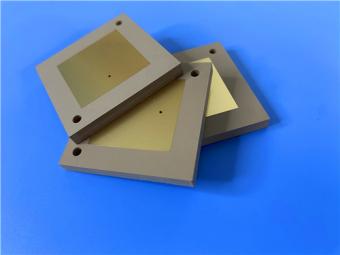

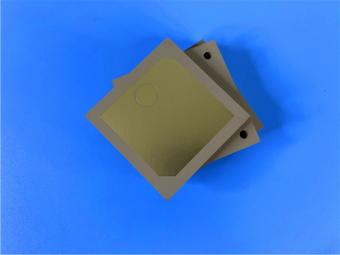

10-layer RO3003 Laminate FR-28 Prepreg 1.66mm Finished Thickness ENIG PCB Blind Via

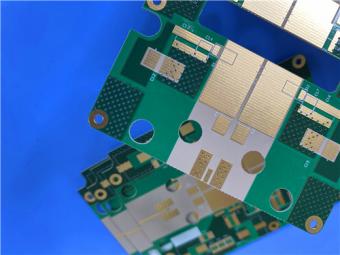

This advanced 10-layer printed circuit board represents a specialized solution engineered for demanding high-frequency RF and microwave applications. Constructed with a combination of RO3003 laminate cores and FR-28 prepreg, this 10-layer RO3003 PCB is designed to deliver exceptional electrical performance, signal integrity, and reliability in critical environments such as automotive radar, satellite communications, and cellular infrastructure. The board features a controlled 1.66mm thickness and utilizes a sophisticated stackup with blind vias to optimize high-speed and high-frequency routing. With outer layers finished in bare copper with Immersion Gold (ENIG) plating and no solder mask or silkscreen, this design prioritizes precise RF performance and is subject to rigorous 100% electrical testing prior to shipment.

PCB Construction Details

The following table summarizes the complete physical and fabrication specifications of this multilayer PCB.

|

Parameter

|

Specification

|

|

Base Material

|

RO3003 Core Laminate with FR-28 Prepreg

|

|

Layer Count

|

10 Layers

|

|

Board Dimensions

|

75mm x 63mm (1 PCS)

|

|

Minimum Trace / Space

|

4 mils / 5 mils

|

|

Minimum Hole Size (Finished)

|

0.35mm

|

|

Blind Via Specifications

|

L7-L10, L9-L10

|

|

Finished Board Thickness

|

1.66mm ± 10%

|

|

Finished Copper Weight (All Layers)

|

1 oz (approx. 35μm)

|

|

Via Plating Thickness (Minimum)

|

20 μm

|

|

Final Surface Finish

|

Immersion Gold (ENIG)

|

|

Top / Bottom Silkscreen

|

None

|

|

Top / Bottom Solder Mask

|

None (Bare Copper on Outer Layers)

