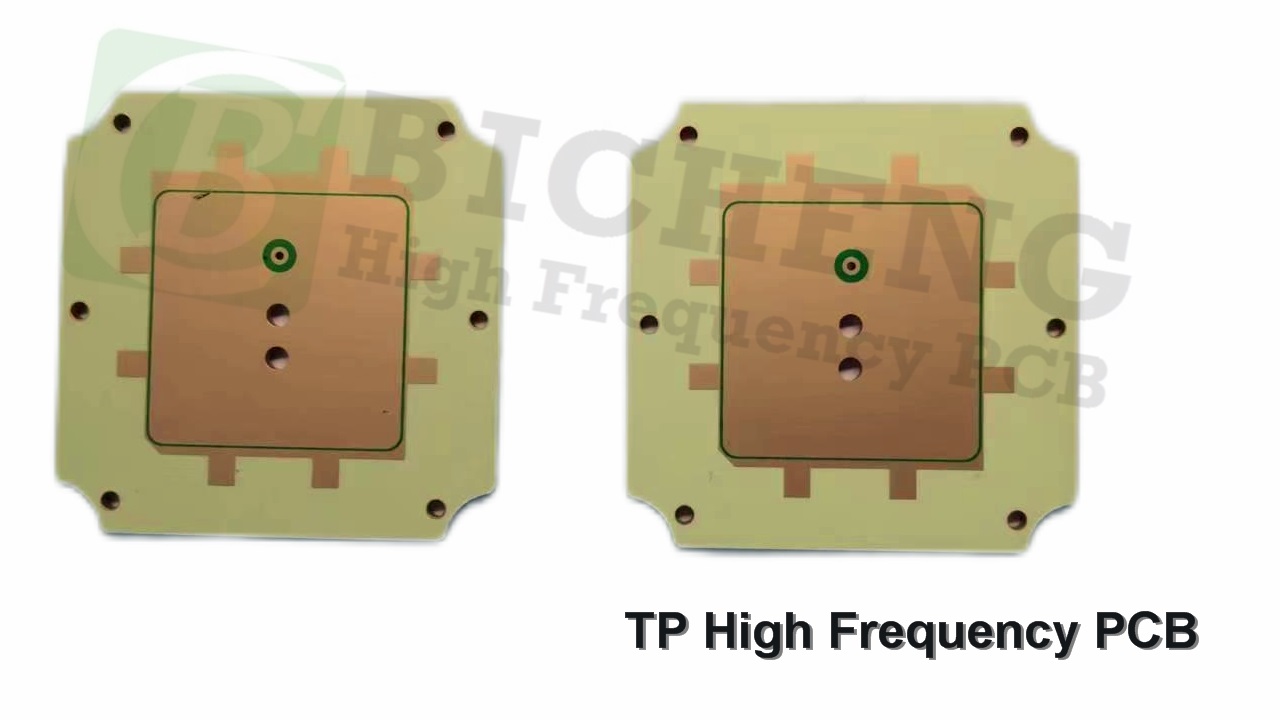

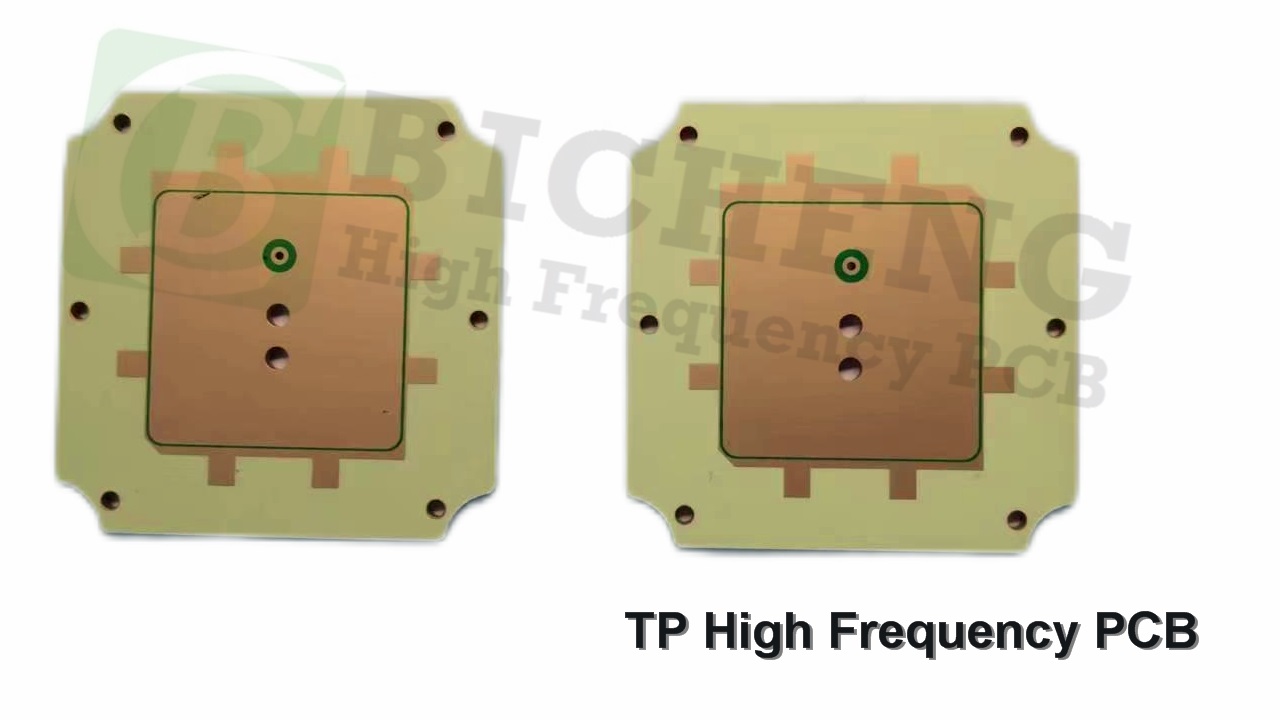

Wangling TP1020 Material 0.8mm Wholesale High Frequency PCB Supplier

Introduction

Wangling TP material is an exceptional high-frequency thermoplastic material that stands out in the industry. The TP-type laminates feature a dielectric layer composed of ceramics and polyphenylene Oxide resin (PPO), devoid of fiberglass reinforcement. The unique production process results in outstanding dielectric performance and high reliability. TP material is available in different variants, including TP without copper cladding, TP-1 with copper cladding on one side, and TP-2 with copper cladding on both sides.

Features

1)Precisely Adjustable Dielectric Constant:

One of the remarkable features of TP material is the ability to select the dielectric constant within a wide range of 3 to 25, catering to specific circuit requirements. The dielectric constant remains stable, and common values include 3.0, 4.4, 6.0, 6.15, 9.2, 9.6, 10.2, 11, 16, and 20. TP material exhibits low dielectric loss, with a minimal increase as the frequency rises, making it ideal for applications up to 10 GHz.

2)Wide Operating Temperature Range:

TP1020 PCBs can withstand long-term operating temperatures ranging from -100°C to +150°C. The material exhibits excellent low-temperature resistance. However, it's important to note that temperatures exceeding 180°C may cause deformation, copper foil peeling, and significant changes in electrical performance.

3)Versatile Thickness Options:

TP1020 PCBs are available in various thicknesses, with a minimum thickness of 0.5mm. The flexibility in thickness allows for customization, ensuring compatibility with diverse application requirements.

4)Radiation Resistance and Low Outgassing:

TP material demonstrates resistance to radiation and exhibits low outgassing properties, making it suitable for applications in sensitive environments.

5)Ideal for Specialized Applications:

TP1020 PCBs are particularly well-suited for Beidou systems, missile-borne equipment, fuzes, and miniaturized antennas. The material's unique properties make it a reliable choice for these specialized applications.

