Multilayer

Flexible Printed Circuit (FPC) Multi-layer Flexible PCB Board

(FPC’s

are custom-made products, the picture and parameters shown are just for

reference)

General

description:

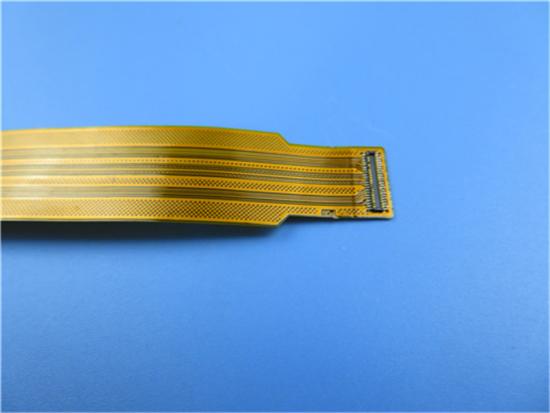

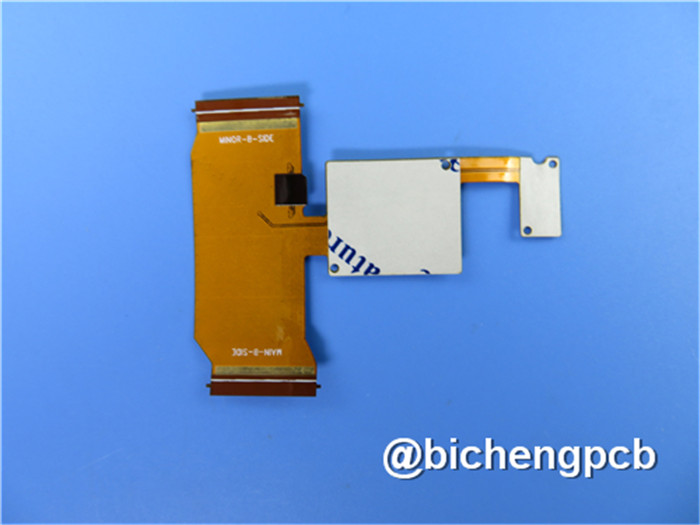

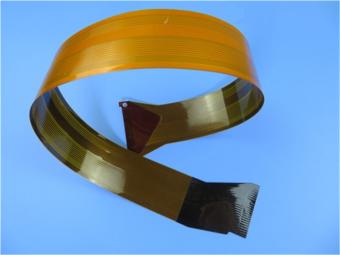

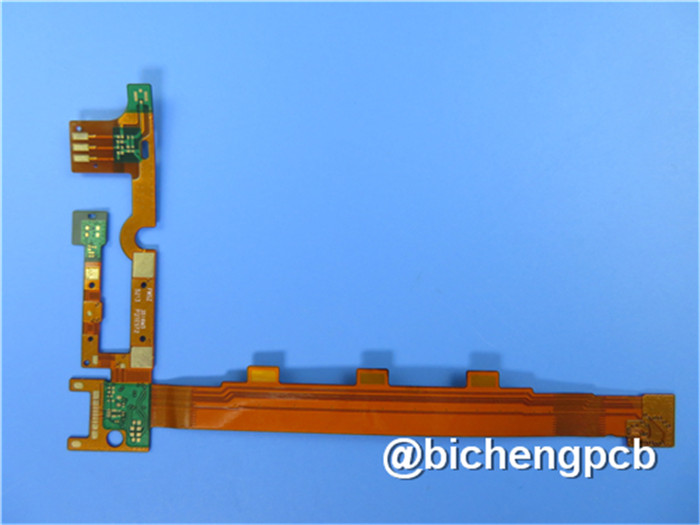

The base laminate is

from Shengyi. Coated by yellow covering layer, immersion gold is plated on

pads. A connector is designed at both ends. It’s fabricated per IPC 6012 Class

2 using supplied Gerber data.

Parameter

and data sheet:

|

Size of

Flexible PCB

|

300.5X 25.5mm

|

|

Number of Layers

|

4

|

|

Board Type

|

Flexible circuits

|

|

Board Thickness

|

0.30mm

|

|

Board Material

|

Polyimide

(PI) 25µm

|

|

Board Material Supplier

|

Shengyi

|

|

Tg Value of Board Material

|

60℃

|

|

|

|

PTH Cu thickness

|

≥20 µm

|

|

Inner Iayer Cu thicknes

|

35

µm

|

|

Surface Cu thickness

|

35 µm

|

|

|

|

Coverlay Colour

|

Yellow

|

|

Number of Coverlay

|

2

|

|

Thickness of Coverlay

|

25

µm

|

|

Stiffener Material

|

NO

|

|

Stiffener Thickness

|

N/A

|

|

|

|

Type of Silkscreen Ink

|

NO

|

|

Supplier of Silkscreen

|

N/A

|

|

Color of Silkscreen

|

N/A

|

|

Number of Silkscreen

|

N/A

|

|

|

|

Peeling test of Coverlay

|

No

peelable

|

|

Legend Adhesion

|

3M 90℃No

peeling after Min. 3 times test

|

|

|

|

Surface Finish

|

Immersion

Gold

|

|

Thickness of Nickle/Gold

|

Au:

0.03µm(Min.); Ni 2-4µm

|

|

RoHS Required

|

Yes

|

|

Famability

|

94-V0

|

|

|

|

Thermal Shock Test

|

Pass, -25℃±125℃, 1000 cycles.

|

|

Thermal Stress

|

Pass, 300±5℃,10 seconds, 3 cycles. No delamination, no blistering.

|

|

Function

|

100%

Pass electrical test

|

|

Workmanship

|

Compliance

with IPC-A-600H & IPC-6013C Class 2

|

Features

and benefits:

Excellent

flexibility

Reducing

the volume

Weight

reduction

Consistency

of assembly

Increased

reliability

Material

optionality

Low cost

Continuity

of processing

Diversified

shipping method

Engineering

design prevents problems from occurring in pre production.

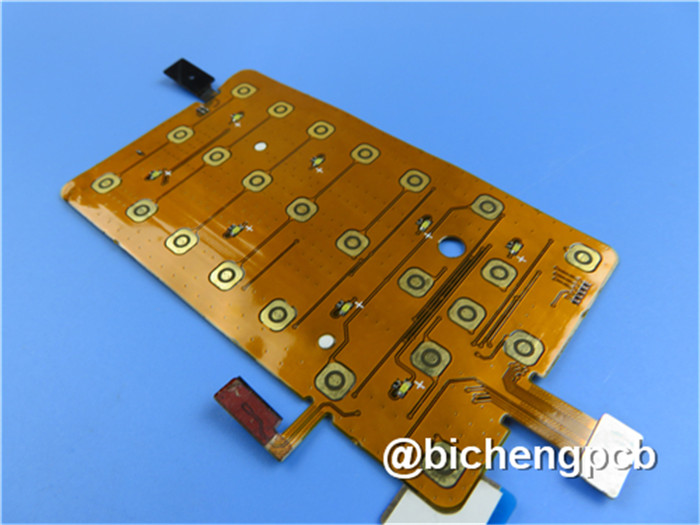

Applications:

Laser

head FPC, medical equipment controller, Tablet antenna soft board

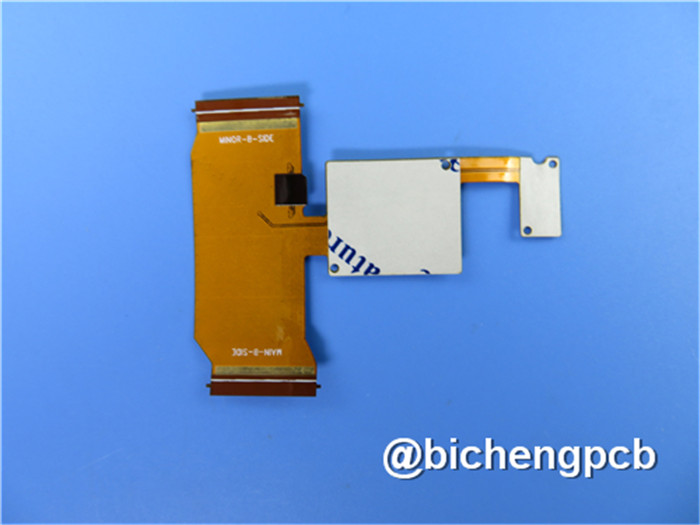

Multilayer

Flexible Circuits:

For the

most part, manufacture of multilayer flexible circuits is based upon processes

of single sided flexible PCB and double sided PTH flexible PCB. Both types

evolve from the conventional covercoated double-sided flexible circuits that

are bonded together. For a number of reasons, it is not recommended to combine

too many flexible circuits into a multilayer flexible circuit.

Materials

and Thicknesses of Multilayer FPC

It

is common practice to use the materials listed below.

Dielectric

Substrates

50

µm (2 mil) polyimide because of its higher stability and easier handling

compared with 25 µm (1 mil) polyimide.

Copper

Foil

35

µm (1 oz.) copper foil, provided this thickness is compatible with the current

carrying requirements of the finished circuit.

Covercoat

25

µm (1 mil) polyimide for a 35 µm (1.4 mil) thick copper foil, since it ensures

a better encapsulation of the conductors than a 50 µm (2 mil) polyimide.

