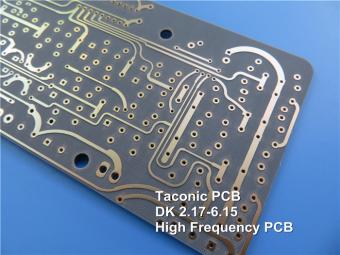

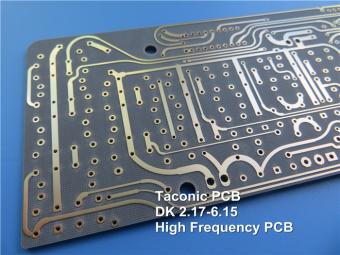

Rogers

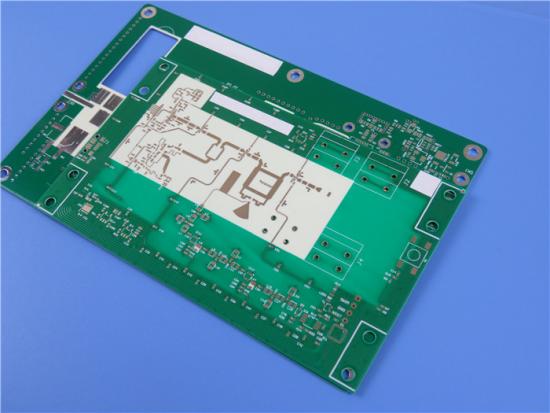

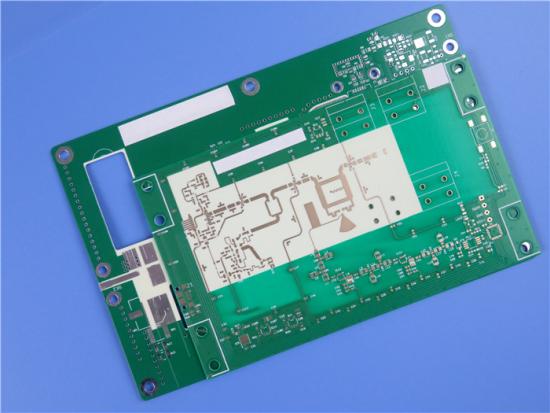

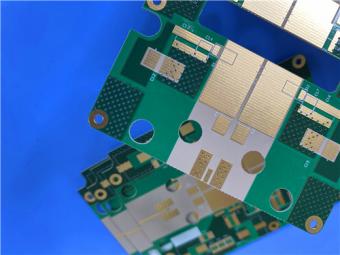

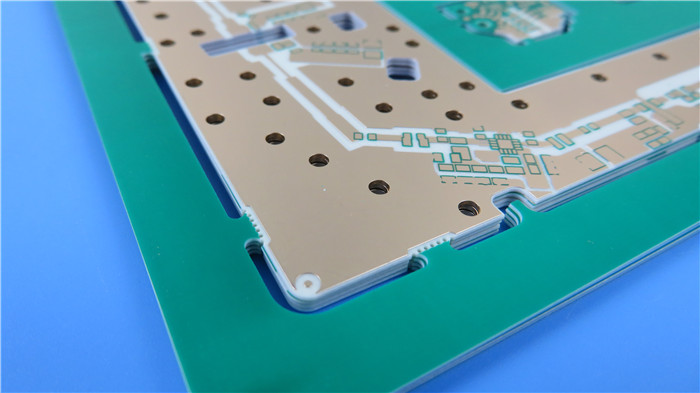

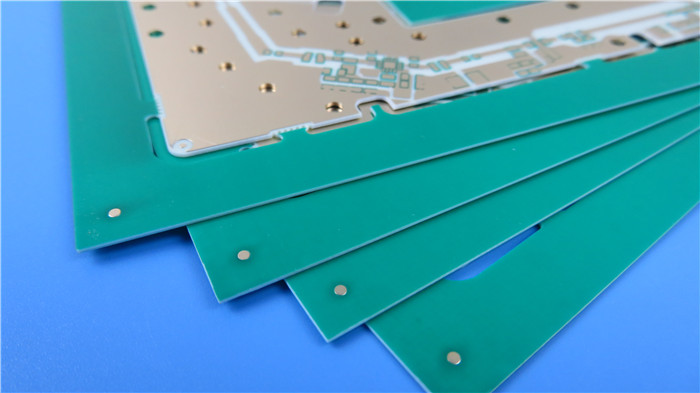

RO4360 RF PCB 12mil Double Sided High Frequency PCB with Immersion Gold for

Base Station Power Amplifiers

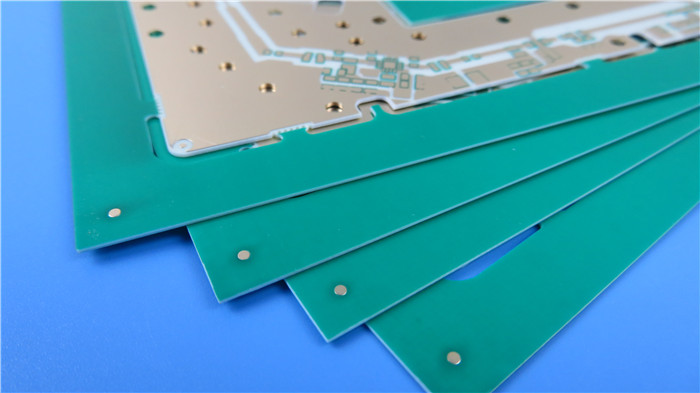

RO4360G2 laminates extend Rogers' portfolio

of high performance materials by providing customers with a product that is

lead-free process capable and offers better rigidity for improved

processability in multi-layer board constructions, while reducing material and

fabrication costs.

RO4360G2

laminates process similar to FR-4 and are automated assembly compatible. They

have a low Z-axis CTE for design flexibility and have the same high Tg as all

of the RO4000 product line. RO4360G2 laminates can be paired with RO4450F

prepreg and lower-Dk RO4000 laminate in multi-layer designs.