|

|

Electrical Test

|

100% Testing Prior to Shipment

|

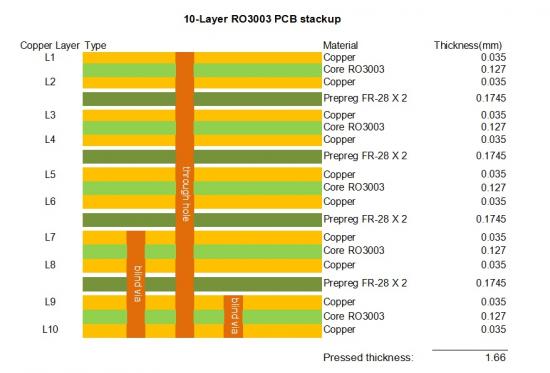

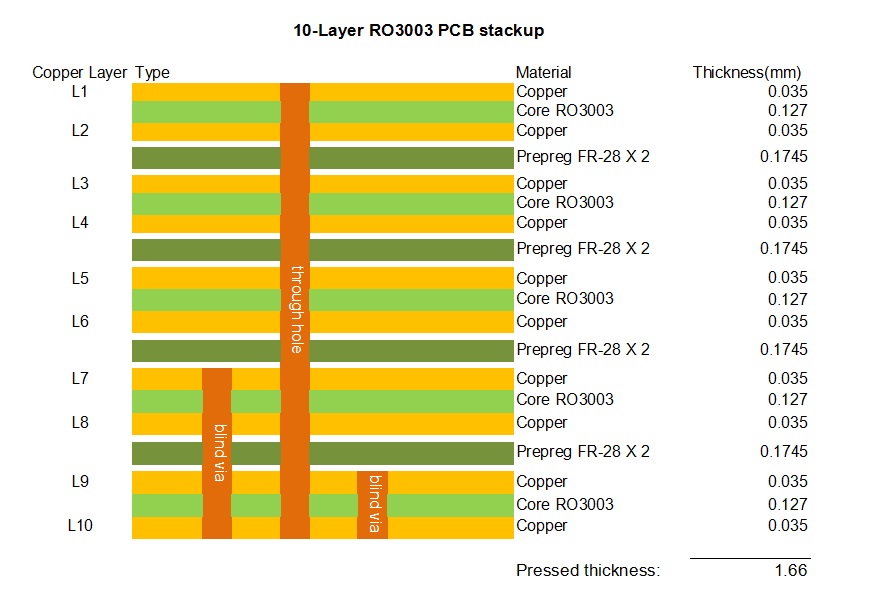

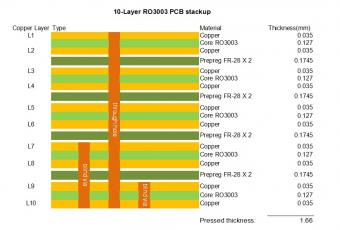

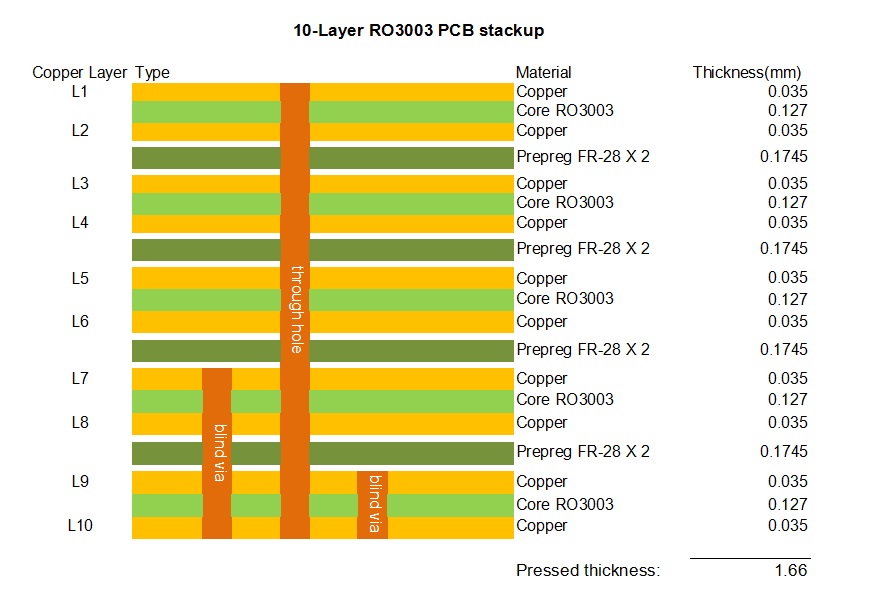

PCB Stackup Configuration

The layer stackup is detailed below, showing the symmetrical build-up designed for optimal electrical and mechanical performance.

