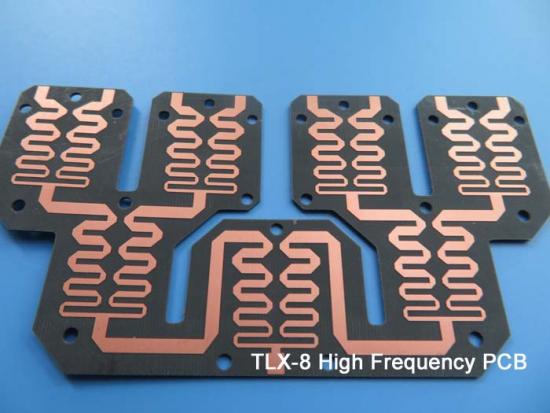

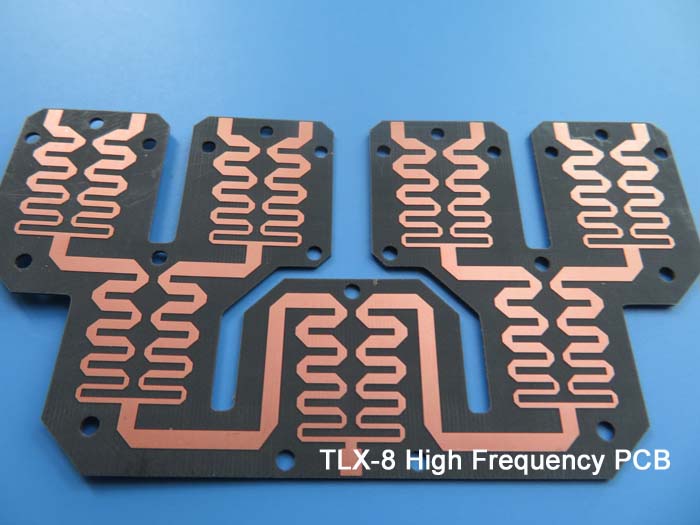

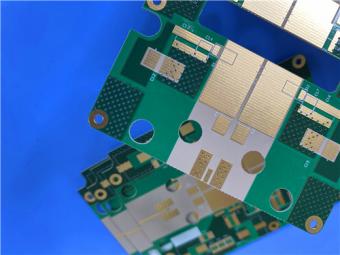

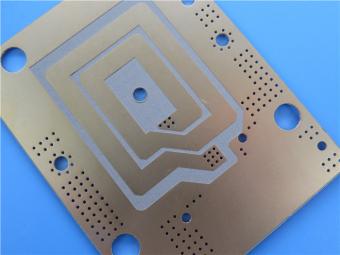

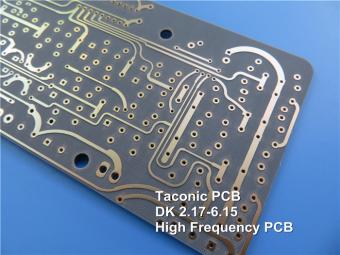

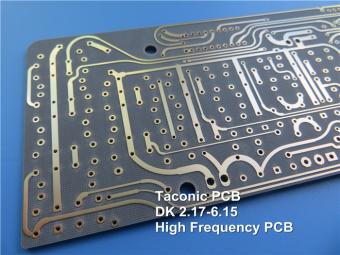

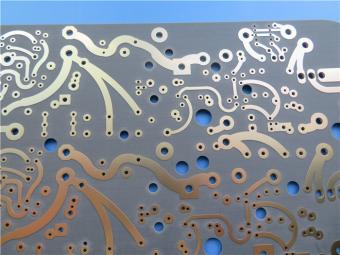

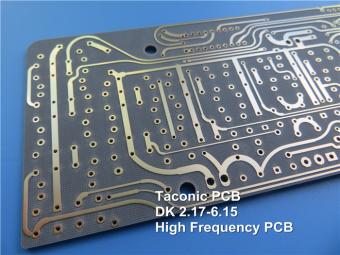

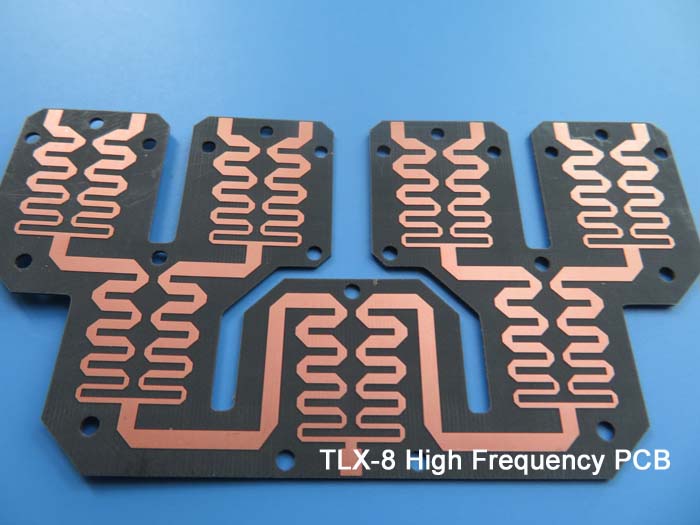

Taconic High Frequency PCB Buitl on TLX-8 62mil

1.575mm with OSP for Directional Couplers

(Printed

Circuit Boards are custom-made products, the picture and parameters shown are

just for reference)

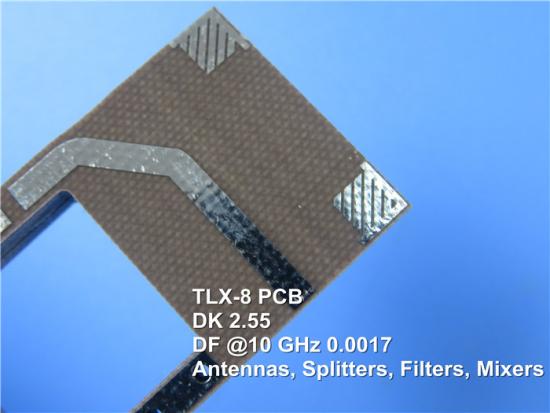

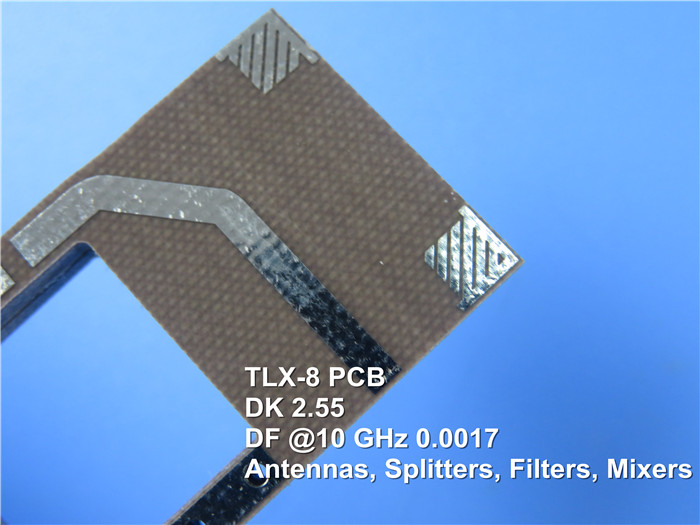

TLX offers reliability in a wide range of RF

applications. This material is versatile due to its 2.45 - 2.65 DK range and

available thicknesses and copper cladding. It is suitable for low layer count

microwave designs.

TLX is a workhorse in the RF microwave

substrate world where the fiberglass offers mechanical reinforcement wherever a

substrate experiences severe environments such as: resistance to creep for PCBs

bolted to a housing that encounter high levels of vibration during space

launch, high temperature exposure in engine modules, radiation resistance in

space, antenna for warships that undergo extreme environments at sea and a

substrate for altimeters that see a wide range of temperatures during flight.

There're TLX-0 (dk2.45), TLX-9 (dk2.50), TLX-8

(dk2.55), TLX-7 (dk2.60) and TLX-6 (dk2.65) in the TLX family. Dielectric

thickness of TLX-0 ranges from 0.127mm to 6.35mm (5mil-250mil), TLX-9 ranges

from 0.05mm to 6.35mm (2mil - 250mil), TLX-8 ranges from 0.064mm to 6.35mm

(2.5mil to 250mil), TLX-7 ranges from 0.089mm to 6.35mm (3.5mil - 250mil),

TLX-6 ranges from 0.089mm to 6.35mm (3.5mil to 250mil).

