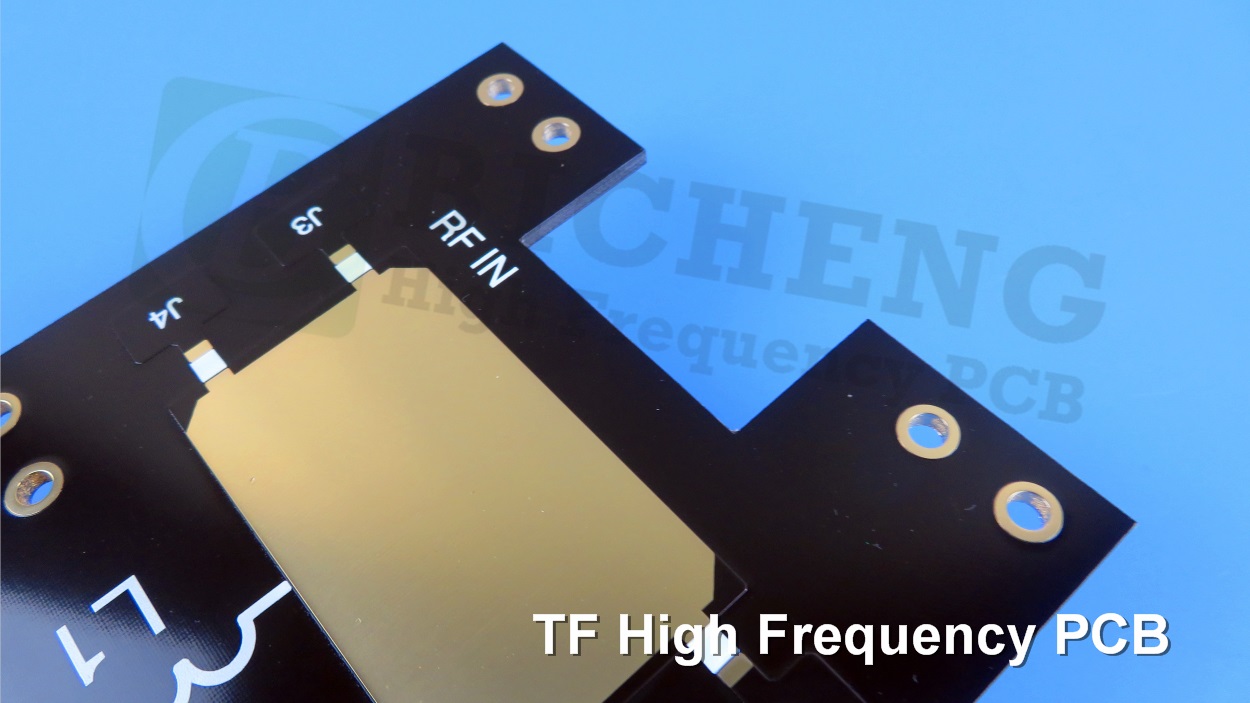

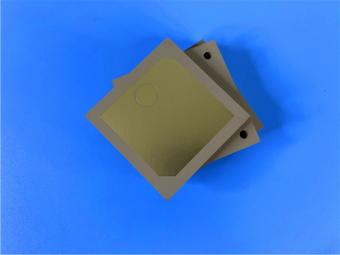

TF Series High Frequency PCB Double-sided 2.0mm Smooth Surface Material

Introduction

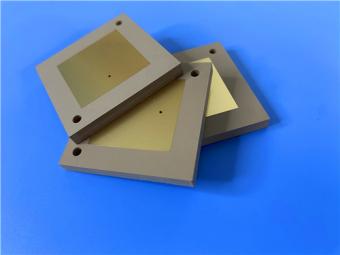

This TF series laminates is a composite of microwave and temperature-resistant polytetrafluoroethylene (PTFE) resin material and ceramics. It does not contain fiberglass cloth. The dielectric constant is precisely adjusted by adjusting the ratio between ceramics and PTFE resin. It has special production processes and exhibits excellent dielectric performance and high reliability. TF refers to the smooth surface material without copper cladding, TF-1 refers to the material with copper cladding on one side, and TF-2 refers to the material with copper cladding on both sides.

Product Features:

-

The dielectric constant ranges from 3 to 16 and is stable. Common dielectric constants include 3.0, 6.0, 9.2, 9.6, 10.2, and 16, with low dielectric loss.

-

Used for the fabrication of microwave and millimeter-wave printed circuit boards.

