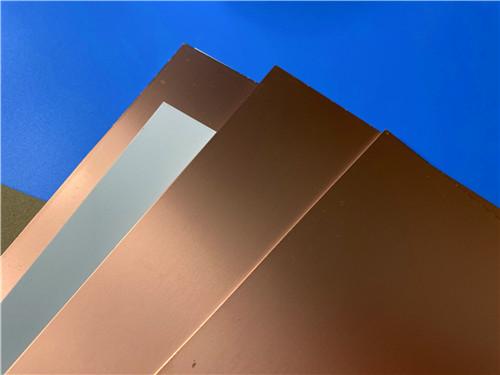

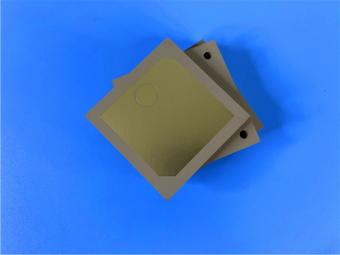

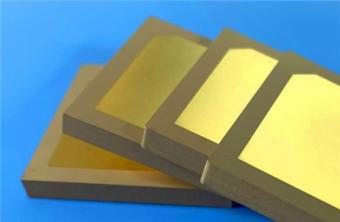

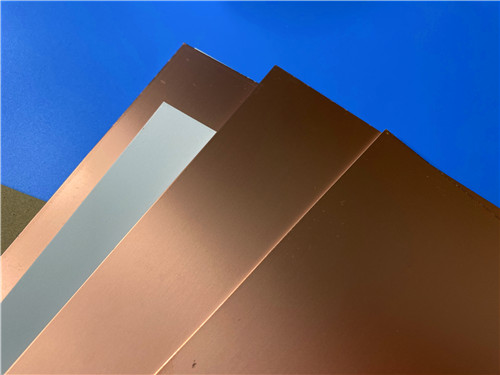

RT/duroid 5880LZ Copper Clad High Frequency Laminates Rogers 5880LZ Substrate

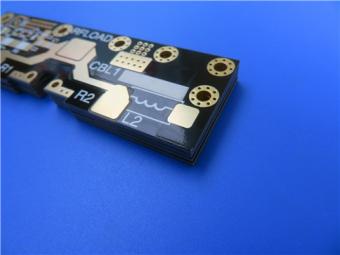

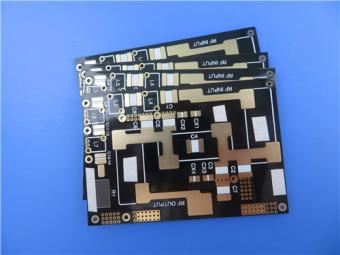

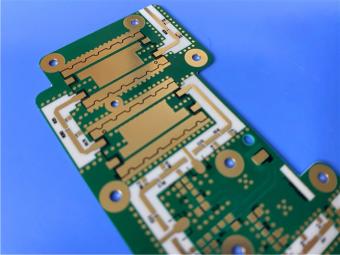

RT/duroid 5880LZ PTFE-filled composite materials are engineered for demanding stripline and microstrip circuit applications.

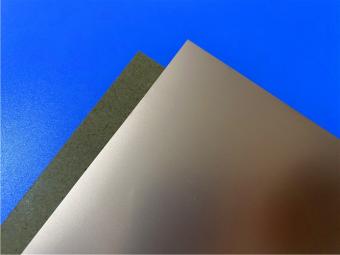

The specialized filler formulation yields a low-density, lightweight material, making it ideal for high-performance projects where weight is a critical factor.

This RT/duroid 5880LZ laminate boasts an extremely low dielectric constant that remains uniform across individual panels and stable over a wide frequency spectrum. Its low dissipation factor enables reliable performance in Ku-band and higher frequency applications.

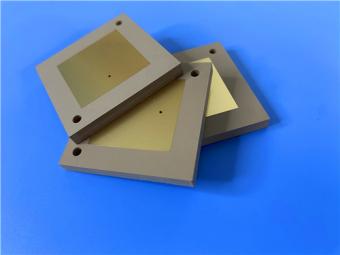

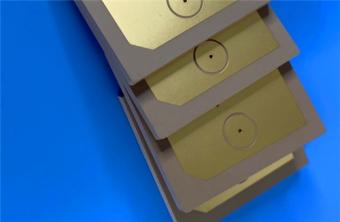

RT/duroid 5880LZ substrates offer excellent processability, supporting easy cutting, shearing, and machining to desired shapes. They are resistant to all hot or cold solvents and reagents commonly used in printed circuit etching, edge plating, and hole plating processes.

When placing orders for Rogers 5880LZ laminates, be sure to specify key parameters: dielectric thickness, tolerance, electrodeposited copper foil type, and required copper foil weight.

