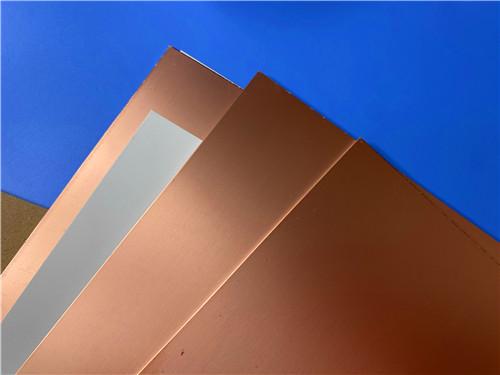

F4BTMS233 F4BTMS CCL Series Ultra-Fine Glass Fiber Reinforced PTFE Ceramic-Filled Substrate

1. Product Overview

Wangling F4BTMS233 is an upgraded version of the F4BTM laminate series, featuring innovative material formulation and advanced manufacturing processes. It incorporates a high proportion of special nano-ceramics uniformly blended with polytetrafluoroethylene (PTFE) resin, reinforced by ultra-thin and ultra-fine glass fiber cloth. This unique composition minimizes the glass fiber effect during electromagnetic wave propagation, reduces dielectric loss, and enhances dimensional stability—while also lowering the material's X/Y/Z anisotropy. The laminate boasts improved operating frequency, elevated electrical strength, and increased thermal conductivity, complemented by excellent low coefficient of thermal expansion and stable dielectric-temperature characteristics.

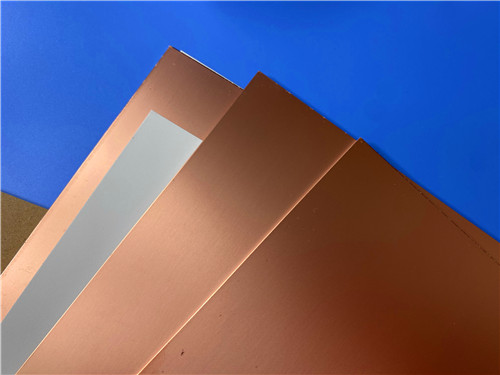

As an aerospace-grade high-reliability material, F4BTMS233 substrate is fully capable of replacing equivalent foreign products. It comes standard with RTF low-roughness copper foil, which reduces conductor loss while ensuring excellent peel strength. Additionally, it can be paired with copper or aluminum substrates to meet diverse application requirements. The DK2.33 F4B laminate is compatible with standard PTFE board processing technologies, offering superior mechanical and physical properties that make it suitable for multi-layer, high-multi-layer, and backplane fabrication. It also exhibits excellent processability for dense holes and fine circuits.

2. Key Features

-

Narrow dielectric constant tolerance with exceptional batch-to-batch consistency.

-

Ultra-low dielectric loss for high-performance signal transmission.

-

Stable dielectric constant and low loss values within the 40GHz operating frequency range, ideal for phase-sensitive applications.

-

Excellent temperature coefficient of dielectric constant, maintaining reliable frequency and phase stability across the temperature range of -55℃to 150℃.

-

Superior radiation resistance, retaining stable dielectric and physical properties even after exposure to specified radiation doses.

-

Low outgassing performance, meeting aerospace vacuum outgassing requirements as tested by standard vacuum volatility methods.

-

Minimal coefficient of thermal expansion (CTE) in X/Y/Z directions, ensuring dimensional thermal stability and via copper reliability.

-

Enhanced thermal conductivity, suitable for high-power application scenarios.

-

Outstanding dimensional stability and low water absorption.

