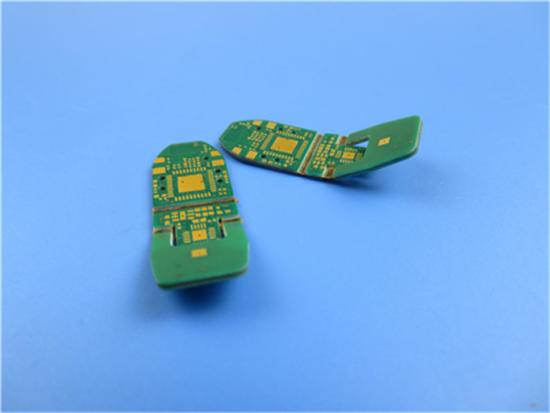

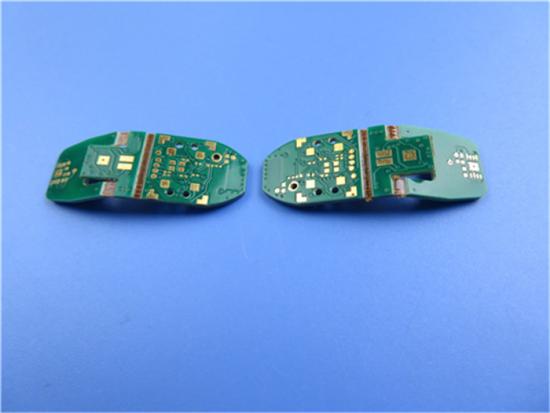

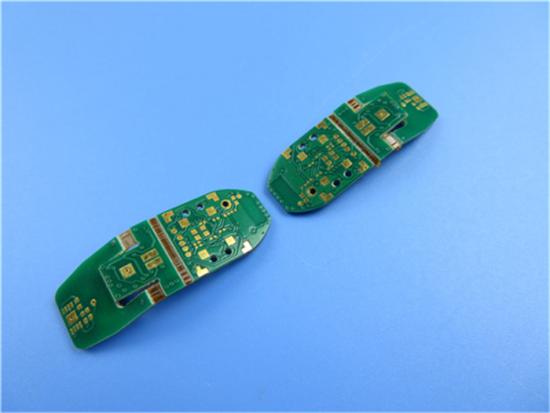

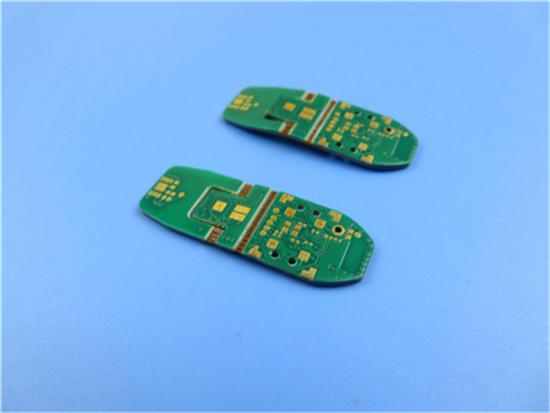

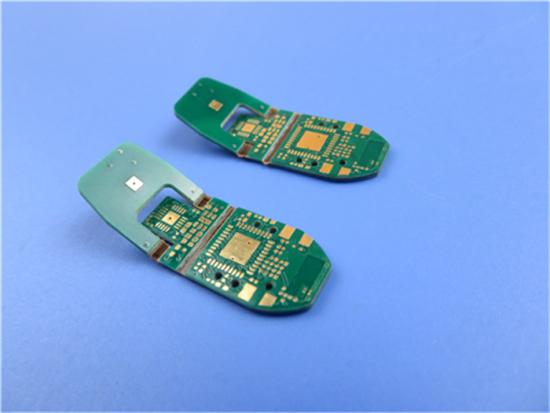

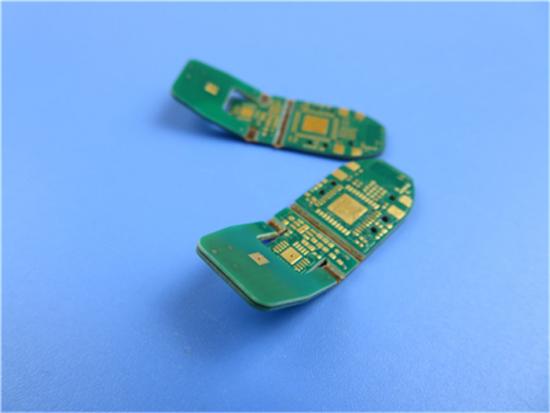

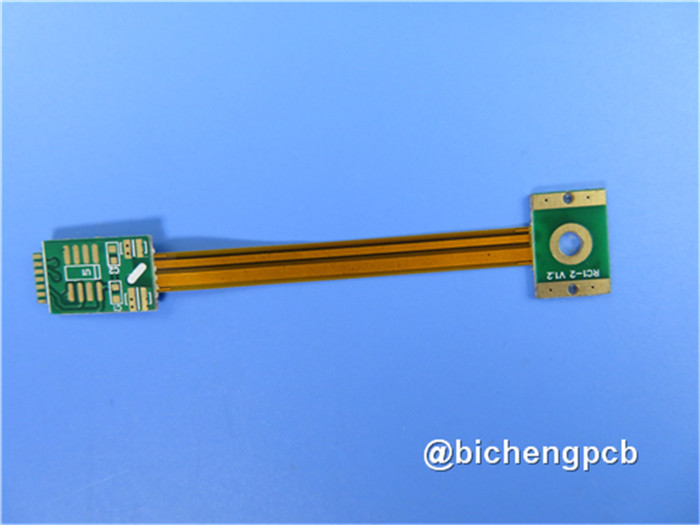

Rigid-Flex

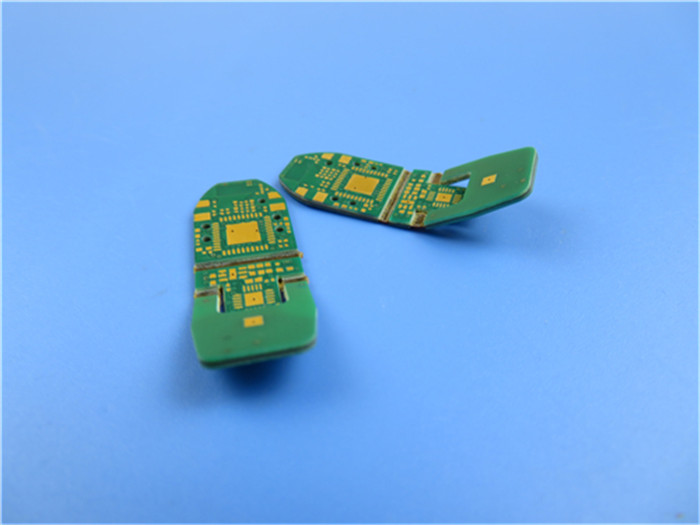

