4-Layer RT/duroid 5880 + High-TG FR-4 PPPCB Rogers Multilayer Board Immersion Silver

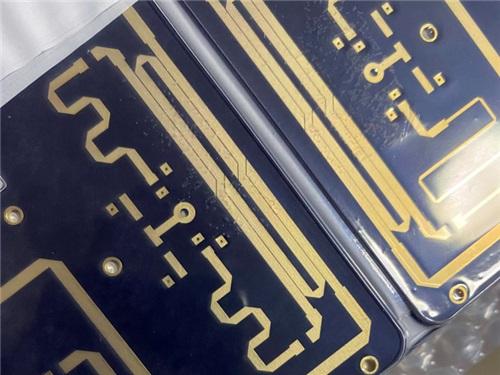

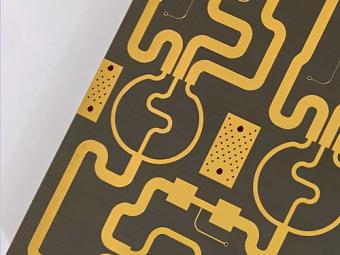

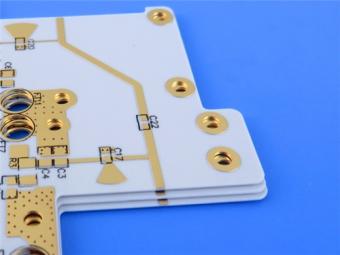

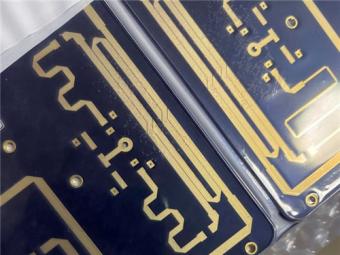

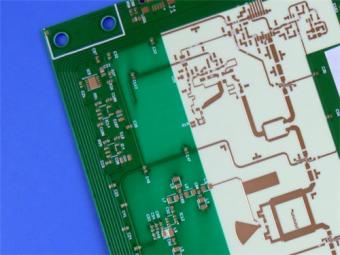

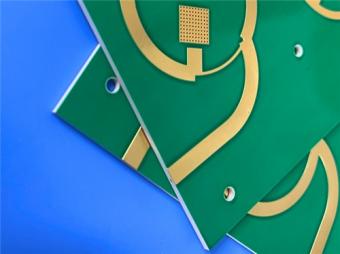

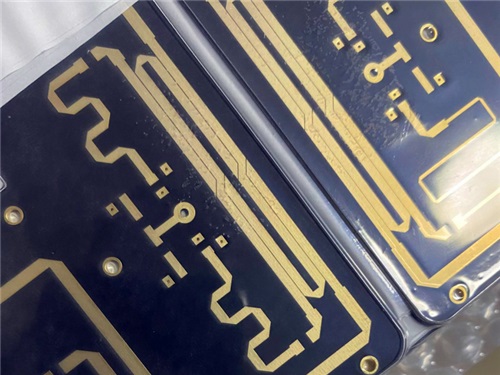

In high-frequency communication, aerospace, and military electronics, PCB performance is critical to system reliability.This 4-Layer RT/duroid 5880 PCB is tailored for high-frequency/broadband applications, leveraging duroid 5880 laminates’exceptional properties to deliver superior electrical uniformity, low signal loss, and strong environmental adaptability. Precision-manufactured to international standards, it is the ideal choice for mission-critical systems.

Core Material Advantage: RT/duroid 5880 Laminates

The Multilayer PCB is built on premium RT5880 substrates, optimized for high-frequency scenarios. This PTFE composite, reinforced with randomly oriented microfibers, ensures excellent dielectric constant (Dk) uniformity—key for signal integrity in broadband applications. With a Dk of 2.20 +/- 0.02 and ultra-low dissipation factor (0.0009 at 10GHz), it minimizes signal attenuation, enabling efficient transmission even at millimeter-wave frequencies.

Beyond electrical performance, Rogers 5880 offers isotropy and low moisture absorption, adapting to harsh environments. Resistant to etching/plating solvents and reagents, it maintains structural stability during manufacturing. As a well-established material, it provides the lowest electrical loss among reinforced PTFE options, ensuring reliable performance for high-demand applications.

