RF-10

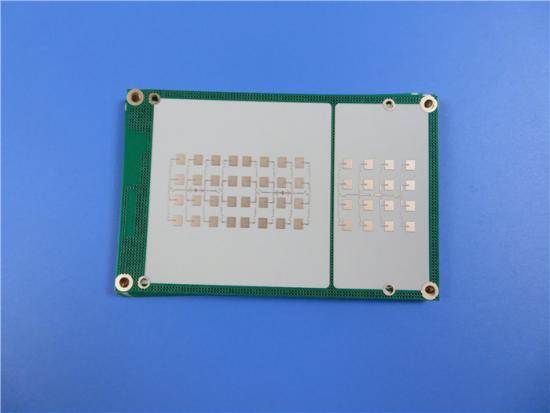

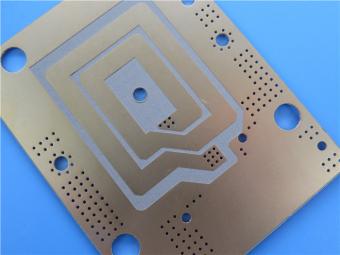

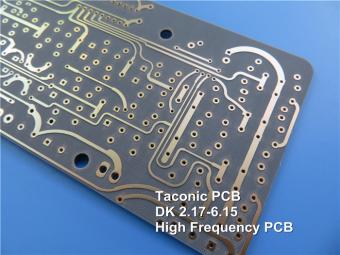

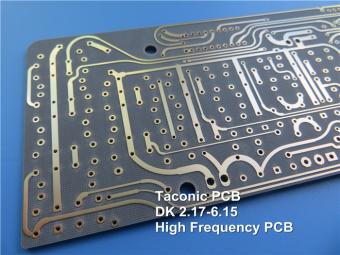

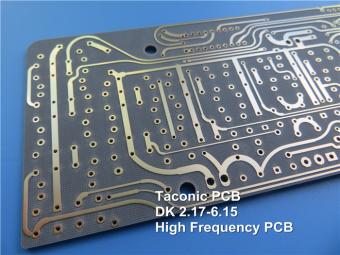

Printed Circuit Board 10mil 20mil 60mil Taconic RF-10 High Frequency PCB Low

Loss High DK RF PCB

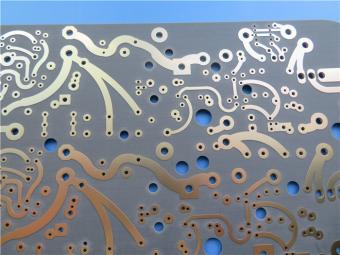

(Printed

Circuit Boards are custom-made products, the picture and parameters shown are

just for reference)

General

Description

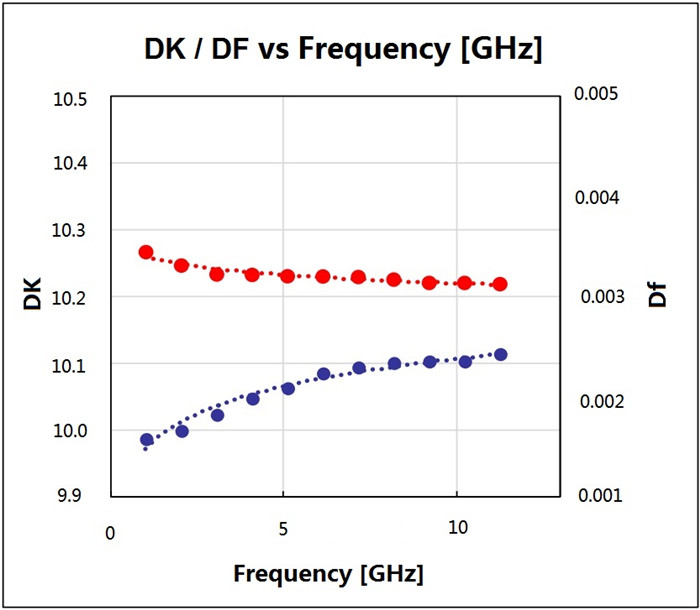

Taconic's

RF-10 laminates are composites of ceramic filled PTFE and woven fiberglass,

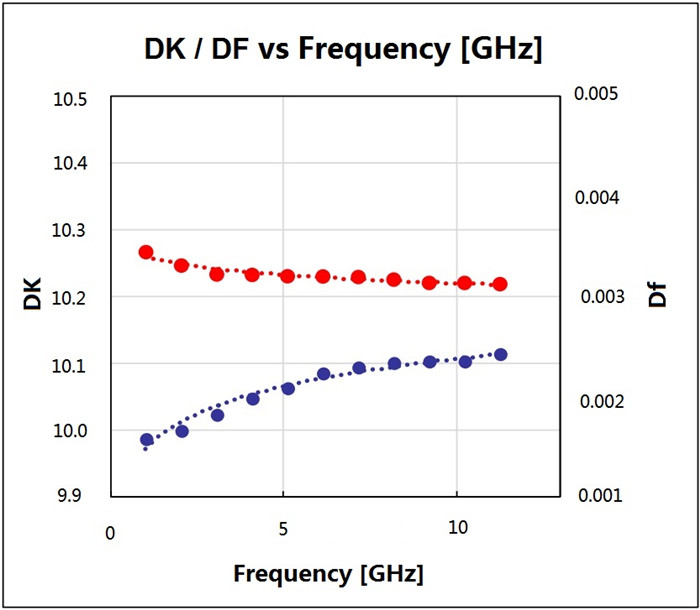

which have the advantage of high dielectric constant (10.2 10GHz) and low

dissipation factor (0.0025 10GHz). Thin woven fiberglass reinforcement is used

to offer both low dielectric loss and improved rigidity for ease of handling

and improved dimensional stability for multilayer circuits.

