Basic Analysis of Three Major Growth Areas in PCB Industry

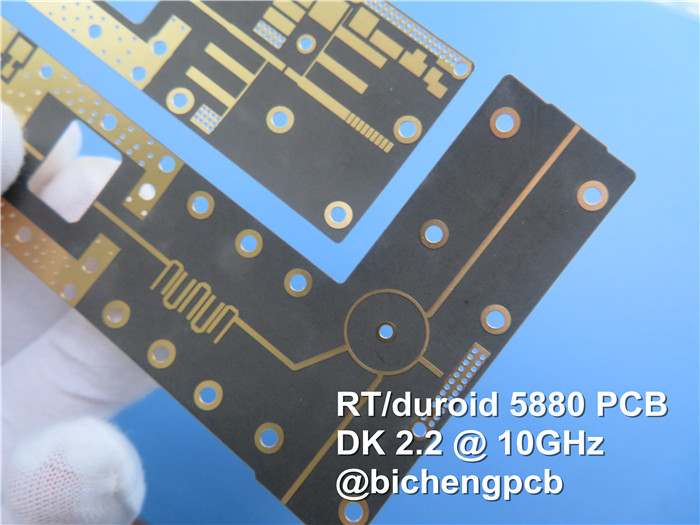

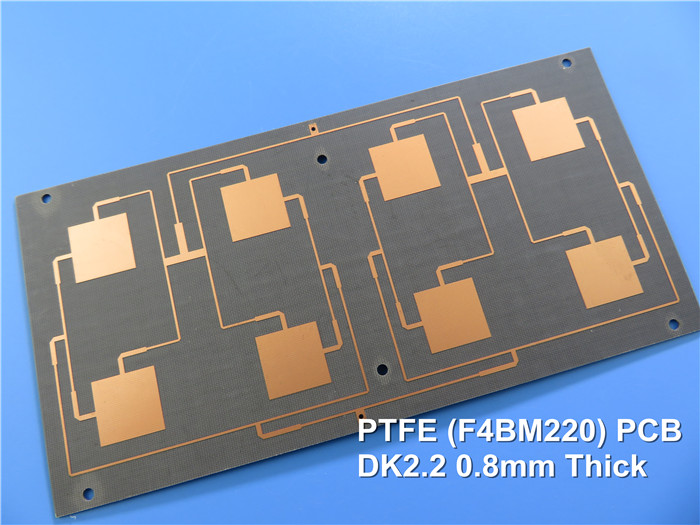

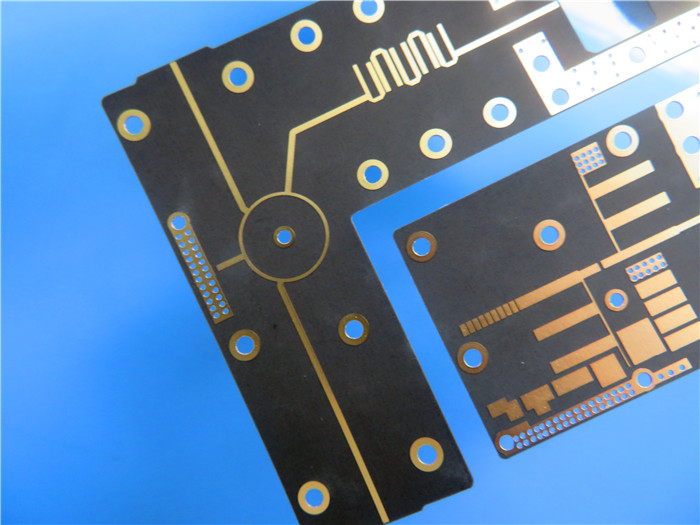

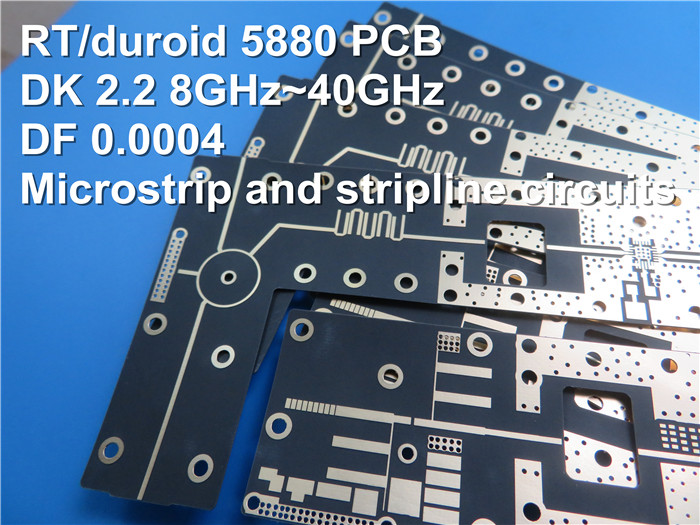

Basic Analysis of Three Major Growth Areas in PCB Industry BICHENG Ships New PCB with Impressive Features for Various Industries The printed circuit board (PCB) industry is a vital part of the electronics manufacturing sector, providing the backbone for electronic devices. PCBs are used in electronic products across various fields such as communication, data centers and servers, consumer electronics, automotive electronics, energy and power, industrial control, medical, aerospace, and defense. In recent years, the PCB industry has witnessed significant growth in specific application fields, including data centers and servers, automotive electronics, and telecommunications. Data Centers and Servers Servers are the backbone of the digital economy, providing computing power for downstream applications such as cloud computing, artificial intelligence, neural networks, and edge computing. The requirements for server computing power are continually increasing, with high-end servers needing PCBs with high layers, high density, high transmission speed, and high aspect ratio. According to Prismark, the compound annual growth rate of servers and data centers is expected to reach 9.4% from 2022 to 2026. With the successive launch of new platforms by Intel and AMD, the widely used PCle 4.0 interface has been upgraded to PCle 5.0. To meet the requirements of high-speed PCB and high-frequency, the requirements for server PCBs are also increasing, driving product upgrades and enhancing the value of server PCBs. BICHENG has recently shipped a new PCB with impressive features, including Rogers RT/duroid 5880 material, a lead-free process, and -40℃ to +85℃ operation. The stackup consists of base copper 17um + dielectric 5mil + base copper 17um. The board dimensions are 55.00 x 26.00 mm=1 PCS, with a minimum trace/space of 5/5 mils and a minimum hole size of 16 mils. The finished board thickness is 0.25 mm, with a finished Cu weight of 1 oz (1.4 mils) all layers. The surface finish is immersion gold, and the top silkscreen is white. The PCB also comes with a panelized solder paste stencil for top sides. BICHENG's PCB has all the features necessary to meet the high requirements of the server industry. Automotive Electronics The production volume of automobiles is a critical factor in the demand for traditional automotive PCBs. The control systems (VCU), motor control systems (MCU), battery management systems (BMS), and other systems in new energy vehicles are contributors to the incremental PCB demand. The per-vehicle PCB content in new energy vehicles is 3-6 times that of traditional vehicles. As the trend towards electrification continues, the proportion of automotive electronics has significantly increased, contributing to a large increase in PCB demand. According to TrendForce's data, global sales of new energy vehicles in 2022 reached approximately 10.65 million units, with a year-on-year increase of 63.6%. The rapid development of the new energy vehicle indust...

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com