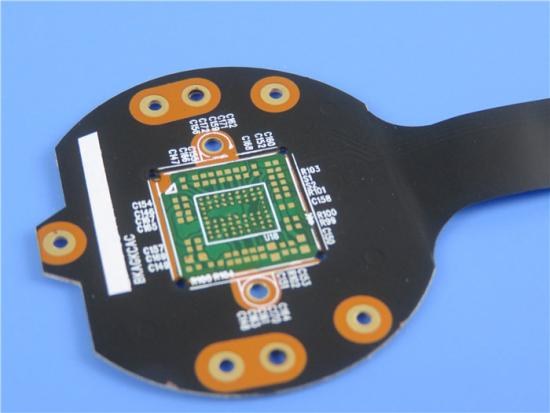

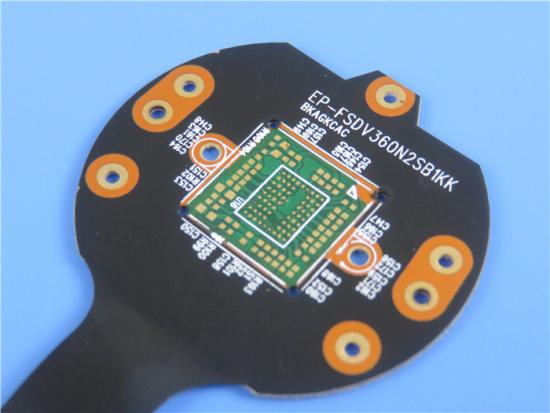

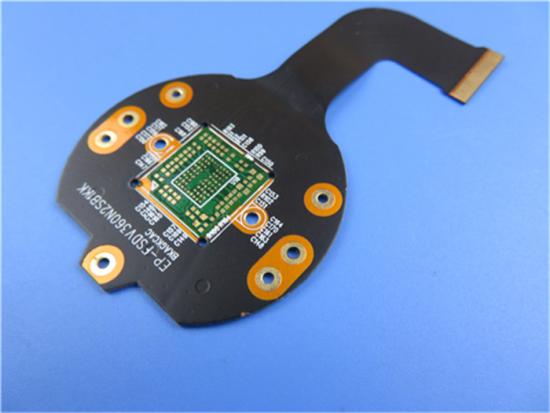

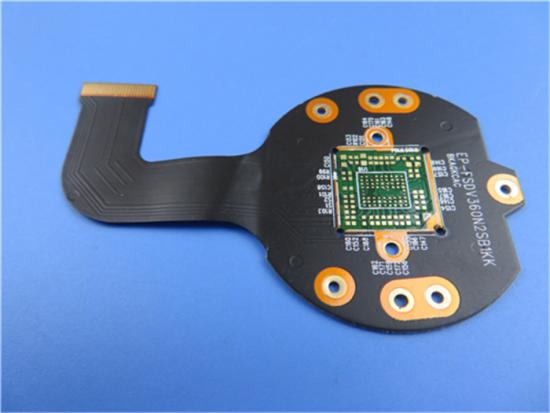

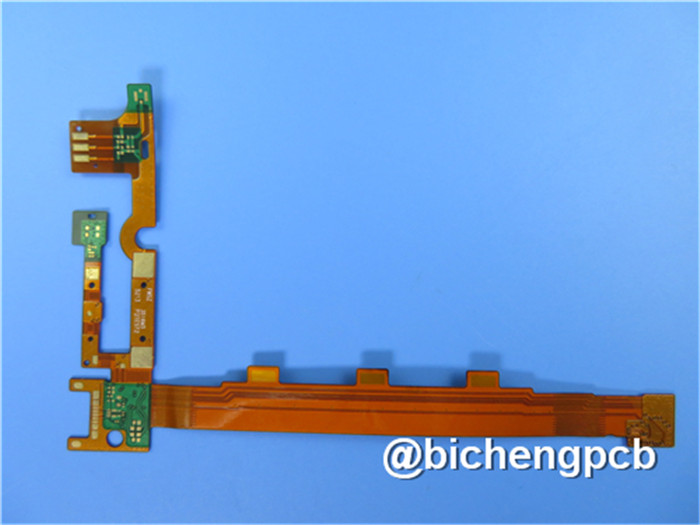

Flexible

Printed Circuit (FPC) Flexible PCB With Partial Green Solder Mask

(FPC’s

are custom-made products, the picture and parameters shown are just for

reference)