RF-10 bonds well to

smooth low profile copper too. The low dissipation combined with the use of

very smooth copper results in optimal insertion losses at higher frequency

where skin effect losses play a substantial role.

Features

Benefits

1.Excellent adhesion to smooth coppers

2.Excellent dimensional stability

3.Excellent price/performance ratio

4.High thermal conductivity for enhanced

thermal management

5.High DK for RF circuit size reduction

6.Low 0.0025 loss tangent @ 10 GHz

7.Low X, Y, Z expansion

8.Tight DK tolerance (10.2 +/-0.3)

Typical

Applications

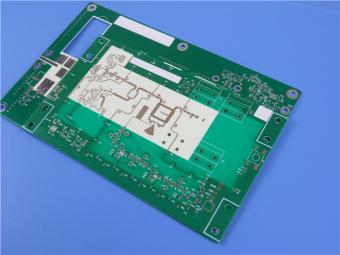

1.Aircraft Collision Avoidance Systems

2.GPS Antennas

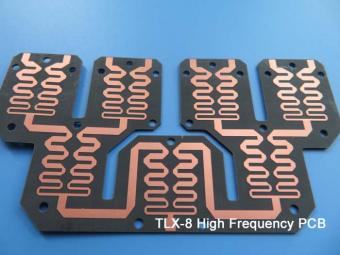

3.Microstrip Patch Antennas

4.Passive Components (filters, couplers,

power dividers)

5.Satellite Components

Our

PCB Capability (RF-10)

|

PCB Capability (RF-10)

|

|

PCB Material:

|

Composites of

Ceramic Filled PTFE and Woven Fiberglass

|

|

Designation:

|

RF-10

|

|

Dielectric constant:

|

10.2

|

|

Dissipation Factor

|

0.0025 10GHz

|

|

Layer count:

|

Double Sided PCB, Multilayer PCB, Hybrid PCB

|

|

Copper

weight:

|

0.5oz (17 µm), 1oz (35µm), 2oz (70µm)

|

|

PCB thickness:

|

10mil

(0.254mm), 20mil (0.508mm), 25mil (0.635mm), 60mil (1.524mm ), 125mil ( 3.175mm )

|

|

PCB size:

|

≤400mm X 500mm

|

|

Solder mask:

|

Green, Black, Blue,

Yellow, Red etc.

|

|

Surface

finish:

|

Bare

copper, HASL, ENIG, Immersion silver, Immersion tin, OSP etc..

|

RF-10

Typical Values

|

RF-10

Typical Values

|

|

Property

|

Test Method

|

Unit

|

Value

|

Unit

|

Value

|

|

Dk @ 10 GHz

|

IPC-650 2.5.5.5.1

Mod.

|

|

10.2±0.3

|

|

10.2±0.3

|

|

Df @ 10 GHz

|

IPC-650 2.5.5.5.1

Mod.

