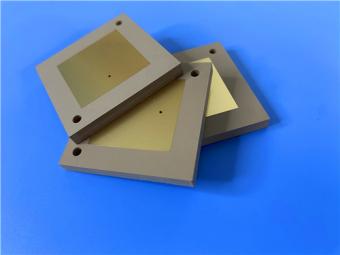

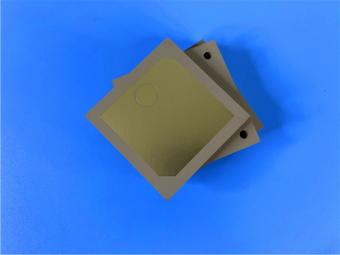

Rogers TC600 PCB 2-layer 60mil 1.524mm 1oz Immersion Tin High Frequency Circuit Board

1.Introduction

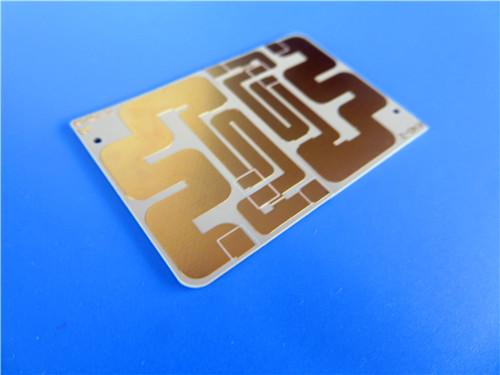

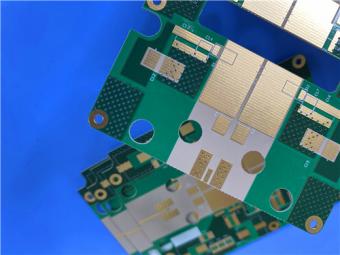

The TC600 PCB (60mil, 2-layer) is a high-performance printed circuit board engineered for RF/microwave and high-power applications where thermal management, signal integrity, and reliability are critical. Manufactured using Rogers TC600 laminate, this Rogers 60mil PCB delivers exceptional thermal conductivity (1.1 W/mK), low dielectric loss, and stable electrical performance across a wide temperature range.

With a 1.6mm finished thickness, 1oz copper layers, and immersion gold surface finish, this Rogers TC600 PCB ensures superior solderability, corrosion resistance, and consistent RF performance. The absence of solder mask and silkscreen makes it ideal for high-frequency applications where minimal dielectric interference is essential.

2.TC600 PCB Construction Details

At the core of the TC600 60 mil substrate PCB lies the exceptional TC600 base material, renowned for its superior quality and performance. This double-sided board boasts meticulous specifications:

|

Parameter

|

Specification

|

|

Base Material

|

Rogers TC600

|

|

Layer Count

|

Double-sided (2-layer)

|

|

Board Dimensions

|

76mm x 57 mm=4Types = 4PCS, +/- 0.15mm

|

|

Minimum Trace/Space

|

4/5 mils

|

|

Minimum Hole Size

|

0.3mm

|

|

Blind/Buried Vias

|

No

|

|

Finished Thickness

|

1.6mm (60mil)

|

|

Copper Weight (Outer Layers)

|

1oz (1.4 mils) outer layers

|

|

Via Plating Thickness

|

20μm

|

|

Surface Finish

|

Immersion Tin

|

|

Silkscreen (Top/Bottom)

|

No

|

|

Solder Mask (Top/Bottom)

|

No

|

|

Electrical Testing

|

100% tested prior to shipment

|

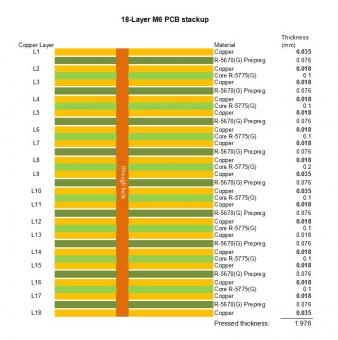

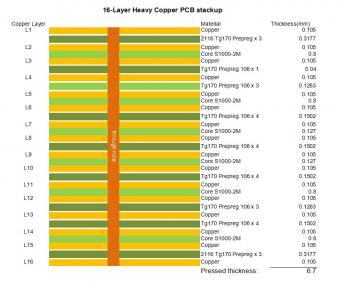

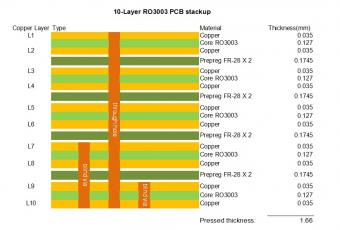

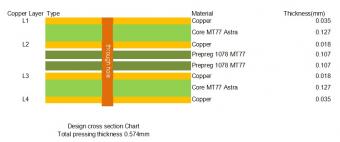

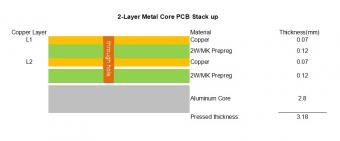

3.PCB Stack-up

The TC600 1.524 mm laminate PCB features a robust 2-layer rigid stackup, with copper layers sandwiching the TC600 core:

|

Layer

|

Thickness

|

|

Copper (Top Layer)

|

35μm (18μm base + 17μm plating)

|

|

TC600 Core

|

1.524mm (60mil)

|

|

Copper (Bottom Layer)

|

35μm (18μm base + 17μm plating)

|

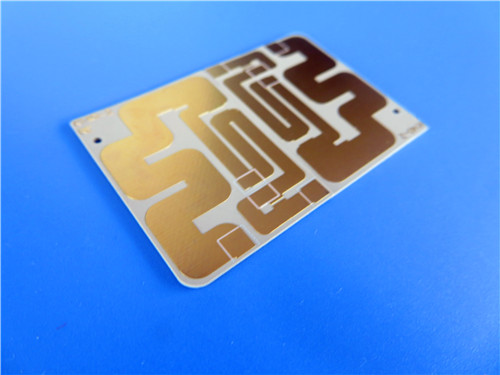

4.PCB Statistics

This Rogers PCB material is designed to deliver outstanding performance metrics:

|

Category

|

Count

|

|

Total Components

|

24

|

|

Total Pads

|

141

|

|

Through-Hole Pads

|

65

|

|

Top SMT Pads

|

76

|

|

Bottom SMT Pads

|

0

|

|

Vias

|

101

|

|

Nets

|

2

|

5.The Essence of TC600 Laminates

Rogers TC600 substrates redefine the very essence of superior PCB performance, combining PTFE, thermally conductive ceramic fillers, and woven glass reinforcement to deliver unparalleled thermal conductivity, minimal dielectric loss, and exceptional mechanical integrity. These laminates pave the way for enhanced heat transfer, optimal signal integrity, and increased efficiency in a compact footprint.

6.Features

The TC600 PCB stands out with its distinctive features:

6.1)Dielectric Constant (Dk):

6.15 at 1.8MHz and 10 GHz/23°C, setting new benchmarks in signal reliability and consistency.

6.2)Dissipation Factor:

A low 0.0017 and 0.0020 at 1.8 and 10 GHz/23°C respectively, ensuring minimal signal degradation.

6.3)Thermal Conductivity:

A staggering 1.1W/mK, facilitating efficient heat dissipation and enhanced power handling capabilities.

6.4)Temperature Resilience:

Stable Dk across a wide temperature range of -75ppm/°C from -40°C to 140°C, ensuring consistent performance in diverse environments.

6.5)Expansion Coefficient:

Low coefficients of thermal expansion on all axes (X, Y, Z-9, 9 and 35 ppm/°C) ensure structural integrity and reliability.

6.6)Moisture Absorption:

Minimal absorption of 0.03%, contributing to long-term performance stability.

7.Benefits

By integrating the TC600 PCB into your designs, you unlock a world of benefits:

-Size Reduction: Streamline your PCB designs effortlessly

-Heat Reduction: Combat transmission line loss effectively

-Enhanced Reliability: Ensure long-term performance

-Stress-Free Compatibility: Perfectly aligns with active components

8.Applications

The possibilities with the TC600 PCB are endless. Some typical applications include:

- Power Amplifiers, Filters and Couplers

- Microwave Combiner and Power Divider Boards in Avionics Applications

- Small Footprint Antennas

- Digital Audio Broadcasting (DAB) Antennas(Satellite Radio)

- GPS & Hand-held RFID Reader Antennas

9.Conclusion

The TC600 PCB (60mil, 2-layer, immersiontin finish) is a high-performance solution for RF, microwave, and high-power applications requiring thermal stability, low loss, and high reliability. Its Rogers TC600 substrate, 1oz copper layers, and precision manufacturing make it ideal for avionics, antennas, and power amplifiers.

For engineers and designers seeking a thermally efficient, high-frequency PCB with excellent signal integrity, this product delivers superior performance in demanding environments.

Contact us today for pricing, lead times, and custom configurations!

BICHENG PCB CERTIFICATE:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com