Material Technology: RO3003 Laminate & FR-28 Prepreg

RO3003 Laminate Introduction:

Rogers RO3003 is part of the RO3000 series, a family of ceramic-filled Polytetrafluoroethylene (PTFE) composite materials specifically engineered for commercial microwave and RF applications. Its primary benefits stem from a unique combination of electrical stability and uniform mechanical properties. A key advantage is its exceptionally stable dielectric constant (Dk~3.00) across wide temperature and frequency ranges, which is critical for components like band-pass filters and oscillators. Mechanically, its in-plane Coefficient of Thermal Expansion (CTE) of 17 ppm/°C is matched to copper, ensuring outstanding dimensional stability and reliability for surface mount assemblies. Its Z-axis CTE of 24 ppm/°C further guarantees superior plated through-hole reliability. This consistency in mechanical properties across different Dk values allows Rogers 3003 to be reliably used in hybrid multilayer designs with materials like FR-4, minimizing warpage concerns.

RO3003 Data Sheet:

|

RO3003 Typical Value

|

|

Property

|

RO3003

|

Direction

|

Units

|

Condition

|

Test Method

|

|

Dielectric Constant,εProcess

|

3.0±0.04

|

Z

|

|

10 GHz/23℃

|

IPC-TM-650 2.5.5.5 Clamped Stripline

|

|

Dielectric Constant,εDesign

|

3

|

Z

|

|

8GHz to 40 GHz

|

Differential Phase Length Method

|

|

Dissipation Factor,tanδ

|

0.001

|

Z

|

|

10 GHz/23℃

|

IPC-TM-650 2.5.5.5

|

|

Thermal Coefficient of ε

|

-3

|

Z

|

ppm/℃

|

10 GHz -50℃to 150℃

|

IPC-TM-650 2.5.5.5

|

|

Dimensional Stability

|

0.06

|

X

|

mm/m

|

COND A

|

IPC-TM-650 2.2.4

|

|

0.07

|

Y

|

|

Volume Resistivity

|

107

|

|

MΩ.cm

|

COND A

|

IPC 2.5.17.1

|

|

Surface Resistivity

|

107

|

|

MΩ

|

COND A

|

IPC 2.5.17.1

|

|

Tensile Modulus

|

930

|

X

|

MPa

|

23℃

|

ASTM D 638

|

|

823

|

Y

|

|

Moisture Absorption

|

0.04

|

|

%

|

D48/50

|

IPC-TM-650 2.6.2.1

|

|

Specific Heat

|

0.9

|

|

j/g/k

|

|

Calculated

|

|

Thermal Conductivity

|

0.5

|

|

W/M/K

|

50℃

|

ASTM D 5470

|

|

Coefficient of Thermal Expansion

|

17

|

X

|

ppm/℃

|

23℃/50% RH

|

IPC-TM-650 2.4.4.1

|

|

(-55 to 288℃)

|

16

|

Y

|

|

|

25

|

Z

|

|

Td

|

500

|

|

℃TGA

|

|

ASTM D 3850

|

|

Density

|

2.1

|

|

gm/cm3

|

23℃

|

ASTM D 792

|

|

Copper Peel Stength

|

12.7

|

|

Ib/in.

|

1oz,EDC After Solder Float

|

IPC-TM 2.4.8

|

|

Flammability

|

V-0

|

|

|

|

UL 94

|

|

Lead-free Process Compatible

|

Yes

|

|

|

|

|

FR-28 Prepreg Introduction:

FR-28 is a fastRise prepreg system designed for use in high-performance multilayer builds. It is characterized by a very low initial degree of cure, which allows for controlled flow and fill during the lamination process. Successful lamination requires a specific thermal profile: an extended hold at around 225°F (107°C) under high pressure to achieve optimal resin flow, followed by a carefully controlled ramp to the final cure temperature. This process ensures complete filling of intricate geometries and reliable bonding between core layers. It is important to note that as a high-performance material, its compatibility with specific core materials must be validated by the fabricator or end-user for each application to ensure reliability.

