RT/duroid 6006 PCB Rogers 6006 50mil Materialhigh-frequency printed circuit boards

Introduction

RT/duroid 6006 high-frequency printed circuit boards (PCBs) are ceramic-PTFE composites designed for electronic and microwave circuits that require a high dielectric constant.

The RT/duroid 6006 PCBs offer a high dielectric constant, which allows for circuit size reduction. They have low loss properties, making them ideal for operation at X-band or below. Additionally, the tight control of dielectric constant and thickness ensures consistent circuit performance.

RT/duroid 6006 Typical Properties

Let's explore the technical specifications and characteristics provided in the data sheet.

Starting with the dielectric properties, the RT/duroid 6006 shows a process dielectric constant, εProcess, of 6.15±0.15 at 10 GHz and 23℃. This ensures excellent signal performance and stability. The design dielectric constant, εDesign, is 6.45, covering a frequency range of 8 GHz to 40 GHz using the Differential Phase Length Method. The high dielectric constant allows for more space in PCB circuit design, enabling product miniaturization.

Moving on to the dissipation factor, or tanδ, the RT/duroid 6006 has a low value of 0.0027 at 10 GHz, guaranteeing minimal signal loss and high signal integrity.

Lastly, the Rogers 6006 PCB is fully compatible with lead-free processes, making it an ideal choice for modern, environmentally conscious manufacturing.

There is full Typical properties of Rogers 6006 PCB.

|

Property

|

RT/duroid 6006

|

Direction

|

Units

|

Condition

|

Test Method

|

|

Dielectric Constant,εProcess

|

6.15±0.15

|

Z

|

|

10 GHz/23℃

|

IPC-TM-650 2.5.5.5 Clamped stripline

|

|

Dielectric Constant,εDesign

|

6.45

|

Z

|

|

8GHz to 40 GHz

|

Differential Phase Length Method

|

|

Dissipation Factor,tanδ

|

0.0027

|

Z

|

|

10 GHz/A

|

IPC-TM-650 2.5.5.5

|

|

Thermal Coefficient of ε

|

-410

|

Z

|

ppm/℃

|

-50℃-170℃

|

IPC-TM-650 2.5.5.5

|

|

Volume Resistivity

|

7 x 107

|

|

Mohm.cm

|

A

|

IPC 2.5.17.1

|

|

Surface Resistivity

|

2 x 107

|

|

Mohm

|

A

|

IPC 2.5.17.1

|

|

Tensile Properties

|

ASTM D638 (0.1/min. strain rate)

|

|

Young's Modulus

|

627(91) 517(75)

|

X Y

|

MPa(kpsi)

|

A

|

|

Ultimate Stress

|

20(2.8) 17(2.5)

|

X Y

|

MPa(kpsi)

|

A

|

|

Ultimate Strain

|

12 to 13 4 to 6

|

X Y

|

%

|

A

|

|

Compressive Properties

|

|

ASTM D695 (0.05/min. strain rate)

|

|

Young's Modulus

|

1069 (115)

|

Z

|

MPa(kpsi)

|

A

|

|

Ultimate Stress

|

54(7.9)

|

Z

|

MPa(kpsi)

|

A

|

|

Ultimate Strain

|

33

|

Z

|

%

|

|

|

Flexural Modulus

|

2634 (382) 1951 (283)

|

X

|

MPa(kpsi)

|

A

|

ASTM D790

|

|

Ultimate Stress

|

38 (5.5)

|

X Y

|

MPa(kpsi)

|

A

|

|

Deformation under load

|

0.33 2.1

|

Z Z

|

%

|

24hr/50℃/7MPa 24hr/150℃/7MPa

|

ASTM D261

|

|

Moisture Absorption

|

0.05

|

|

%

|

D48/50℃ 0.050"(1.27mm) thick

|

IPC-TM-650 2.6.2.1

|

|

Thermal Conductivity

|

0.49

|

|

W/m/k

|

80℃

|

ASTM C518

|

|

Coefficient of Thermal Expansion

|

47

34

117

|

X

Y

Z

|

ppm/℃

|

23℃/50% RH

|

IPC-TM-650 2.4.41

|

|

Td

|

500

|

|

℃ TGA

|

|

ASTM D3850

|

|

Density

|

2.7

|

|

g/cm3

|

|

ASTM D792

|

|

Specific Heat

|

0.97(0.231)

