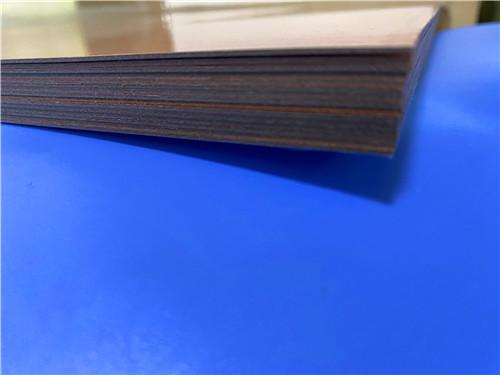

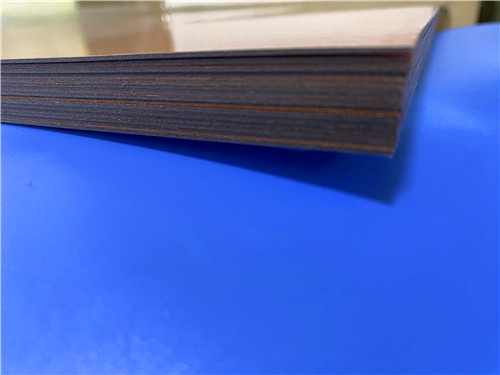

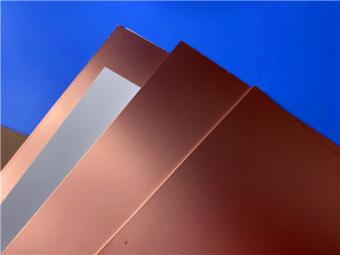

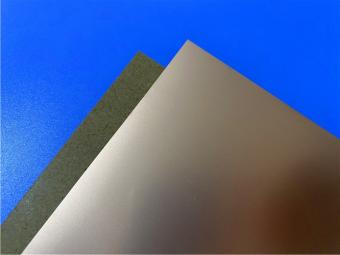

Wangling F4BM233 DK2.33 PTFE Glass Fiber Cloth Copper Clad Laminates

Product Overview

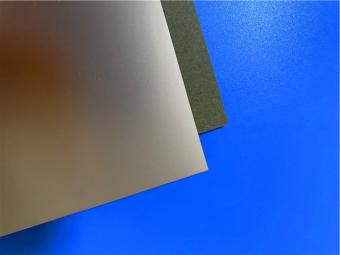

Wangling F4BM233 is a premium PTFE fiberglass cloth copper-clad laminate produced byTaizhou Wangling Insulation Material Factory. It is fabricated through advanced scientific formulation and rigorous manufacturing processes, combining high-quality fiberglass cloth, polytetrafluoroethylene (PTFE) resin, and PTFE film as its core components. Compared to the standard F4B PCB substrate series, F4BM233 CCL delivers enhanced electrical performance, characterized by a well-defined dielectric constant range, minimal dielectric loss, elevated insulation resistance, and exceptional performance stability—making it a cost-effective alternative to comparable international products.

Key Product Advantages

-

Targeted dielectric constant: Typical value of 2.33 (tested at 10GHz) with a precise tolerance of±0.04

-

Low loss performance: Delivers minimal dielectric loss for efficient signal transmission

-

Compatibility with ED copper foil: Ideal for applications without strict PIM requirements

-

Versatile dimensional options: Available in standard and custom sizes to optimize cost-efficiency

-

Robust environmental resistance: Features radiation resistance and low outgassing properties

-

Industrial-grade reliability: Suitable for mass production with high cost-performance ratio

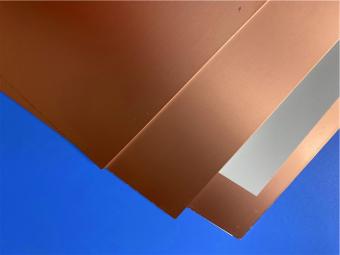

The core dielectric layer is the same for both F4BM and F4BME, but they differ in the copper foil used:

-

F4BM uses ED copper foil and is suitable for applications without PIM requirements.

-

F4BME uses reverse-treated RTF copper foil, offering excellent PIM performance, more precise circuit control, and lower conductor loss.