PCB Built on FR-4 and Poyimide With Immersion Gold and 90ohm Impedance Control

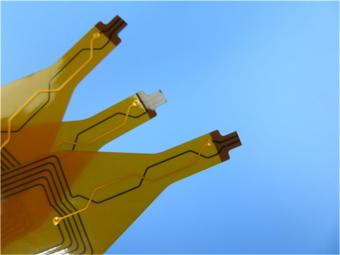

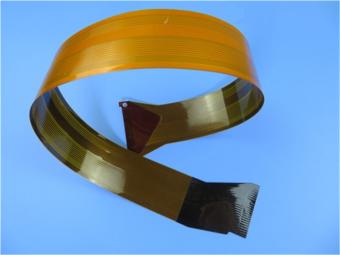

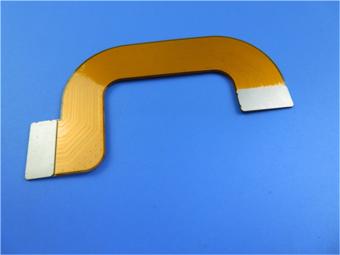

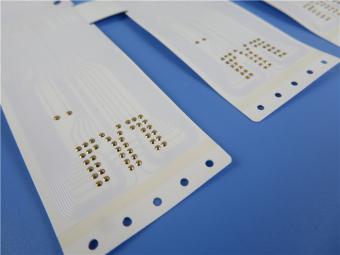

(Flexible

printed circuits are custom-made products, the picture and parameters shown are

just for reference)

General

description:

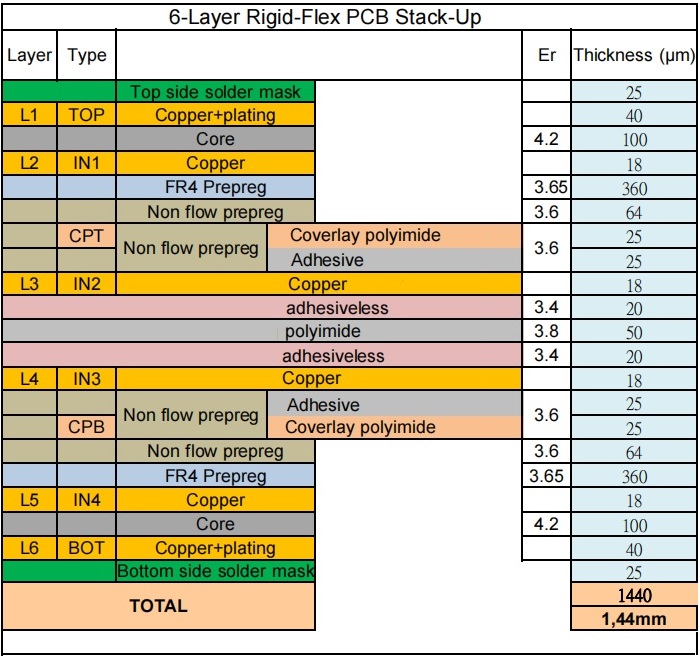

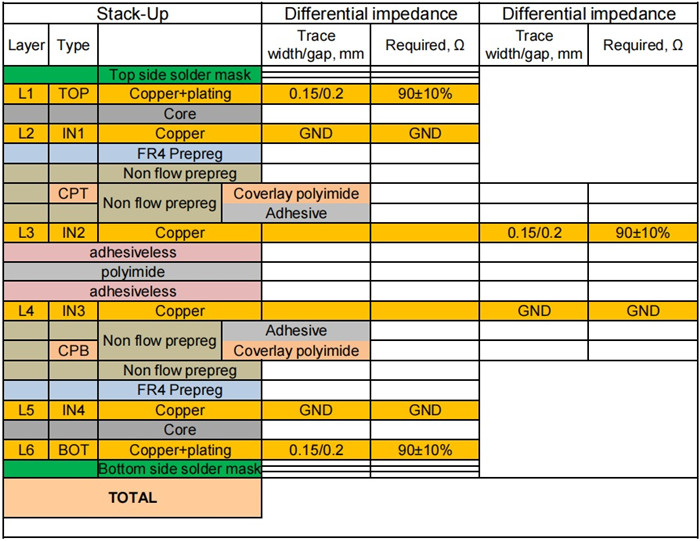

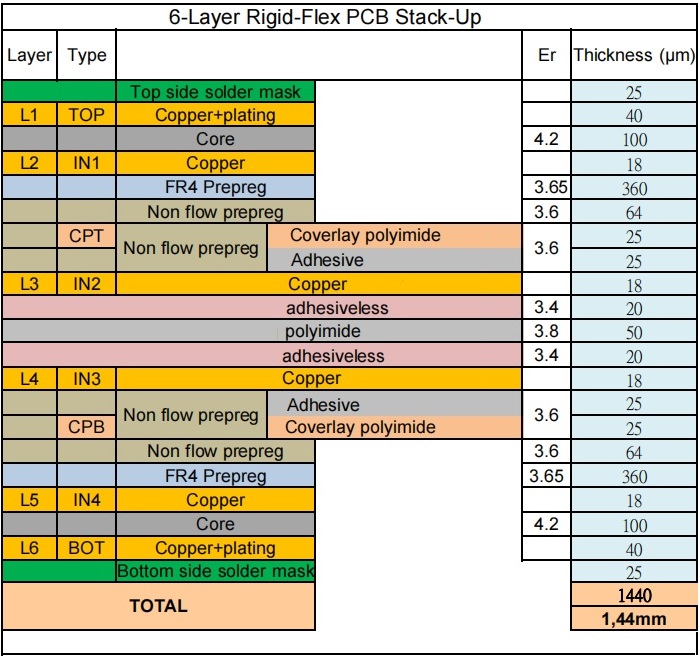

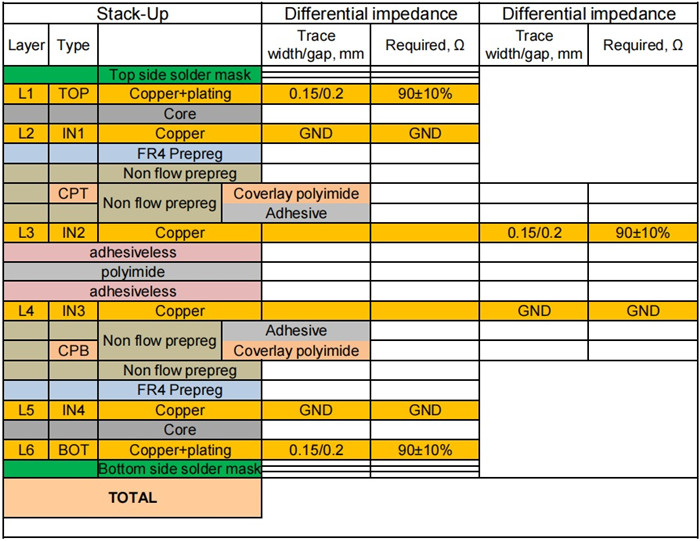

It is also an impedance controlled design on outer layers and inner

flexible circuit. Immersion gold is plated on pads for latter SMT. The base

laminate is from Shengyi, It’s fabricated per IPC 6012 Class 2 using supplied

Gerber data.

Parameter

and data sheet:

|

Size of

Flexible PCB

|

20.61 X 50.17mm

|

|

Number of Layers

|

6

|

|

Board Type

|

Rigid flex PCB

|

|

Board Thickness

|

1.4mm

|

|

Board Material

|

FR-4

/ Polyimide

|

|

Board Material Supplier

|

Shengyi

|

|

Tg Value of Board Material

|

130℃

|

|

|

|

PTH Cu thickness

|

≥20 µm

|

|

Inner Iayer Cu thicknes

|

18

µm

|

|

Surface Cu thickness

|

35

µm

|

|

|

|

|

Coverlay Colour

|

Yellow

coverlay / Green solder mask

|

|

Number of Coverlay

|

2

|

|

Thickness of Coverlay

|

25

µm

|

|

Stiffener Material

|

N/A

|

|

Stiffener Thickness

|

N/A