6)Reliable Copper Foil Adhesion:

Compared to ceramic substrates with vacuum coating, TP material offers more dependable adhesion between the copper foil and the dielectric layer. This improved adhesion, combined with the material's machinability, enables various processing methods such as drilling, turning, grinding, shearing, and etching, surpassing the capabilities of ceramic substrates.

TP1020PCB Stackup

2-layer rigid PCB

Copper_layer_1 - 35 μm

TP1020 Core - 0.8 mm

Copper_layer_2 - 35 μm

PCB Construction Details

The TP1020 PCB features a double layer circuit rigid PCB stackup with copper layers on both sides of the 0.8mm TP1020 core. The key construction details are as follows:

|

PCB Construction Details

|

Specifications

|

|

Board Dimensions

|

43.35mm x 36.56mm (+/- 0.15mm)

|

|

Minimum Trace/Space

|

5 mils / 7 mils

|

|

Minimum Hole Size

|

0.3mm

|

|

Blind Vias

|

No

|

|

Finished Board Thickness

|

0.9mm

|

|

Finished Cu Weight

|

1oz (1.4 mils) outer layers

|

|

Via Plating Thickness

|

20 μm

|

|

Surface Finish

|

Immersion Gold

|

|

Top Silkscreen

|

No

|

|

Bottom Silkscreen

|

No

|

|

Top Solder Mask

|

No

|

|

Bottom Solder Mask

|

No

|

|

Electrical Testing

|

100% prior to shipment

|

PCB Statistics

The TP1020 PCB variant exhibits the following statistics:

|

PCB Statistics

|

Quantity

|

|

Components

|

6

|

|

Total Pads

|

24

|

|

Thru Hole Pads

|

16

|

|

Top SMT Pads

|

8

|

|

Bottom SMT Pads

|

0

|

|

Vias

|

5

|

|

Nets

|

2

|

Type of Artwork Supplied

The TP1020 PCB requires Gerber RS-274-X files for the manufacturing process. These industry-standard files contain the necessary information to precisely create the PCB layout and manufacturing specifications.

Quality Standard

The TP1020 PCB adheres to the IPC-Class-2 quality standard, ensuring that the manufacturing process meets the industry's established guidelines. This standard guarantees a high level of reliability and performance for the PCB.

Availability

The TP1020 PCB is available for worldwide distribution. Customers from various locations can benefit from its unique features and exceptional performance characteristics.

Some Typical Applications

Due to its excellent dielectric properties, stability, and reliability, the TP1020 PCB finds applications in a range of industries. Some typical applications include:

1.GPS Antennas:

TP1020 PCBs are well-suited for GPS antenna designs. The material's stable dielectric constant and low loss make it an ideal choice for achieving precise signal reception and transmission.

2.Missile-Borne Equipment:

In the field of defense, TP1020 PCBs find application in missile-borne equipment. Their resistance to radiation, excellent dielectric performance, and reliability ensure optimal operation in demanding environments.

3.Fuzes:

Fuzes, crucial components in munitions and explosives, benefit from the properties offered by TP1020 PCBs. The material's stability, low loss, and resistance to high temperatures make it a reliable choice for fuzes used in critical defense applications.

4.Miniaturized Antennas:

TP1020 high frequency PCBs provide an ideal substrate for miniaturized antennas. The material's unique dielectric properties, combined with its ability to achieve precise thicknesses and customized designs, enable the development of compact and high-performance antennas.

Conclusion

In conclusion, the TP1020 high frequency PCB offers a high-frequency thermoplastic solution with exceptional dielectric performance, stability, and reliability. Its unique material composition, adjustable dielectric constant, wide operating temperature range, and machinability make it an excellent choice for a variety of applications. With its reliable copper foil adhesion, resistance to radiation, and low outgassing, the Wangling TP1020 PCB is well-suited for challenging environments. Whether used in GPS antennas, missile-borne equipment, fuzes, or miniaturized antennas, the TP1020 PCB delivers optimal performance and reliability. Its availability worldwide ensures that customers can benefit from its remarkable features in diverse industries.

BICHENG PCB CERTIFICATE:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com