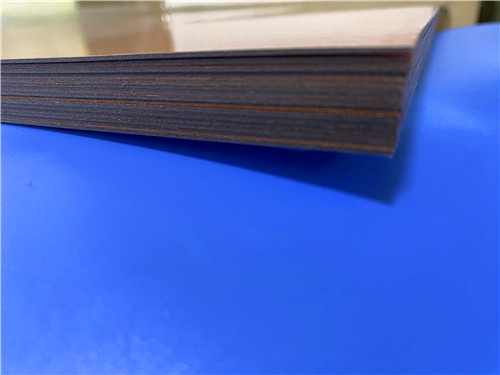

Both F4B laminate series allow precise adjustment of the dielectric constant by varying the PTFE-to-glass fiber ratio, achieving low loss while enhancing dimensional stability. Higher dielectric constants correspond to a higher glass fiber content, resulting in better dimensional stability, lower thermal expansion coefficient, improved temperature drift performance, and a slight increase in dielectric loss.

F4BM233–Key Features

-

Dielectric Constant (Dk): 2.33±0.04

-

Low Loss Tangent: 0.0011 @ 10GHz, 0.0015 @ 20GHz

-

High Thermal Reliability: Withstands 260°C for 10s (3 cycles) without delamination

-

Low Water Absorption:≤0.08%

-

Excellent Electrical Insulation: Volume resistivity≥6×10⁶MΩ·cm, surface resistivity≥1×10⁶MΩ

-

High Peel Strength: >1.8 N/mm (with ED copper foil)

-

Wide Operating Temperature Range: -55°C to +260°C

-

Flame Retardant: UL 94 V-0

Typical Application Scenarios

-

Microwave, radio frequency (RF), and radar systems

-

Phase shifters and passive electronic components

-

Power dividers, couplers, and combiners

-

Feeding networks and phased array antennas

-

Satellite communication equipment and base station antennas

F4BM233 Technical Parameters

|

Technical Parameter

|

Test Conditions

|

Unit

|

F4BM233 Specification

|

|

Dielectric Constant (Typical Value)

|

10GHz

|

-

|

2.33

|

|

Dielectric Constant Tolerance

|

-

|

-

|

±0.04

|

|

Loss Factor (Typical Value)

|

10GHz

|

-

|

0.0011

|

|

Loss Factor (Typical Value)

|

20GHz

|

-

|

0.0015

|

|

Temperature Coefficient of Dielectric Constant

|

-55℃~150℃

|

PPM/℃

|

-130

|

|

Peel Strength (1 OZ)

|

-

|

N/mm

|

>1.8

|

|

Volume Resistivity

|

Normal State

|

MΩ.cm

|

≥6×10⁶

|

|

Surface Resistivity

|

Normal State

|

MΩ

|

≥1×10⁶

|

|

Electrical Strength (Z-direction)

|

5KW, 500V/s

|

KV/mm

|

>23

|

|

Breakdown Voltage (XY-direction)

|

5KW, 500V/s

|

KV

|

>32

|

|

Coefficient of Thermal Expansion (CTE) - XY Direction

|

-55℃~288℃

|

ppm/℃

|

22-30

|

|

Coefficient of Thermal Expansion (CTE) - Z Direction

|

-55℃~288℃

|

ppm/℃

|

205

|

|

Thermal Stress Resistance

|

260℃, 10s, 3 cycles

|

-

|

No delamination

|

|

Water Absorption

|

20±2℃, 24 hours

|

%

|

≤0.08

|

|

Density

|

Room Temperature

|

g/cm³

|

2.2

|

|

Long-Term Operating Temperature

|

-

|

℃

|

-55~+260

|

|

Thermal Conductivity (Z-direction)

|

-

|

W/(M.K)

|

0.28

|

|

Flame Retardancy

|

-

|

UL-94

|

V-0

|

|

Material Composition

|

-

|

-

|

PTFE, fiberglass cloth, ED copper foil

|

Copper Foil Options (F4BM):

|

Copper Foil Type

|

Available Thickness Options

|

Corresponding Thickness (mm)

|

|

ED Copper Foil

|

0.5 OZ

|

0.018

|

|

ED Copper Foil

|

1 OZ

|

0.035

|

|

ED Copper Foil

|

1.5 OZ

|

0.05

|

|

ED Copper Foil

|

2 OZ

|

0.07

|

Standard Panel Sizes:

460×610 mm

500×600 mm

850×1200 mm

914×1220 mm

1000×1200 mm

Custom Sizes Available (upon request):

300×250 mm

350×380 mm

500×500 mm

840×840 mm

1000×1500 mm

Note: For thickness≥4.0 mm or≤0.2 mm, max panel size is limited to 500×610 mm.

Standard Thickness & Tolerance:

0.127 (core)±0.01

0.20±0.02

0.25±0.02

0.50±0.04

0.762±0.05

1.0±0.05

1.5±0.06

2.0±0.08

3.0±0.09

*For Dk≤2.65, minimum core thickness = 0.1 mm.

For Dk = 2.7–3.0, minimum core thickness = 0.2 mm.*

BICHENG PCB CERTIFICATE:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com