General

description:

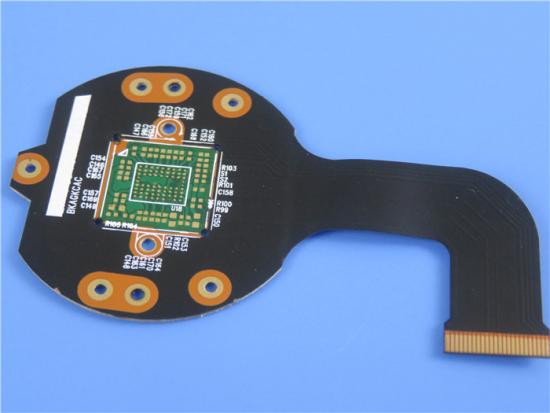

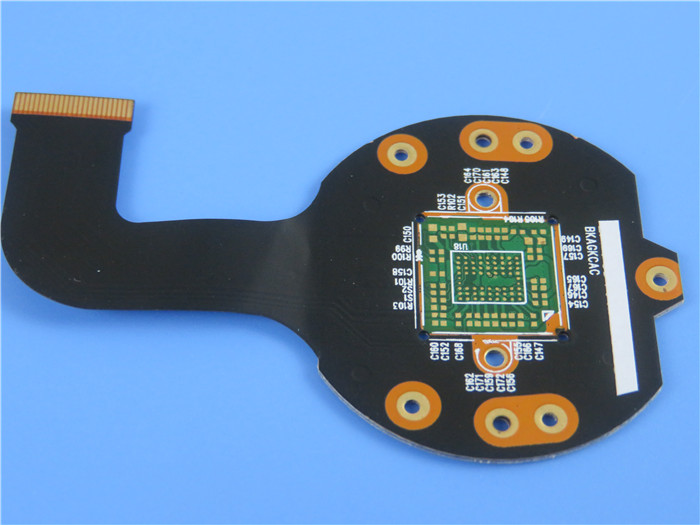

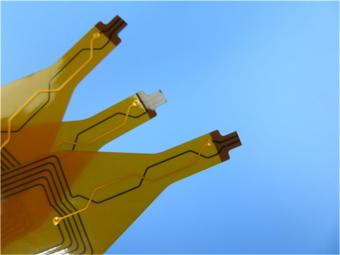

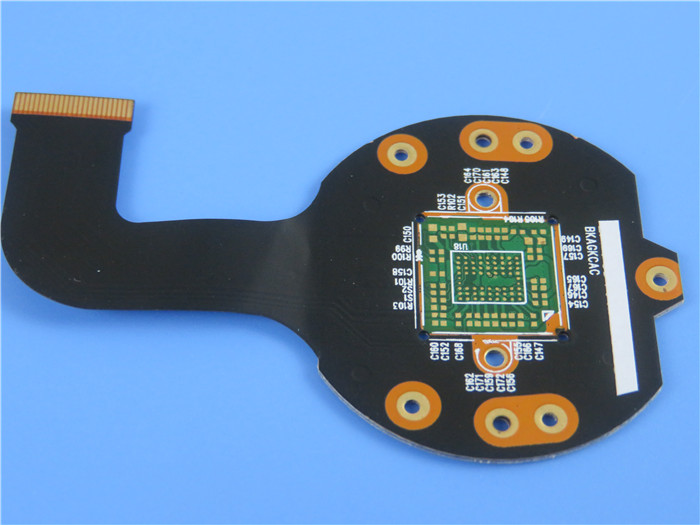

It’s a 2 layer FPC at 0.25mm thick. Green solder mask is

used in the center of the chip area. The base laminate is from Shengyi, It’s

fabricated per IPC 6012 Class 2 using supplied Gerber data. FR-4 stiffeners are

bonded on the inserting head and bottom side.

