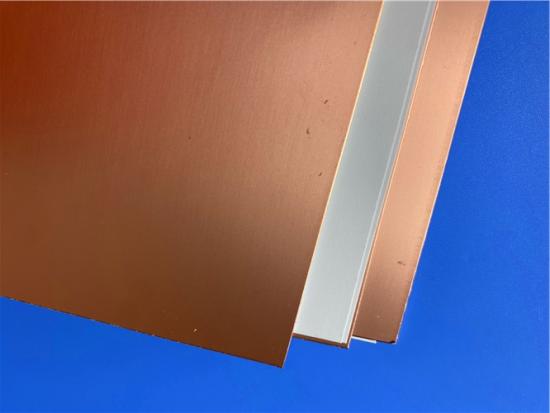

Rogers RT/duroid 5870 DK2.33 High Frequency Laminate

Product Overview

RT/duroid 5870 is a glass microfiber reinforced PTFE composite specifically engineered for high-precision stripline and microstrip circuit applications. The randomly distributed microfibers within the material contribute to outstanding dielectric constant uniformity—this consistency is maintained not only across individual panels but also over a broad frequency spectrum. With its low dissipation factor, the Rogers 5870 laminate extends its utility to Ku-band and higher frequency ranges, making it a reliable choice for demanding high-frequency scenarios.

The RTduroid 5870 material offers excellent processability, as it can be easily cut, sheared, and machined into desired shapes. It exhibits robust resistance to all solvents and reagents—whether hot or cold—that are commonly used in printed circuit etching, as well as edge and hole plating processes.

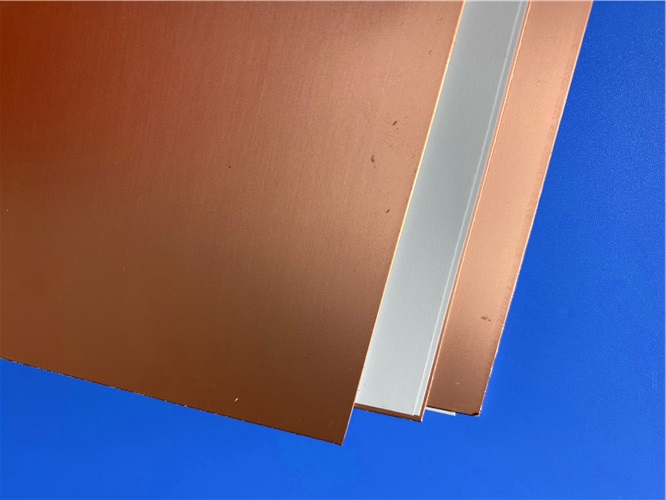

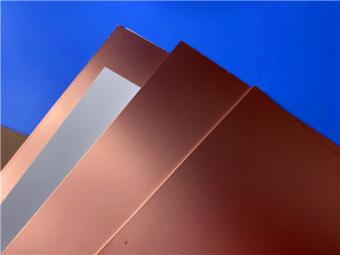

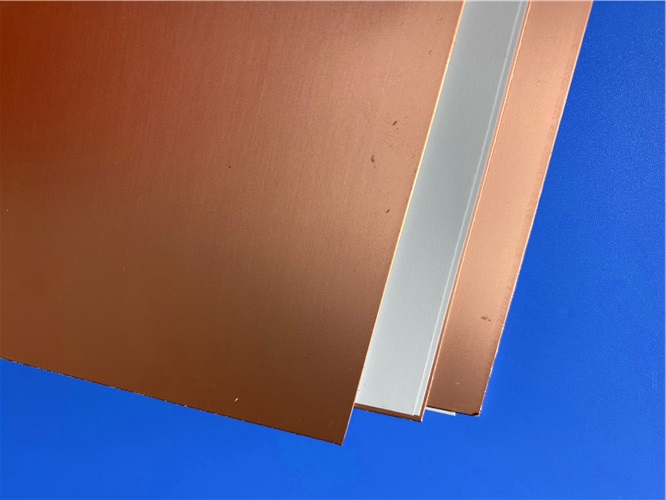

In terms of cladding options, RT/duroid 5870 CCL is typically supplied as a laminate with electrodeposited (EDC) copper or reverse-treated EDC copper on both sides, with copper weights ranging from½ounce/ft²(8μm) to 2 ounces/ft²(70μm). For more critical electrical applications, it can also be clad with rolled copper foil. Additionally, cladding with aluminum, copper, or brass plate is available upon specification.

When placing an order for RT/duroid 5870 substrates, it is crucial to specify key parameters including dielectric thickness, tolerance, the type of copper foil (rolled, electrodeposited, or reverse-treated), and the required copper foil weight.

