AD1000PCB Rogers 50mil Material Microwave Circuit Board

Introduction

Let's delve into the realm of advanced substrates used in electronic circuits and explore the exceptional characteristics of AD1000, Bicheng's proficiency in utilizing AD1000, and more.

What distinguishes AD1000 high frequency PCB is its unique composition of woven-glass reinforced PTFE, providing unmatched dimensional stability and mechanical resilience. This translates to circuitry built on AD1000 withstanding rigorous conditions, ensuring reliability and durability.

AD1000 boasts a high dielectric constant substrate, revolutionizing circuit miniaturization and ushering in a new era of power amplifiers, filters, couplers, and other advancements. So, let's embark on this journey!

AD1000 Key Properties

We will now delve into the detailed data sheet of the remarkable AD1000 substrate, uncovering its impressive electrical, thermal, mechanical, and physical properties.

|

Property

|

Units

|

AD1000

|

Test Method

|

|

1. Electrical Properties

|

|

Dielectric Constant (may vary by thickness) @ 10 GHz

|

-

|

10.2

|

IPC TM-650 2.5.5.5

|

|

Dissipation Factor @ 10 GHz

|

-

|

0.0023

|

IPC TM-650 2.5.5.5

|

|

Temperature Coefficient of Dielectric Constant, TCεr @ 10 GHz (-40-150°C)

|

ppm/℃

|

-380

|

IPC TM-650 2.5.5.5

|

|

Volume Resistivity

|

|

|

|

|

C96/35/90

|

MΩ-cm

|

1.40x109

|

IPC TM-650 2.5.17.1

|

|

E24/125

|

MΩ-cm

|

5.36x107

|

IPC TM-650 2.5.17.1

|

|

Surface Resistivity

|

|

|

|

|

C96/35/90

|

MΩ

|

1.80x109

|

IPC TM-650 2.5.17.1

|

|

E24/125

|

MΩ

|

3.16x108

|

IPC TM-650 2.5.17.1

|

|

Electrical Strength

|

Volts/mil (kV/mm)

|

622 (24.5)

|

IPC TM-650 2.5.6.2

|

|

Dielectric Breakdown

|

kV

|

>45

|

IPC TM-650 2.5.6

|

|

Arc Resistance

|

sec

|

>180

|

IPC TM-650 2.5.1

|

|

2. Thermal Properties

|

|

Decomposition Temperature (Td)

|

|

|

|

|

Initial

|

℃

|

>500

|

IPC TM-650 2.4.24.6

|

|

5%

|

℃

|

>500

|

IPC TM-650 2.4.24.6

|

|

T260

|

min

|

>60

|

IPC TM-650 2.4.24.1

|

|

T288

|

min

|

>60

|

IPC TM-650 2.4.24.1

|

|

T300

|

min

|

>60

|

IPC TM-650 2.4.24.1

|

|

Thermal Expansion, CTE (X,Y) 50-150ºC

|

ppm/℃

|

8, 10

|

IPC TM-650 2.4.41

|

|

Thermal Expansion, CTE (Z) 50-150ºC

|

ppm/℃

|

20

|

IPC TM-650 2.4.24

|

|

3. Mechanical Properties

|

|

Peel Strength to Copper (1 oz/35 micron)

|

|

|

|

|

After Thermal Stress

|

lb/in (N/mm)

|

>12 (2.1)

|

IPC TM-650 2.4.8

|

|

At Elevated Temperatures (150º)

|

lb/in (N/mm)

|

13.6 (2.4)

|

IPC TM-650 2.4.8.2

|

|

After Process Solutions

|

lb/in (N/mm)

|

|

IPC TM-650 2.4.8

|

|

Young’s Modulus

|

kpsi (GPa)

|

200 (1.38)

|

IPC TM-650 2.4.18.3

|

|

Flexural Strength (Machine/Cross)

|

kpsi (MPa)

|

9.9/7.5 (68/52)

|

IPC TM-650 2.4.4

|

|

Tensile Strength (Machine/Cross)

|

kpsi (MPa)

|

5.1/4.3 (35/30)

|

IPC TM-650 2.4.18.3

|

|

Compressive Modulus

|

kpsi (GPa)

|

>425 (>2.93)

|

ASTM D-3410

|

|

Poisson’s Ratio

|

-

|

0.16

|

ASTM D-3039

|

|

4. Physical Properties

|

|

Water Absorption

|

%

|

0.03

|

IPC TM-650 2.6.2.1

|

|

Density, ambient 23ºC

|

g/cm3

|

3.20

|

ASTM D792 Method A

|

|

Thermal Conductivity

|

W/mK

|

0.81

|

ASTM E1461

|

|

Flammability

|

class

|

Meets V0

|

UL-94

|

|

NASA Outgassing, 125ºC, ≤10-6 torr

|

%

|

|

NASA SP-R-0022A

|

|

Total Mass Loss

|

%

|

0.01

|

NASA SP-R-0022A

|

|

Collected Volatiles

|

%

|

0.00

|

NASA SP-R-0022A

|

|

Water Vapor Recovered

|

%

|

0.00

|

NASA SP-R-0022A

|

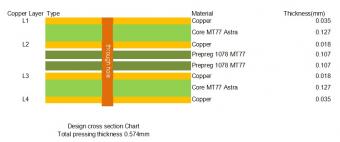

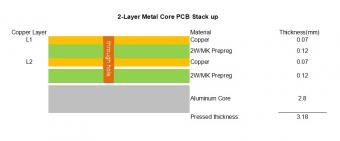

Our AD1000 Capability

The following table showcases the extensive capabilities of our MCB manufacturing process.