|

|

|

|

|

Type of Silkscreen Ink

|

IJR-4000

MW300

|

|

Supplier of Silkscreen

|

TAIYO

|

|

Color of Silkscreen

|

White

|

|

Number of Silkscreen

|

1

|

|

|

|

Peeling test of Coverlay

|

No

peelable

|

|

Legend Adhesion

|

3M 90℃No

peeling after Min. 3 times test

|

|

|

|

Surface Finish

|

Immersion

Gold

|

|

Thickness of Nickle/Gold

|

Au:

0.03µm(Min.); Ni 2-4µm

|

|

RoHS Required

|

Yes

|

|

Famability

|

94-V0

|

|

|

|

Thermal Shock Test

|

Pass, -25℃±125℃, 1000 cycles.

|

|

Thermal Stress

|

Pass, 300±5℃,10 seconds, 3 cycles. No delamination, no blistering.

|

|

Function

|

100%

Pass electrical test

|

|

Workmanship

|

Compliance

with IPC-A-600H & IPC-6013C Class 2

|

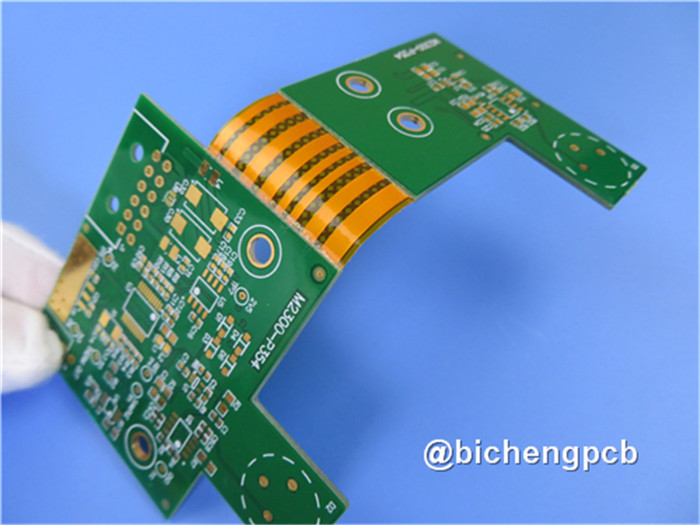

Features

and benefits:

Excellent

flexibility

Reducing

the volume

Weight

reduction

Consistency

of assembly

Increased

reliability

The

end can be whole soldered

Low

cost

Continuity

of processing

No

minimum order quantity and low cost sample.

