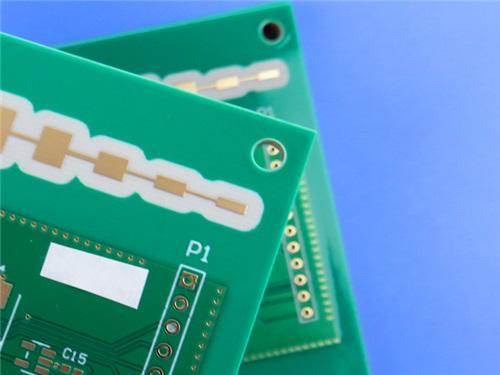

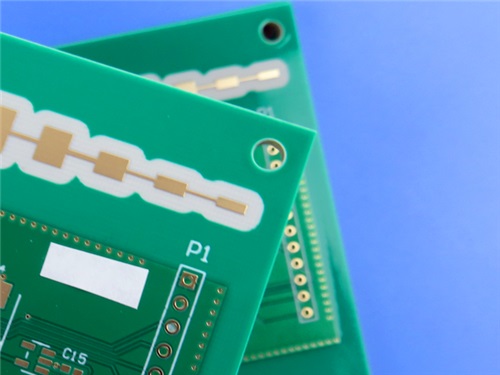

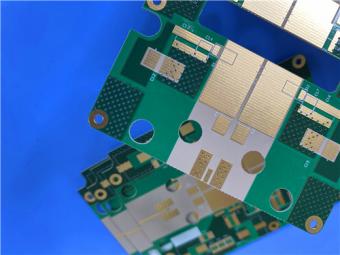

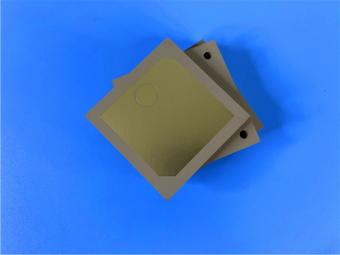

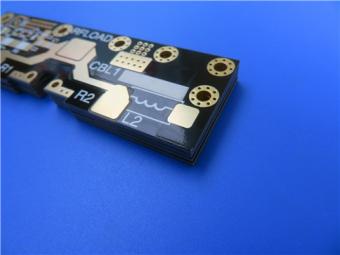

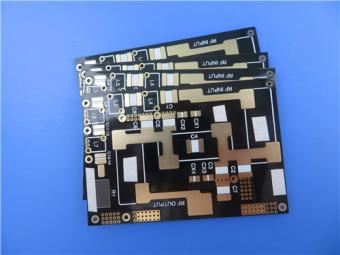

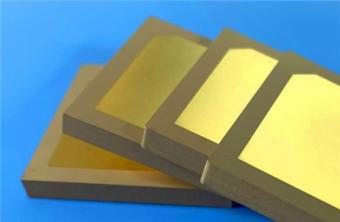

4-layer Hybrid PCB 0.508mm RO4350B+ TG170FR4 0.98mm ENIG Mixed Dielectric Board

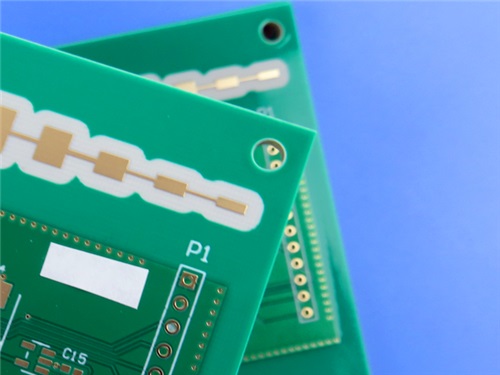

Designed for demanding high-frequency and precision electronic systems, our 4-Layer Hybrid PCB integrates Rogers RO4350B’s exceptional RF performance with TG170 FR-4’s cost-effectiveness, delivering a balanced solution for critical applications. With a finished thickness of 0.98mm, ENIG surface finish, and strict adherence to IPC-Class-2 standards, this Mixed Dielectric Board combines reliability, manufacturability, and electrical excellence—ideal for scenarios requiring stable signal transmission and thermal resilience.

PCB Construction Details

Below is a comprehensive breakdown of the mixed FR-4 +Rogers PCB’s construction parameters, reflecting rigorous manufacturing controls and adherence to industry standards:

|

Parameter

|

Specification

|

|

Base Material

|

RO4350B + TG170 FR-4

|

|

Layer Count

|

4-layer rigid PCB

|

|

Board Dimensions

|

80.22mm x 90mm (1PCS), ±0.15mm tolerance

|

|

Minimum Trace/Space

|

4/6 mils

|

|

Minimum Hole Size

|

0.3mm

|

|

Blind/Buried Vias

|

None

|

|

Finished Board Thickness

|

0.98mm

|

|

Finished Cu Weight

|

Inner layer: 0.5oz (0.7 mils); Outer layers: 1oz

|

|

Via Plating Thickness

|

20 μm

|

|

Surface Finish

|

Immersion Gold (ENIG)