Parameter

and data sheet:

|

Size of

Flexible PCB

|

75.22 X 31.17mm

|

|

Number of Layers

|

2

|

|

Board Type

|

Flexible

PCB

|

|

Board Thickness

|

0.25mm

|

|

Board Material

|

PET

25µm

|

|

Board Material Supplier

|

ITEQ

|

|

Tg Value of Board Material

|

60℃

|

|

|

|

PTH Cu thickness

|

≥20 µm

|

|

Inner Iayer Cu thicknes

|

N/A

|

|

Surface Cu thickness

|

70um

|

|

|

|

|

Coverlay Colour

|

Black

/ Green solder mask

|

|

Number of Coverlay

|

2

|

|

Thickness of Coverlay

|

25

µm

|

|

Stiffener Material

|

FR-4

/ Polyimide

|

|

Stiffener Thickness

|

0.4mm

/0.2mm

|

|

|

|

|

Type of Silkscreen Ink

|

IJR-4000

MW300

|

|

Supplier of Silkscreen

|

TAIYO

|

|

Color of Silkscreen

|

White

|

|

Number of Silkscreen

|

1

|

|

|

|

Peeling test of Coverlay

|

No

peelable

|

|

Legend Adhesion

|

3M 90℃No

peeling after Min. 3 times test

|

|

|

|

Surface Finish

|

Immersion

Gold

|

|

Thickness of Nickle/Gold

|

Au:

0.03µm(Min.); Ni 2-4µm

|

|

RoHS Required

|

Yes

|

|

Famability

|

94-V0

|

|

|

|

Thermal Shock Test

|

Pass, -25℃±125℃, 1000 cycles.

|

|

Thermal Stress

|

Pass, 300±5℃,10 seconds, 3 cycles. No delamination, no blistering.

|

|

Function

|

100%

Pass electrical test

|

|

Workmanship

|

Compliance

with IPC-A-600H & IPC-6013C Class 2

|

Features

and benefits:

Excellent

flexibility

Reducing

the volume

Weight

reduction

Consistency

of assembly

Increased

reliability

Material

optionality

Low

cost

Continuity

of processing

Great

customer service

Make

delivery on time. We keep higher than 98% on-time-delivery rate.

Applications:

Toy

lamp strip, industrial control audio equipment, Tablet PC module soft board

Covercoat

/ Solder Mask:

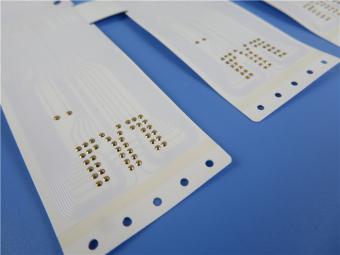

Solder

mask in flexible PCB is different from rigid board, it is usually a polyimide

film coated on one side with a semi-cured and non-tacky adhesive, we call it

covercoat in flexible circuit. It is laminated to the flexible circuit under

heat and pressure, so that the copper pattern is fully encapsulated except for

the solder pads that are exposed through access holes in the covercoat.

The

covercoat production sheet should be cut slightly smaller than the flexible

circuit production sheet to avoid premature edge sealing, which could trap air

bubbles in the package.

The

production sheet for the covercoat is provided with tooling holes in close

register with the tooling holes in the production sheet for the flexible

circuit. The access holes are usually drilled, but in the case of high-volume

production, punching is more cost-effective.

