Heavy

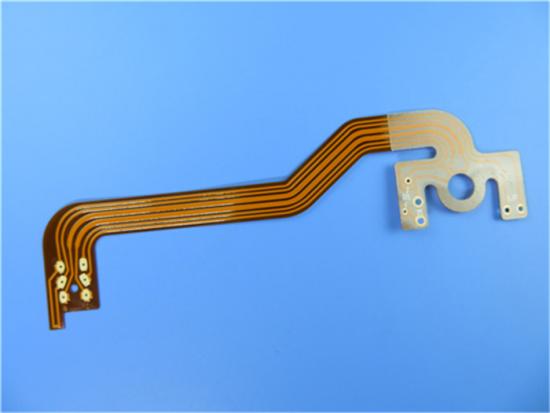

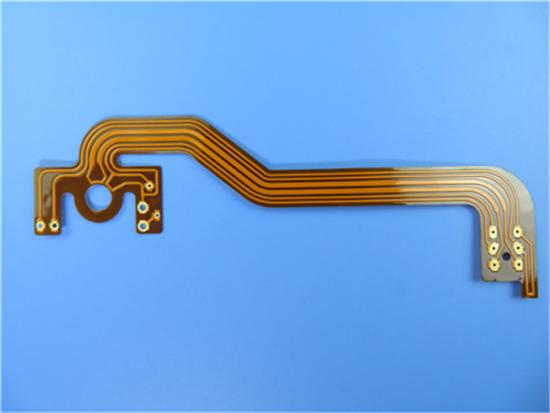

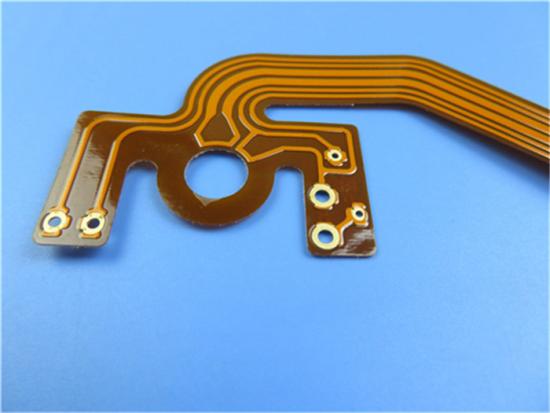

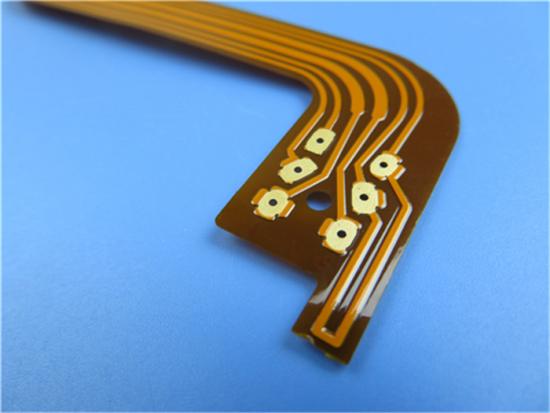

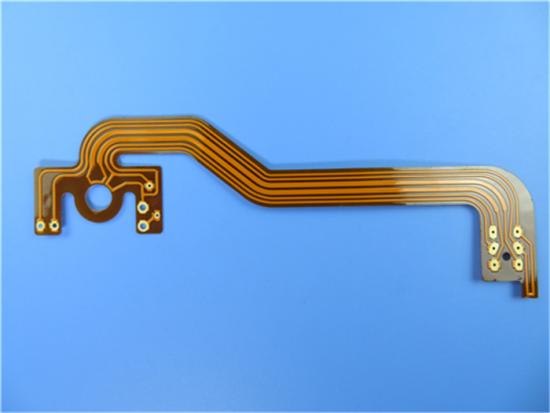

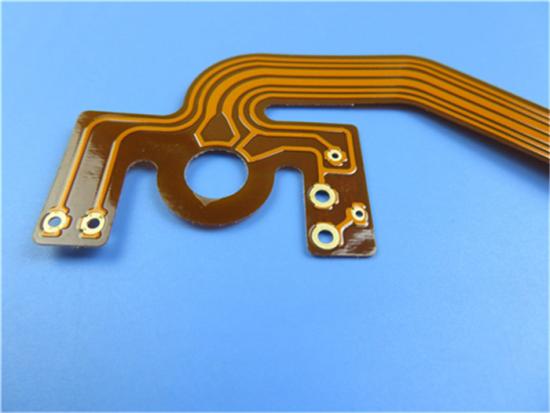

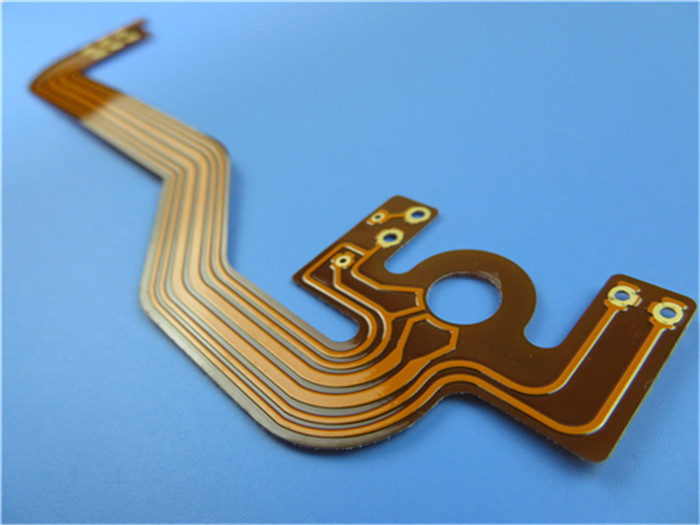

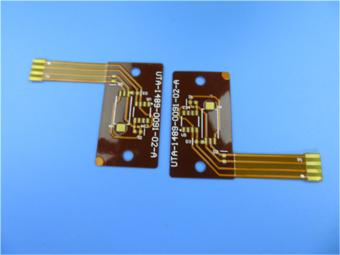

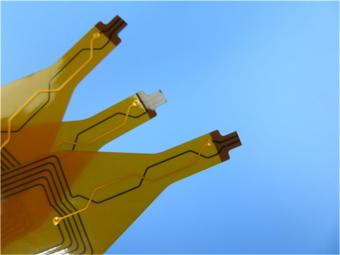

Copper Flexible PCB Built On Polyimide with 2 oz Copper

(Flexible

printed circuits are custom-made products, the picture and parameters shown are

just for reference)

General

description:

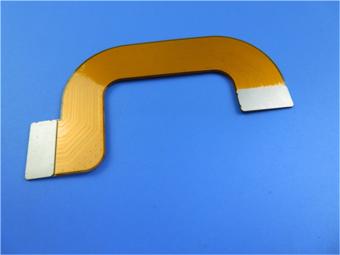

It’s a 2

layer polyimide FPC at 0.3mm thick with 2 oz copper. The base laminate is from Shengyi.On

head of its back is 0.1mm FR-4 stiffener. It’s fabricated per IPC 6012 Class 2

using supplied Gerber data. FR-4 as stiffener is applied on the back side.

Parameter

and data sheet:

|

Size of

Flexible PCB

|

130.66 X

40.67mm

|

|

Number of Layers

|

2

|

|

Board Type

|

Flexible PCB

|

|

Board Thickness

|

0.30mm