RO4360G2

laminates, with a Dk of 6.15 (Design Dk 6.4), allow designers to reduce circuit

dimensions in applications where size and cost are critical. They are the best

value choice for engineers working on designs including power amplifiers, patch

antennas, ground-based radar, and other general RF applications.

Features

and benefits:

1.

Thermoset resin system specially formulated to meet 6.15 Dk

1).

Ease of fabrication / processes similar to FR-4

2).

Material repeatability

3).

Low loss

4). High

thermal conductivity

5).

Lower total PCB cost solution than competing PTFE products,

2.

Low Z-axis CTE / High Tg

1).

Design flexibility

2).

Plated through-hole reliability

3).

Automated assembly compatible

3.

Environmentally friendly

1.)

Lead free process compatible

4.

Regional finished goods inventory

1).

Short lead times / quick inventory turns

2).

Efficient supply chain

Some

Typical Applications:

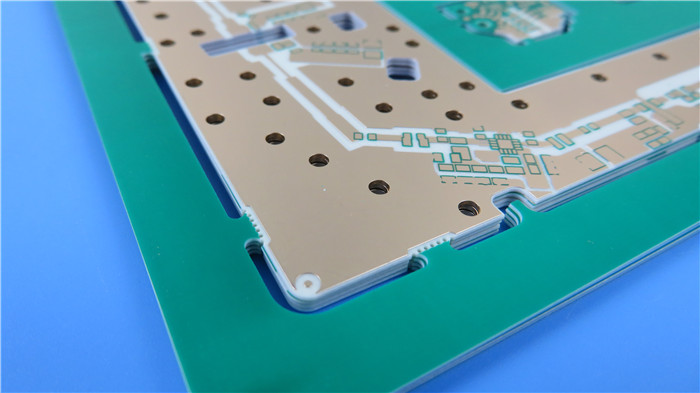

PCB Capability:

|

PCB Capability (RO4360G2)

|

|

PCB Material:

|

Hydrocarbon Ceramic-filled Thermoset

Materials

|

|

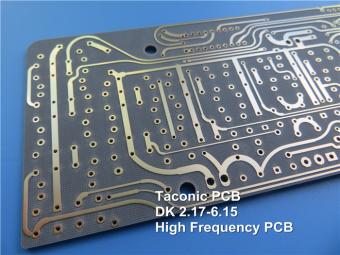

Designation:

|

RO4360G2

|

|

Dielectric constant:

|

6.15 ±0.15

|

|

Layer count:

|

Double Layer, Multilayer, Hybrid PCB

|

|

Copper

weight:

|

0.5oz (17 µm), 1oz (35µm), 2oz (70µm)

|

|

PCB thickness:

|

8mil (0.203mm), 12mil (0.705mm), 16mil

(0.406mm), 20mil(0.508mm), 24mil (0.610mm), 32mil (0.813mm), 60mil(1.524mm)

|

|

PCB size:

|

≤400mm X 500mm

|

|

Solder mask:

|

Green, Black, Blue,

Yellow, Red etc.

|

|

Surface

finish:

|

Bare copper, HASL,

ENIG, OSP etc..

|

Data

Sheet of RO4360G2:

|

RO4360G2

Typical Value

|

|

Property

|

RO4360G2

|

Direction

|

Units

|

Condition

|

Test Method

|

|

Dielectric Constant,εProcess

|

6.15±0.15

|

Z

|

|

10 GHz/23℃

|

IPC-TM-650

2.5.5.5

|

|

2.5 GHz/23℃

|

|

Dissipation Factor,tanδ

|

0.0038

|

Z

|

|

10

GHz/23℃

|

IPC-TM-650 2.5.5.5

|

|

Thermal

Conductivity

|

0.75

|

|

W/mK

|

50℃

|

ASTM D-5470

|

|

Volume Resistivity

|

4.0 X 1013

|

|

Ω.cm

|

Elevated T

|

IPC-TM-650 2.5.17.1

|

|

Surface Resistivity

|

9.0 X 1012

|

|

Ω

|

Elevated T

|

IPC-TM-650 2.5.17.1

|

|

Electrical Strength

|

784

|

Z

|

V/mil

|

|

IPC-TM-650 2.5.6.2

|

|

Tensile Strength

|

131

(19) 97(14)

|

X Y

|

MPa (kpsi)

|

40 hrs 50%RH/23

|

ASTM D638

|

|

Flexural Strength

|

213(31) 145(21)

|

X Y

|

Mpa (kpsi)

|

40 hrs 50%RH/23

|

IPC-TM-650, 2.4.4

|

Coefficient of Thermal Expansion

|

13 14 28

|

X Y Z

|

ppm/℃

|

-50℃to 288℃

After Replicated Heat Cycle

|

IPC-TM-650, 2.1.41

|

|

Tg

|

>280

|

|

℃ TMA

|

|

IPC-TM-650 2.4.24.3

|

|

Td

|

407

|

|

℃

|

|

ASTM D3850 using TGA

|

|

T288

|

>30

|

Z

|

min

|

30

min / 125℃Prebake

|

IPC-TM-650 2.2.24.1

|

|

Moisure Absorption

|

0.08

|

|

%

|

50℃/48hr

|

IPC-TM-650 2.6.2.1

ASTM D570

|

|

Thermal Coefficient of er

|

-131 @10 GHz

|

Z

|

ppm/℃

|

-50℃to 150℃

|

IPC-TM-650, 2.5.5.5

|

|

Density

|

2.16

|

|

gm/cm3

|

RT

|

ASTM D792

|

|

Copper Peel Stength

|

5.2 (0.91)

|

|

pli (N/mm)

|

Condtion B

|

IPC-TM-650 2.4.8

|

|

Flammability

|

V-0

|

|

|

|

UL 94 File QMTS2.

E102765

|

BICHENG PCB WORKSHOP:

BICHENG PCB CERTIFICATE:

BICHENG MIAN COURIERS:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com