25

µm (1 mil) acrylic adhesive for achieving a good encapsulation and a low-flow

lamination. Too much acrylic adhesive leads to reliability problems, e.g.

barrel cracks, foil cracks, and a too deep etchback.

Outer

Layers

Outer

layers should not be provided with any circuitry (conductors) on the bonding

side because of the risk of air entrapment at the interface.

Bonding

Materials

When

using covercoated flexible circuits as inner layers, the circuits and the rigid

parts are bonded together by means of sheet adhesives.

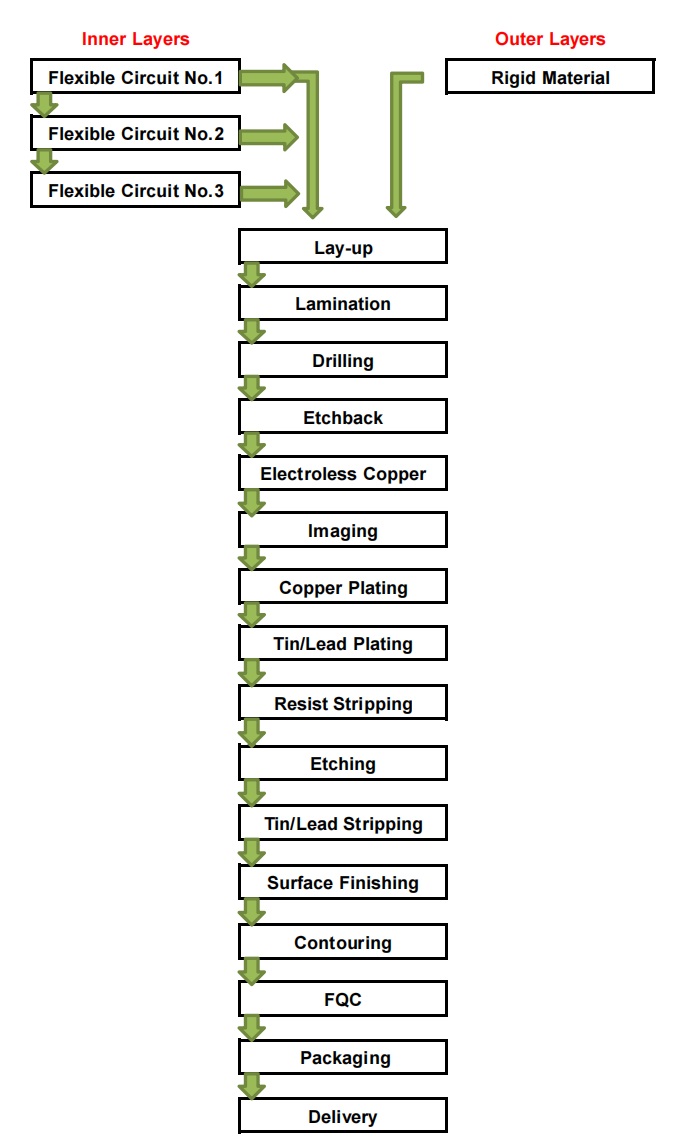

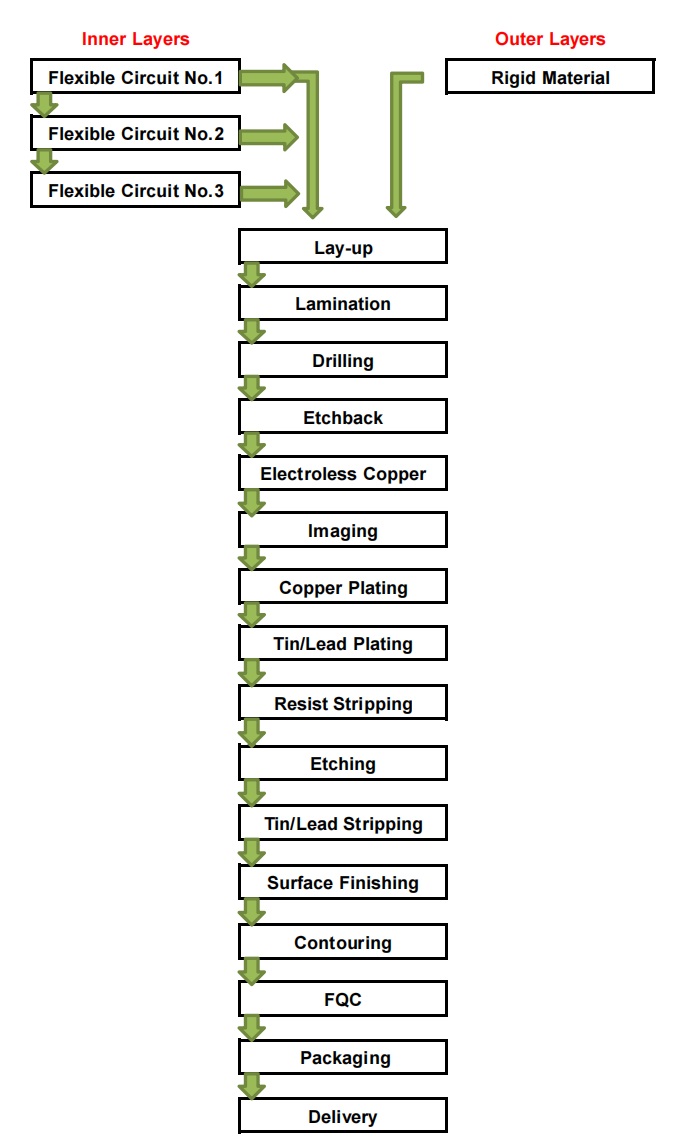

Processes:

A

simplified flow diagram is shown below.

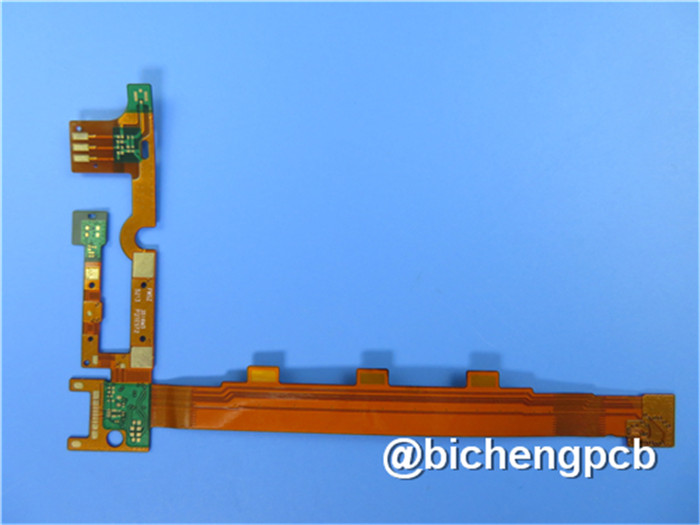

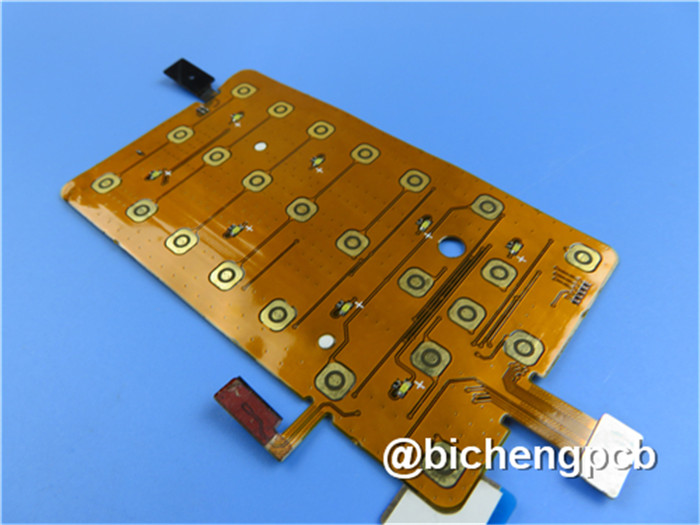

More

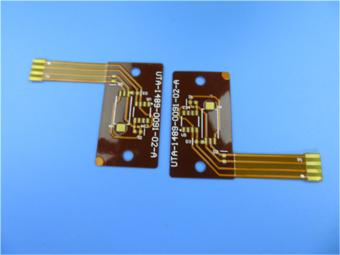

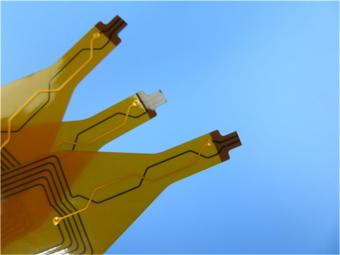

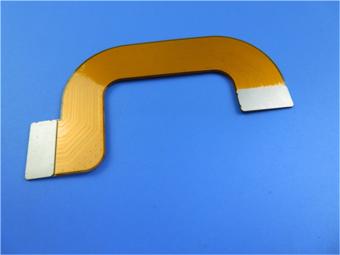

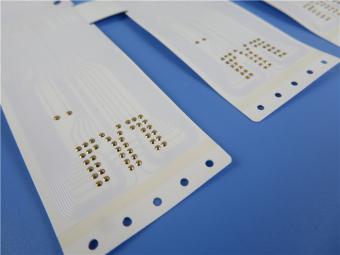

Displays of Multi-layer FPC:

BICHENG PCB WORKSHOP:

BICHENG PCB CERTIFICATE:

BICHENG MAIN COURIERS:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com