|

|

Board Material

|

Polyimide

50µm

|

|

Board Material Supplier

|

ITEQ

|

|

Tg Value of Board Material

|

60℃

|

|

|

|

PTH Cu thickness

|

≥20 µm

|

|

Inner Iayer Cu thicknes

|

N/A

|

|

Surface Cu thickness

|

70

µm

|

|

|

|

|

Coverlay Colour

|

Yellow

|

|

Number of Coverlay

|

2

|

|

Thickness of Coverlay

|

25

µm

|

|

Stiffener Material

|

FR-4

|

|

Stiffener Thickness

|

0.2mm

|

|

|

|

|

Type of Silkscreen Ink

|

IJR-4000

MW300

|

|

Supplier of Silkscreen

|

TAIYO

|

|

Color of Silkscreen

|

White

|

|

Number of Silkscreen

|

1

|

|

|

|

Peeling test of Coverlay

|

No

peelable

|

|

Legend Adhesion

|

3M 90℃No

peeling after Min. 3 times test

|

|

|

|

Surface Finish

|

Immersion

Gold

|

|

Thickness of Nickle/Gold

|

Au:

0.03µm(Min.); Ni 2-4µm

|

|

RoHS Required

|

Yes

|

|

Famability

|

94-V0

|

|

|

|

Thermal Shock Test

|

Pass, -25℃±125℃, 1000 cycles.

|

|

Thermal Stress

|

Pass, 300±5℃,10 seconds, 3 cycles. No delamination, no blistering.