-

Long-term working temperature is higher than TP materials and can be used in the range of -80°C to +200°C.

-

Thickness options range from 0.635mm to 2.5mm.

-

Resistant to radiation and low outgassing.

-

Convenient for PCB processing, can be processed using methods suitable for thermoplastic materials.

Product Models & Data Sheet

|

Product Technical Parameter

|

Product Models & Data Sheet

|

|

Product Features

|

Test Conditions

|

Unit

|

TF TF-1 TF-2

|

|

Dielectric Constant

|

When the dielectric constant is ≤11, the test condition is 10GHz.

When the dielectric constant is >11, the test condition is 5GHz.

|

/

|

3.0±0.06

|

4.4±0.09

|

|

6.0±0.12

|

6.15±0.12

|

|

9.2±0.18

|

9.6±0.19

|

|

10.2±0.2

|

16.0±0.4

|

|

The dielectric constant can be customized within the range of 3.0~16

|

|

Tolerance of Dielectric Constant

|

Dielectric Constant 3.0~11.0

|

/

|

±2%

|

|

Dielectric Constant 11.1~16.0

|

/

|

±2.5%

|

|

Loss Tangent

|

Dielectric Constant 3.0~9.5

|

10GHz

|

/

|

0.0010

|

|

Dielectric Constant 9.6~11.0

|

10GHz

|

/

|

0.0012

|

|

Dielectric Constant 11.1~16.0

|

5GHz

|

/

|

0.0014

|

|

Dielectric Constant Temperature Coefficient

|

Dielectric Constant 3.0~4.5

|

-55 º~150ºC

|

PPM/℃

|

-60

|

|

Dielectric Constant 6.0~6.5

|

-55 º~150ºC

|

PPM/℃

|

-210

|

|

Dielectric Constant 9.0~11.0

|

-55 º~150ºC

|

PPM/℃

|

-260

|

|

Dielectric Constant 12.0~16.0

|

-55 º~150ºC

|

PPM/℃

|

-205

|

|

Peel Strength

|

1 OZ Normal State

|

N/mm

|

>0.6

|

|

1 OZ After AC Humidity Test

|

N/mm

|

>0.4

|

|

Volume Resistivity

|

Normal State 500V

|

MΩ.cm

|

>1×10^9

|

|

Surface Resistivity

|

Normal State 500V

|

MΩ

|

>1×10^7

|

Coefficient of Thermal Expansion

(XY Z)

|

Dielectric Constant 3.00~6.15

|

-55 º~150ºC

|

PPM/℃

|

60,60,80

|

|

Dielectric Constant 6.16~11.0

|

-55 º~150ºC

|

PPM/℃

|

50,50,65

|

|

Dielectric Constant 11.1~16.0

|

-55 º~150ºC

|

PPM/℃

|

40,40,55

|

|

Water Absorption

|

20±2℃, 24 hours

|

%

|

≤0.05

|

|

Long-Term Operating Temperature

|

High-Low Temperature Chamber

|

℃

|

-80~200ºC

|

|

Material Composition

|

Polytetrafluoroethylene (PTFE), ceramic, paired with ED copper foil.

|

|

The density and thermal conductivity data for materials with different dielectric constants are as follows:

|

|

Product Features

|

Unit

|

Dielectric Constant

|

|

3.0

|

4.4

|

6.0

|

6.15

|

9.2

|

9.6

|

10.2

|

16.0

|

|

Density

|

g/cm3

|

2.41

|

2.58

|

2.78

|

2.79

|

3.0

|

3.02

|

3.07

|

3.27

|

|

Thermal Conductivity

|

W/(M.K)

|

0.30

|

0.32

|

0.45

|

0.46

|

0.66

|

0.68

|

0.7

|

0.75

|

Our PCB Capability (TF series)

|

PCB Capability (TF Series)

|

|

PCB Material:

|

Polyphenylene ether, ceramic

|

|

Designation (TF Series)

|

Designation

|

DK

|

DF

|

|

TF300

|

3.0±0.06

|

0.0010

|

|

TF440

|

4.4±0.09

|

0.0010

|

|

TF600

|

6.0±0.12

|

0.0010

|

|

TF615

|

6.15±0.12

|

0.0010

|

|

TF920

|

9.2±0.18

|

0.0010

|

|

TF960

|

9.6±0.19

|

0.0012

|

|

TF1020

|

10.2±0.2

|

0.0012

|

|

TF1600

|

16.0±0.4

|

0.0014

|

|

Layer count:

|

Single Sided, Double Sided PCB

|

|

Copper weight:

|

1oz (35µm), 2oz (70µm)

|

|

Dielectric thickness (Dielectric thickness or overall thickness)

|

0.635mm, 0.8mm, 1.0mm, 1.2mm, 1.5mm, 2.0mm, 2.5mm

|

|

PCB size:

|

≤240mm X 240mm

|

|

Solder mask:

|

Green, Black, Blue, Yellow, Red etc.

