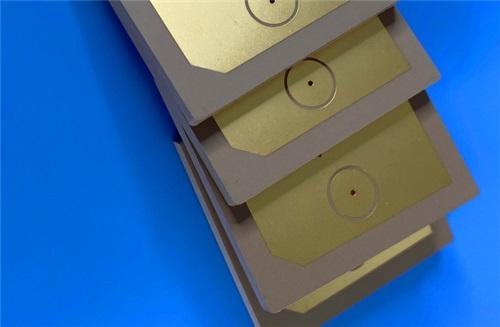

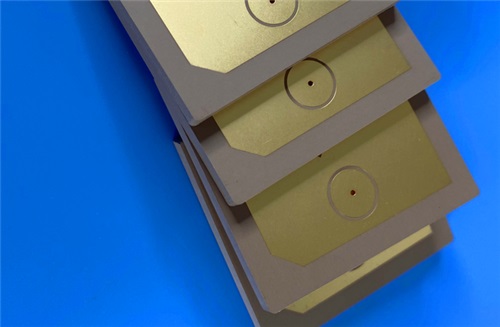

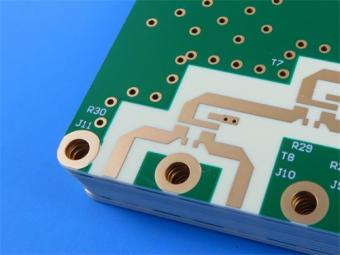

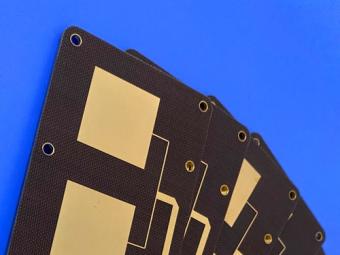

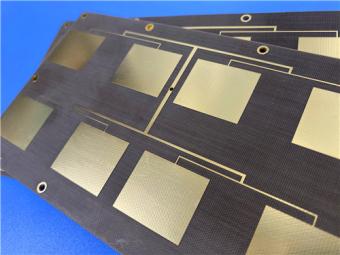

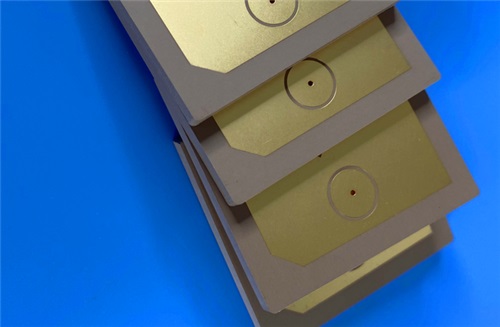

15mil Rogers TMM6 PCB DK6.0 Double-layer ENEPIG 1oz Bare Copper

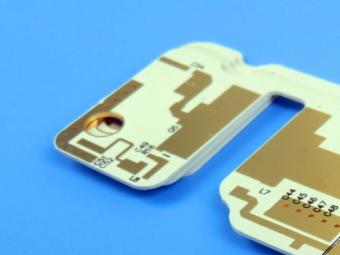

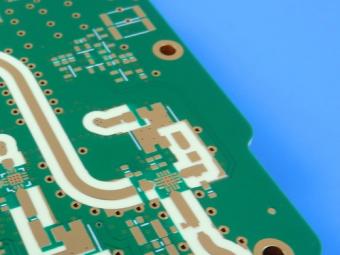

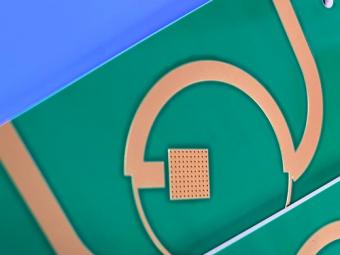

In the demanding world of high-frequency and microwave electronics, the substrate material and construction integrity of a Printed Circuit Board (PCB) are not merely choices but critical determinants of system performance. We present a precision-engineered double-layer DK6.0 PCB crafted from Rogers TMM6, a premier ceramic thermoset composite, designed explicitly for applications where electrical stability, thermal management, and high reliability are non-negotiable. This board exemplifies a perfect synergy between advanced material science and meticulous fabrication, featuring a 15mil (0.381mm) core and an Electroless Nickel Electroless Palladium Immersion Gold (ENEPIG) surface finish. Tailored for strip-line and micro-strip designs, it offers a stable dielectric constant (Dk=6.0) and excellent plated through-hole reliability, making it an ideal, robust foundation for sensitive RF and microwave circuitry.

