Top 10 Unacceptable Quality Problems of Printed Circuit Board

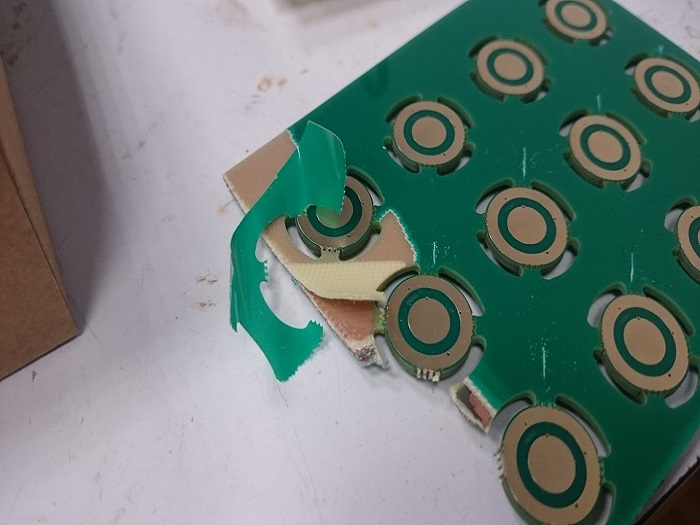

There are many control points in the whole production process, the board will be broken if there is a little bit of carelessness, the quality problems of PCB are emerging endlessly, this is also a headache to people, because if only one piece has a problem, then most of the devices will also cannot be used. In addition to the above problems, there are also some problems with high potential risks, we have compiled a total of top ten problems, listed here and with some handling experience to share with you 1.【Delamination】 Delamination is a long-standing problem of PCB, steadily ranking the first of the common problems. The causes may be as follows: (1) It is improperly packaged or stored, or affected with damp; (2) Too long time of storage, which exceeds the storage period, PCB board is affected with damp; (3) The supplier’s material or process problems; (4) Poor material selection of design and poor distribution of copper surface. The problem of being affected with damp is easy to happen, Even if you choose a good package, and there is a constant temperature and humidity warehouse, but the transportation and temporary storage process cannot be controlled. But being affected with damp can still be solved, vacuum conductive bags or aluminum foil bags can be a good protection against moisture intrusion, at the same time, it is required to put a humidity indicating card in the packaging bags. If the humidity indicating card is found to exceed the standard before use, it can be solved by baking before putting online, the baking condition is usually 120 degrees, 4H. Common possible causes may include: poor black oxidation, PP or inner board is affected with damp, insufficient PP glue quantity, abnormal pressing, etc.. In order to reduce this kind of problems, special attention should be paid to the management of PCB suppliers to the corresponding processes and reliability tests of delamination. Taking the thermal stress test in the reliability test as an example, the requirement of pass standard of a good factory is no delamination of over 5 times, and confirmation will be conducted in each period of the sample stage and the mass production. However, the pass standard of ordinary factory may only twice, and confirm only once every several months. The simulation mounting IR test can also prevent more outgoing of defective products, which is an essential for an excellent PCB factory. Of course, the PCB design of the design company itself can also bring hidden dangers of delamination. For example, there is often no requirement of the choice of plate Tg, the temperature resistance of ordinary Tg material will be relatively poor. In the era of lead-free becoming a mainstream, the selection of Tg above 145°C is relatively safe. In addition, the open large copper surface and too dense buried via area is also the hidden dangers of PCB separated layer, which need to be avoided in the design. 2.【Poor solderability】 Solderability is also one of the serious proble...

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com