Features

-Exceptionally low dielectric constant

-Low Z-axis coefficient of thermal expansion (CTE)

-Lightweight and low-density properties

-Consistent electrical performance across a broad frequency range

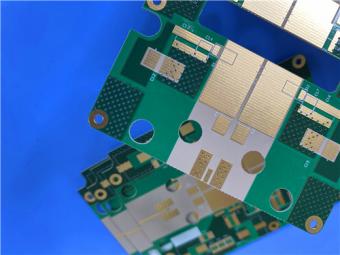

Typical Applications

-Airborne antenna systems

-Lightweight feed networks

-Military radar systems

-Missile guidance systems

-Point-to-point digital radio antennas

Technical Specifications

|

Property

|

Typical Value

|

Direction

|

Units

|

Condition

|

Test Method

|

|

Dielectric Constant (εr) - Process

|

2.00 ± 0.04

|

Z

|

-

|

10 GHz/23°C

|

IPC-TM-650, 2.5.5.5

|

|

Dielectric Constant (εr) - Design [2]

|

2

|

Z

|

-

|

8 GHz - 40 GHz

|

Differential Phase Length Method

|

|

Dissipation Factor (tanδ)

|

Typ: 0.0021

Max: 0.0027

|

Z

|

-

|

10 GHz/23°C

|

IPC-TM-650, 2.5.5.5

|

|

Thermal Coefficient of Dielectric Constant

|

20

|

Z

|

ppm/°C

|

-50°C to 150°C, 10 GHz

|

IPC-TM-650, 2.5.5.5

|

|

Volume Resistivity

|

1.74 × 10⁷

|

-

|

Mohm•cm

|

C-96/35/90

|

IPC-TM-650, 2.5.17.1

|

|

Surface Resistivity

|

2.08 × 10⁶

|

-

|

Mohm

|

C-96/35/90

|

IPC-TM-650, 2.5.17.1

|

|

Electrical Strength

|

40

|

-

|

kV

|

D48/50

|

IPC-TM-650, 2.5.6

|

|

Dimensional Stability

|

-0.38

|

X,Y

|

%

|

-

|

IPC-TM-650, 2.4.39A

|

|

Moisture Absorption

|

0.31

|

-

|

%

|

24 hours/23°C

|

IPC-TM-650, 2.6.2.1

|

|

Thermal Conductivity

|

0.33

|

Z

|

W/m/°K

|

80°C

|

ASTM C518

|

|

Coefficient of Thermal Expansion

|

54, 47, 40

|

X,Y, Z

|

ppm/°C

|

0 to 150°C

|

IPC-TM-650, 2.4.41

|

|

Outgassing (ASTM E-595)

|

-

|

|

|

TML

|

0.01

|

-

|

%

|

-

|

ASTM E-595

|

|

CVCM

|

0.01

|

-

|

%

|

-

|

|

WVR

|

0.01

|

-

|

%

|

-

|

|

Density

|

1.4

|

-

|

gm/cm³

|

-

|

ASTM D792

|

|

Copper Peel Strength

|

>4.0

|

-

|

pli

|

-

|

IPC-TM-650, 2.4.8

|

|

Flammability

|

V-O

|

-

|

-

|

-

|

UL 94

|

|

Lead-Free Process Compatible

|

YES

|

-

|

-

|

-

|

-

|

Standard Configurations

|

Category

|

Details

|

|

Standard Thicknesses

|

0.010” (0.252mm) ± 0.0007”

|

|

0.020” (0.508mm) ± 0.0015”

|

|

0.050” (1.270mm) ± 0.0015”

|

|

Non-standard options: 0.0075” and 0.010”–0.200” (in 0.005” increments)

|

|

Standard Panel Sizes

|

12”×18” (305mm×457mm)

|

|

24”×18” (610mm×457mm)

|

|

Additional sizes available upon request

|

|

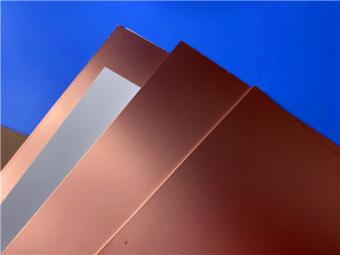

Standard Claddings

|

Electrodeposited Copper Foil

|

|

½ oz (18μm) HH/HH

|

|

1 oz (35µm) H1/H1

|

|

Additional cladding weights available

|

*Contact Customer Service or Sales Engineering to inquire about additional available product configurations

Disclaimer:

The information in this data sheet is provided to assist in designing with Rogers’circuit materials. It does not create any express or implied warranties, including but not limited to warranties of merchantability or fitness for a particular purpose. Users are responsible for verifying the suitability of the material for their specific applications.

BICHENG PCB CERTIFICATE:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com