|

|

Function

|

100%

Pass electrical test

|

|

Workmanship

|

Compliance

with IPC-A-600H & IPC-6013C Class 2

|

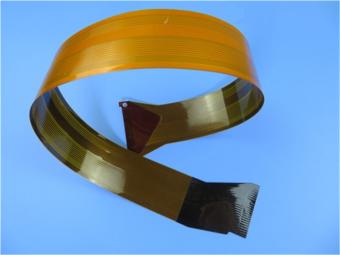

Features

and benefits:

Excellent

flexibility

Reducing

the volume

Weight

reduction

Consistency

of assembly

Increased

reliability

The

end can be whole soldered

Low

cost

Continuity

of processing

On-time

service

Quick

Lead time: 3-5 days

Applications:

General

purpose LED soft light strip, mobile phone antenna flex board, industrial

control, temperature controller soft board

Copper

Foils:

There

are two different types of copper foils: Electro-Deposited (ED) copper foils

and Rolled and annealed (RA) copper foils.

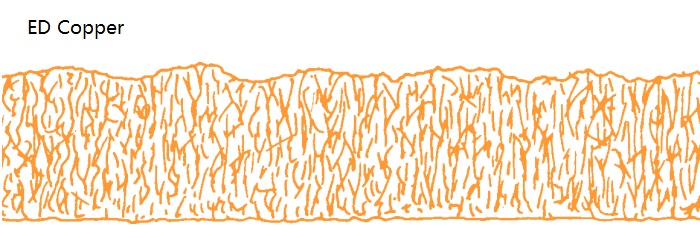

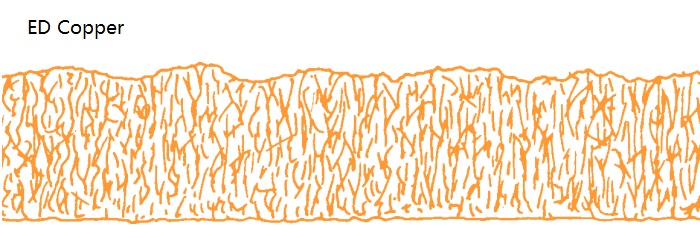

Electro-Deposited

copper foilsare produced by depositing copper on a stainless steel drum that rotates in a

plating tank with anodes of very pure copper. The thickness of the copper foil

is determined by the length of the plating process, i.e. the rotation speed of

the drum. The copper is then removed from the drum and wound on a roll. The finished copper foil is very smooth on the drum side and fairly rough on the

other side. The rough side has the advantage of giving better adhesion to the

base

laminate.

The

main characteristic of ED copper is its grain structure, which is vertical in

nature because of the electrolytic process. This implies a relatively low

ductility of the copper foil, thus it is not recommended for dynamic

applications. The drawing below shows the vertical grain structure of ED

copper.

Common

foil thicknesses for flexible circuits are 17.5, 35, 70, 105 and 175 µm (0.5,

1, 2, 3 and 5 oz.).

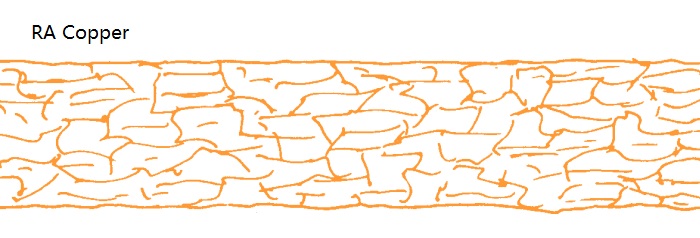

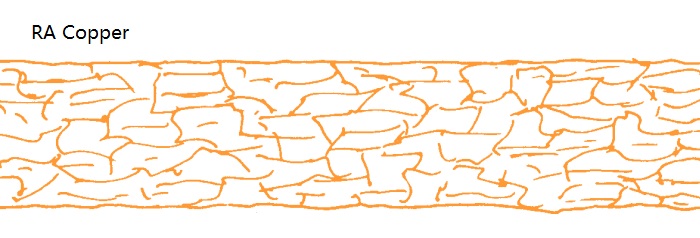

RA

Copper

This

copper is a rolled and annealed copper foil produced from electrolytically

deposited cathode copper, which is melted and cast into ingots. The ingots are

first hot-rolled to a certain size, and milled on all surfaces. The copper is

then cold-rolled and annealed, until the desired thickness is obtained.

Contrary

to electro-deposited copper, rolled and annealed copper has a horizontal grain

structure as shown below. The horizontal grain structure provides for much

higher flexibility and a better flex life endurance than ED copper, therefore

RA copper always should be used for dynamic applications.

A

disadvantage of RA copper is that the bonding surface is fairly smooth, so that

a relatively low adhesion is obtained. The bond, however, can be enhanced by an

electrolytic copper flash without deteriorating the flexing characteristics of

the copper foil.

