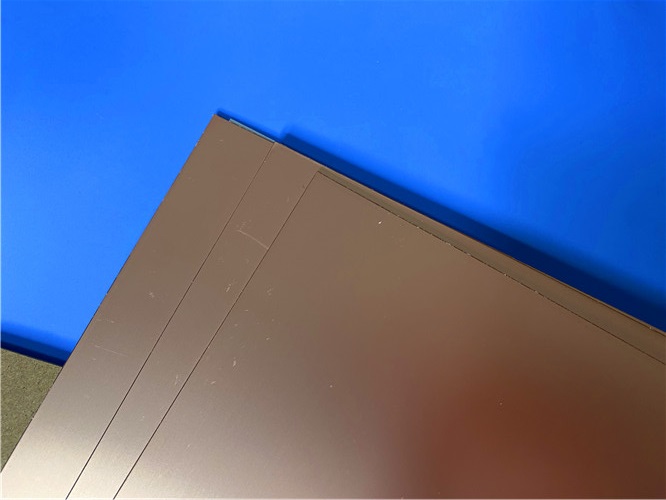

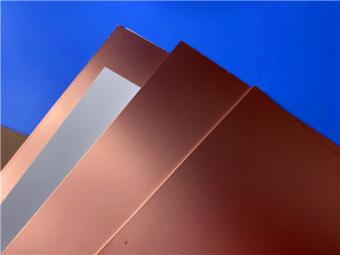

Taconic TLY-3 DK2.33 Avionics & Aerospace Grade Low DK Base Material

Overview

TLY-3 laminates are crafted using ultra-lightweight woven fiberglass, boasting significantly enhanced dimensional stability compared to chopped fiber reinforced PTFE composites. The woven matrix integrated into the TLY-3 material results in a laminate with superior mechanical stability, making it well-suited for high-volume production processes. Thanks to its low dissipation factor, this TLY-3 copper clad laminate can be successfully applied in 77 GHz automotive radar systems as well as various millimeter-wave frequency antennas.

In comparative OEM testing conducted at 77 GHz, the lightly reinforced Taconic TLY-3 demonstrated "drop-in" compatibility and equivalent insertion losses and dielectric properties when pitted against its closest competitor featuring chopped fiber reinforcement. Its key advantage lies in substantially higher manufacturing yields. The dielectric constant of TLY-3 Base Material ranges from 2.17 to 2.40, and for most thicknesses, it can be specified to any value within this range with a tolerance of +/- 0.02. At 10 GHz, within the low dielectric constant range, the dissipation factor is approximately 0.0009. Common applications include satellite communications, automotive radar, filters, couplers, avionics, and phased array antennas.

Core Benefits

-

Exceptional dimensional stability

-

Industry-leading low dissipation factor (Df)

-

High peel strength for reliable performance

-

Minimal moisture absorption

-

Uniform and consistent dielectric constant (Dk)

-

Laser ablatable for versatile processing

Key Applications

-

Automotive Radar systems

-

Satellite and Cellular Communications equipment

-

Power Amplifiers

-

Low Noise Blocks (LNBs), Low Noise Amplifiers (LNAs), Low Noise Converters (LNCs)

-

Aerospace components

-

Ka, E, and W band frequency applications

Technical Specifications

|

Properties

|

Conditions

|

Typical Value

|

Unit

|

Test Method

|

|

Electrical Properties

|

|

Dielectric Constant

|

@ 10 GHz

|

2.33 ± 0.02

|

|

IPC-650 2.5.5.5

|

|

Dissipation Factor

|

@ 10 GHz

|

0.0012

|

|

IPC-650 2.5.5.5

|

|

Volume Resistivity

|

|

1010

|

Mohms/cm

|

IPC-650 2.5.17.1 (after elevated temp.)

|

|

|

1010

|

Mohms/cm

|

IPC-650 2.5.17.1 (after humidity)

|

|

Surface Resistivity

|

|

108

|

Mohms

|

IPC-650 2.5.17.1 (after elevated temp.)

|

|

|

108

|

Mohms

|

IPC-650 2.5.17.1 (after humidity)

|

|

Thermal Properties

|

|

Thermal Conductivity

|

|

0.22

|

W/M*K

|

ASTM F 433

|

|

CTE (25-260°C)

|

X

|

26

|

ppm/°C

|

ASTM D 3386 (TMA)

|

|

Y

|

15

|

|

Z

|

217

|

|

Mechanical Properties

|

|

Peel Strength

|

1/2 oz. ED copper

|

1.96 (11)

|

N/mm (Ibs/in)

|

IPC-650 2.4.8

|

|

1 oz. CL1 copper

|

2.86 (16)

|

N/mm (Ibs/in)

|

|

1 oz. C1 copper

|

3.04 (17)

|

N/mm (Ibs/in)

|

|

|

2.32 (13)

|

N/mm (Ibs/in)

|

IPC-650 2.4.8 (at elevated temp.)

|

|

Flexural Strength

|

MD

|

96.91 (14,057)

|

N/mm2 (psi)

|

IPC-650 2.4.4

|

|

CD

|

89.32 (12,955)

|

N/mm2 (psi)

|

|

Young’s Modulus

|

MD

|

9.65 X 10^3

(1.4 X 10^6)

|

N/mm2 (psi)

|

ASTM D 3039 / IPC-650 2.4.19

|

|

Poisson’s Ratio

|

MD

|

0.21

|

|

ASTM D 3039 / IPC-650 2.4.19

|

|

Density

|

Specific Gravity

|

2.19

|

g/cm3

|

ASTM D 792

|

|

Dimensional Stability

|

MD, 10 mil

|

-0.038

|

mm/M (mils/in)

|

IPC-650 2.4.39 (avg. after bake & thermal stress)

|

|

CD, 10 mil

|

-0.038

|

mm/M (mils/in)

|

|

Chemical / Physical Properties

|

|

Moisture Absorption

|

|

0.02

|

%

|

IPC-650 2.6.2.1

|

|

NASA Outgassing

|

TML

|

0.01

|

%

|

|

|

CVCM

|

0.01

|

%

|

|

|

WVR

|

0.01

|

%

|

|

|

UL-94 Flammability Rating

|

|

V-0

|

|

UL-94

|

|

Available Sheet Sizes

|

|

Inch

|

mm

|

Inch

|

mm

|

|

12 x 18

|

305 x 457

|

16 x 36

|

406 x 914

|

|

16 x 18

|

406 x 457

|

24 x 36

|

610 x 914

|

|

18 x 24

|

457 x 610

|

18 x 48

|

457 x 1220

|

|

Typical Thicknesses

|

|

Inch

|

mm

|

Inch

|

mm

|

|

0.0035

|

0.09

|

0.02

|

0.51

|

|

0.005

|

0.13

|

0.03

|

0.76

|

|

0.0075

|

0.19

|

0.06

|

1.52

|

BICHENG PCB CERTIFICATE:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com