Make

delivery on time. We keep higher than 98% on-time-delivery rate.

Applications:

Contact

belt of inkjet printer, industrial surveying and mapping instrument, Tablet PC

camera soft board

Flexible

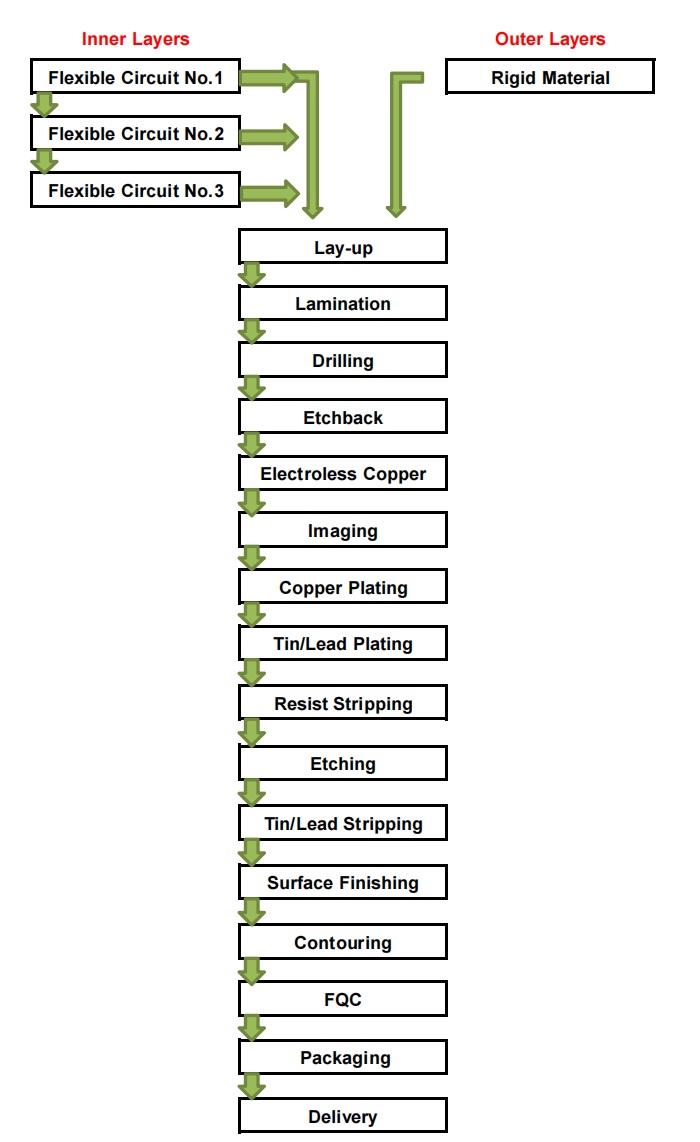

Inner Layers:

Inner

layers are produced as single- or double-sided flexible circuits in the same

way i.e., imaged, etched and covercoated, but not drilled and plated.

Covercoating of the individual inner layer circuits requires an extra process,

but the advantage is less risk of air entrapment.

The

inner layers in the flexible section can also be bonded together . Although it

is a simpler design that involves fewer process steps, the finished circuit has

the disadvantage of being fairly rigid, and therefore difficult to bend. This

is reflected in a rather limited number of bend cycles, e.g., maximum 25.

Another

method is to avoid bonding of the flexible circuits in the flexible area. In

the case of many inner layers, or when there is a short distance between the

rigid sections of a flex/rigid circuit, a staggered build-up can be employed.

This prevents buckling of the individual layers when the circuit is to be bent

into its installed position, but the manufacture is somewhat more complicated.

