Wangling F4BME220 DK2.2 F4B F4BME Series PCB Copper Clad Laminate

1. Product Overview

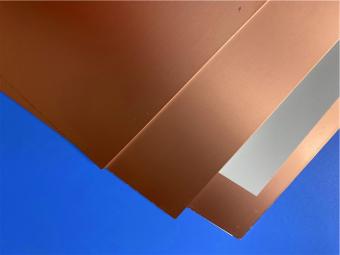

F4BME220 is a premium PTFE glass fiber clothcopper-clad laminate developed by Taizhou Wangling Insulation Materials Factory. It is meticulously crafted through scientific formulation and rigorous process pressing, combining glass fiber cloth, polytetrafluoroethylene (PTFE) resin, and PTFE film as core raw materials.

Compared with conventionalF4B laminates, Wangling F4BME220 boasts enhanced electrical performance, featuring a wider dielectric constant range, lower dielectric loss, higher insulation resistance, and exceptional performance stability. This product is fully capable of replacing equivalent foreign counterparts, offering a cost-effective solution for high-performance applications.

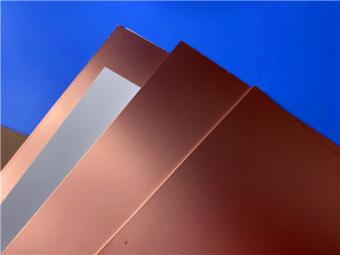

A key distinction of the F4BME series, including F4BME220, lies in its copper foil configuration. It is paired with reversed RTF copper foil, which endows the laminate with excellent Passive Intermodulation (PIM) performance, more precise circuit control capabilities, and reduced conductor loss. This makes F4BME220 particularly suitable for scenarios requiring strict PIM compliance.

The dielectric constant of F4BME220 substrate is precisely calibrated by optimizing the ratio between PTFE and glass fiber cloth. This precise tuning not only achieves low loss characteristics but also significantly enhances the material's dimensional stability. The well-balanced composition ensures the laminate maintains reliable performance across a wide range of operating conditions.

2. Core Product Features

-

Dielectric Constant (DK): Typical value of 2.2 at 10GHz, with a tight tolerance of±0.04

-

Low Loss Factor: 0.001 at 10GHz and 0.0014 at 20GHz, ensuring efficient signal transmission

-

Excellent PIM Performance:≤-159 dBc, ideal for high-frequency communication systems

-

Superior Dimensional Stability: Optimized PTFE-to-glass fiber ratio minimizes deformation under temperature variations

-

Wide Operating Temperature Range: -55℃to +260℃for harsh environment adaptability

-

High Insulation Performance: Volume resistivity≥6×10⁶MΩ.cm and surface resistance≥1×10⁶MΩ

-

Flame Retardant: Complies with UL-94 V-0 standard for enhanced safety

-

Anti-irradiation and Low Outgassing: Suitable for aerospace and high-reliability applications

-

Cost-Effective: Commercialized mass production ensures competitive pricing

3. Typical Applications

-

Microwave, RF, and radar systems

-

Phase shifters and passive components

-

Power dividers, couplers, and combiners

-

Feeding networks and phased array antennas

-

Satellite communication equipment

-

Base station antennas

4. Technical Specifications Table

|

Performance Parameter

|

Test Conditions

|

Unit

|

F4BME220 Specification

|

|

Dielectric Constant (Typical Value)

|

10GHz

|

-

|

2.2

|

|

Dielectric Constant Tolerance

|

-

|

-

|

±0.04

|

|

Loss Factor (Typical Value)

|

10GHz

|

-

|

0.001

|

|

Loss Factor (Typical Value)

|

20GHz

|

-

|

0.0014

|

|

Dielectric Constant Temperature Coefficient

|

-55℃~150℃

|

PPM/℃

|

-142

|

|

Peel Strength (1 OZ)

|

-

|

N/mm

|

>1.6

|

|

Volume Resistivity

|

Normal Condition

|

MΩ.cm

|

≥6×10⁶

|

|

Surface Resistance

|

Normal Condition

|

MΩ

|

≥1×10⁶

|

|

Electrical Strength (Z-direction)

|

5KW, 500V/s

|

KV/mm

|

>23

|

|

Breakdown Voltage (XY-direction)

|

5KW, 500V/s

|

KV

|

>30

|

|

Coefficient of Thermal Expansion (XY-direction)

|

-55℃~288℃

|

ppm/℃

|

25-34

|

|

Coefficient of Thermal Expansion (Z-direction)

|

-55℃~288℃

|

ppm/℃

|

240

|

|

Thermal Stress Resistance

|

260℃, 10s, 3 cycles

|

-

|

No delamination

|

|

Water Absorption

|

20±2℃, 24 hours

|

%

|

≤0.08

|

|

Density

|

Room Temperature

|

g/cm³

|

2.18

|

|

Continuous Operating Temperature

|

-

|

℃

|

-55~+260

|

|

Thermal Conductivity (Z-direction)

|

-

|

W/(M.K)

|

0.24

|

|

PIM Value

|

-

|

dBc

|

≤-159

|

|

Flame Retardancy

|

-

|

UL-94

|

V-0

|

|

Material Composition

|

-

|

-

|

PTFE, glass fiber cloth, reversed RTF copper foil

|

Test Method Notes:

1.Dielectric constant (typical value) is tested in the Z-direction of the material, following GB/T 12636-1990 or IPC-TM650 2.5.5.5 stripline method.

