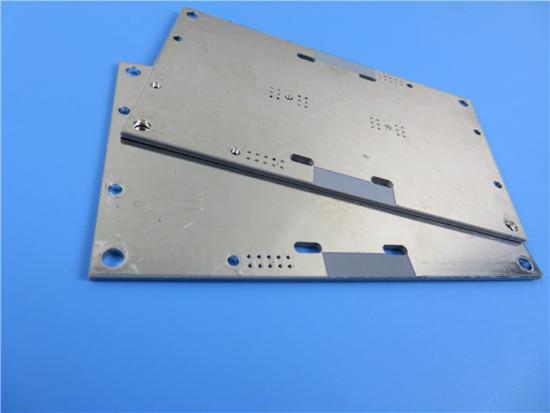

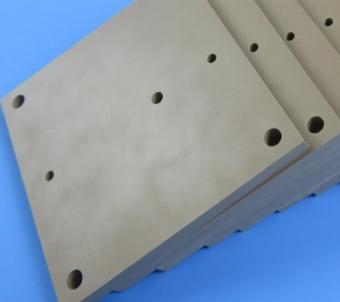

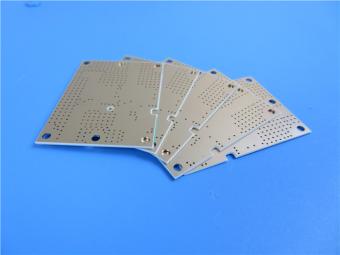

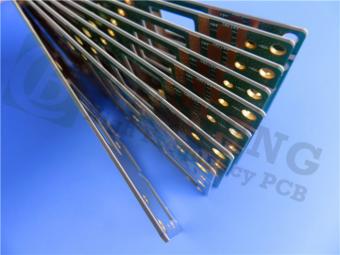

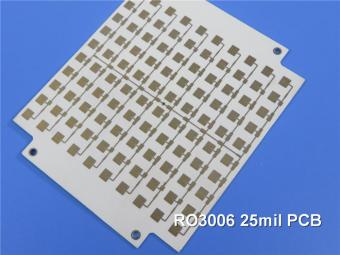

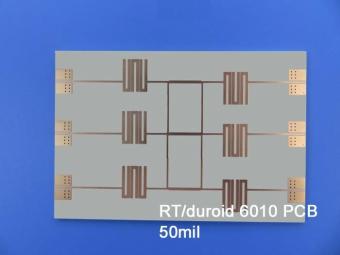

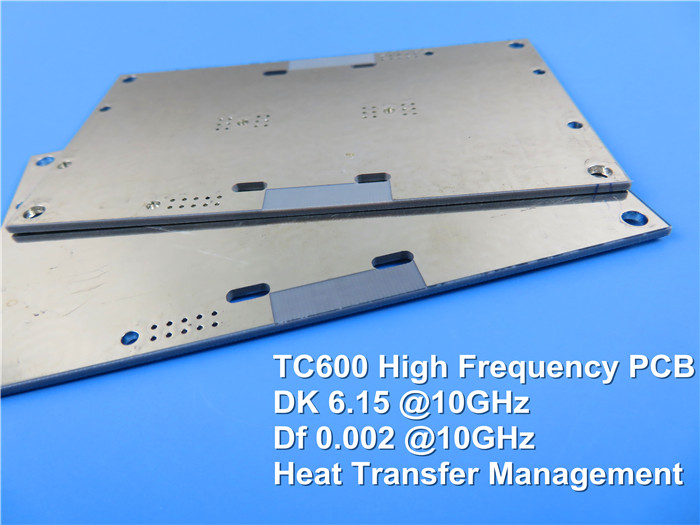

TC600 Microwave PCB with 15mil 20mil

30mil 50mil 60mil Thickness TC600 High Frequency PCB with Immersion Silver

(Printed

Circuit Boards are custom-made products, the picture and parameters shown are

just for reference)

General

Description:

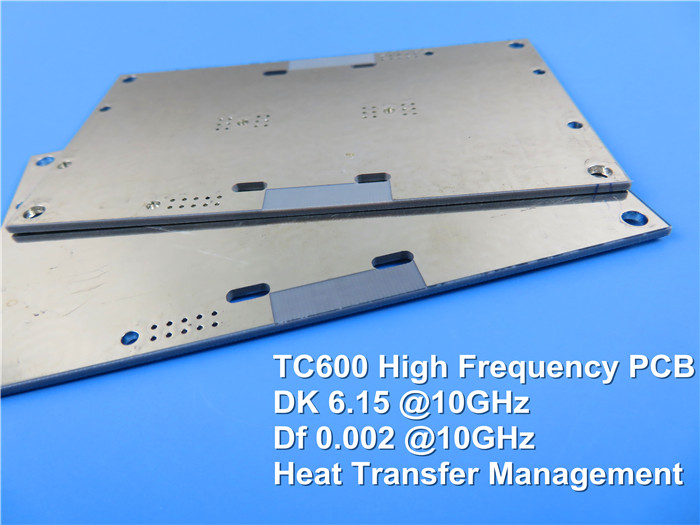

Rogers'