Rigid

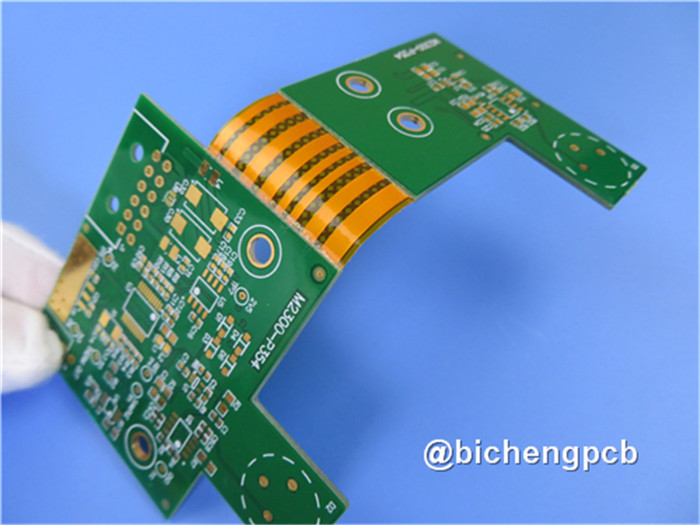

Outer Layers:

In

the case of flex/rigid circuits, rigid materials such as FR-4 are cut to size,

and bonded to the circuit in the lamination process. It is possible to produce

the flex/rigid circuit as a temporarily rigid board to facilitate handling

during manufacture, assembly and soldering. This is achieved by extending the

rigid layers across the flexible section. By covering both sides of the

flexible section with release films, bonding of the rigid outer layers to the

flexible section is prevented. The non-bonded sections of the rigid material

can be removed by a snap-action, provided grooves are cut before lamination at

the interfaces in both sides of each rigid outer

layer.

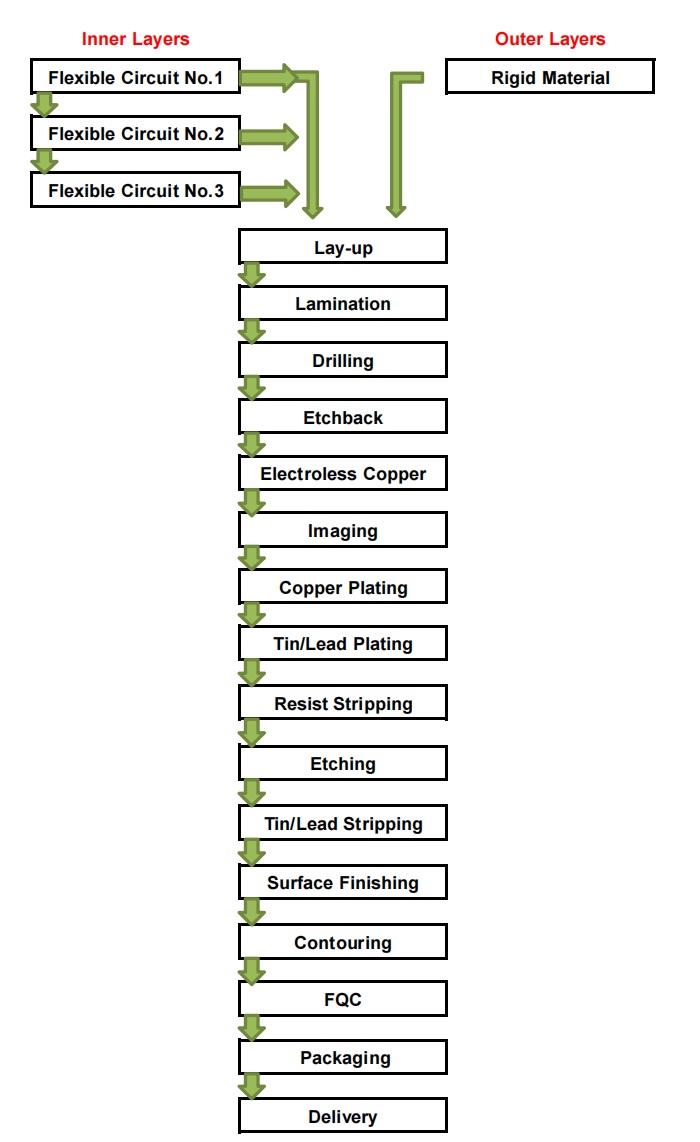

Processes:

A

simplified flow diagram is shown below.

