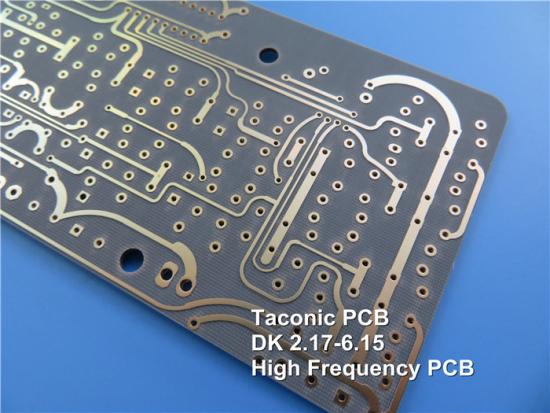

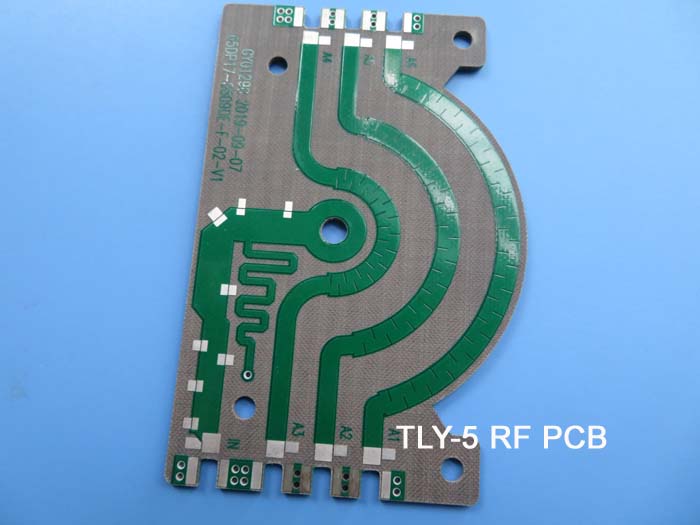

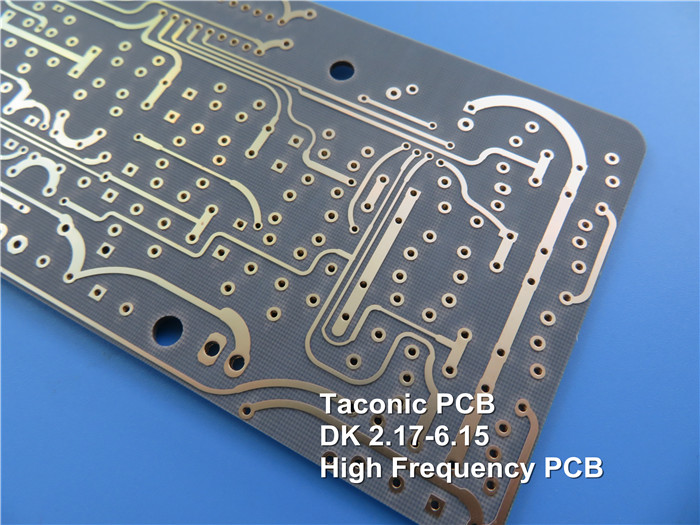

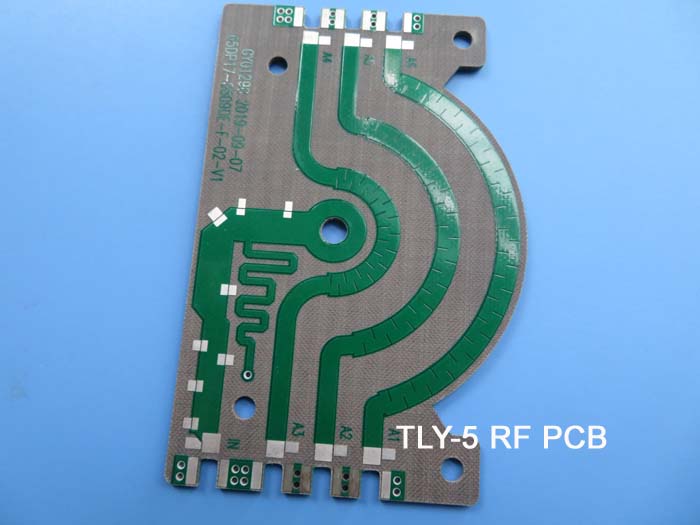

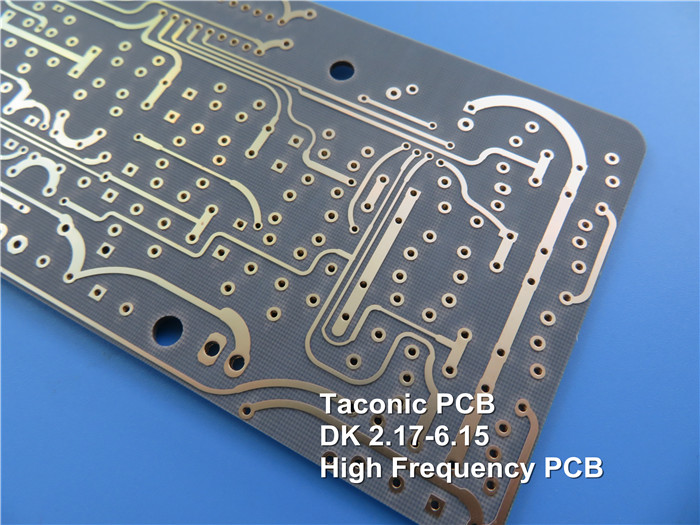

Taconic High Frequency PCB Made on TLY-5 7.5mil

0.191mm With DK2.2 for Automotive Radar

The woven matrix yields a more mechanically stable laminate that is suitable

for high volume manufacturing. The low dissipation factor enables successful

deployment for automotive radar applications designed at 77 GHz as well as other

antennas in millimeter wave frequencies.

The dielectric constant is as low as 2.17-2.20

+/-0.02, and dissipation factor is as low as 0.0009.

Benefits:

Dimensionally stable

Lowest DF

Low moisture absorption

High copper peel strength

Uniform & consistent DK

Laser ablatable

Applications:

Automotive radar

Satellite/cellular communications

Power amplifiers

LNBs, LNAs, LNCs

Aerospace

Ka, E and W band applications

PCB Specifications:

|

PCB SIZE

|

76 x 51mm=1PCS

|

|

BOARD TYPE

|

Double

sided PCB

|

|

Number

of Layers

|

2 layers

|

|

Surface

Mount Components

|

YES

|

|

Through

Hole Components