|

|

0.0025

|

|

0.0025

|

|

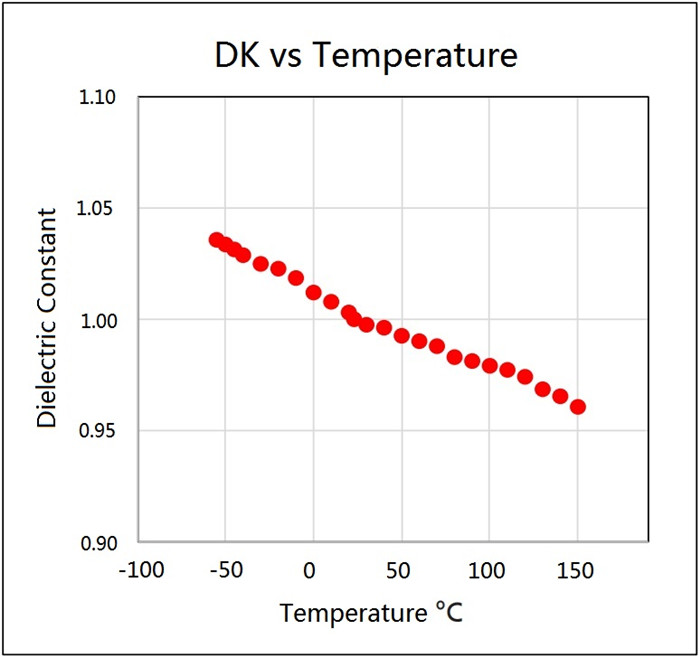

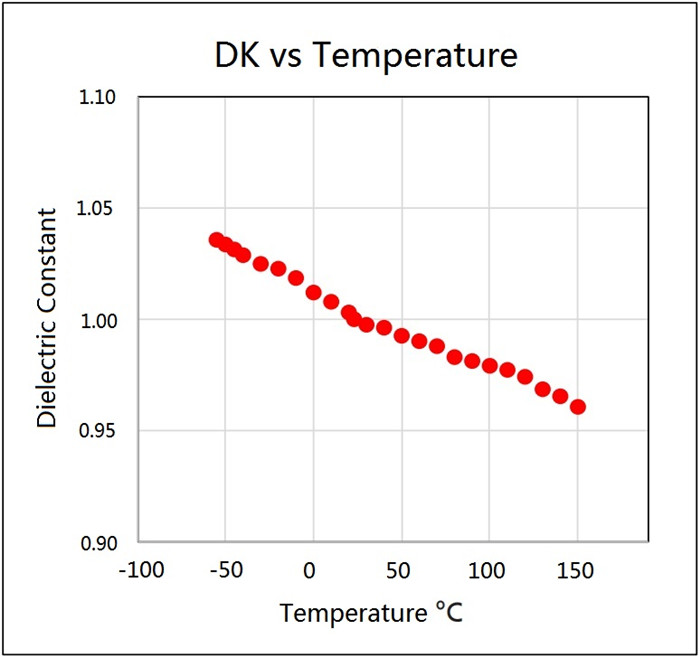

TcK†(-55 to 150 °C)

|

IPC-650 2.5.5.6

|

ppm/°C

|

-370

|

ppm/°C

|

-370

|

|

Moisture

Absorption

|

IPC-650 2.6.2.1

|

%

|

0.08

|

%

|

0.08

|

|

Peel Strength(1 oz. RT copper)

|

IPC-650 2.4.8

(solder)

|

lbs/in

|

10

|

N/mm

|

1.7

|

|

Volume

Resistivity

|

IPC-650 2.5.17.1

|

Mohm/cm

|

6.0 x 107

|

Mohm/cm

|

6.0 x 107

|

|

Surface

Resistivity

|

IPC-650 2.5.17.1

|

Mohm

|

1.0 x 108

|

Mohm

|

1.0 x 108

|

|

Flexural

Strength(MD)

|

IPC - 650 - 2.4.4

|

psi

|

14,000

|

N/mm2

|

96.53

|

|

Flexural

Strength(CD)

|

IPC - 650 - 2.4.4

|

psi

|

10,000

|

N/mm2

|

68.95

|

|

Tensile

Strength(MD)

|

IPC - 650 - 2.4.19

|

psi

|

8,900

|

N/mm2

|

62.57

|

|

Tensile

Strength(CD)

|

IPC - 650 - 2.4.19

|

psi

|

5,300

|

N/mm2

|

37.26

|

|

Dimensional

Stability

|

IPC-650 2.4.39(After Etch)

|

% (25 mil-MD)

|

-0.0032

|

% (25 mil-CD)

|

-0.0239

|

|

Dimensional

Stability

|

IPC-650 2.4.39(After Bake)

|

% (25 mil-MD)

|

-0.0215

|

% (25 mil-CD)

|

-0.0529

|

|

Dimensional

Stability

|

IPC-650 2.4.39(After Stress)

|

% (25 mil-MD)

|

-0.0301

|

% (25 mil-CD)

|

-0.0653

|

|

Dimensional

Stability

|

IPC-650 2.4.39(After Etch)

|

% (60 mil-MD)

|

-0.0027

|

% (60 mil-CD)

|

-0.0142

|

|

Dimensional

Stability

|

IPC-650 2.4.39(After Bake)

|

% (60 mil-MD)

|

-0.1500

|

% (60 mil-CD)

|

-0.0326

|

|

Dimensional

Stability

|

IPC-650 2.4.39(After Stress)

|

% (60 mil-MD)

|

-0.0167

|

% (60 mil-CD)

|

-0.0377

|

|

Density(Specific Gravity)

|

IPC-650-2.3.5

|

g/cm3

|

2.77

|

g/cm3

|

2.77

|

|

Specific Heat

|

IPC-650-2.4.50

|

J/g°C

|

0.9

|

J/g°C

|

0.9

|

|

Thermal

Conductivity(Unclad)

|

IPC-650-2.4.50

|

W/M*K

|

0.85

|

W/M*K

|

0.85

|

|

CTE (X -Y

axis)(50 to 150 °C)

|

IPC-650 2.4.41

|

ppm/°C

|

16-20

|

ppm/°C

|

16-20

|

|

CTE (Z axis)(50 to 150 °C)

|

IPC-650 2.4.41

|

ppm/°C

|

25

|

ppm/°C

|

25

|

|

Flammability

Rating

|

Internal

|

|

V-0

|

|

V-0

|

BICHNEG PCB WORKSHOP:

BICHNEG PCB CERTIFICATION:

BICHENG PCB MAIN COURIERS:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com