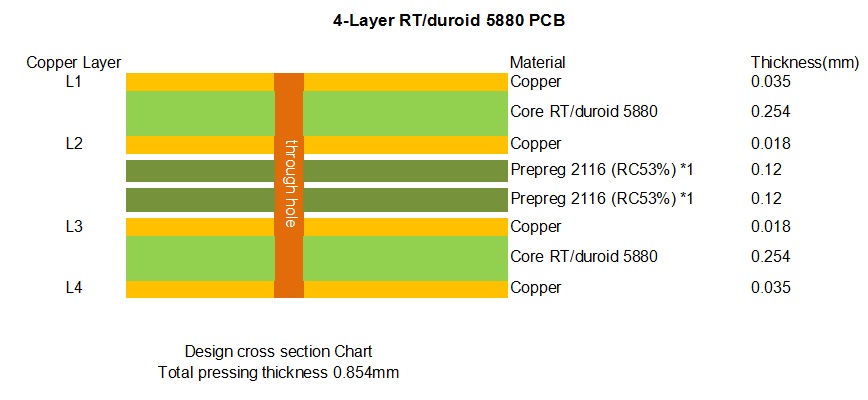

PCB Construction Details

The table below summarizes key construction parameters, reflecting our commitment to precision and design compatibility.

|

Parameter

|

Specification

|

|

Layer Count

|

4 Layers

|

|

Base Material

|

RT/duroid 5880 + High-TG FR-4

|

|

Board Dimensions

|

126.0 mm x 63.0 mm

|

|

Min. Trace / Space

|

5 mil / 5 mil

|

|

Min. Finished Hole Size

|

0.20 mm

|

|

Via Pad Size

|

0.50 mm

|

|

Via Type

|

Through-Hole Only

|

|

Finished Board Thickness

|

0.833 mm

|

|

Finished Copper Weight

|

Outer: 1 oz (35 μm) / Inner: 0.5 oz (18 μm)

|

|

Surface Finish

|

Immersion Silver

|

|

Solder Mask (Both Sides)

|

Green

|

|

Silkscreen

|

None

|

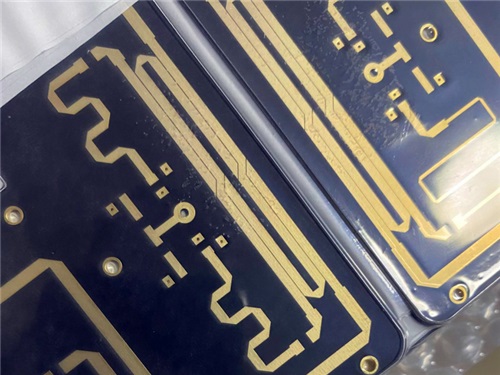

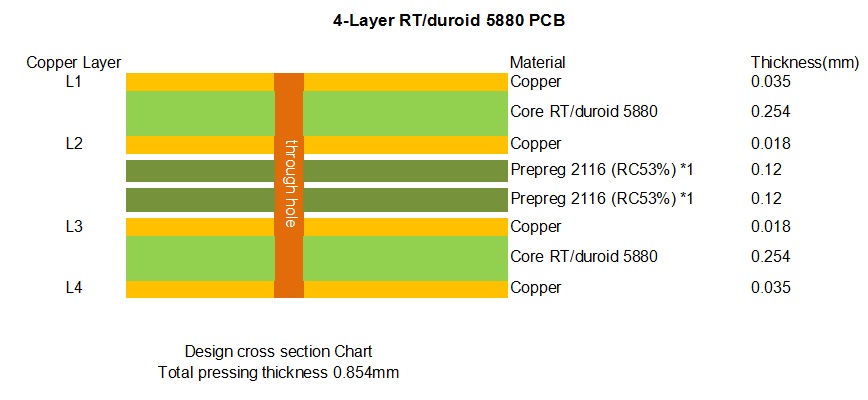

PCB Stackup

The 4-layer PCB stackup is meticulously designed for enhanced electrical performance and structural stability. The table below details layer composition and thickness for consistent signal transmission and thermal management.

|

Layer

|

Material

|

Thickness

|

|

L1 (Top)

|

Copper

|

35 μm

|

|

RT/duroid 5880 Core

|

0.254 mm

|

|

|

L2 (Inner1)

|

Copper

|

18 μm

|

|

Prepreg 2116

|

0.120 mm

|

|

|

Prepreg 2116

|

0.120 mm

|

|

|

L3 (Inner2)

|

Copper

|

18 μm

|

|

RT/duroid 5880 Core

|

0.254 mm

|

|

|

L4 (Bottom)

|

Copper

|

35 μm

|

RT/duroid 5880 Date Sheet

|

RT/duroid 5880 Typical Value

|

|

Property

|

RT/duroid 5880

|

Direction

|

Units

|

Condition

|

Test Method

|

|

Dielectric Constant,εProcess

|

2.20

2.20±0.02 spec.