|

NO

|

|

LAYER STACKUP

|

copper

------- 18um(0.5 oz)+plate TOP layer

|

|

TLY-5 0.191mm

|

|

copper ------- 18um(0.5 oz) + plate BOT Layer

|

|

TECHNOLOGY

|

|

|

Minimum Trace and Space:

|

10

mil / 10 mil

|

|

Minimum

/ Maximum Holes:

|

0.4mm

/ 2.0mm

|

|

Number

of Different Holes:

|

0

|

|

Number

of Drill Holes:

|

0

|

|

Number

of Milled Slots:

|

0

|

|

Number

of Internal Cutouts:

|

0

|

|

Impedance

Control:

|

no

|

|

Number

of Gold finger:

|

0

|

|

BOARD

MATERIAL

|

|

|

Glass

Epoxy:

|

TLY-5

|

|

Final

foil external:

|

1oz

|

|

Final

foil internal:

|

N/A

|

|

Final

height of PCB:

|

0.25

mm ±0.1

|

|

PLATING AND COATING

|

|

|

Surface Finish

|

OSP

|

|

Solder

Mask Apply To:

|

NO

|

|

Solder

Mask Color:

|

N/A

|

|

Solder

Mask Type:

|

N/A

|

|

CONTOUR/CUTTING

|

Routing

|

|

MARKING

|

|

|

Side of

Component Legend

|

N/A

|

|

Colour

of Component Legend

|

White

|

|

Manufacturer

Name or Logo:

|

Marked on the

board in a conductor and leged FREE AREA

|

|

VIA

|

N/A

|

|

FLAMIBILITY RATING

|

UL

94-V0 Approval MIN.