(Arlon) TC600 is a woven fiberglass reinforced, enhanced thermal conductivity

ceramic filled, PTFE-based composite. The increased thermal conductivity (1.1

W/mk) provides higher power handling, reduces hot-spots and improves device

reliability. Lower losses result in higher amplifier and antenna gains/efficiencies. Stable dielectric constant is across a wide temperature

range (-75 ppm/oC -40°C to 140°C). It helps power amplifier and antenna

designers maximize gain and minimize dead bandwidth lost to dielectric constant

drift as operating temperature changes. It has low Z-Direction CTE and

mechanical robustness is also greatly improved for the 6.15 dielectric constant market.

Features

1.

Very Low Loss Tangent (0.002 at 10 GHz) provides Higher Amplifier or Antenna

Efficiency

2.

Mechanically Robustness improves processing and reliability, replaces brittle

laminates that cannot withstand processing, impact or High Gain forces

3.

Low coefficient of thermal expansion on X,Y and Z axis (9, 9 and 35 ppm/°C)

matches active components for low stress solder joints

4.

High Peel Strength for Reliable narrow lines

Benefits

1.

Reduced Heat Generated through Transmission Line Loss

2.

Heat Dissipation and Management

3.

Replace Ceramic in Some Applications

4.

Large Panel Sizes for Multiple Circuit Layout for lowered Processing Costs

Our

PCB Capability (TC600)

|

PCB

Material:

|

Ceramic Filled

PTFE/Woven Fiberglass

|

|

Designation:

|

TC600

|

|

Dielectric constant:

|

6.15 (10 GHz)

|

|

Dissipation Factor

|

0.002 (10 GHz)

|

|

Layer count:

|

Double Sided PCB, Multilayer PCB, Hybrid PCB

|

|

Copper

weight:

|

0.5oz (17 µm), 1oz (35µm), 2oz (70µm)

|

|

Dielectric

thickness:

|

15mil

(0.381mm), 20mil (0.508mm), 25mil (0.635mm), 30mil (0.762mm), 50mil (1.27mm),

60mil (1.524mm), 75mil (1.905mm), 100mil (2.54mm), 125mil (3.175mm), 150mil

(3.81mm), 200mil (5.08mm), 250mil

(6.35mm), 275mil (6.985mm), 500mil (12.7mm)

|

|

PCB size:

|

≤400mm X 500mm

|

|

Solder mask:

|

Green, Black, Blue,

Yellow, Red etc.

|

|

Surface

finish:

|

Bare

copper, HASL, ENIG, Immersion silver, Immersion tin, OSP, Pure gold plated

etc..

|

Typical

Applications:

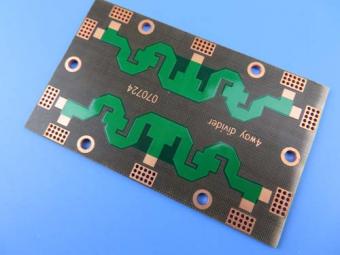

1.

Digital Audio Broadcasting (DAB) Antennas (Satellite Radio)

2.

GPS & Hand-held RFID Reader Antennas

3.

Microwave Combiner and Power Divider Boards in Avionics Applications

4.

Power Amplifiers, Filters and Couplers

5.

Small Footprint Antennas

Appendix:

Typical Properties TC600

|

Property

|

Unit

|

Value

|

Test Method

|

|

1. Electrical Properties

|

|

Dielectric Constant (may vary by thickness)

|

|

|

|

|

@1.8 MHz

|

-

|

6.15

|

Resonant Cavity

|

|

@10 GHz

|

-

|

6.15

|

IPC TM-650 2.5.5.5

|

|

Dissipation Factor

|

|

|

|

|

@1.8 GHz

|

-

|

0.0017

|

Resonant Cavity

|

|

@10 GHz

|

-

|

0.002

|

IPC TM-650 2.5.5.5

|

|

Temperature Coefficient of Dielectric

|

-

|

|

|

|

TCεr @ 10 GHz (-40-150°C)

|

ppm/ºC

|

-75

|

IPC TM-650 2.5.5.5

|

|

Volume Resistivity

|

|

|

|

|

C96/35/90

|

MΩ-cm

|

1.6x109

|

IPC TM-650 2.5.17.1

|

|

E24/125

|

MΩ-cm

|

2.4x108

|

IPC TM-650 2.5.17.1

|

|

Surface Resistivity

|

|

|

|

|

C96/35/90

|

MΩ

|

3.1x109

|

IPC TM-650 2.5.17.1

|

|

E24/125

|

MΩ

|

9.0x108

|

IPC TM-650 2.5.17.1

|

|

Electrical Strength

|

Volts/mil (kV/mm)