In

principle, drilling of the covercoat is accomplished in the same way as when

drilling rigid boards, i.e., a number of covercoat sheets are stacked, either

5-up or 10-up. The drilling parameters, however, are somewhat different,

because of the polyimide material and the absence of copper foil, which

otherwise could have removed some of the heat from the holes being drilled.

When

drilling/punching large covercoat production sheets, it is necessary to

compensate for the dimensional changes of the flexible circuit production

sheet, which can amount to as much as 0.2%.

More

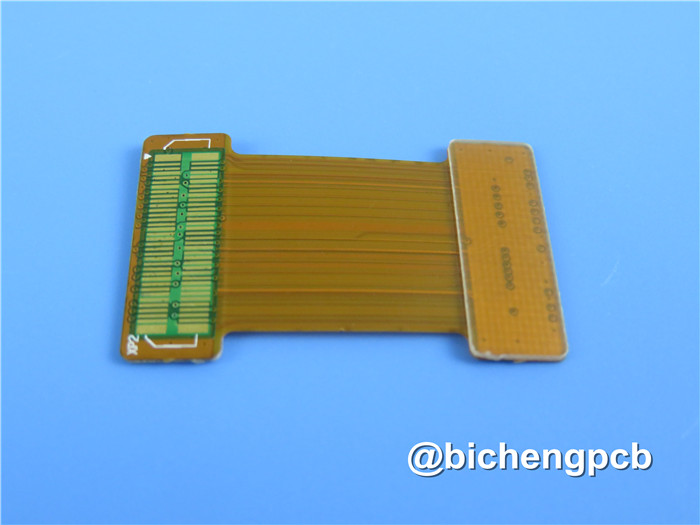

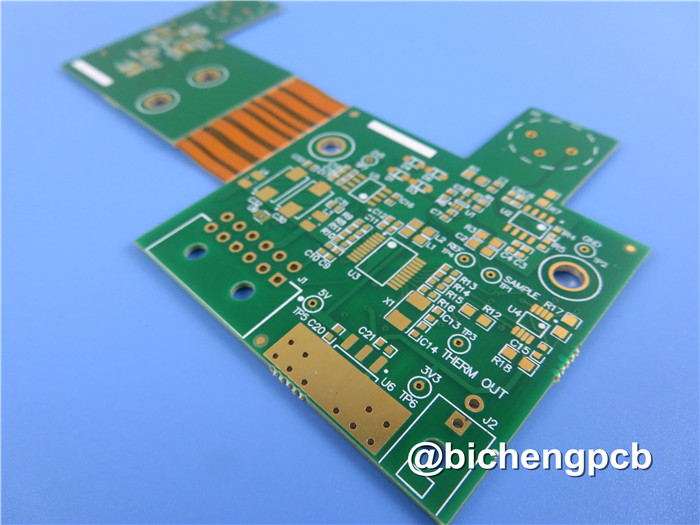

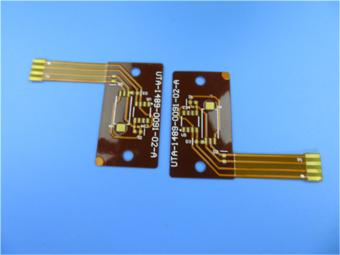

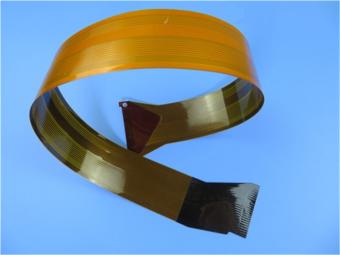

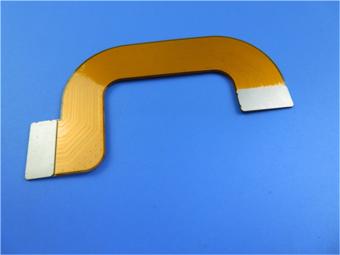

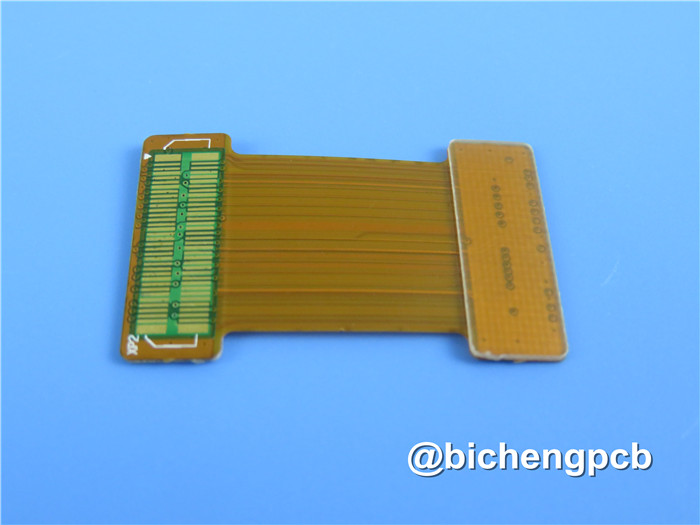

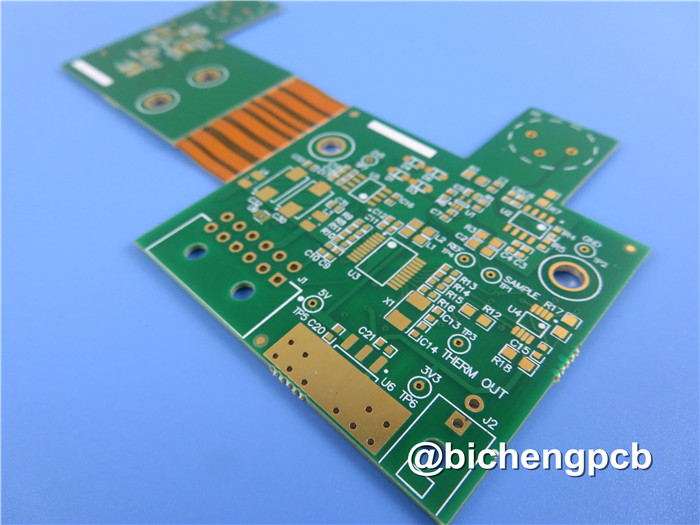

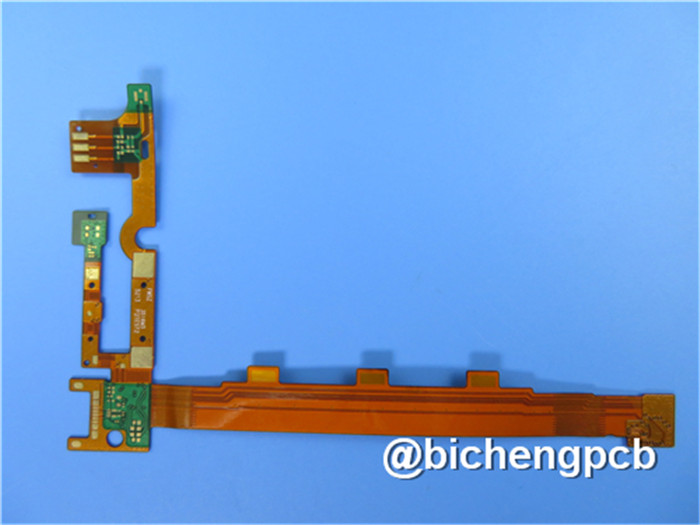

Displays of Flexible Circuits with Partial Green Solder Mask:

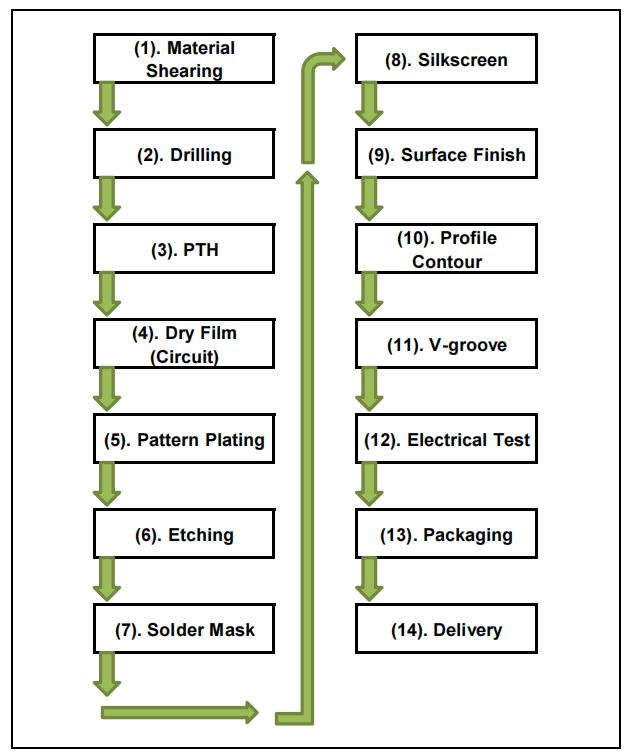

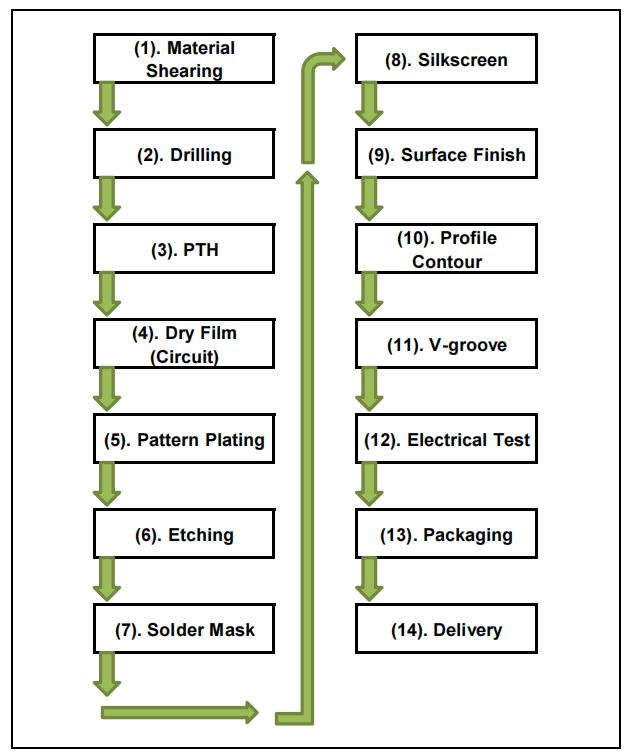

MANUFACTURING PROCESS:

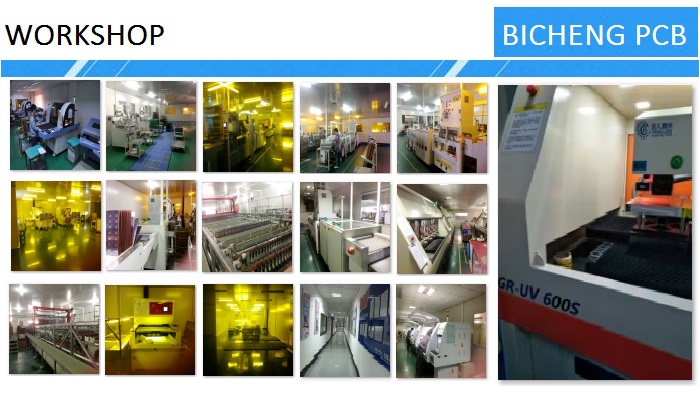

BICHENG PCB WORKSHOP:

BICHENG PCB CERTIFICATE:

BICHENG MAIN COURIERS:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com