|

|

Surface finish:

|

Bare copper, HASL, ENIG, Immersion silver, Immersion tin, OSP, Pure gold, ENEPIG etc..

|

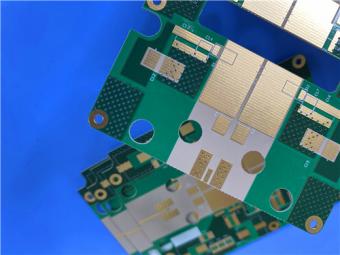

A TF PCB and Applications

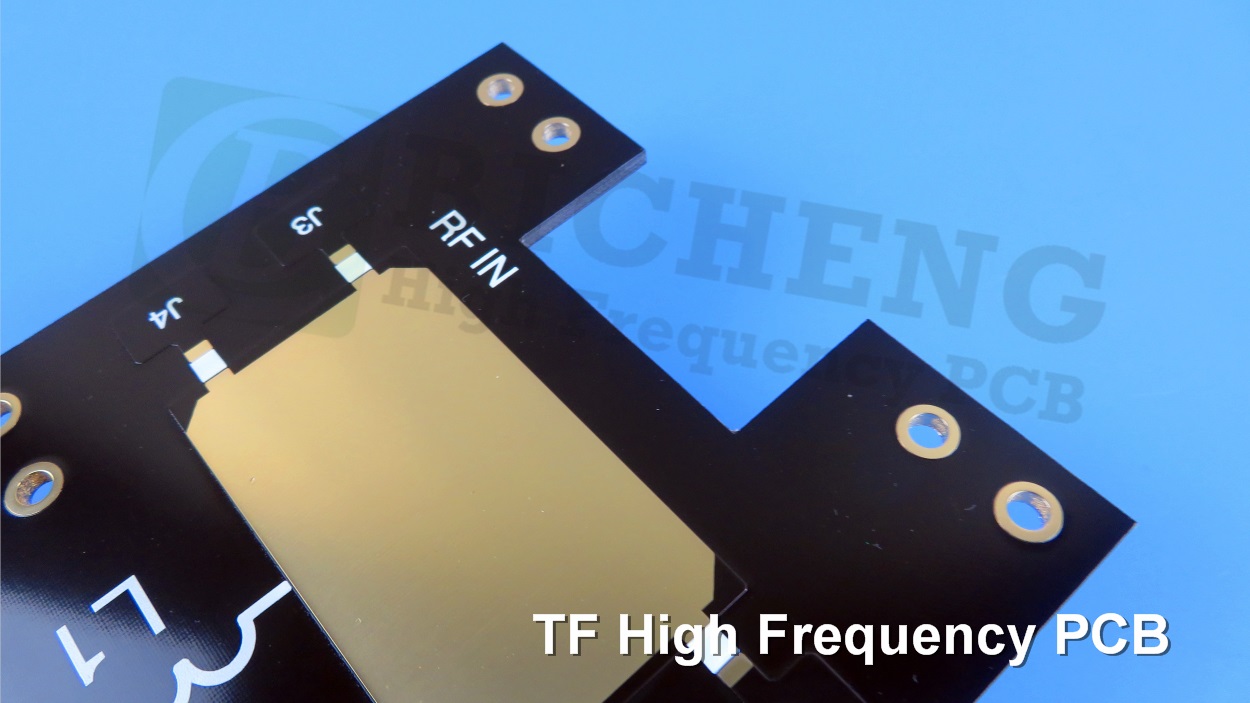

Displayed on the screen is a double-sided 2.0mm TF high-frequency PCB with a black solder mask and immersion gold on the pads. TF high-frequency PCBs are utilized in applications of microwave and millimeter-wave printed circuit boards, such as millimeter-wave radar sensors, antennas, transceivers, modulators, multiplexers, as well as power supply equipment and automatic control equipment.

BICHENG PCB CERTIFICATE:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com