Benefits:

Excellent mechanical & thermal properties

Low & stable DK

Dimensionally stable

Low moisture absorption

UL 94 V-O rating

Tightly controlled DK

Low DF

For low layer count microwave designs

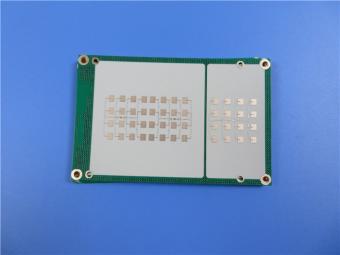

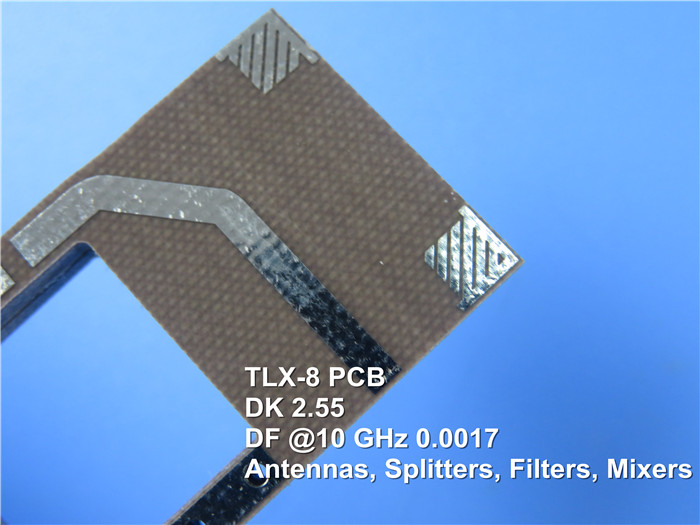

Applications:

Antennas

Couplers, Splitters, Combiners,

Amplifiers, Mixers, Filters

Passive components

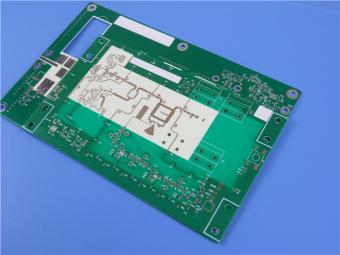

PCB Specifications:

|

PCB SIZE

|

99 x 88mm=1PCS

|

|

BOARD TYPE

|

Double

sided PCB

|

|

Number

of Layers

|

2 layers

|

|

Surface

Mount Components

|

YES

|

|

Through

Hole Components

|

NO

|

|

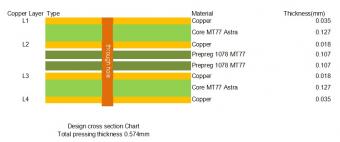

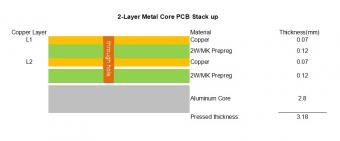

LAYER STACKUP

|

copper

------- 35um(1 oz)+plate TOP layer

|

|

TLX-8 1.575mm

|

|

copper ------- 35um(1oz) + plate BOT Layer

|

|

TECHNOLOGY

|

|

|

Minimum Trace and Space:

|

15

mil / 10 mil

|

|

Minimum

/ Maximum Holes:

|

0.5mm/2.0mm

|

|

Number

of Different Holes:

|

N/A

|

|

Number

of Drill Holes:

|

N/A

|

|

Number

of Milled Slots:

|

0

|

|

Number

of Internal Cutouts:

|

0

|

|

Impedance

Control:

|

no

|

|

Number

of Gold finger:

|

0

|

|

BOARD

MATERIAL

|

|

|

Glass

Epoxy:

|

TLX-8

1.575mm

|

|

Final

foil external:

|

1

oz

|

|

Final

foil internal:

|

N/A

|

|

Final

height of PCB:

|

1.6

mm ±10%

|

|

PLATING AND COATING

|

|

|

Surface Finish

|

OSP

|

|

Solder

Mask Apply To:

|

N/A

|

|

Solder

Mask Color:

|

N/A

|

|

Solder

Mask Type:

|

N/A

|

|

CONTOUR/CUTTING

|

Routing

|

|

MARKING

|

|

|

Side of

Component Legend

|

N/A

|

|

Colour

of Component Legend

|

N/A

|

|

Manufacturer

Name or Logo:

|

N/A

|

|

VIA

|

N/A

|

|

FLAMIBILITY RATING

|

UL

94-V0 Approval MIN.

|

|

DIMENSION TOLERANCE

|

|

|

Outline

dimension:

|

0.0059"

|

|

Board

plating:

|

0.0029"

|

|

Drill

tolerance:

|

0.002"

|

|

TEST

|

100%

Electrical Test prior shipment

|

|

TYPE OF ARTWORK TO BE SUPPLIED

|

email

file, Gerber RS-274-X, PCBDOC etc

|

|

SERVICE AREA

|

Worldwide,

Globally.