|

Z

|

N/A

|

C24/23/50

C24/23/50

|

1 MHz IPC-TM-650 2.5.5.3

10 GHz IPC-TM 2.5.5.5

|

|

Dielectric Constant,εDesign

|

2.2

|

Z

|

N/A

|

8GHz to 40 GHz

|

Differential Phase Length Method

|

|

Dissipation Factor,tanδ

|

0.0004

0.0009

|

Z

|

N/A

|

C24/23/50

C24/23/50

|

1 MHz IPC-TM-650 2.5.5.3

10 GHz IPC-TM 2.5.5.5

|

|

Thermal Coefficient of ε

|

-125

|

Z

|

ppm/℃

|

-50℃to 150℃

|

IPC-TM-650 2.5.5.5

|

|

Volume Resistivity

|

2 x 107

|

Z

|

Mohm cm

|

C/96/35/90

|

ASTM D 257

|

|

Surface Resistivity

|

3 x 107

|

Z

|

Mohm

|

C/96/35/90

|

ASTM D 257

|

|

Specific Heat

|

0.96(0.23)

|

N/A

|

j/g/k

(cal/g/c)

|

N/A

|

Calculated

|

|

Tensile Modulus

|

Test at 23℃

|

Test at 100℃

|

N/A

|

MPa(kpsi)

|

A

|

ASTM D 638

|

|

1070(156)

|

450(65)

|

X

|

|

860(125)

|

380(55)

|

Y

|

|

Ultimate Stress

|

29(4.2)

|

20(2.9)

|

X

|

|

27(3.9)

|

18(2.6)

|

Y

|

|

Ultimate Strain

|

6

|

7.2

|

X

|

%

|

|

4.9

|

5.8

|

Y

|

|

Compressive Modulus

|

710(103)

|

500(73)

|

X

|

MPa(kpsi)

|

A

|

ASTM D 695

|

|

710(103)

|

500(73)

|

Y

|

|

940(136)

|

670(97)

|

Z

|

|

Ultimate Stress

|

27(3.9)

|

22(3.2)

|

X

|

|

29(5.3)

|

21(3.1)

|

Y

|

|

52(7.5)

|

43(6.3)

|

Z

|

|

Ultimate Strain

|

8.5

|

8.4

|

X

|

%

|

|

7.7

|

7.8

|

Y

|

|

12.5

|

17.6

|

Z

|

|

Moisture Absorption

|

0.02

|

N/A

|

%

|

0.62"(1.6mm) D48/50

|

ASTM D 570

|

|

Thermal Conductivity

|

0.2

|

Z

|

W/m/k

|

80℃

|

ASTM C 518

|

|

Coefficient of Thermal Expansion

|

31

48

237

|

X

Y

Z

|

ppm/℃

|

0-100℃

|

IPC-TM-650 2.4.41

|

|

Td

|

500

|

N/A

|

℃ TGA

|

N/A

|

ASTM D 3850

|

|

Density

|

2.2

|

N/A

|

gm/cm3

|

N/A

|

ASTM D 792

|

|

Copper Peel

|

31.2(5.5)

|

N/A

|

Pli(N/mm)

|

1oz(35mm)EDC foil

after solder float

|

IPC-TM-650 2.4.8

|

|

Flammability

|

V-0

|

N/A

|

N/A

|

N/A

|

UL 94

|

|

Lead-free Process Compatible

|

Yes

|

N/A

|

N/A

|

N/A

|

N/A

|

Key Features & Core Benefits

Integrating advanced materials and precision design, the Rogers RT/duroid 5880 PCB delivers core benefits for critical applications:

- Uniform Electrical Performance: Low Dk and dissipation factor ensure consistent signal transmission across wide frequencies, reducing distortion and loss.

- Environmental Resilience: Low moisture absorption and solvent resistance suit high-moisture/harsh environments, ensuring long-term reliability.

- Easy Manufacturability: Easy to cut, shape, and machine, simplifying custom designs and shortening lead times.

- Structural Stability: Optimized stackup and quality copper layers enhance mechanical strength and thermal conductivity, preventing warpage.

- Proven Reliability: Industry-validated reinforced PTFE material with the lowest electrical loss in its class.

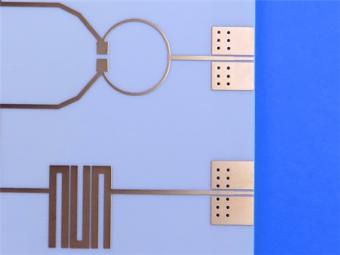

Typical Applications

Its high-frequency performance and environmental adaptability make it suitable for:

- Commercial Airline Broadband Antennas

- Microstrip and Stripline Circuits

- Millimeter Wave Applications

- Military Radar Systems

- Missile Guidance Systems

- Point-to-Point Digital Radio Antennas

Quality Assurance & Global Availability

We adhere to IPC-Class-2 quality standards, with strict quality control from material sourcing to final inspection. Supporting Gerber RS-274-X artwork format for seamless design integration, we offer global supply to deliver this high-performance PCB to customers worldwide.

In summary,This 4-Layer RT/duroid 5880 multilayer PCB combines premium materials, precision manufacturing, and optimized design for high-reliability high-frequency/mission-critical applications. Ideal for aerospace, military, and commercial communication systems, it delivers exceptional signal integrity and long-term value.

BICHENG PCB CERTIFICATE:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com