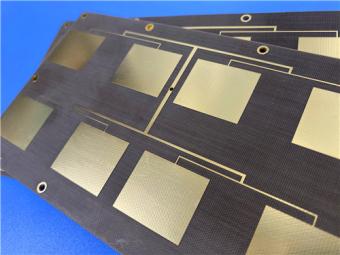

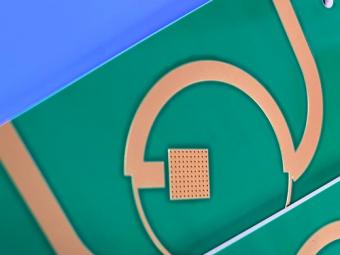

High Demand for HDI: Printed Circuit Board Industry Seizes New Opportunities The global printed circuit board (PCB) industry is witnessing a surge in demand for high-density interconnect (HDI) boards, driven by the thriving development of artificial intelligence (AI). As companies embrace new opportunities in the AI sector, the demand for advanced PCBs that can meet the requirements of AI servers is on the rise. Leading PCB companies are strategically positioning themselves to seize these development opportunities and capitalize on the growing market. HDI boards are characterized by their small size, light weight, high wiring density, and excellent electrical performance. They are particularly suited for AI servers, which demand efficient space utilization, heat dissipation, and high-speed signal transmission capabilities. Compared to traditional through-hole boards, HDI boards can achieve the same functionality with fewer layers, resulting in improved reliability and cost-effectiveness in mass production. These boards also offer advantages in terms of transmission speed and heat dissipation, making them ideal for the AI industry. According to a research report by Founder Securities, the market size of HDI boards is projected to reach $14.58 billion by 2027, with a compound annual growth rate of 6.2% from 2023 to 2028. This growth rate surpasses the compound annual growth rate of the overall PCB industry, which stands at 5.4%. In response to the increasing demand for HDI boards, several leading PCB companies have experienced significant stock price increases. Pengding Holdings (002938) saw a 56.97% increase in stock price, Shanghai Electric Power (002463) rose by 70.17%, and Shenghong Technology (300476) increased by 80.05% from January 1st to June 14th, 2024. Pengding Holdings, a prominent PCB company, has focused its development efforts on AI servers and is currently engaged in mass production. The company has upgraded its production models to accommodate 16 to 20 layers, entering the supply chain of globally renowned server customers. Additionally, Pengding Holdings' PCB products are utilized in the field of AI consumer electronics, including AI smartphones. Shenghong Technology has made significant investments in research and development, leading to breakthroughs in computing power and AI server fields. The company has introduced multi-stage HDI boards and high multi-layer products based on AI server acceleration modules. With certification and industrial operation for 5-stage 20-layer HDI board products, Shenghong Technology aims to meet the strong global demand for AI-related PCBs, driving the core business growth in the coming years. Zhongjing Electronics (002579) has reported relatively full HDI board orders and plans to expand its capacity gradually through product architecture optimization and technological transformation. Shanghai Electric Power is actively seizing the structural demand ...

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com