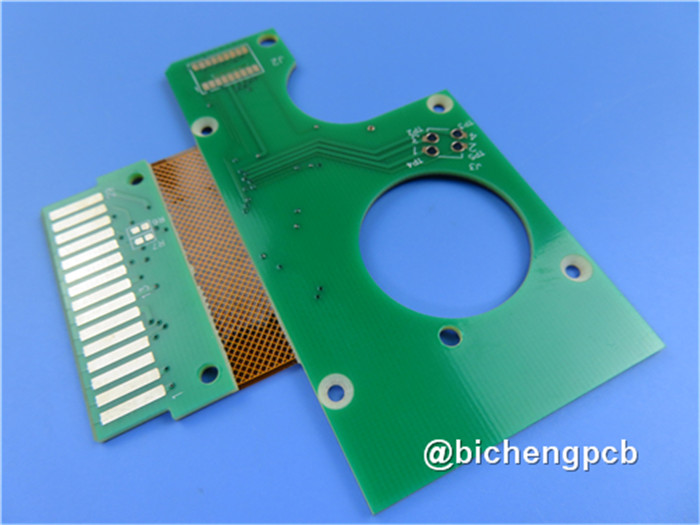

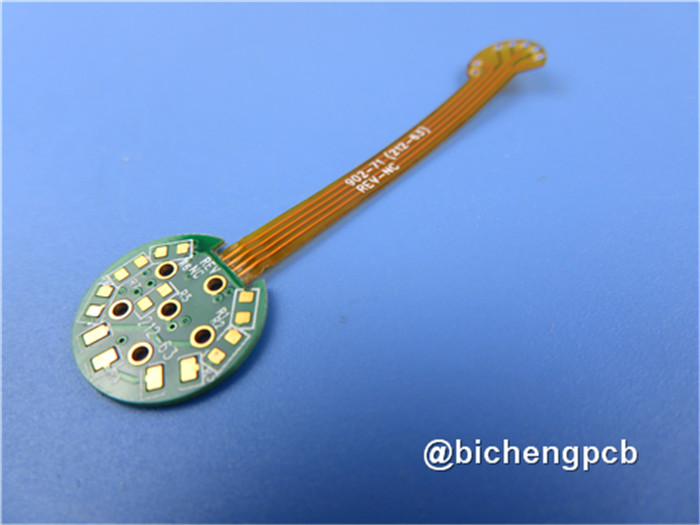

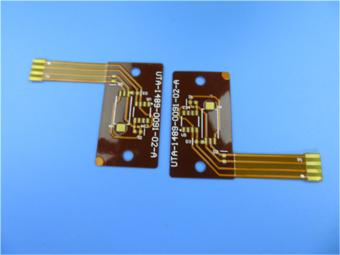

More

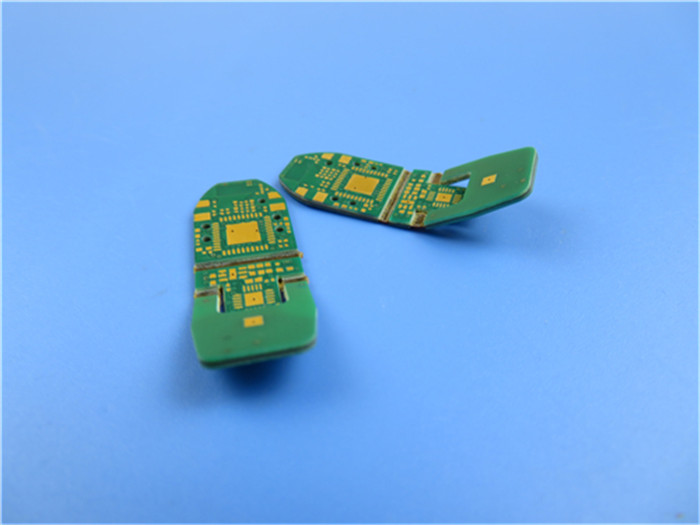

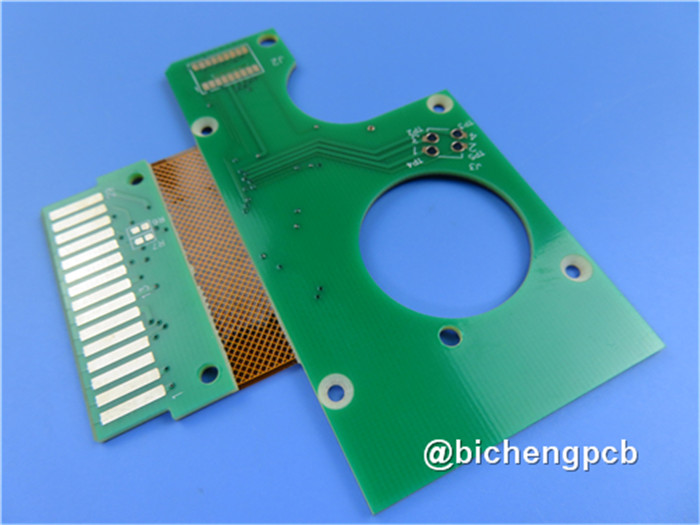

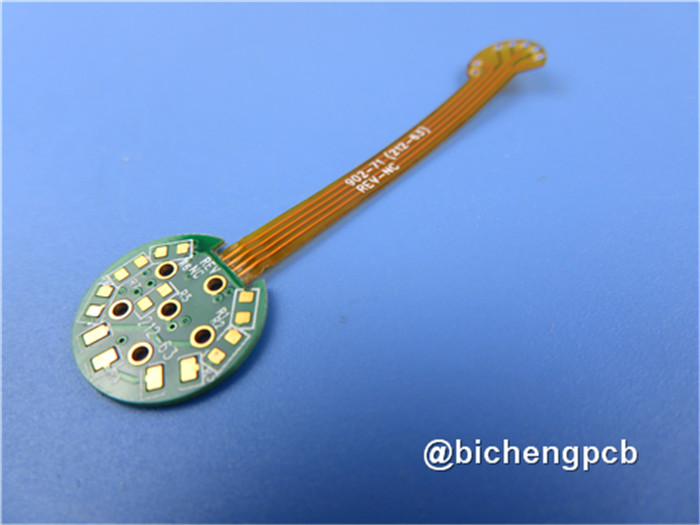