3. Typical Applications

-

Aerospace equipment (space and in-cabin devices)

-

Microwave and radio frequency (RF) systems

-

Radar systems (including military radar)

-

Feed networks

-

Phase-sensitive antennas and phased array antennas

-

Satellite communication systems

4. Technical Specifications Table

|

Property

|

Test Condition

|

Unit

|

F4BTMS233

|

|

Dielectric Constant (Typ.)

|

10 GHz

|

–

|

2.33

|

|

Dielectric Constant Tolerance

|

–

|

–

|

±0.03

|

|

Design Dielectric Constant

|

10 GHz

|

–

|

2.33

|

|

Dissipation Factor (Typ.)

|

10 GHz

|

–

|

0.001

|

|

20 GHz

|

–

|

0.0011

|

|

|

40 GHz

|

–

|

0.0015

|

|

|

TCDK

|

–55°C to +150°C

|

ppm/°C

|

–122

|

|

Peel Strength

|

1 oz RTF Cu

|

N/mm

|

>2.4

|

|

Volume Resistivity

|

Room Temp.

|

MΩ·cm

|

≥1×10⁸

|

|

Surface Resistance

|

Room Temp.

|

MΩ

|

≥1×10⁸

|

|

Electric Strength (Z-axis)

|

5 kV, 500 V/s

|

kV/mm

|

>30

|

|

Breakdown Voltage (XY-plane)

|

5 kV, 500 V/s

|

kV

|

>38

|

|

CTE (X, Y)

|

–55°C to +288°C

|

ppm/°C

|

35–40

|

|

CTE (Z)

|

–55°C to +288°C

|

ppm/°C

|

220

|

|

Thermal Stress

|

260°C, 10 s, 3 cycles

|

–

|

No delamination

|

|

Water Absorption

|

20±2°C, 24 h

|

%

|

0.02

|

|

Density

|

Room Temp.

|

g/cm³

|

2.22

|

|

Operating Temperature Range

|

–

|

°C

|

–55 to +260

|

|

Thermal Conductivity (Z-axis)

|

–

|

W/(m·K)

|

0.28

|

|

Flammability

|

–

|

UL-94

|

V-0

|

|

Material Composition

|

–

|

–

|

PTFE, ultra-thin glass fiber, ceramic

|

5. Optional Configurations

5.1 Copper Foil Options

-

Thickness: 0.5OZ (0.018mm), 1OZ (0.035mm); other thicknesses available upon customization.

-

Type: Standard RTF low-roughness copper foil; optional 50Ωembedded resistor copper foil, aluminum substrate, or copper substrate.

5.2 50ΩEmbedded Resistor Copper Foil Details

-

Resistive film composition: Nickel-phosphorus alloy.

-

Resistive film thickness: 0.2μm.

-

Sheet resistance: 50±5Ωper square centimeter.

6. Available Sizes & Thickness Specifications

6.1 Standard Sizes (Custom sizes available upon request)

305×460mm (12×18 inches)

460×610mm (18×24 inches)

610×920mm (24×36 inches)

6.2 Dielectric Layer Thickness & Tolerance

-

Minimum thickness: 0.09mm.

-

Available thicknesses: Multiples of 0.09mm or 0.127mm (custom thicknesses available).

|

Thickness (mm/mil)

|

Tolerance (mm/mil)

|

|

0.090mm (3.5mil)

|

±0.010mm (0.4mil)

|

|

0.127mm (5.0mil)

|

±0.0127mm (0.5mil)

|

|

0.254mm (10mil)

|

±0.02mm (1.0mil)

|

|

0.508mm (20mil)

|

±0.03mm (1.19mil)

|

|

0.635mm (25mil)

|

±0.04mm (1.58mil)

|

|

0.762mm (30mil)

|

±0.04mm (1.58mil)

|

|

0.787mm (30.1mil)

|

±0.04mm (1.58mil)

|

|

1.016mm (40mil)

|

±0.05mm (2.0mil)

|

|

1.270mm (50mil)

|

±0.05mm (2.0mil)

|

|

1.50mm (59mil)

|

±0.06mm (2.5mil)

|

|

1.524mm (60mil)

|

±0.06mm (2.5mil)

|

|

1.575mm (62mil)

|

±0.06mm (2.5mil)

|

|

2.03mm (80mil)

|

±0.08mm (3.2mil)

|

|

2.54mm (100mil)

|

±0.10mm (4.0mil)

|

|

3.175mm (125mil)

|

±0.13mm (5.0mil)

|

|

4.06mm (160mil)

|

±0.18mm (7.0mil)

|

|

5.08mm (200mil)

|

±0.20mm (8.0mil)

|

|

6.35mm (250mil)

|

±0.25mm (10mil)

|

BICHENG PCB CERTIFICATE:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com