|

|

DIMENSION TOLERANCE

|

|

|

Outline

dimension:

|

0.0059"

|

|

Board

plating:

|

0.0029"

|

|

Drill

tolerance:

|

0.002"

|

|

TEST

|

100%

Electrical Test prior shipment

|

|

TYPE OF ARTWORK TO BE SUPPLIED

|

email

file, Gerber RS-274-X, PCBDOC etc

|

|

SERVICE AREA

|

Worldwide,

Globally.

|

Data Sheet of Taconic TLY Material:

|

TLY TYPICAL VALUES

|

|

Property

|

Test Method

|

Unit

|

Value

|

Unit

|

Value

|

|

DK at 10 GHz

|

IPC-650 2.5.5.5

|

|

2.2

|

|

2.2

|

|

Df at 10 GHz

|

IPC-650 2.5.5.5

|

|

0.0009

|

|

0.0009

|

|

Moisture

Absorption

|

IPC-650 2.6.2.1

|

%

|

0.02

|

%

|

0.02

|

|

Dielectric

Breakdown

|

IPC-650 2.5.6

|

kV

|

>45

|

kV

|

>45

|

|

Dielectric

Strength

|

ASTM D 149

|

V/mil

|

2,693

|

V/mil

|

106,023

|

|

Volume

Resistivity

|

IPC-650

2.5.17.1(after elevated temp.)

|

Mohms/cm

|

1010

|

Mohms/cm

|

1010

|

|

Volume

Resistivity

|

IPC-650

2.5.17.1(after humidity)

|

Mohms/cm

|

1010

|

Mohms/cm

|

109

|

|

Surface

Resistivity

|

IPC-650

2.5.17.1(after elevated temp.)

|

Mohms

|

108

|

Mohms

|

108

|

|

Surface

Resistivity

|

IPC-650

2.5.17.1(after humidity)

|

Mohms

|

108

|

Mohms

|

108

|

|

Flex

Strength(MD)

|

IPC-650 2.4.4

|

psi

|

14,057

|

N/mm2

|

96.91

|

|

Flex

Strength(CD)

|

IPC-650 2.4.4

|

psi

|

12,955

|

N/mm2

|

89.32

|

|

Peel

Stength(½ oz.ed copper)

|

IPC-650 2.4.8

|

Ibs./inch

|

11

|

N/mm

|

1.96

|

|

Peel

Stength(1 oz.CL1 copper)

|

IPC-650 2.4.8

|

Ibs./inch

|

16

|

N/mm

|

2.86

|

|

Peel

Stength(1 oz..CV1 copper)

|

IPC-650 2.4.8

|

Ibs./inch

|

17

|

N/mm

|

3.04

|

|

Peel Stength

|

IPC-650 2.4.8(after

elevated temp.)

|

Ibs./inch

|

13

|

N/mm

|

2.32

|

|

Young's

Modulus(MD)

|

ASTM D 3039/IPC-650

2.4.19

|

psi

|

1.4 x 106

|

N/mm2

|

9.65 x 103

|

|

Poisson's

Ratio(MD)

|

ASTM D 3039/IPC-650

2.4.19

|

|

0.21

|

|

0.21

|

|

Thermal

Conductivity

|

ASTM F 433

|

W/M*K

|

0.22

|

W/M*K

|

0.22

|

|

Dimensional

Stability(MD,10mil)

|

IPC-650

2.4.39(avg.after bake&thermal stress)

|

mils/inch

|

-0.038

|

|

-0.038

|

|

Dimensional

Stability(CD,10mil)

|

IPC-650

2.4.39(avg.after bake&thermal stress)

|

mils/inch

|

-0.031

|

|

-0.031

|

|

Density(Specific

Gravity)

|

ASTM D 792

|

g/cm3

|

2.19

|

g/cm3

|

2.19

|

|

CTE(X

axis)(25-260℃)

|

ASTM D 3386(TMA)