Common

foil thicknesses for flexible circuits are 17.5, 35, 70, 105 and 175 µm (0.5,

1, 2, 3 and 5 oz.)

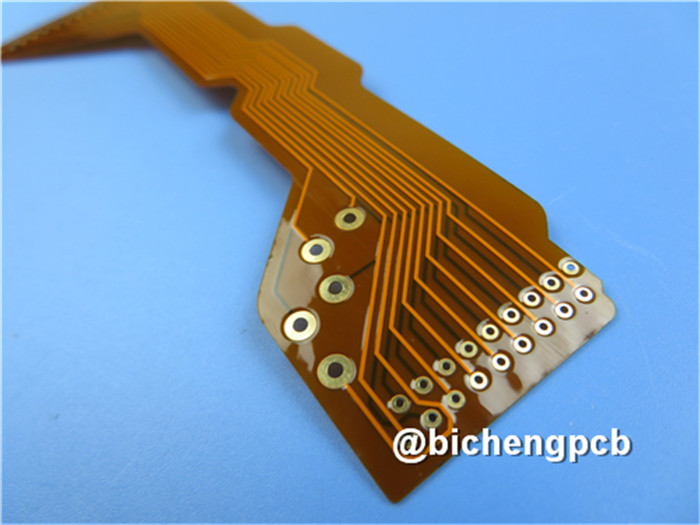

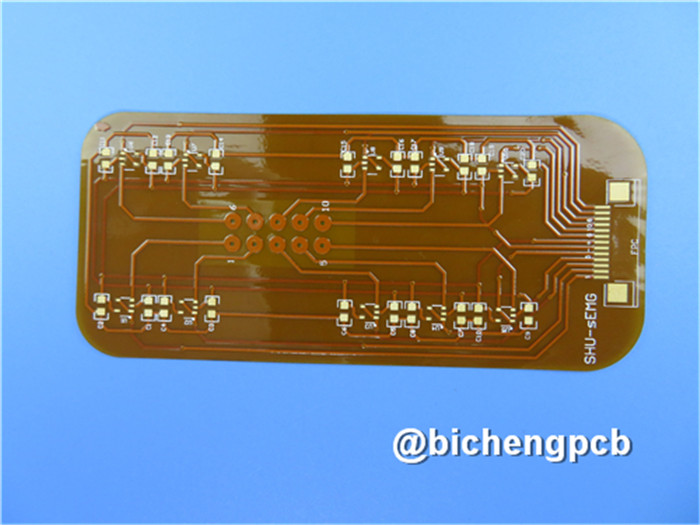

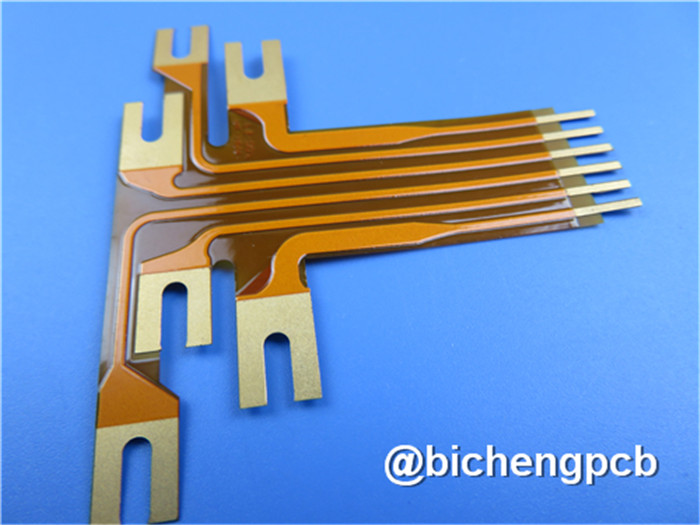

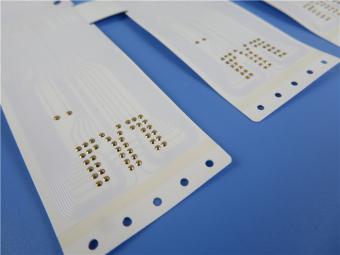

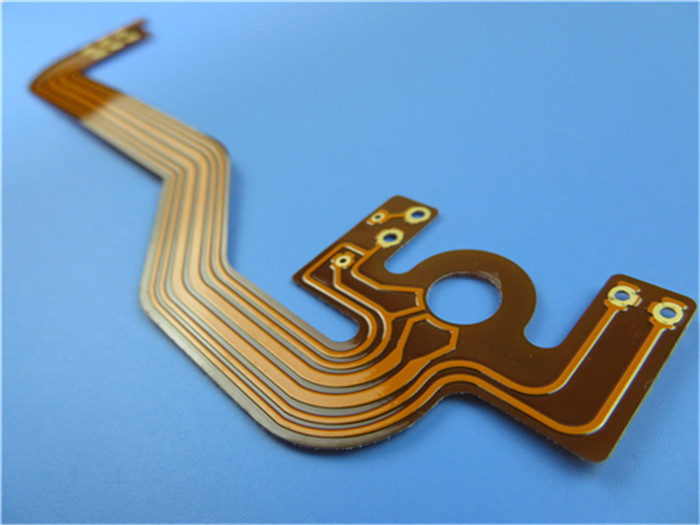