|

Data Sheet of TLX-8:

|

TLX-8

TYPICAL VALUES

|

|

Property

|

Test Method

|

Unit

|

Value

|

Unit

|

Value

|

|

DK @10 GHz

|

IPC-650 2.5.5.3

|

|

2.55

|

|

2.55

|

|

Df @1.9 GHz

|

IPC-650 2.5.5.5.1

|

|

0.0012

|

|

0.0012

|

|

Df @10 GHz

|

IPC-650 2.5.5.5.1

|

|

0.0017

|

|

0.0017

|

|

Dielectric

Breakdown

|

IPC-650 2.5.6

|

kV

|

>45

|

kV

|

>45

|

|

Moisture

Absorption

|

IPC-650 2.6.2.1

|

%

|

0.02

|

%

|

0.02

|

|

Flexural

Strength(MD)

|

ASTM D 709

|

psi

|

28,900

|

N/mm2

|

|

|

Flexural

Strength(CD)

|

ASTM D 709

|

psi

|

20,600

|

N/mm2

|

|

|

Tensile

Strength(MD)

|

ASTM D 902

|

psi

|

35,600

|

N/mm2

|

|

|

Tensile

Strength(CD)

|

ASTM D 902

|

psi

|

27,500

|

N/mm2

|

|

|

Elongation at

Break(MD)

|

ASTM D 902

|

%

|

3.94

|

%

|

3.94

|

|

Elongation at

Break(CD)

|

ASTM D 902

|

%

|

3.92

|

%

|

3.92

|

|

Young's

Modulus(MD)

|

ASTM D 902

|

kpsi

|

980

|

N/mm2

|

|

|

Young's

Modulus(CD)

|

ASTM D 902

|

kpsi

|

1,200

|

N/mm2

|

|

|

Young's

Modulus(MD)

|

ASTM D 3039

|

kpsi

|

1,630

|

N/mm2

|

|

|

Poisson's

Ratio

|

ASTM D 3039

|

|

0.135

|

N/mm

|

|

|

Peel

Stength(1 oz.ed)

|

IPC-650 2.4.8

Sec.5.2.2(Thermal Stress.)

|

Ibs./linear inch

|

15

|

N/mm

|

|

|

Peel

Stength(1 oz.RTF)

|

IPC-650 2.4.8

Sec.5.2.2(Thermal Stress.)

|

Ibs./linear inch

|

17

|

N/mm

|

|

|

Peel

Stength(½ oz.ed)

|

IPC-650

2.4.8.3(Elevated Temp.)

|

Ibs./linear inch

|

14

|

N/mm

|

|

|

Peel

Stength(½ oz.ed)

|

IPC-650 2.4.8

Sec.5.2.2(Thermal Stress.)

|

Ibs./linear inch

|

11

|

N/mm

|

|

|

Peel

Stength(1 oz.rolled)

|

IPC-650 2.4.8

Sec.5.2.2(Thermal Stress.)

|

Ibs./linear inch

|

13

|

N/mm

|

2.1

|

|

Thermal

Conductivity

|

ASTM F433/ASTM

1530-06

|

W/M*K

|

0.19

|

W/M*K

|

0.19

|

|

Dimensional

Stability(MD)

|

IPC-650 2.4.39

Sec.5.5(After Bake.)

|

mils/in.

|

0.06

|

mm/M

|

|

|

Dimensional

Stability(CD)

|

IPC-650 2.4.39

Sec.5.4(After Bake.)

|

mils/in.

|

0.08

|

mm/M

|

|

|

Dimensional

Stability(MD)

|

IPC-650 2.4.39

Sec.5.5(Thermal Stress.)

|

mils/in.

|

0.09

|

mm/M

|

|

|

Dimensional

Stability(CD)

|

IPC-650 2.4.39

Sec.5.5(Thermal Stress.)

|

mils/in.

|

0.1

|

mm/M

|

|

|

Surface

Resistivity

|

IPC-650 2.5.17.1

Sec.5.2.1(Elevated Temp.)

|

Mohm

|

6.605 x 108

|

Mohm

|

6.605 x 108

|

|

Surface

Resistivity

|

IPC-650 2.5.17.1

Sec.5.2.1(Humidity Cond.)

|

Mohm

|

3.550 x 106

|

Mohm

|

3.550 x 106

|

|

Volume

Resistivity

|

IPC-650 2.5.17.1

Sec.5.2.1(Elevated Temp.)

|

Mohm/cm

|

1.110 x 1010

|

Mohm/cm

|

1.110 x 1010

|

|

Volume

Resistivity

|

IPC-650 2.5.17.1

Sec.5.2.1(Humidity Cond.)