|

ppm/℃

|

26

|

ppm/℃

|

26

|

|

CTE(Y

axis)(25-260℃)

|

ASTM D 3386(TMA)

|

ppm/℃

|

15

|

ppm/℃

|

15

|

|

CTE(Z

axis)(25-260℃)

|

ASTM D 3386(TMA)

|

ppm/℃

|

217

|

ppm/℃

|

217

|

|

NASA

Outgassing(% TML)

|

|

|

0.01

|

|

0.01

|

|

NASA

Outgassing(% CVCM)

|

|

|

0.01

|

|

0.01

|

|

NASA

Outgassing(% WVR)

|

|

|

0.00

|

|

0.00

|

|

UL-94

Flammability Rating

|

UL-94

|

|

V-0

|

|

V-0

|

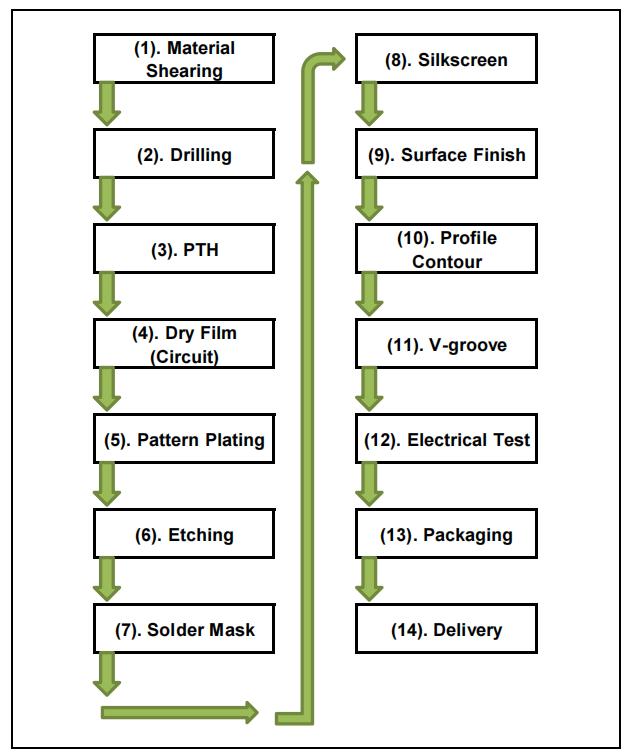

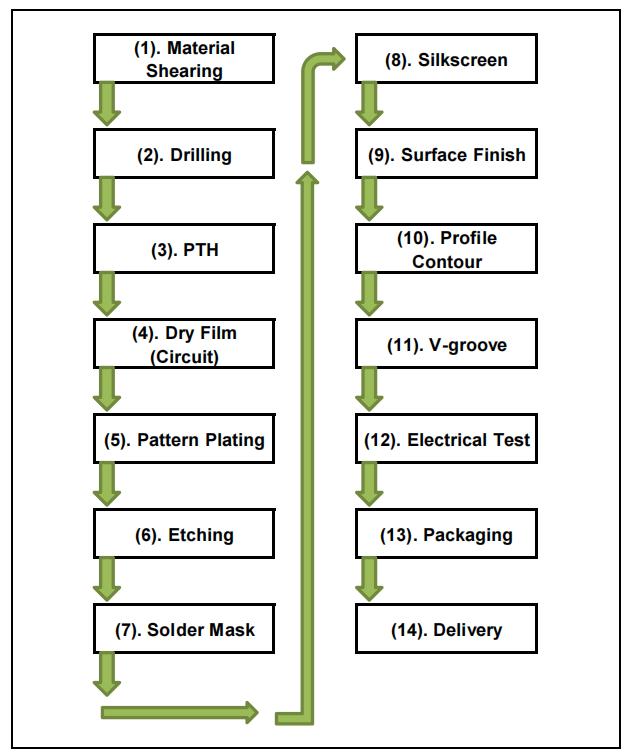

MANUFACTURING PROCESS:

BICHENG PCB EQUIPMENT:

BICHENG PCB CERTIFICATE:

BICHENG PCB MAIN COURIERS:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com