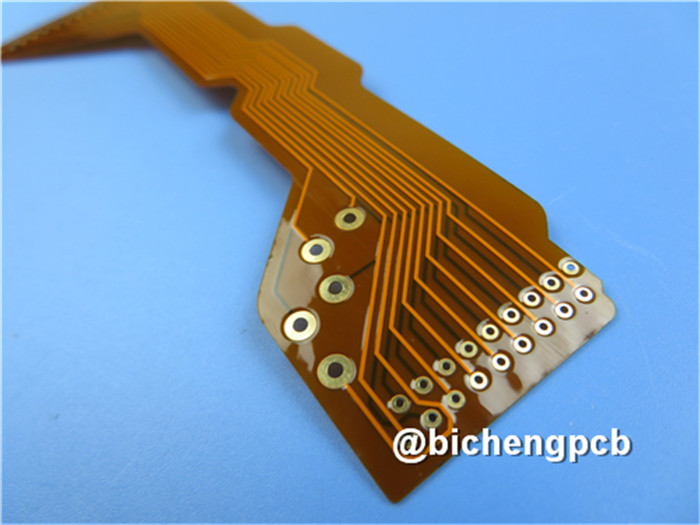

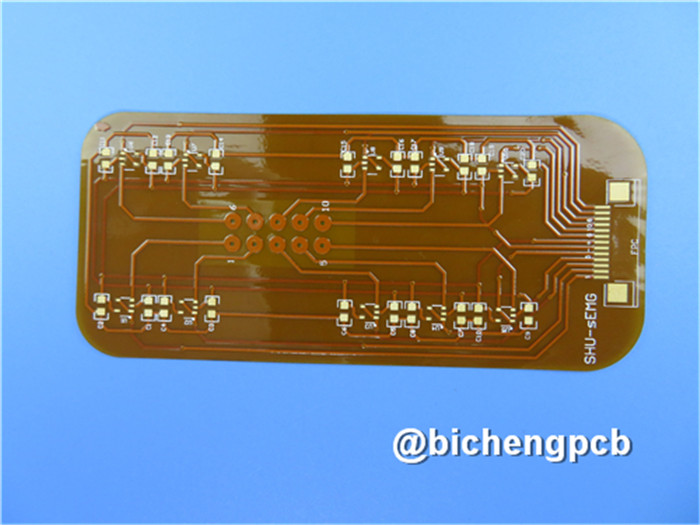

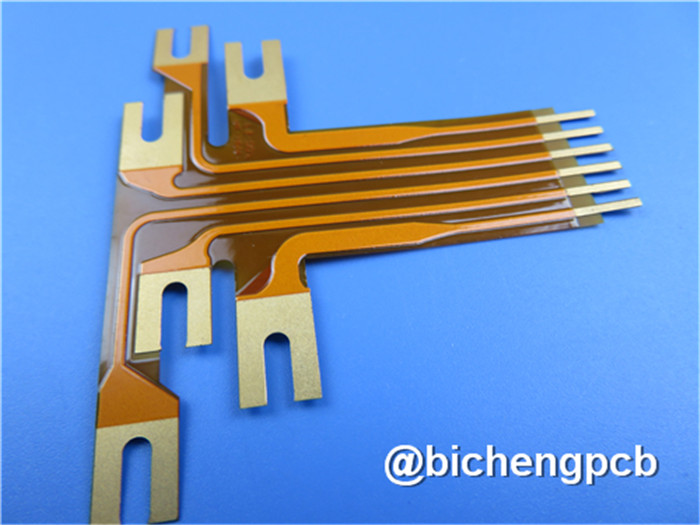

More

Displays of Heavy Copper Flex:

BICHENG PCB WORKSHOP:

BICHENG PCB CERTIFICATE:

BICHENG MAIN COURIERS:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com