|

|

Top Silkscreen

|

White

|

|

Bottom Silkscreen

|

White

|

|

Top Solder Mask

|

Green

|

|

Bottom Solder Mask

|

Green

|

|

Quality Control

|

100% Electrical test prior to shipment

|

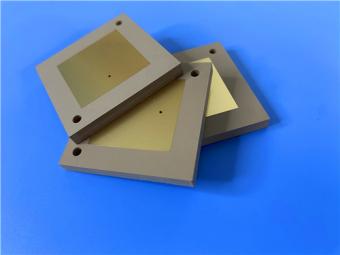

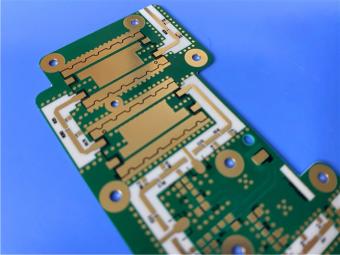

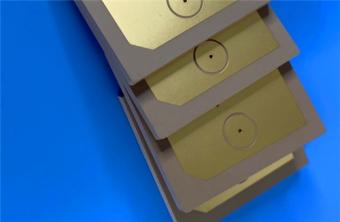

PCB Stackup

The carefully designed stackup balances electrical performance and mechanical strength, ensuring efficient signal propagation and thermal management:

|

Layer

|

Material/Component

|

Thickness

|

|

Copper Layer 1 (Outer)

|

Copper

|

35 μm (1oz)

|

|

Core Layer

|

Rogers RO4350B

|

0.508mm (20mil)

|

|

Copper Layer 2 (Inner)

|

Copper

|

18 μm (0.5oz)

|

|

Prepreg Layer

|

FR-4 Prepreg

|

0.2mm

|

|

Copper Layer 3 (Inner)

|

Copper

|

18 μm (0.5oz)

|

|

Core Layer

|

TG170 FR-4

|

0.102mm (4mil)

|

|

Copper Layer 4 (Outer)

|

Copper

|

35 μm (1oz)

|

PCB Statistics

Key layout metrics highlight the hybrid circuit board PCB’s optimized component integration and connectivity:

|

Category

|

Value

|

|

Total Components

|

26

|

|

Total Pads

|

59

|

|

Thru Hole Pads

|

37

|

|

Top SMT Pads

|

22

|

|

Bottom SMT Pads

|

0

|

|

Vias

|

125

|

|

Nets

|

10

|

Why Rogers RO4350B?

RO4350B PCB is a proprietary woven glass-reinforced hydrocarbon/ceramic laminate. Its primary advantage lies in offering electrical performance nearing that of costly PTFE-based materials while maintaining the familiar, reliable processing techniques of standard FR-4. This eliminates the need for special via treatments or handling procedures, drastically simplifying fabrication and reducing cost.

Key material properties that benefit your design include:

1) Stable Electrical Performance: Tightly controlled Dk of 3.48±0.05 and a very low loss tangent (Df) of 0.0037 at 10 GHz ensure predictable, high-performance signal propagation.

2) Exceptional Thermal & Dimensional Stability: A high Tg >280°C and a CTE closely matched to copper result in outstanding dimensional stability during thermal cycles. This is crucial for reliable plated through-holes (PTH) and the integrity of multi-layer constructions, especially in applications involving thermal shock.

3) Proven Reliability: Features like low water absorption (0.06%) and a UL 94 V-0 flammability rating contribute to long-term reliability in harsh environments.

Full Product Specifications & Benefits:

-

Artwork Format: Gerber RS-274-X

-

Quality Standard: IPC-A-600 Class 2

-

Availability: Worldwide support and shipping.

Key Benefits:

1) Optimized Cost-Performance Ratio: The hybrid design delivers RF performance where needed without the expense of a full Rogers board.

2) FR-4 Compatibility: Processes using standard epoxy/glass PCB methods, ensuring wider fabricator availability and faster turnaround.

3) Superior Reliability: Excellent PTH reliability and dimensional stability under thermal stress.

4) Design Flexibility: Ideal for complex multi-layer board (MLB) constructions requiring mixed dielectrics.

Typical Applications:

This Hybrid PCB Board is ideally suited for:

Cellular Base Station Antennas and Power Amplifiers

Automotive Radar Systems (e.g., ADAS) and Sensors

RF Identification (RFID) Tags and Readers

Low-Noise Block Downconverters (LNB) for Satellite Communication

High-Frequency Test Equipment and Prototyping

In summary, this 4 Layer RO3350B Hybrid PCB represents a smart, engineered choice for advanced electronic systems. It provides the radio frequency prowess required for cutting-edge applications through its strategic use ofRogers4350B, while its robust FR-4 foundation ensures manufacturability, mechanical strength, and cost control. We are confident it offers the perfect foundation for your next high-performance product.

BICHENG PCB CERTIFICATE:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com