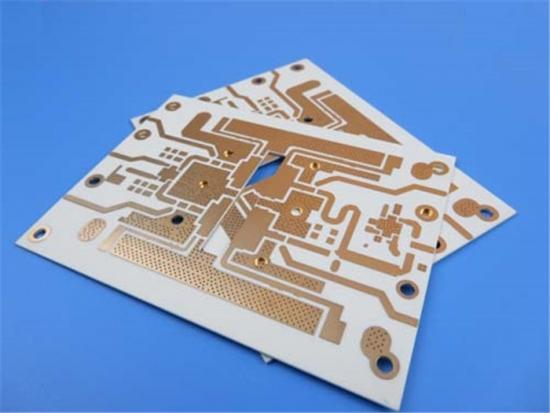

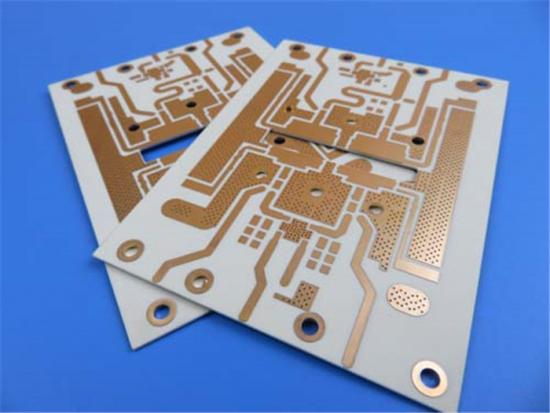

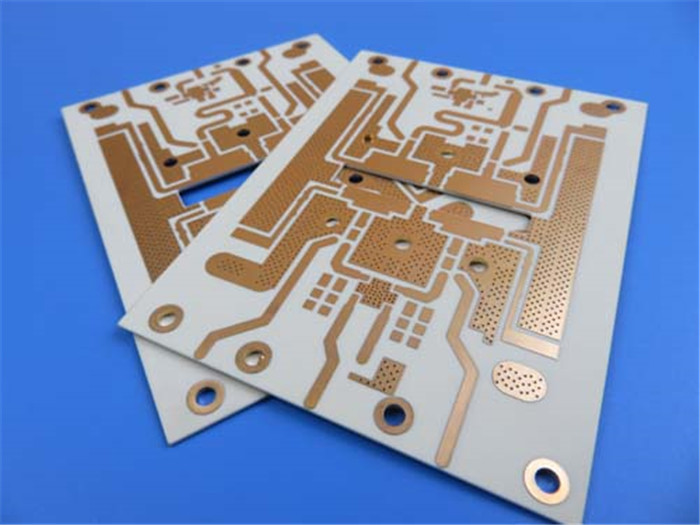

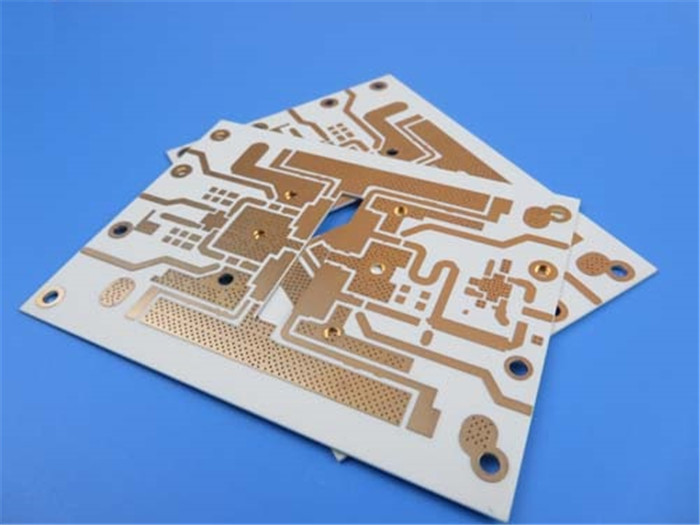

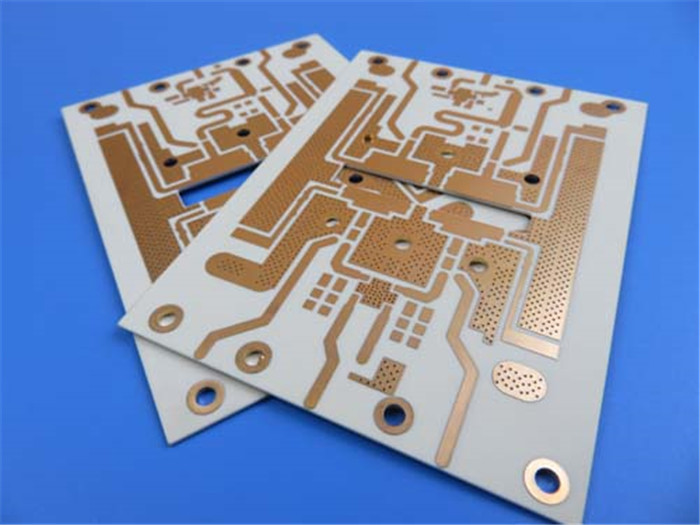

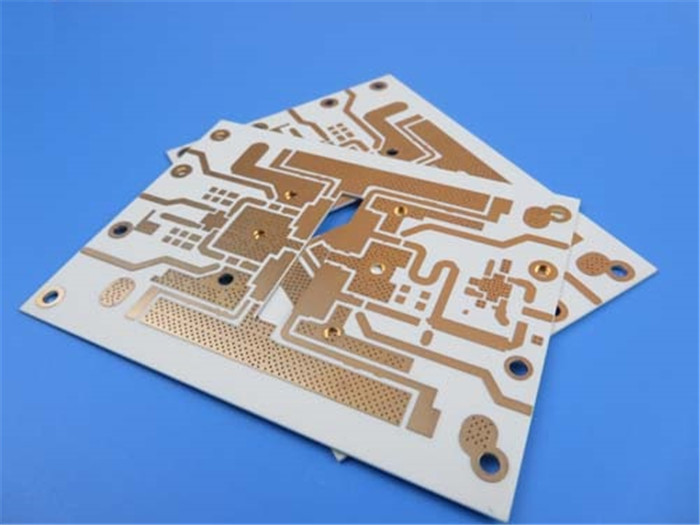

RO4003C Rogers PCB 32mil 0.813mm Immersion Gold High Frequency Board

Introducing the Rogers RO4003C Hydrocarbon Ceramic woven glass PCB, a cutting-edge solution designed for performance-sensitive, high-volume applications. This PCB is engineered with precision and boasts exceptional features and benefits that will elevate your electronic projects to new heights.

Crafted from the robust Rogers RO4003C material, this PCB offers a Dielectric Constant (DK) of 3.38 at 10 GHz, ensuring reliable and accurate signal transmission. With a Dissipation Factor of 0.0027 at 10GHz, it minimizes signal loss, enabling your applications to achieve optimal performance.

Operating within a temperature range of -40℃ to +85℃, Rogers RO4003C PCB Board exhibits outstanding thermal stability, making it suitable for a wide range of environments and applications. Its Tg value surpasses 280 °C, ensuring RO4003C Circuit Board remains durable and functional even under high-temperature conditions, with a Td value exceeding 425°C for enhanced reliability.

Specification Details:

|

Construction Details

|

Specifications

|

|

Board dimensions

|

335.15mm x 150.8 mm

|

|

Number of Types

|

3

|

|

Dimension Tolerance

|

+/- 0.15mm

|

|

Minimum Trace/Space

|

5/5 mils

|

|

Minimum Hole Size

|

0.45mm

|

|

Blind Vias

|

No

|

|

Finished board thickness

|

0.9mm

|

|

Finished Cu weight

|

1oz (1.4 mils) outer layers

|

|

Via plating thickness

|

25 μm

|

|

Surface finish

|

Immersion Gold

|

|

Top Silkscreen

|

No

|

|

Bottom Silkscreen

|

No

|

|

Top Solder Mask

|

Green

|

|

Bottom Solder Mask

|

No

|

|

Electrical Test

|

100% Electrical test used prior to shipment

|

Now let's explore the remarkable features and benefits of the Rogers RO4003C PCB:

A) Reinforced hydrocarbon/ceramic laminates:

Notably superior to PTFE alternatives

Specifically designed for performance-sensitive applications

Ensures exceptional electrical performance and reliability

B) Low dielectric tolerance and low loss:

Delivers excellent electrical performance

Enables applications with higher operating frequencies