FR-28 Prepreg Data Sheet:

|

FastRise-28 (FR-28) Typical Value

|

|

Property

|

Value

|

Direction

|

Units

|

Condition

|

Test Method

|

|

Dielectric Constant,ε

|

2.78

|

-

|

-

|

10 GHz

|

IPC-TM-650 2.5.5.5.1

|

|

Dissipation Factor,tanδ

|

0.0015

|

-

|

-

|

10 GHz

|

IPC-TM-650 2.5.5.5.1

|

|

Water Absorption

|

0.08

|

|

%

|

|

IPC TM-650 2.6.2.1

|

|

Dielectric breakdown voltage

|

49

|

|

KV

|

|

IPC TM-650 2.5.6

|

|

Dielectric strength

|

1090

|

|

V/mil

|

|

ASTM D 149

|

|

Volume Resistivity

|

8.00 x 108

|

|

MΩ/cm

|

|

IPC-TM-650 2.5.17.1

|

|

Surface Resistivity

|

3.48 x 108

|

|

MΩ

|

|

IPC-TM-650 2.5.17.1

|

|

Tg

|

188

|

|

℃

|

|

ASTM E 1640

|

|

Tensil strength

|

1690

|

X

|

psi

|

|

ASTM D 882

|

|

1480

|

Y

|

psi

|

|

Tensil modulus

|

304

|

X

|

psi

|

|

ASTM D 882

|

|

295

|

Y

|

psi

|

|

Density

|

1.82

|

|

gm/cm³

|

|

ASTM D-792 Method A

|

|

Td

|

709

|

|

°F

|

|

IPC TM-650 2.4.24.6

|

|

Peel Strength

|

7

|

|

lbs/in

|

|

IPC-TM-650 2.4.8

|

|

Thermal Conductivity

|

0.25

|

|

W/mk

|

|

ASTM F433

|

|

Coefficient of Thermal Expansion

|

59

|

X

|

ppm/℃

|

|

IPC-TM-650 2.4.41

|

|

70

|

Y

|

|

72

|

Z

|

|

Hardness

|

68

|

|

Shore D

|

|

ASTM D 2240

|

Consolidated Features & Benefits:

1) Low Loss & High-Frequency Operation: RO3003's low dielectric loss makes it suitable for applications up to 77 GHz, minimizing signal attenuation.

2) Stable Electrical Performance: The dielectric constant remains stable with temperature and frequency, ensuring predictable circuit behavior.

3) Excellent Mechanical Reliability: Matched CTE to copper and uniform properties enable robust stripline constructions and reliable multilayer boards, even in thermal cycling environments.

4) Hybrid Design Compatibility: Its mechanical stability allows for integration with epoxy-glass (e.g., FR-4) systems in hybrid designs for cost-effective mixed-signal boards.

5) Manufacturing Efficiency: Based on a volume manufacturing process, it offers a cost-effective solution for high-frequency laminates.

Typical Applications

This RO3003 multilayer PCB technology is ideally suited for:

-

Automotive Radar Sensors (e.g., Adaptive Cruise Control, Collision Avoidance)

-

Global Positioning System (GPS) and Satellite Communication Antennas

-

Cellular Telecommunications Infrastructure, including power amplifiers and base station antennas

-

Microstrip and Patch Antennas for wireless communication systems

-

Direct Broadcast Satellite (DBS) and Cable Datacom Systems

-

High-Speed Digital Backplanes requiring controlled impedance and low loss

-

Voltage-Controlled Oscillators (VCOs) and Band-Pass Filters

In summary, this 10-layer RO3003/FR-28 PCB is a premium, application-specific circuit solution that leverages advanced material science to meet the rigorous demands of next-generation high-frequency and high-speed electronic systems.

BICHENG PCB CERTIFICATE:

Call Us Now !

Tel : +86 755 27374946

Call Us Now !

Tel : +86 755 27374946

Order Online Now !

Email : info@bichengpcb.com

Order Online Now !

Email : info@bichengpcb.com