|

850 (34)

|

IPC TM-650 2.5.6.2

|

|

Dielectric Breakdown

|

kV

|

62

|

IPC TM-650 2.5.6

|

|

Arc Resistance

|

sec

|

>240

|

IPC TM-650 2.5.1

|

|

|

|

2. Thermal Properties

|

|

Decomposition Temperature (Td)

|

|

|

|

|

Initial

|

°C

|

512

|

IPC TM-650 2.4.24.6

|

|

5%

|

°C

|

572

|

IPC TM-650 2.4.24.6

|

|

T260

|

min

|

>60

|

IPC TM-650 2.4.24.1

|

|

T288

|

min

|

>60

|

IPC TM-650 2.4.24.1

|

|

T300

|

min

|

>60

|

IPC TM-650 2.4.24.1

|

|

Thermal Expansion, CTE (x,y) 50-150ºC

|

ppm/ºC

|

9, 9

|

IPC TM-650 2.4.41

|

|

Thermal Expansion, CTE (z) 50-150ºC

|

ppm/ºC

|

35

|

IPC TM-650 2.4.24

|

|

% z-axis Expansion (50-260ºC)

|

%

|

1.5

|

IPC TM-650 2.4.24

|

|

|

|

3. Mechanical Properties

|

|

Peel Strength to Copper (1 oz/35 micron)

|

|

|

|

|

After Thermal Stress

|

lb/in (N/mm)

|

10 (1.8)

|

IPC TM-650 2.4.8

|

|

At Elevated Temperatures (150ºC)

|

lb/in (N/mm)

|

10 (1.8)

|

IPC TM-650 2.4.8.2

|

|

After Process Solutions

|

lb/in (N/mm)

|

9 (1.6)

|

IPC TM-650 2.4.8

|

|

Young’s Modulus

|

kpsi (MPa)

|

280 (1930)

|

IPC TM-650 2.4.18.3

|

|

Flexural Strength (Machine/Cross)

|

kpsi (MPa)

|

9.60/9.30 (66/64)

|

IPC TM-650 2.4.4

|

|

Tensile Strength (Machine/Cross)

|

kpsi (MPa)

|

5.0/4.30 (34/30)

|

IPC TM-650 2.4.18.3

|

|

Compressive Modulus

|

kpsi (MPa)

|

|

ASTM D-3410

|

|

Poisson’s Ratio

|

-

|

|

ASTM D-3039

|

|

|

|

4. Physical Properties

|

|

Water Absorption

|

%

|

0.02

|

IPC TM-650 2.6.2.1

|

|

Density, ambient 23ºC

|

g/cm3

|

2.9

|

ASTM D792 Method A

|

|

Thermal Conductivity (z-axis)

|

W/mK

|

1.1

|

ASTM E1461

|

|

Thermal Conductivity (x, y)

|

W/mK

|

1.4

|

ASTM E1461

|

|

Specific Heat

|

J/gK

|

0.94

|

ASTM E1461

|

|

Flammability

|

class

|

V0

|

UL-94

|

|

NASA Outgassing, 125ºC, ≤10-6torr

|

|

|

|

|

Total Mass Loss

|

%

|

0.02

|

NASA SP-R-0022A

|

|

Collected Volatiles

|

%

|

0

|

NASA SP-R-0022A

|

|

Water Vapor Recovered

|

%

|

0

|

NASA SP-R-0022A

|

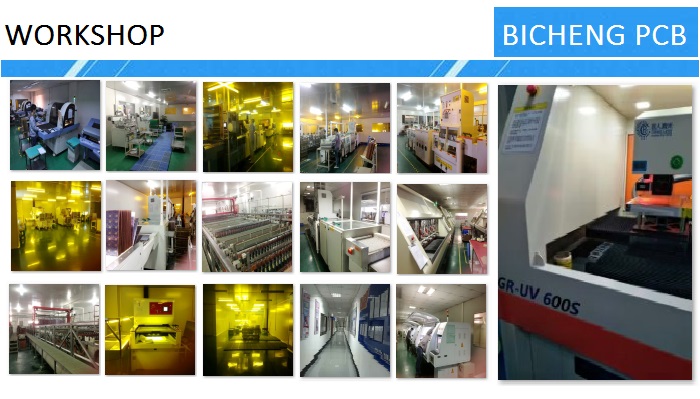

BICHNEG PCB WORKSHOP:

BICHNEG PCB CERTIFICATION:

BICHENG PCB MAIN COURIERS:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com