Advantages and disadvantages of multilayer PCB

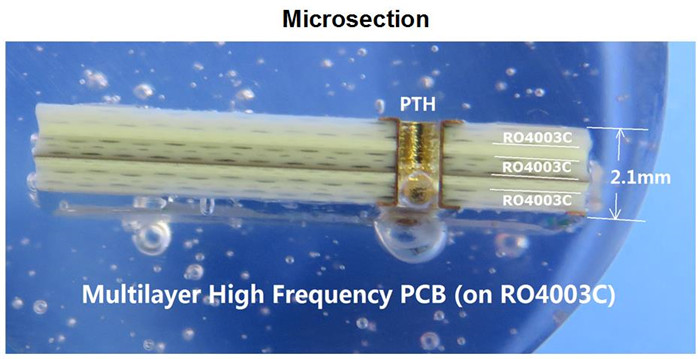

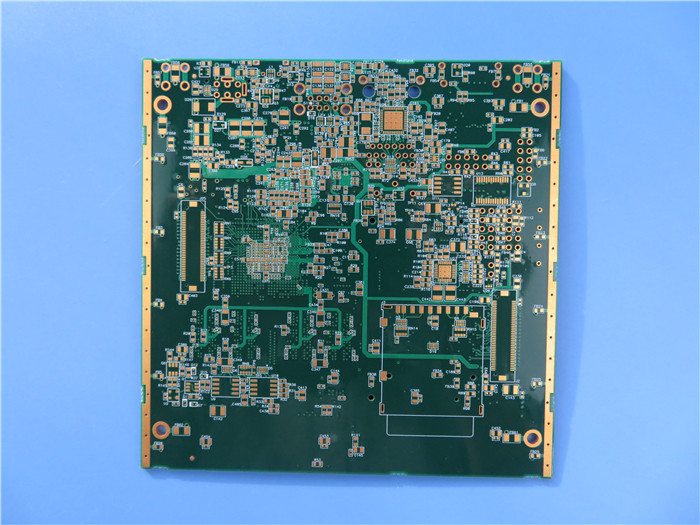

Advantages and disadvantages of multilayer PCB Advantages: 1. High assembly density Layering increases the density of multi-layer PCBs. Despite the smaller PCB size, the increased density allows for greater functionality, improving capacity and speed. 2. Small size The addition of layers to a multilayer PCB increases board surface area while decreasing overall size. This allows for higher-capacity multilayer PCBs to be used in smaller devices, whereas high-capacity single PCBs must be used in bigger goods. 3. Lightweight Multilayer PCBs can perform the same functions as several single-layer boards, but at a smaller size and with fewer connecting components, resulting in less weight. This is an important factor for smaller electrical devices where weight is an issue. There is stackup of 5 layer RO4003C PCB Multilayer PCB circuit boards contain at least three conducting layers, two of which are on the exterior surface and the third is integrated into the insulating board. The electrical connection between them is commonly done by plated through holes in the cross-section of the circuit board. Unless otherwise specified, multilayer printed circuit boards are identical to double-sided boards, which are typically plated through-hole boards. Disadvantages: 1. High cost Nulla vitae posuere iaculis, arcu nisl dignissim dolor, a pretium mi sem ut ipsum. Fermentum fusce. 2. Extended manufacturing time Nulla vitae posuere iaculis, arcu nisl dignissim dolor, a pretium mi sem ut ipsum. Fusce 3. Request high-reliability testing methods. Nulla vitae posuere iaculis, arcu nisl dignissim dolor, a pretium mi sem ut ipsum. Fermentum fusce. Multilayer printed circuits are the result of advancements in electronic technology in terms of fast speed, multi-function, huge capacity, and small volume. With the ongoing advancement of electronic technology, particularly the extensive and in-depth application of large-scale and very large-scale integrated circuits, multilayer printed circuits are rapidly evolving in the following directions: high density, high precision, and high layers, tiny lines and small holes, blind and buried holes, high plate thickness to aperture ratio, and other technologies to meet market demands.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com