Ideal for broadband applications

C) Stable electrical properties vs. frequency:

Facilitates controlled impedance transmission lines

Enables the repeatable design of filters

D) Low thermal coefficient of dielectric constant:

Offers excellent dimensional stability

Ensures reliable performance over a wide range of temperatures

E) Low Z-axis expansion:

Guarantees the reliability of plated through holes

F) Low in-plane expansion coefficient:

Maintains stability throughout various circuit processing temperatures

G) Volume manufacturing process:

Compatible with standard glass epoxy fabrication processes

Provides a cost-effective solution without compromising quality

H) CAF resistant:

Offers resistance against Conductive Anodic Filament (CAF) formation, ensuring long-term performance and reliability

Rogers 4003C 32mil PCB Statistics:

|

PCB Statistics

|

Quantity

|

|

Components

|

158

|

|

Total Pads

|

291

|

|

Thru Hole Pads

|

221

|

|

Top SMT Pads

|

77

|

|

Bottom SMT Pads

|

0

|

|

Vias

|

351

|

|

Nets

|

17

|

This 2-layer rigid PCB features a stack-up of 35 μm copper layer 1, a 32mil 0.813 mm Rogers 4003C core, and a 35 μm copper layer 2. It has a finished board thickness of 0.9mm, with a finished copper weight of 1oz (1.4 mils) on the outer layers. The PCB dimensions are precisely measured at 335.15mm x 150.8 mm, with a tolerance of +/- 0.15mm. The minimum trace/space is 5/5 mils, allowing for intricate circuit designs, while the minimum hole size is 0.45mm.

To ensure the highest quality, each 20 mil RO4003C High Frequency PCB undergoes a thorough 100% electrical test before shipment. It adheres to the IPC-Class-2 quality standard, guaranteeing reliable and consistent performance.

Typical Applications:

With availability worldwide, this PCB is suitable for a variety of applications:

Including Cellular Base Station Antennas and Power Amplifiers, RF Identification Tags, Automotive Radar and Sensors, and LNB's for Direct Broadcast Satellites.

Experience the unparalleled performance and reliability of the Rogers RO4003C Hydrocarbon Ceramic woven glass PCB. Take your electronic projects to new heights with this exceptional solution. Order now and witness the difference it can make in your applications.

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com