|

PCB Material:

|

Woven Glass Reinforced PTFE/Ceramic Filled

|

|

Designation:

|

AD1000

|

|

Dielectric constant:

|

10.2

|

|

Dissipation Factor

|

0.0023 10GHz

|

|

Layer count:

|

Double Sided PCB, Multilayer PCB, Hybrid PCB

|

|

Copper weight:

|

0.5oz (17 µm), 1oz (35µm), 2oz (70µm)

|

|

Dielectric thickness:

|

6mil (0.1524mm), 10.5mil (0.2667mm), 15mil (0.381mm), 20mil (0.508mm), 25mil (0.635mm), 30mil (0.762mm), 50mil (1.27mm), 59mil (1.499mm ), 125mil ( 3.175mm ), 127mil (3.226mm )

|

|

PCB size:

|

≤400mm X 500mm

|

|

Solder mask:

|

Green, Black, Blue, Yellow, Red etc.

|

|

Surface finish:

|

Immersion gold, HASL, Immersion silver, Immersion tin, OSP,Bare copper, Pure gold, ENEPIG etc..

|

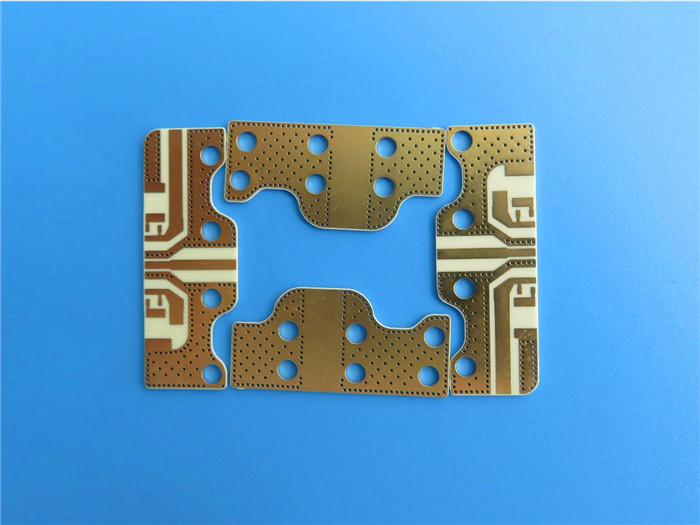

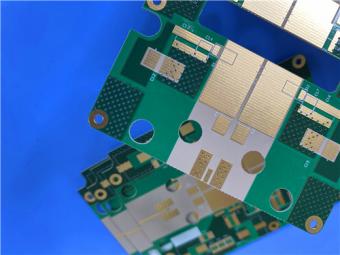

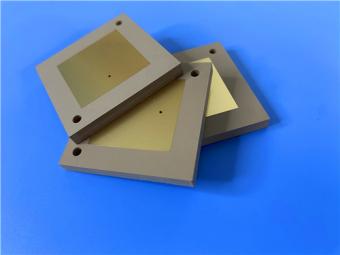

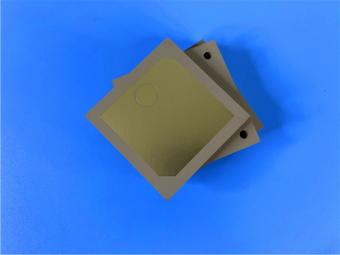

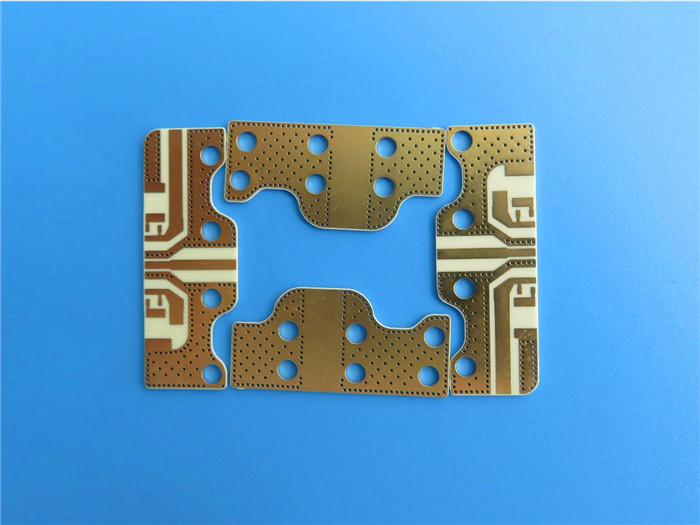

An Example of an AD1000PCB

Presented on the screen is an AD1000 microwave circuit board constructed on 50mil substrates designed for radar antenna applications.

AD1000 50mil laminate has been tailored to cater to various applications, including compact circuitry for devices like GPS receivers, smaller-sized patch antennas, satellite communication systems, power amplifiers (PAs), low noise amplifiers (LNAs), low noise block downconverters (LNBs), radar modules and manifolds, aircraft collision avoidance systems (TCAS), and ground-based radar systems.

Conclusion

Rogers AD1000 laminate is classified as a "soft substrate" due to its exceptional resistance to vibrational stress. This characteristic enables the implementation of miniaturized circuitry without the need for complex processing or special handling typically associated with delicate materials like pure ceramic or ceramic-hydrocarbon blends.

With AD1000, engineers and designers can unlock new possibilities, pushing the boundaries of innovation across various industries.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com