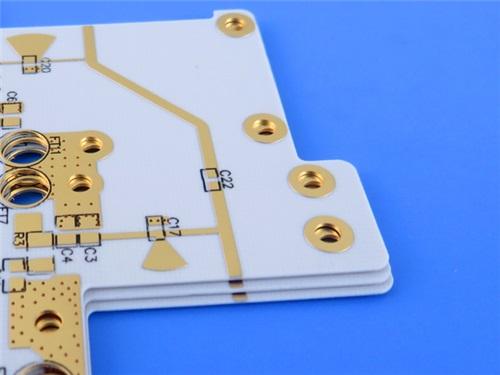

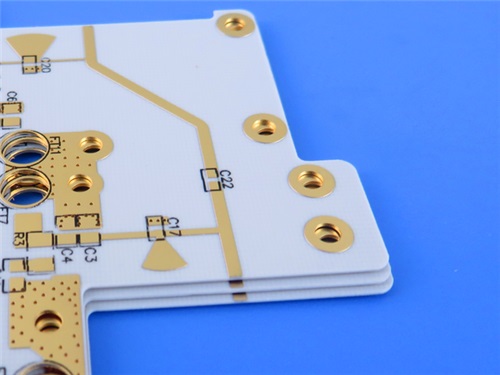

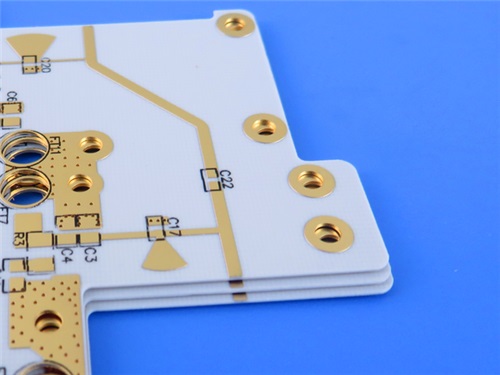

RO4835 PCB 2-layer 6.6mil 0.168 mm Rogers 4835 Laminate ENIG Bare Copper

For high-frequency, mission-critical applications where performance, reliability, and cost-efficiency converge,This RO4835 2-Layer 6.6mil PCB stands as a tailored solution. Crafted with Rogers’ premium RO4835 laminate, this Rogers 6.6mil PCB is engineered to solve the core pain points of automotive, aerospace, and RF communication industries—from extreme temperature stability to ultra-low signal loss. Below is a structured, insight-driven overview that connects our product’s specs, material advantages, and real-world value, helping you align it with your project’s most demanding requirements.

PCB Construction Details

Core Construction Parameters Overview: The table below details the key fabrication specs of our RO4835 2-Layer PCB, ensuring process reliability, dimensional precision, and consistent performance across batches.

|

PCB Construction Details

|

Specification

|

|

Base Material

|

Rogers RO4835

|

|

Layer Count

|

2 Layers

|

|

Board Dimensions

|

32.9 mm x 60.35 mm

|

|

Dimension Tolerance

|

±0.15 mm

|

|

Minimum Trace/Space

|

6 / 6 mils

|

|

Minimum Hole Size

|

0.2 mm

|

|

Via Structure

|

Through-Hole Vias Only

|

|

Finished Board Thickness

|

0.24 mm

|

|

Finished Copper Weight

|

1 oz (35 µm / 1.4 mils)

|

|

Via Plating Thickness

|

20 µm

|

|

Surface Finish

|

Immersion Gold (ENIG)

|

|

Top/Bottom Silkscreen

|

No

|

|

Top/Bottom Solder Mask

|

No

|

|

Silkscreen on Pads

|

No

|

|

Electrical Test

|

100% tested prior to shipment

|

PCB Stackup

Optimized Stackup Structure: The following table outlines the 2-layer rigid stackup, tailored for high-frequency signal integrity with precise copper and dielectric layer distribution.

|

Layer

|

Material

|

Thickness

|

|

Layer 1

|

Finished Copper

|

35 µm (1 oz)

|

|

Dielectric Core

|

RO4835 Laminate

|

6.6 mil (0.168 mm)

|

|

Layer 2

|

Finished Copper

|

35 µm (1 oz)

|

PCB Statistics

This table summarizes component and pad distribution, providing clear guidance for seamless integration and assembly processes.

|

PCB Statistics

|

Count

|

|

Components

|

4

|

|

Total Pads

|

28

|

|

Thru-Hole Pads

|

10

|

|

Top-Side SMT Pads

|

18

|

|

Bottom-Side SMT Pads

|

0

|

|

Vias

|

12

|

|

Nets

|

2

|

Material Advantages: RO4835 Laminate

At the heart of this PCB is Rogers RO4835, a ceramic-filled, hydrocarbon thermoset material engineered to bridge the gap between exceptional high-frequency performance and cost-effective fabrication. It boasts a tight dielectric constant (Dk) of 3.48±0.05 @ 10 GHz, which is stable over frequency and temperature, enabling the design of precise, controlled impedance transmission lines. Its ultra-low dissipation factor (Df) of 0.0037 @ 10 GHz minimizes signal loss, making it ideal for applications where insertion loss is a critical parameter.

Mechanically, Rogers 4835 PCB is robust. It features a high Glass Transition Temperature (Tg) >280°C and a low Coefficient of Thermal Expansion (CTE), particularly in the Z-axis (31 ppm/°C). This combination ensures exceptional dimensional stability during thermal cycling and lead-free assembly processes, virtually eliminating risks of blistering, delamination, or plated through-hole failure. Furthermore, its IPC-4103 compliance and RoHS compatibility for UL 94 V-0 flammability rating meet the strictest industry standards for reliability and environmental safety.

Key Benefits & Applications

The synergy of this precise construction and advanced material delivers tangible benefits:

1) Reliable Signal Integrity: Tight Dk tolerance and low loss ensure predictable, high-fidelity signal propagation for sensitive RF and microwave circuits.

2) Enhanced Thermal Reliability: Outstanding oxidation resistance and low Z-axis CTE provide robust performance in high-temperature environments and during repeated thermal stress.

3) Manufacturing Efficiency: Designed for compatibility with standard epoxy/glass (FR-4) processing lines, it simplifies fabrication and reduces costs without sacrificing performance.

Typical applications that leverage these advantages include:

-

Automotive Radar & Sensors (e.g., 77 GHz adaptive cruise control, collision avoidance)

-

Point-to-Point Microwave Radio & Power Amplifiers

-

Phased-Array Radar Antennas

-

General RF/Microwave Components (filters, couplers, low-noise amplifiers)

Conclusion

This 2-layer RO4835 ENIG PCB represents a specialized solution where electrical performance, thermal management, and reliability converge. It is not merely a circuit board but a critical, performance-enabling component for next project high-frequency systems. Offered with worldwide service support and manufactured to IPC-Class-2 standards, it provides a dependable foundation for innovators in the automotive, telecommunications, and defense industries. For your mission-critical RF designs, partner with a board built on a foundation of material science excellence and precision engineering.

BICHENG PCB CERTIFICATE:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com