PCB Construction Details

This table outlines the core physical attributes and manufacturing tolerances of the board, defining its form and fabrication capabilities.

|

Parameter

|

Specification

|

|

Base Material

|

Rogers TMM 6

|

|

Layer Count

|

2 Layers

|

|

Board Dimensions

|

60mm x 96mm (1 PCS), Tolerance: ±0.15mm

|

|

Min. Trace / Space

|

5 mil / 7 mil

|

|

Min. Finished Hole Size

|

0.4 mm

|

|

Blind/Buried Vias

|

No

|

|

Finished Board Thickness

|

0.5 mm

|

|

Finished Cu Weight (Outer)

|

1 oz (35 μm / 1.4 mils)

|

|

Via Plating Thickness

|

20 μm (min)

|

|

Surface Finish

|

ENEPIG

|

|

Top/Bottom Silkscreen

|

No

|

|

Top/Bottom Solder Mask

|

No

|

|

Electrical Test

|

100% Tested

|

PCB Stackup

The stackup defines the material composition and thickness of each layer, which is essential for impedance calculation and signal integrity analysis.

|

Layer

|

Material

|

Thickness

|

|

Layer 1 (Top)

|

Copper

|

35 μm (1 oz)

|

|

Core

|

Rogers TMM 6

|

0.381 mm (15 mil)

|

|

Layer 2 (Bottom)

|

Copper

|

35 μm (1 oz)

|

PCB Statistics

This data quantifies the board's component placement and interconnect density, reflecting its assembly and routing complexity.

|

Item

|

Quantity

|

|

Components

|

20

|

|

Total Pads

|

26

|

|

Thru-Hole Pads

|

9

|

|

Top-Side SMT Pads

|

17

|

|

Bottom-Side SMT Pads

|

0

|

|

Vias

|

16

|

|

Nets

|

2

|

Advanced Material: Rogers TMM6

The heart of this PCB is Rogers TMM6, a ceramic thermoset polymer composite. It bridges the gap between the performance of traditional PTFE materials and the processability of standard epoxy systems. With a tightly controlled dielectric constant (Dk) of 6.00±0.08 at 10 GHz and a low dissipation factor (Df) of 0.0023, it ensures minimal signal loss and consistent phase stability. Its coefficient of thermal expansion (CTE) is matched to copper, dramatically enhancing plated through-hole reliability by minimizing stress during thermal cycling. Furthermore, its high decomposition temperature (Td > 400°C) and resistance to process chemicals make it exceptionally robust during fabrication and assembly, including wire bonding processes enabled by its thermoset resin base.

Key Features & Benefits for Your Application

1) Stable Electrical Performance: The low thermal coefficient of Dk (-11 ppm/°K) ensures consistent electrical properties across a wide temperature range, crucial for outdoor and automotive applications.

2) Enhanced Reliability: Copper-matched CTE (X/Y: 18 ppm/K, Z: 26 ppm/K) and robust thermoset chemistry prevent via cracking and delamination, meeting IPC-Class-2 standards as a minimum.

3) Superior Processability: Unlike some high-frequency materials, TMM6 is compatible with all standard PCB fabrication processes (drilling, plating, etching), reducing manufacturing complexity and cost.

4) Premium Surface Finish–ENEPIG: This finish provides a flat, wire-bondable surface with excellent shelf life. The nickel provides a diffusion barrier, the palladium prevents nickel corrosion ("black pad" syndrome), and the gold ensures superior solderability and contact resistance.

5) Global Availability & Support: Supported by a worldwide supply chain and fabrication network, this board is available for prototyping and volume production.

Typical Applications

This Rogers TMM6 PCB is ideally suited for:

-

RF & Microwave Circuits, Power Amplifiers, and Combiners

-

Filters, Couplers, and Phase Shifters

-

Satellite Communication Subsystems and GPS Antennas

-

Patch Antenna Arrays

-

Dielectric Polarizers, Lenses, and Chip Test Fixtures

Ordering & Documentation

The design is supplied in the universally accepted Gerber RS-274-X format, ensuring accurate and seamless translation from design to production. Every board undergoes 100% electrical testing to verify continuity and isolation, guaranteeing functionality as designed.

This 15mil TMM6 ENEPIG PCB represents a reliable, high-performance solution for engineers pushing the boundaries of frequency and precision. We are confident it will provide the stable foundation required for your most demanding applications.

BICHENG PCB CERTIFICATE:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com