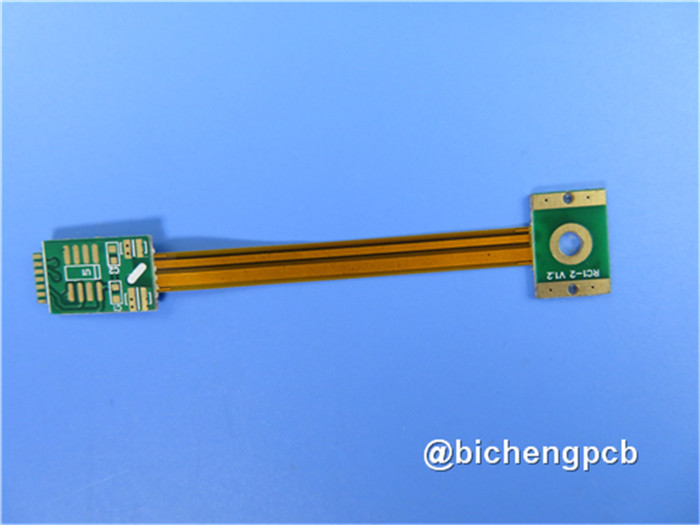

Displays of rigid-flex PCB:

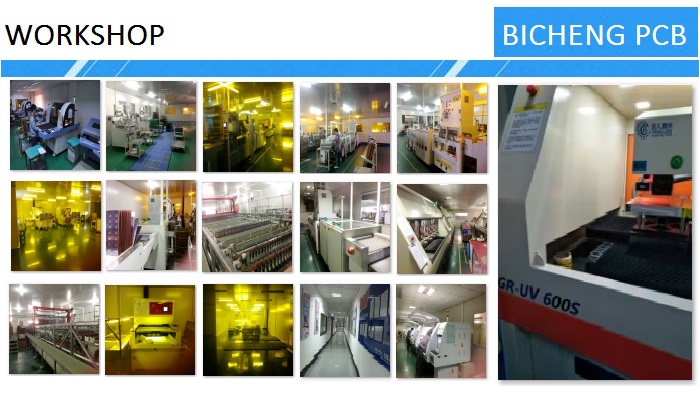

BICHENG PCB WORKSHOP:

BICHENG PCB CERTIFICATE:

BICHENG MAIN COURIERS:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com