|

Mohm/cm

|

1.046 x 1010

|

Mohm/cm

|

1.046 x 1010

|

|

CTE(X

axis)(25-260℃)

|

IPC-650 2.4.41/ASTM D

3386

|

ppm/℃

|

21

|

ppm/℃

|

21

|

|

CTE(Y

axis)(25-260℃)

|

IPC-650 2.4.41/ASTM D

3386

|

ppm/℃

|

23

|

ppm/℃

|

23

|

|

CTE(Z

axis)(25-260℃)

|

IPC-650 2.4.41/ASTM D

3386

|

ppm/℃

|

215

|

ppm/℃

|

215

|

|

Density(Specific

Gravity)

|

ASTM D 792

|

g/cm3

|

2.25

|

g/cm3

|

2.25

|

|

Td(2% Weight Loss)

|

IPC-650 2.4.24.6(TGA)

|

℃

|

535

|

℃

|

|

|

Td(5% Weight Loss)

|

IPC-650 2.4.24.6(TGA)

|

℃

|

553

|

℃

|

|

|

Flammability

Rating

|

UL-94

|

|

V-0

|

|

V-0

|

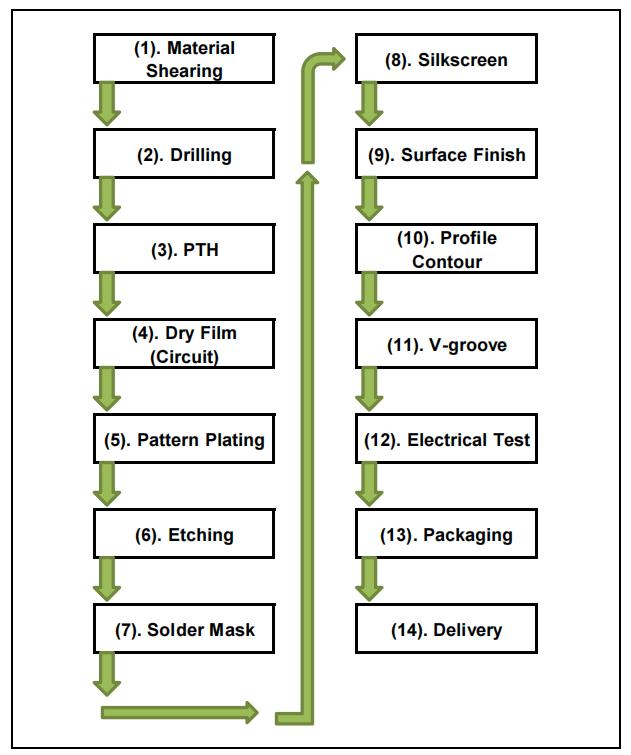

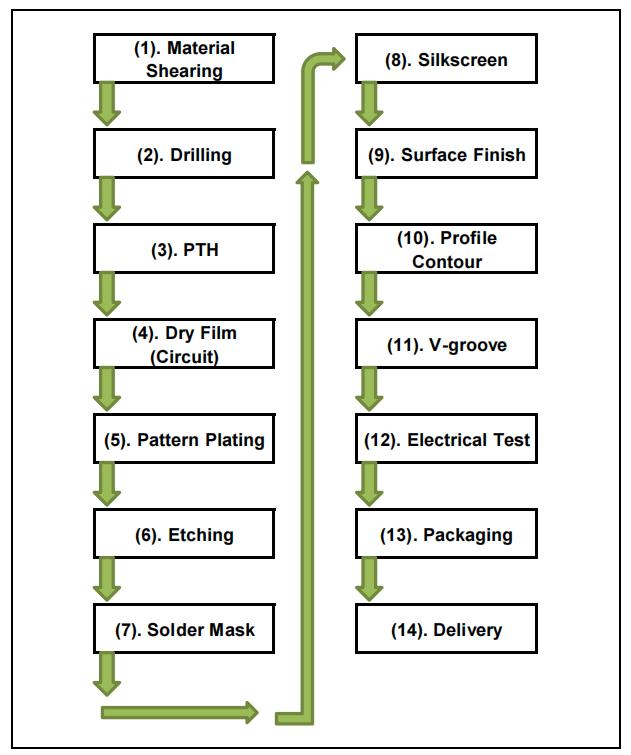

MANUFACTURING PROCESS:

BICHENG PCB EQUIPMENT:

BICHENG PCB CERTIFICATION:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com