2.Other performance tests are conducted in accordance with or with reference to IPC-TM-650 or GBT4722-2017 test methods.

3.All test data provided are typical measurement values for material selection reference only, and do not constitute any express or implied warranties. Customers are responsible for verifying the suitability of the material for specific applications.

5. Copper Foil Options

Copper Foil Type: Reversed RTF copper foil

Available Thicknesses:

0.5 OZ (0.018mm)

1 OZ (0.035mm)

6. Dimension Specifications

Standard Sizes (mm):

460×610

500×600

850×1200

914×1220

1000×1200

Customizable Non-Standard Sizes (mm):

300×250

350×380

500×500

840×840

1000×1500

Special Note:

For products with thickness≥4.0mm or≤0.2mm, the maximum size is limited to 500×610mm.

7. Thickness and Tolerance

|

Thickness Type

|

Thickness (mm)

|

Tolerance (mm)

|

|

Dielectric Thickness

|

0.1

|

±0.01

|

|

Dielectric Thickness

|

0.127

|

±0.01

|

|

Total Thickness (Including Copper)

|

0.2

|

±0.02

|

|

Total Thickness (Including Copper)

|

0.25

|

±0.02

|

|

Total Thickness (Including Copper)

|

0.5

|

±0.04

|

|

Total Thickness (Including Copper)

|

0.508

|

±0.04

|

|

Total Thickness (Including Copper)

|

0.762

|

±0.05

|

|

Total Thickness (Including Copper)

|

0.8

|

±0.05

|

|

Total Thickness (Including Copper)

|

1

|

±0.05

|

|

Total Thickness (Including Copper)

|

1.5

|

±0.06

|

|

Total Thickness (Including Copper)

|

1.524

|

±0.06

|

|

Total Thickness (Including Copper)

|

1.575

|

±0.06

|

|

Total Thickness (Including Copper)

|

2

|

±0.08

|

|

Total Thickness (Including Copper)

|

2.5

|

±0.08

|

|

Total Thickness (Including Copper)

|

3

|

±0.09

|

|

Total Thickness (Including Copper)

|

4

|

±0.1

|

|

Total Thickness (Including Copper)

|

5

|

±0.1

|

|

Total Thickness (Including Copper)

|

6

|

±0.12

|

|

Total Thickness (Including Copper)

|

8

|

±0.15

|

|

Total Thickness (Including Copper)

|

10

|

±0.18

|

|

Total Thickness (Including Copper)

|

12

|

±0.2

|

Special Note:

The minimum available dielectric thickness for F4BME220 CCL (dielectric constant≤2.65) is 0.1mm.

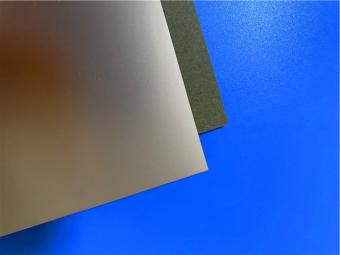

8. Aluminum/Copper Base Version

F4BME220 PCB material is also available in aluminum-based or copper-based configurations, designed for shielding or heat dissipation applications. The product features a dielectric layer with copper foil on one side and aluminum/copper base on the other side.

Model Designation:

F4BME220-AL: Aluminum-based version

F4BME220-CU: Copper-based version

Base Material Specifications:

|

Base Type

|

Material

|

Specific Gravity

|

Thermal Conductivity (W/(M.K))

|

Available Thickness (mm)

|

Thickness Tolerance (mm)

|

Available Sizes (mm)

|

|

Copper Base

|

Red Copper/Brass

|

8.9

|

380

|

0.48, 0.98, 1.48, 1.98, 2.98, 3.98 (Customizable)

|

+0.02, -0.05

|

460×610, 460×305 (Customizable)

|

|

Aluminum Base

|

Aluminum

|

2.7

|

180

|

0.48, 0.98, 1.48, 1.98, 2.98, 3.98 (Customizable)

|

+0.02, -0.05

|

460×610, 460×305 (Customizable)

|

BICHENG PCB CERTIFICATE:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com