|

|

j/g/k

(BTU/ib/OF)

|

|

Calculated

|

|

Copper Peel

|

14.3 (2.5)

|

|

pli (N/mm)

|

after solder float

|

IPC-TM-650 2.4.8

|

|

Flammability

|

V-0

|

|

|

|

UL 94

|

|

Lead-free Process Compatible

|

Yes

|

|

|

|

|

RT/duroid 6006PCB Capability

|

PCB material:

|

Ceramic-PTFE Composites

|

|

Designation:

|

RT/duroid 6006

|

|

Dielectric constant:

|

6.15

|

|

Dissipation factor

|

0.0027 10GHz

|

|

Layer count:

|

Single-sided PCB, Double-sided PCB, Multi-layer PCB, Hybrid types

|

|

Dielectric thickness:

|

10mil(0.254mm), 25mil (0.635mm), 50mil (1.27mm), 75mil (1.905mm), 100mil(2.54mm)

|

|

Copper weight:

|

1oz (35µm), 2oz (70µm)

|

|

PCB size:

|

≤400mm X 500mm

|

|

Solder mask:

|

Green, Black, Blue, Yellow, Red etc.

|

|

Surface finish:

|

Immersion gold, HASL, Immersion silver, Immersion tin, Bare copper, OSP, ENEPIG, Pure gold etc..

|

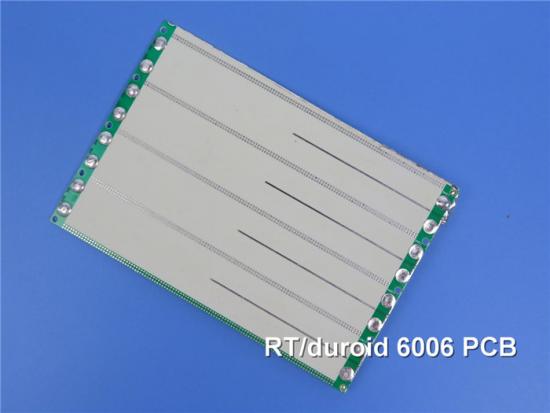

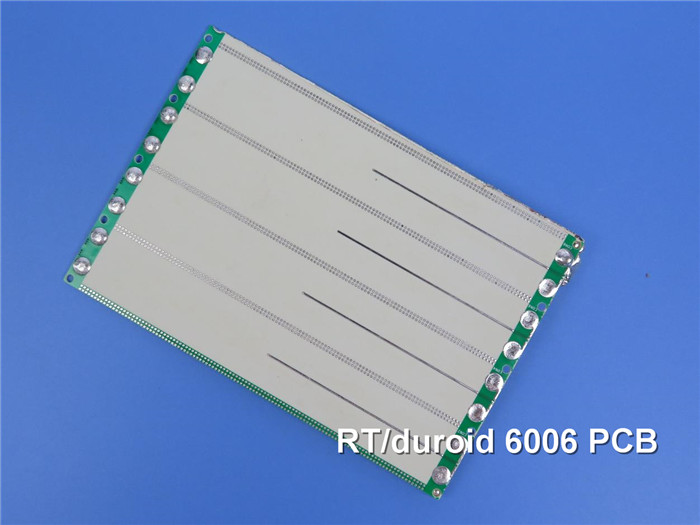

A Sample RT/duroid 6006 PCB

There is a 50mil RT/duroid 6006 PCB with immersion silver for patch antennas.

RT/duroid 6006 Rogers 50mil substrate PCBs can be utilized in telecommunications, aerospace, defense, and other applications operating in the 8 to 40 GHz range. They are commonly used in aircraft collision avoidance systems, ground radar warning systems, and satellite communications systems, among others.

Conclusion

That concludes our overview of the exceptional properties and characteristics of the RT/duroid 6006 and the PCBs manufactured using it. If you have any further inquiries or need more information, please don't hesitate to ask.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com