Key Features

-

Delivers the lowest electrical loss among reinforced PTFE materials

-

Boasts low moisture absorption properties

-

Exhibits isotropic characteristics

-

Maintains uniform electrical performance across a wide frequency range

-

Offers excellent chemical resistance

Typical Applications

-

Commercial airline broadband antennas

-

Microstrip and stripline circuits

-

Millimeter wave applications

-

Military radar systems

-

Missile guidance systems

-

Point-to-point digital radio antennas

Technical Properties

|

RT/duroid 5870 Typical Value

|

|

Property

|

RT/duroid 5870

|

Direction

|

Units

|

Condition

|

Test Method

|

|

Dielectric Constant,εProcess

|

2.33

2.33±0.02 spec.

|

Z

|

N/A

|

C24/23/50

C24/23/50

|

1 MHz IPC-TM-650 2.5.5.3

10 GHz IPC-TM 2.5.5.5

|

|

Dielectric Constant,εDesign

|

2.33

|

Z

|

N/A

|

8GHz to 40 GHz

|

Differential Phase Length Method

|

|

Dissipation Factor,tanδ

|

0.0005

0.0012

|

Z

|

N/A

|

C24/23/50

C24/23/50

|

1 MHz IPC-TM-650 2.5.5.3

10 GHz IPC-TM 2.5.5.5

|

|

Thermal Coefficient of ε

|

-115

|

Z

|

ppm/℃

|

-50℃to 150℃

|

IPC-TM-650 2.5.5.5

|

|

Volume Resistivity

|

2 x 107

|

Z

|

Mohm cm

|

C/96/35/90

|

ASTM D 257

|

|

Surface Resistivity

|

3 x 107

|

Z

|

Mohm

|

C/96/35/90

|

ASTM D 257

|

|

Specific Heat

|

0.96(0.23)

|

N/A

|

j/g/k

(cal/g/c)

|

N/A

|

Calculated

|

|

Tensile Modulus

|

Test at 23℃

|

Test at 100℃

|

N/A

|

MPa(kpsi)

|

A

|

ASTM D 638

|

|

1300(189)

|

490(71)

|

X

|

|

1280(185)

|

430(63)

|

Y

|

|

Ultimate Stress

|

50(7.3)

|

34(4.8)

|

X

|

|

42(6.1)

|

34(4.8)

|

Y

|

|

Ultimate Strain

|

9.8

|

8.7

|

X

|

%

|

|

9.8

|

8.6

|

Y

|

|

Compressive Modulus

|

1210(176)

|

680(99)

|

X

|

MPa(kpsi)

|

A

|

ASTM D 695

|

|

1360(198)

|

860(125)

|

Y

|

|

803(120)

|

520(76)

|

Z

|

|

Ultimate Stress

|

30(4.4)

|

23(3.4)

|

X

|

|

37(5.3)

|

25(3.7)

|

Y

|

|

54(7.8)

|

37(5.3)

|

Z

|

|

Ultimate Strain

|

4

|

4.3

|

X

|

%

|

|

3.3

|

3.3

|

Y

|

|

8.7

|

8.5

|

Z

|

|

Moisture Absorption

|

0.02

|

N/A

|

%

|

0.62"(1.6mm) D48/50

|

ASTM D 570

|

|

Thermal Conductivity

|

0.22

|

Z

|

W/m/k

|

80℃

|

ASTM C 518

|

|

Coefficient of Thermal Expansion

|

22

28

173

|

X

Y

Z

|

ppm/℃

|

0-100℃

|

IPC-TM-650 2.4.41

|

|

Td

|

500

|

N/A

|

℃ TGA

|

N/A

|

ASTM D 3850

|

|

Density

|

2.2

|

N/A

|

gm/cm3

|

N/A

|

ASTM D 792

|

|

Copper Peel

|

27.2(4.8)

|

N/A

|

Pli(N/mm)

|

1oz(35mm)EDC foil

after solder float

|

IPC-TM-650 2.4.8

|

|

Flammability

|

V-0

|

N/A

|

N/A

|

N/A

|

UL 94

|

|

Lead-free Process Compatible

|

Yes

|

N/A

|

N/A

|

N/A

|

N/A

|

Standard Specifications

Standard Thicknesses (with Tolerances)

-

0.005”(0.127mm)±0.0005”

-

0.010”(0.252mm)±0.0007”

-

0.020”(0.508mm)±0.0015”

-

0.031”(0.787mm)±0.0020”

-

0.062”(1.575mm)±0.0030”

Additional thicknesses are available ranging from 0.0035”to 0.375”in various increments.

Standard Panel Sizes

-

18”X 12”(457 X 305mm)

-

18”X 24”(457 X 610mm)

Additional panel sizes can be requested.

Standard Claddings

-

Electrodeposited Copper Foil:½oz. (18µm) HH/HH; 1 oz. (35µm) H1/H1

-

Rolled Copper Foil:½oz. (18µm) ; 1 oz. (35µm)

Additional cladding options (e.g., heavy metal, resistive foil) and unclad configurations are available. For inquiries about custom product configurations, contact Customer Service or Sales Engineering.

Important Notes

BICHENG PCB CERTIFICATE:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com